September 2015

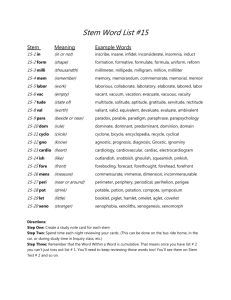

advertisement