Ready; Catalysis Isomerization/cyclization-1

advertisement

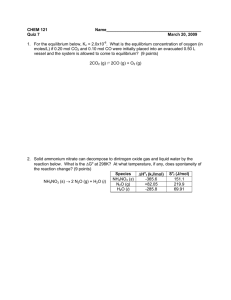

Ready; Catalysis Isomerization/cyclization-1 Olefin insertion into Metal alkyl can be followed by hydride elimination or additional olefin insertions: R R' R' R R M -dimerization/oligomerization -small molecules MH M H R' R H M R' -polymerization R' Recall: M M H H electron rich M (late transition metal) Keq < 1 ->dimerization, etc electron poor M (early transition metal) Keq > 1 ->polymerization Ready; Catalysis Isomerization/cyclization-2 Shell Higher Olefin Process (SHOP) Terminal Olefin 1-Hexene 1-Heptene 1-Octene 1-Nonene 1-Decene 1-Undecene -SHOP process operates on 1 MILLION TON scale -One of the largest applications of homogeneous transition metal catalysis -Explains Adrich prices: O O Ni P Ph2 H S/C = 6000/1 n C4-C8 + >C20 Price (100mL) $13 191 23 720 19 640 Isomerization Catalyst C4-C8 C10-C18 >C20 MoO3/Al2O3 (Olefin Metathesis) m n Mixture of short and long internal olefins 41% 40% 19% sold (recall hydroformylation) C7-C14 C1-C3 Chauvin, Schrock, Grubbs: 2005 nobel prize in chemistry. For a history, see; http://nobelprize.org/chemistry/laureates/2005/chemadv05.pdf C7-C14 C1-C3 HCo(CO)4 H2/CO Isomerization Hydroformylation Hydrogenation HO C10-C18 See CHNF, Capter 11, p593 Ready; Catalysis Isomerization/cyclization-3 Ph O O Ph O O O Ni Ni O H Ni P Ph2 P PPh3 Ph2 O O P P Ph2 Ph2 Pre-catalyst Catalytically inactive: Catalyst death J Mol Cat, 1987, 123 O O H n only linear products are formed Ni P H Ph2 Migratory insertion ethylene association associative displacement O O O Ni P Ph2 H n H Ni P Ph2 "-Hydride elimination Relative rate of insertion vs elimination/displacement balanced to give low mw olefins H O O H n O H Ni P Ph2 !-complex Ready; Catalysis Isomerization/cyclization-4 Ligand change gives polymer insead of oligomer note Ziegler-Natta catalysts (TiCl3/AlCl3) and cationic metallocene catalysts not able to incorporate polar monomers. Late TM = functional group tolerant + O Ph Ni PPh3 N i-Pr 1 1 n i-Pr m HO n 3.7 x 106g PE/mol Ni/Hr MW > 250,000 linear polyethylene !-Hydride elim ethylene association H HO O mw = >73,000 termination Ni H n H Psycho-big ligand destabilizes 5-coordinate intermediate en route to termination N O H Ni H N O Ni ethylene association N polymer Grubbs, Science, 2000, (287) 460 Ready; Catalysis Isomerization/cyclization-5 Cl Ni-Catalyzed Dimerization aka hydrovinylation catalyst activation Cl Ni Ni 1/2 Cl Ni Ni Cl P(iPr)2(tBu), EtAlCl 2 Cl PR3 Ni major product Cl---AlCl2Et EtAlCl2 Cl---AlCl2Et Ni PR3 Ni PR3 PR3 H H H Cl---AlCl2Et Ni Cl---AlCl2Et PR3 Ni PR3 Cl---AlCl2Et Ni PR3 minor product Catalytic cycle Cl---AlCl2Et rate = 60,000/sec at rt!! Wilke, ACIEE, 1980, 622 ACIEE, 1988, 186 Historical account: ACIEE, 2003, 5000 Ni PR3 Ready; Catalysis Isomerization/cyclization-6 Enantioselective Hydrovinylation common side products Ethylene (1atm), [Ni(allyl)Cl]2 NaBAr4, CH2Cl2, low temp + oligomers + Ligand Br Br Br Ligand Ph O O (Ph-Me-5,3)2P Ni 1 mol% Ni 98% y >99% selectivity 89% ee O O NHAc OBn 1 Ph 0.04 mol% Ni 82% y 92% ee O P little N ~1% <1% O 2 Bulky ligand minimizes styrene dimerization Ph O Ni 3 steps Br Active olefin minimizes ethlene polymerization i-Bu ibuprofen OH hydrovinylation of i-Bu-Styrene with 1: 74% ee w/ 2: 68% ee 1: Rajanbabu, JACS, 2001, 734 2: Leitner, JACS, 2001, 736 