Integrating Digital Design and Fabrication and Craft Production

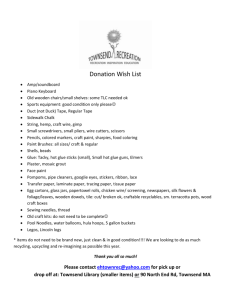

advertisement