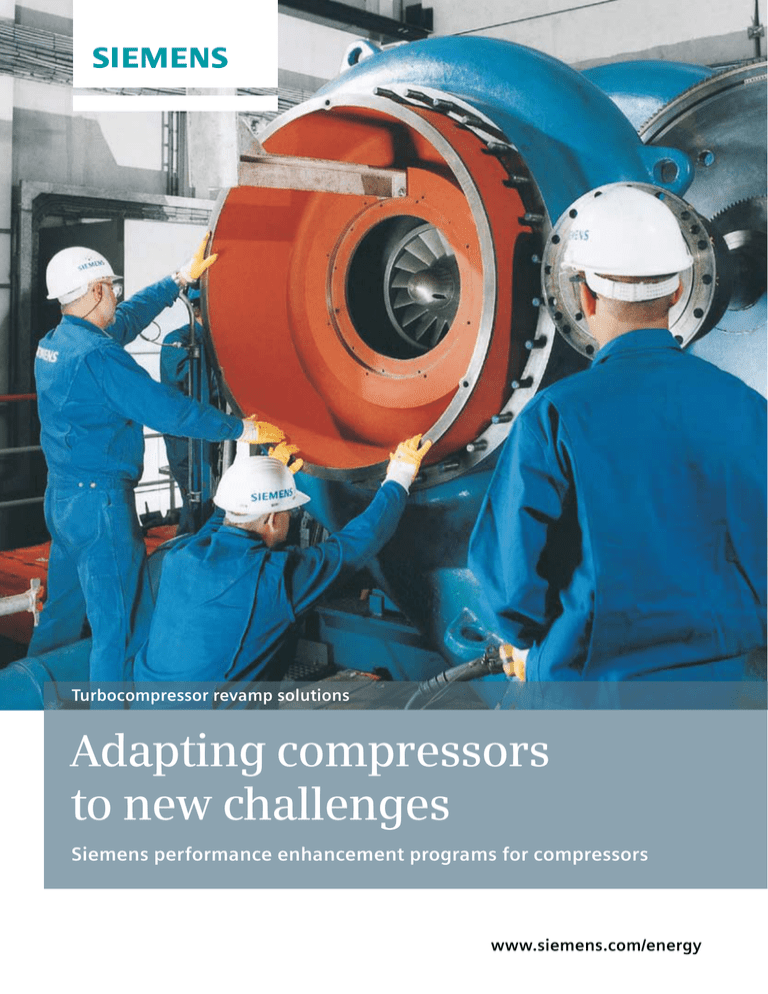

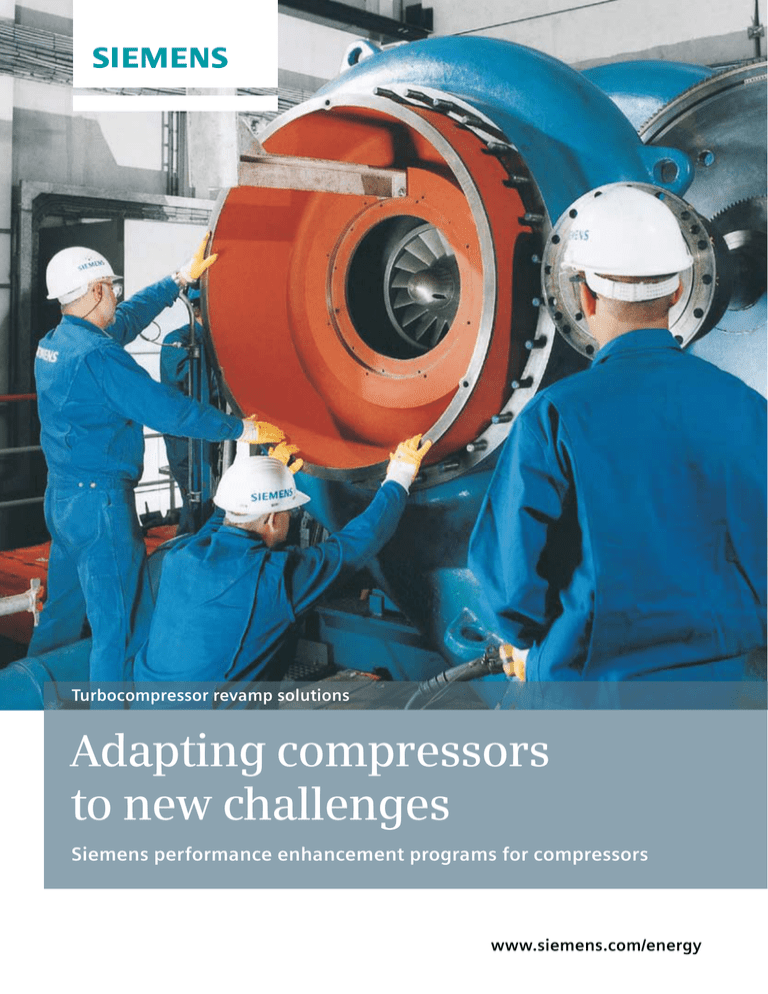

Turbocompressor revamp solutions

Adapting compressors

to new challenges

Siemens performance enhancement programs for compressors

www.siemens.com/energy

The optimal strategy to

meet new requirements

Siemens compressor performance enhancement

protects investments and creates value added.

