in Heavy Weather

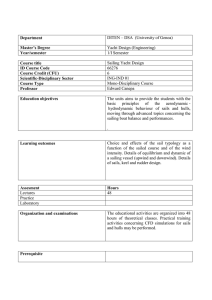

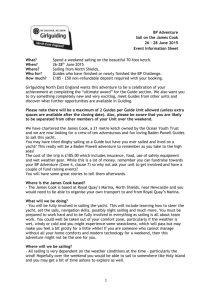

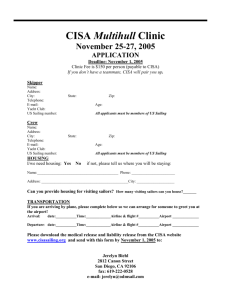

advertisement