STAR* Fuel Systems

For Industrial Gas Turbines up to 15 MW

Answers for Energy

Gas Fuel Valve

Gas Fuel System Benefits

Replacement for hydro/pneumatic / mechanical

governor and in-house throttle valve

Improved reliability – by simplified robust ball valve

design with greater operational tolerance

Utilizes V-notch rotary ball valve with metal wiping

surfaces

Improved response and controllability – gas turbine

and fuel supply parameters constantly updated to

provide improved starting, load shedding, etc.

Optimizes gas turbine performance by continuously

monitoring pressure and temperature, adjusting fuel

delivery to meet demand

Electric actuator with position transmitter delivers

high operating torque and accuracy

The Fuel Valve and Actuator combination ensures

accurate and reliable operation even under the most

arduous conditions

Will tolerate poor quality gas fuel but the gas supply

must be within the parameters of Siemens Fluid

Specification Report 65/0027

*STAR is a Small Turbine Advanced Modernization and Upgrade.

Improved availability – maintenance downtime is

significantly reduced

Less susceptible to fuel borne contamination – the

new fuel control valve has a self-cleaning action

which incorporates a wiping surface arrangement and

a high torque actuator

Reduced gas fuel supply pressure – it may be possible

to run at reduced loads on lower gas fuel supply

pressures

Smoother gas turbine running characteristics –

accurate fuel control, reduced component stress and

wear throughout the operating range

For specific turbine models, please contact your Siemens Industrial Gas

Turbines Ltd representative.

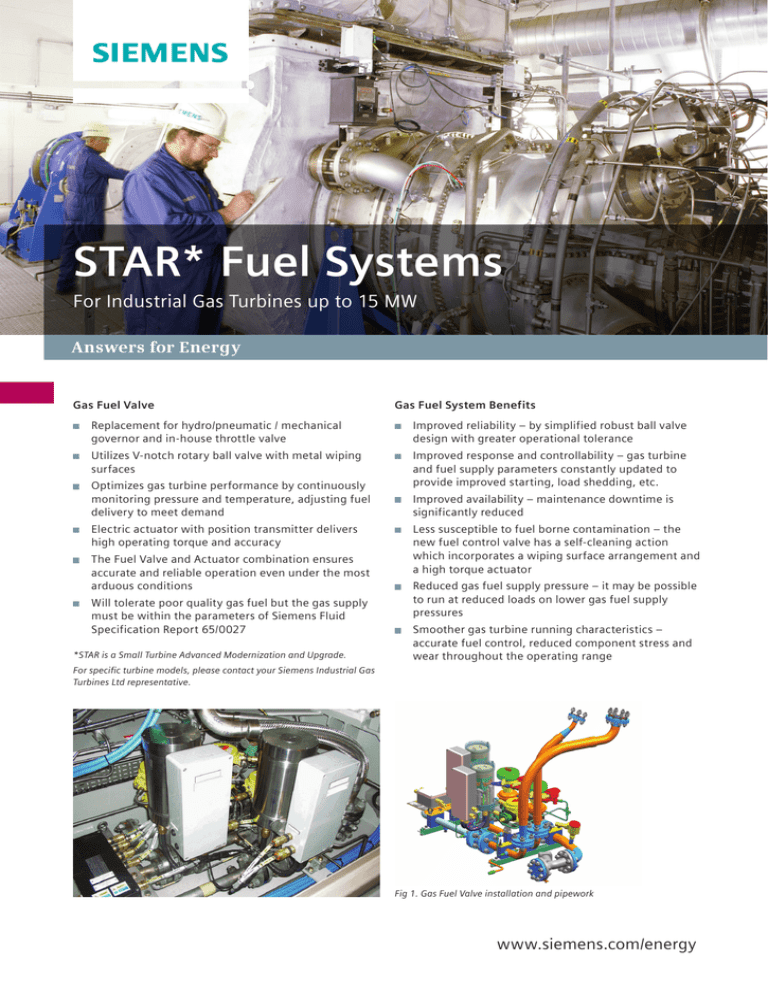

Fig 1. Gas Fuel Valve installation and pipework

www.siemens.com/energy

Liquid Fuel System Benefits

Obsolescence

Cost

Reduction

Health &

Safety

Benefit by

Mods & Ups

Reliability

Performance

Environment

Liquid Fuel Valve

Replaces hydro / pneumatic /

mechanical governor and in-house

throttle

The modernization assembly is

typically made up of two individual

parts, a Fuel metering module and a

High Pressure Filter but in some

instances (on TA turbines) a relief

valve may also be included

Direct Mods & Ups

Liquid fuel feed protection – new

protective devices reduce the

possibility of damage to components

and fuel leakage into the surrounding

area

Better fuel changeover on dual fuel

engines – new gas fuel valve, in

conjunction with the new liquid fuel

valve, provides gradual ‘bump-less’

transfer

Smoother gas turbine running

characteristics – resulting from

accurate fuel control, reduce

component stress and wear

throughout the gas turbines’

operating range.

If not already fitted then, for safety,

it is strongly recommended that

these devices be installed:

Gas Block and Vent Valve (OffPackage)

Liquid Fuel Block & ThermalRelief Valve Assembly Upgrade

(Off-Package)

On-skid Gas Fuel fast acting

Block valve

Associated modernization and

upgrades:

TB S7-300TM Microcontroller

STA-RMS – Remote Monitoring

System

Improved Air Inlet Filtration –

HEPA Filtration

Core/Package uprates

Please contact your local Siemens

representative for further information.

ISCAP (In Service Capability)

Modifications

Halon replacement F&G system

The Fuel Metering Module comprises

of a Direct drive valve with electric

actuator and position transmitter

The direct drive valve acts as a

variable electronic orifice. The linear

relationship between signal and flow

is maintained by a regulating valve,

which senses outlet pressure and

maintains a set pressure drop across

the direct drive valve. Excess flow is

returned to pump suction

Fig 2: Liquid Fuel Valve installation

and pipework

Published by and copyright © 2013:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Energy, Inc.

4400 Alafaya Trail

Orlando, FL 32826-2399, USA

For more information, please contact

our Customer Support Center.

Phone: +49 180 524 70 00

Fax:

+49 180 524 24 71

(Charges depending on provider)

E-mail:support.energy@siemens.com

www.siemens.com/energy

Energy Service Division

LCN 2013 - F33.14 LN

Printed on elementary chlorine-free

bleached paper.

All rights reserved. Trademarks mentioned in

this document are the property of Siemens AG,

its affiliates, or their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should

therefore be specified in the contract.