Kiln Humidity and Air Psychrometrics Temperature Relative Humidity

advertisement

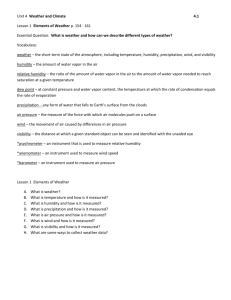

1/18/2015 Kiln Humidity and Air Psychrometrics Bill Smith SUNY ESF Wood Products Syracuse, NY Temperature Relative Humidity Dew Point Vapor Pressure EMC – equilibrium moisture content 1 1/18/2015 Temperature • Temperature— Degree of hotness or coldness. • Dry-bulb—The temperature of the kiln air. • Wet-bulb—The temperatures indicated by any temperature measuring device, the sensitive element of which is covered by a smooth, clean, soft, water-saturated cloth (wet-bulb wick or porous sleeve). Temperature • Temperature— Degree of hotness or coldness. • Drop across the load—The reduction in the dry-bulb temperature of the air as it flows through the load and is cooled by evaporating moisture from the load of lumber. 2 1/18/2015 Relative Humidity • Humidity, relative—Ratio of the amount of water vapor present in the air to that which the air would hold at saturation at the same temperature. It is usually considered on the basis of the weight of the vapor, but for accuracy it should be considered on the basis of vapor pressures. • Humidity, absolute—The weight of water vapor per unit volume of space. Dew Point • Dew point—The temperature at which steam or water vapor begins to condense. 3 1/18/2015 EMC • Equilibrium moisture content—The moisture content at which wood neither gains nor loses moisture when surrounded by air at a given relative humidity and temperature. Interior use applications must be: • Kiln dried hardwoods to 6-7% MC – (North American market; export perhaps somewhat higher) • Eastern white pine perhaps to ~10-12% MC 4 1/18/2015 5 1/18/2015 Equilibrium Moisture Content and Relative Humidity • RH % – 90 – 80 – 65 – 50 – 30 –0 • EMC % – 20 – 16 – 12 –9 –6 –0 6 1/18/2015 RH and EMC “sorption isotherm” 7 1/18/2015 8 1/18/2015 9 1/18/2015 Kiln Drying Schedules • The purpose is to dry as rapidly as possible, to be economical. • However, drying must be controlled to avoid value reducing defects. • Typically, the temperature and the relative humidity (wood EMC) are controlled. • Temperature is raised and relative humidity lowered as wood dries. Kiln Drying Schedules • • • • • So, we know what we want. And we know what we need. Do we always get what we want? Really, you can’t always get what you want. But, do we get what we need! 10 1/18/2015 Some typical schedules - Some typical schedules - 11 1/18/2015 Some typical schedules - Some typical schedules - 12 1/18/2015 Some typical schedules - Schedule Control - 13 1/18/2015 14 1/18/2015 15 1/18/2015 Schedule Control - 16 1/18/2015 17 1/18/2015 18 1/18/2015 19 1/18/2015 20 1/18/2015 21 1/18/2015 Maintainining %MC in Storage (warehouse) really the same issue 22 1/18/2015 Temperature Relative Humidity % EMC – Relationships Temperature – down? Air “holds” less H2O Relative Humidity - higher % EMC – higher lumber %MC - higher 23 1/18/2015 Temperature Relative Humidity % EMC – Relationships 24 1/18/2015 Add heat Temperature – higher air can “hold” more H2O Relative Humidity - lower lumber drier Remember – outdoor RH - 100% in early morning - 30-40% in later afternoon 25 1/18/2015 Enclosed storage - Keep doors closed, especially when %RH and vapor pressure is high. - warm air can be dry - cool air can be humid Thank you! • Questions? • Comments? – Bill Smith – wbsmith@esf.edu – 315/470-6832 26