Ready; Catalysis Isomerization/cyclization-7 Metal-mediated dimerization: -common use -mild conditions -many applications General Story: Concerted M Mn+2 n 1 new C-C bond 2 new C-M bonds stepwise Mn+2 R3P Ni R3P favored for e- rich PR3 Ni(COD)2 R P 3 PR3 Ni Ni w/ PPhEt2 Ni -2 COD w/P(OMe)3 Ni PR3 favored for small e- poor PR3 Product distribution dependent on nature of ligand and L/Ni. PR3 Houk, JACS, 1994, 330 Weimann, ACIEE, 1980, 569 PR3 R3P Ni Ni w/ P(OPh)3 favored for big e- poor PR3 Ready; Catalysis Isomerization/cyclization-9 Metal-Catalyzed [4+4] cycloaddition H E E Ni(COD)2 (11 mol%) PPh3 (33 mol%) 60 oC E E + E E H 70% (19:1 cis:trans) 2.6% (major product if P(tol)3 is used) PR3 Ni Ni cis 5,5 system favored E E H E Ni(COD)2 (11 mol%) PPh3 (33 mol%) 60 oC Ni H PPh3 H H 85% y 20:1 cis:trans 99:1 d.r. Trans 6,5 system favored Recall thermal [4+4] forbidden under Woodward-Hoffman rules Wender JACS, 1986, 4678; TL 1987, 2451 Ready; Catalysis Isomerization/cyclization-10 Synthetic Applications of [4+4] O O O O O Ni(COD)2 (11 mol%) PPh3 (33 mol%) 60 oC Me Me 67% O H H H O (+)-Asteriscanolide Wender, Jacs, 1988, 5904 H Ni(COD)2 (11 mol%) PO PPh3 (33 mol%) PO 110 oC AcO 52% O OH Ni(COD)2 (11 mol%) PPh3 (33 mol%) RO 110 oC 92% H E H O OH OBz Taxol E But in the end... O O O O O Ni(0): Wender, TL, 1987, 2221 Taxol syn: Wender, JACS, 1997, 2755, 2757 DABCO (cat) HO OH O OP Ready; Catalysis OP Isomerization/cyclization-11 Catalytic [4+2] Cycloadditions R R' Ni(COD)2 (10 mol%) P(O-Biphenyl)3 (30 mol%) X H H or CH2OP R 1:1 - 2:1 n alkynes poor dienophiles for thermal diels-alder X Me, TMS R' O, NTs, NBoc, CH2 n 1 or 2 Ni Wender Jacs 1989, 6432 jacs 1995, 1843 Ni(0) Ni OTBS OTBS H Ni(COD)2 (10 mol%) P(O-Biphenyl)3 (30 mol%) 97% [Rh(COD)Cl]2 (5 mol%) P(O-Biphenyl)3 (48 mol%) 90% Ni(0) may prefer the less hindered olefin while Rh(I) prefers the more e- rich olefin H OTBS Ready; Catalysis Isomerization/cyclization-12 Ready; Catalysis Isomerization/cyclization Ni(cod)2 (20 mol%) PR3 (40 mol%) (mostly PAr3) O + + H Ar Et3SiOTf OSiEt3 + Et3N HOTf Ar Et3N O R H Ar Et3SiOTf Ni(cod)2 (20 mol%) Et3N, tol, rt PCy2Ph (40 mol%) (big, e- rich) P(OEt)Ph2 (40 mol%) (small, e- poor) cf. R H/M + O OSiEt3 R' Ar OTES OTES C5H11 Ph 85% 95:5 homoallyl:allyl 75:25 E/Z C5H11 OTES Ph 75%, 71:29 E/Z M O + Ar OTES O O H3C 64% 95:5 78:22 E/Z cf. R OSiEt R OTES N 82% 84:16 allyl:homoallyl 60% 83:17 Jamison, JACS, 2006, 11513 Ph Ready; Catalysis Isomerization/cyclization Dissociation required for good alignment Favored with big P, Small substrates Ready; Catalysis Intercepted hydrogenation Ready; Catalysis Isomerization/cyclization-13 [5+2] Cycloaddition E alkenes/alkynes RhCl(PPh3)3 (0.1 mol%-0.5 mol%) AgOTf (0.1 mol%- 0.5 mol%) 110 oC R X H 83% allenes H R = Me, 83% TMS, 83% CO2Me, 74% t-Bu E E H H RhCl(PPh3)3 (0.1 mol%-0.5 mol%) X E E X 110 oC R Me R R' R' X O E H R' H Me not clear if ring expansion or cyclization occurs first 96% 92% RhIII X RhIII X or X Rh X Ready; Catalysis X Wender, Jacs 1995, 4720; 1998, 1998, 10976; 1940; 1999, 5348 Isomerization/cyclization-14 Ready; Catalysis Isomerization/cyclization Metal-mediated trimerization: Key early discoveries: Vollhardt, ACIEE, 1984, 539 H Ph CpCo(CO) 2 + CoIII [4+2]/retro [4+1] or insertion/R.E. Ph Ph 48% Volhardt, Bergman JACS, 1974, 4996 Ph H Proposed Mechanism Rovis, JACS, 2006, 12370 Ready; Catalysis Isomerization/cyclization-15 Ru-Catalyzed enyne isomerization R R' + CpRu(COD)Cl (cat) + R' R Can tune b:l (better for b-selective) Trost, JACS, 1995, 615; JACS, 2001, 12504 R R' Intramolecular version: X = O, NTs, C(ewg)2 X PhO2S [CpRu(CH3CN)3]PF6 R n n = 1,2 R' 82% E 80% Ph n R E PhO2S R X R R' O N Ts 75% 62% (8:1) Rxns also referred to as Alder-ene or metallo-ene reactions, but that is misleading given the most likely mechanism: oxidative cyclization X R RuIV X !