Traction transformers from Nuremberg traveling the U.S.

advertisement

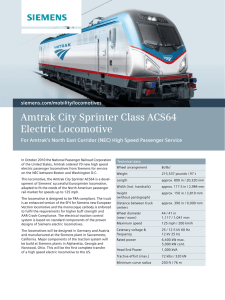

Traction transformers from Nuremberg traveling the U.S. Nuremberg traction plant supplies 70 high-tech transformers for Amtrak electric locomotives in the U.S. siemens.com/energy/transformers The traction transformer plant in Nuremberg, Germany, is making an important contribution to the success the Business Unit Power Transmission has on the U.S. market: It produces the transformers for the Amtrak ACS-64 electric locomotives, which play an important role in the development of rail transport in the U.S. As early as 2012, the plant delivered the first few of a total of 70 transformers, with further deliveries scheduled until mid-2015. The trans­ formers have already been proven in practice. In the summer of 2013, the first three ACS-64 electric locomotives, which are manufactured by the Siemens Infrastructure & Cities Sector, passed muster, and the first locomotives are used in passenger service on the highly frequented Northeast Corridor between Washington, DC, New York, and Boston. The last of the 70 Amtrak locomotives that have been ordered is scheduled for delivery by the end of 2015. 200 km/h and three UIC voltages handled reliably The transformers from Nuremberg that are used in the locomotives have been designed for a power output of up to 6.4 megawatts. This enables the locomotives to pull up to 18 passenger cars at a top speed of approximately 125 mph. The existence of several different railroad systems using different frequencies and voltages poses a particular challenge in the U.S. This means that every locomotive needs to have a transformer that is able to handle the three North-American UIC voltages of 25, 12.5, and 12 kV. The solution from Nuremberg: the voltage change between the three UIC voltages is not performed in the conventional way on the low-voltage side, but on the high-voltage side of the winding. The 3-system transformer from Siemens makes this possible at any time without any problems. »The passenger doesn’t notice the voltage or frequency change and arrives completely undisturbed. This way, our transformer once more proves to be an absolute high-tech product,« says Berthold Sedlmaier, head of the Traction Transformers sub-segment (E T TR DT TT) and plant manager of the Nuremberg traction transformer plant. Braking energy recovery saves $300 million The transformer also makes it possible to re-feed recovered braking energy into the contact wire. This way, the American railway company Amtrak can save electricity costs of approximately $300 million per year. Left: The first Amtrak electric locomotives from Siemens are already operating on the railroad track between Washington, DC, New York, and Boston Right: On the entire track, the power trans­ former from Nuremberg ensures a smooth voltage change that remains unnoticed by the passengers Siemens AG Energy Sector Power Transmission Division Transformatoren Berthold Sedlmaier, E T TR DT TT berthold.sedlmaier@siemens.com Publisher and copyright 2014: Siemens AG Energy Sector Freyeslebenstrasse 1 91058 Erlangen, Germany Answers for energy.