Energy savings of 35 % achieved by

drive modernization in Chemnitz

Electrical Solutions Reference

Instrumentation, Controls & Electrical

SPPA-E3000 Drive Modernization

is the modernization of drive systems with

frequency converters and energy-efficient

motors. This energy engineering solution

is helping the CHP plant Chemnitz-Nord to

achieve energy and thus cost savings of 35 %.

The Result

■ Lower energy costs for

auxiliaries service thanks

to state-of-the-art drive

technology

■ Reduced maintenance

costs through electronic

speed regulation

■ Short payback time thanks

to efficient technology

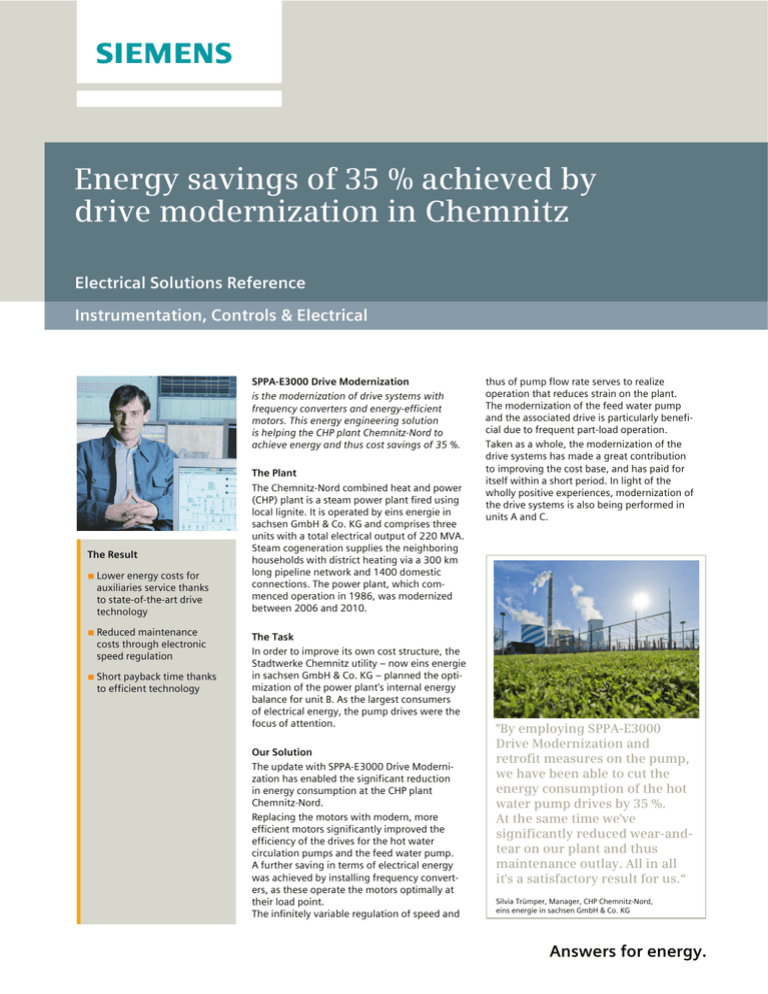

The Plant

The Chemnitz-Nord combined heat and power

(CHP) plant is a steam power plant fired using

local lignite. It is operated by eins energie in

sachsen GmbH & Co. KG and comprises three

units with a total electrical output of 220 MVA.

Steam cogeneration supplies the neighboring

households with district heating via a 300 km

long pipeline network and 1400 domestic

connections. The power plant, which commenced operation in 1986, was modernized

between 2006 and 2010.

The Task

In order to improve its own cost structure, the

Stadtwerke Chemnitz utility – now eins energie

in sachsen GmbH & Co. KG – planned the optimization of the power plant's internal energy

balance for unit B. As the largest consumers

of electrical energy, the pump drives were the

focus of attention.

Our Solution

The update with SPPA-E3000 Drive Modernization has enabled the significant reduction

in energy consumption at the CHP plant

Chemnitz-Nord.

Replacing the motors with modern, more

efficient motors significantly improved the

efficiency of the drives for the hot water

circulation pumps and the feed water pump.

A further saving in terms of electrical energy

was achieved by installing frequency converters, as these operate the motors optimally at

their load point.

The infinitely variable regulation of speed and

thus of pump flow rate serves to realize

operation that reduces strain on the plant.

The modernization of the feed water pump

and the associated drive is particularly beneficial due to frequent part-load operation.

Taken as a whole, the modernization of the

drive systems has made a great contribution

to improving the cost base, and has paid for

itself within a short period. In light of the

wholly positive experiences, modernization of

the drive systems is also being performed in

units A and C.

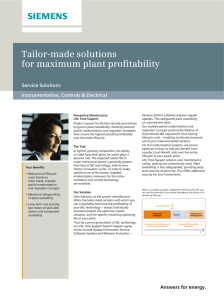

"By employing SPPA-E3000

Drive Modernization and

retrofit measures on the pump,

we have been able to cut the

energy consumption of the hot

water pump drives by 35 %.

At the same time we've

significantly reduced wear-andtear on our plant and thus

maintenance outlay. All in all

it's a satisfactory result for us.“

Silvia Trümper, Manager, CHP Chemnitz-Nord,

eins energie in sachsen GmbH & Co. KG

Answers for energy.

Published by and copyright © 2012:

Siemens AG, Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

For more information contact

sppa-e3000.energy@siemens.com

www.siemens.com/energy/sppa-e3000

Siemens AG

Fossil Power Generation

Instrumentation, Controls & Electrical

Siemensallee 84

76187 Karlsruhe, Germany

E306_FR_DrMod_Chemnitz_e_V2-0

Order no. E50001-G230-A287-X-4A00

Printed in Germany

Dispo 05401, c4bs-Nr. 7465

Printed on elementary chlorine-free

bleached paper.

All rights reserved.

Trademarks mentioned in this document are

the property of Siemens AG, its affiliates, or

their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should therefore

be specified in the contract.