-Hydride elim. X RuIVH R.E. H X R H R RuII Trost, jacs 1995, 615; 2000, 714 Ready; Catalysis Isomerization/cyclization-16 Synthetic Examples: O O Cp*Ru(CH3CN)3PF6 O o (10 mol%) 50 C O + 46%, 3.5:1 branched:linear 5 equiv) OFmoc O OFmoc O O O O O O L Ru Linear R L Ru R Branched RO Bulky L (eg. Cp*) disfavors linear product O O O HO O O 1.CpRu(CH3CN)3PF6 (10 mol%) 0.001M 58% y 2. acid 61% y O HO O O O O HO OH proposed structure of amphidinolide A Trost, JACS, 2002, 12421 Ready; Catalysis Isomerization/cyclization-16 Similar mechanism observed with Ti(II)... E Cp2Ti(CO)2 (10 mol%) E E E note thorpe-engold effect common Only with E olefins E E TiCp2 E H both CO's gone 89% 1 isomer E 20 mol% Cp2Ti(CO)2 E Buchwald, JACS, 1999, 1976 E [4+2] substrate with Ni(0) ...and Rh(I) O CH3 CH3 H3C [Rh(COD)Cl]2 (S)-BINAP (±)- O O H3C + O CH3 OH O only with Z olefins O 40% >99% ee O OH 46% >99% ee Zhang, TL, 2005, 1823 Ready; Catalysis Isomerization/cyclization General mechanism with electron rich transition metals: Catalytic Pauson-Khand type reactions (reveiw: ACIEE, 2003, 1800) EtOOC EtOOC [Cp2Ti(CO) 2] (5 mol%) 1.2 atm CO EtOOC TiIVCp2 EtOOC EtOOC O EtOOC 91% Buchwald, JACS, 1999, 5881 " Ru3(CO)12 (2 mol %) CO (10 atm) EtOOC EtOOC [RhCl(CO)2]2 (5 mol %) CO2Et CO (0.1 atm) Ph Ready; Catalysis [RuIICO] EtOOC " 86% Murai, JOC, 1997, 3762 EtOOC [RhIII] EtOOC CO2Et TolBINAP (20 mol%) [Ir(cod)2Cl]2 CO (1atm) O EtOOC O [IrIII] Ph Isomerization/cyclization EtOOC O EtOOC CO2Et 91% JOMC, 2001, 624, 73 O Ph Shibata JACS, 2000, 9852 O Ready; Catalysis Isomerization/cyclization-17 O NR2 NR2 NEt2 Starting Materials: LiNEt2/HNEt2 + or geranylamine NEt2 3 1 NEt2 NEt2 2 4 NEt2 LiNEt2/HNEt2 Nerylamine NEt2 Isomerization/Rxns NEt2 Catalyst Substrate 4 (100%) CoH(N2)(PPh3)3 1 3 (85%); 4 (15%) [Rh(PPh3)3(COD)]+ 1 3 (100%) 1 3 (100%) 22 [Rh(R-BINAP)(COD)]+ 1 S-3 (100%) 97 + 2 S-3 (100%) 96 + [Rh(S-BINAP)(COD)] NEt2 H+ H2/Ni ZnBr2 OH OH menthol ee(%) 1 [Rh(DIOP)(COD)] NEt2 Products Cp2TiCl2/iPrMgBr CHO Citronellal isopulegol Ready; Catalysis Isomerization/cyclization-18 Process Development Catalyst Modification Turnover number Rh(BINAP)(COD)+ none 100 Rh(BINAP)(COD)+ added Red-Al 1,000 Rh(BINAP)(COD)+ Substrate purification 8.000 Rh(BINAP)2 catalyst recycling 400,000 Red-AL = Vitride = (MeOCH2CH2O)2AlH2 Na compound ee (%) Production (tons/yr) CHO use synthetic intermediate those stinky candles 97 1,500 98 10 insect growth regulator 100 1,000 pharmaceuticals tabacco houshold products CHO OMe OH Ready; Catalysis Isomerization/cyclization Mechanism + Rh(S-BINAP) R R + Me NEt2 Me D H Rh(R-BINAP)+ NEt2 D NEt2 Me R2 N P S P H P R2 N Rh Rh H R D P enamine H D ee determining step amine, S R2 N P + P Rh R 2N Rh P P H Axial chirality results in gearing of Ph. It is the location of the Ph's that gives a good "chiral environment" near the metal D Rh H NH R Big group (R) in empty quadrant empty = empty Noyori, JACS, 1990, 4897 +