2

In many industries rotating equipment is the backbone of

core processes. This is why compressors and their drives

are designed to operate continually over a long period

of time. However, market conditions can easily change,

and so can best operational practices and framework

conditions. This means that equipment modifications

become necessary.

Revamp solutions from Siemens:

customized design

state-of-the-art compressor technology

the know-how of a market leader

In such cases, the replacement of main compressor

components or even entire compressors and drives is

usually one of the major cost factors. A revamp can be

a cost-effective solution enabling existing machinery

to work more efficiently, meet new requirements, and

conform to new emission reduction guidelines.

unique knowledge of the entire train history

with OEM equipment

While some main compressor components are replaced

during a revamp, many existing parts and ancillary

equipment can be reused. This minimizes costs and

ensures a relatively short shutdown period.

a unique service partnership

outstanding experience in revamping all types

of turbocompressors

strong rotor dynamic engineering capabilities

Siemens, a global powerhouse in compressor and turbine

technology, has the expertise and experience to provide

revamp solutions for compressors as well as for entire

trains as a one-stop solution.

3

Welding of an impeller

Rotor installation of an axial radial turbocompressor

Knowledge that pays off

Familiarity with the individual machine and its entire

history is what puts the Siemens experts one step ahead.

Every plant has specific technical, operational, financial,

and environmental requirements. This is why knowing

the entire history of an individual machine is a real

advantage – just like the wide experience in revamping

compressors of all types the Siemens experts have

acquired over several decades.

This rare combination makes possible unique insights

that enable implementing the latest state-of-the-art

technology, precisely identify hidden potential, and

enhance both short and long-term turbomachinery

performance.

There is a single point of contact for the customer for

all questions, as each revamp project is assigned to a

dedicated service team. This ensures that the entire project

keeps running like clockwork. Be it replacement parts,

professional advice on delivery, and installation or project

coordination: the Siemens expert in charge is just a phone

call away.

4

Single-shaft compressor rotating element ready for installation

Precise planning is half the story

The adaptation of a compressor is a cost-efficient way

of answering to new process conditions. However, there

are several factors to be considered in order to make

the investment pay off quickly. This is why the Siemens

experts offer their support as early as when the customer

defines the new operating conditions. The experts then

perform a feasibility study as a first step. Such a study

helps evaluate whether a revamp is economically feasible

and the scope of engineering required.

In a next step, a number of investigations, which can be

relatively extensive, enable precise findings on how the

compressor can be adapted to new process parameters in

a highly efficient manner. Necessary and advantageous

changes to mechanical items are defined. Furthermore,

applicable environmental regulations are taken into

account.

The exact knowledge of the operational and maintenance

history of a plant and its compressor trains provides a

clear view of its improvement capacity. It even makes

possible the incorporation of new features in a way that

facilitates future revamps. This keeps the compressor

as versatile as possible and opens new potential for the

optimization of capital and operational expenditures.

Back on track faster

One part of the story is the extensive reuse of existing

parts that yield economical benefits. Revamps also provide

even more advantages that deserve to be considered:

the installation of new machinery usually goes hand

in hand with long lead times and notable construction

efforts resulting in substantial downtime. A revamp can

be performed much quicker. This means shorter downtime

of the production facility and, therefore, a much better

overall cost situation. Above that, the life cycle of the

machinery is extended, which can translate into further

savings. Stored spare parts can further be used and the

acquired operating experience does not become obsolete.

Experience means value added

Siemens is a manufacturer with a wealth of hands-on

experience in compressors and turbines – experience that

transforms directly into cost advantages for the customer:

the Siemens experts know exactly how to handle a revamp

project of any size. They are aware of a compressor’s

hidden reserve and know how to best make use of them.

They have the know-how it takes to get any revamp done

in the shortest possible time.

Discover for yourself on the following pages how Siemens’

revamp expertise has led to lasting benefits in various

industries and applications.

5

Removal of an old compressor

Cases from offshore

oil and gas production

Pressure change in offshore hydrocarbon production

The pressure in a reservoir dropped due to depletion, so a

reduction in the first-stage suction pressure from 80 bar

to 50 bar was demanded in order to increase the overall

recovery rate. This meant that the entire process had to

change. Major restrictions resulted from the design of the

offshore platform, whose original construction was based

on single-lift mounting. The new compressor needed to fit

the existing stools and bedplate exactly, and a footprint

solution that would run until the end of field life was

demanded by the operator.

An STC-SV vertically split casing with an initial inner bundle of three impellers opened the possibility to retain the

casing and all ancillary systems and react to further reduction in suction pressure by exchanging the inner bundle

alone. All modules were produced, tested, and pre-commissioned onshore to minimize activities on the platform.

Original (left) and modified (right) compressor design

6

2000

1500

1000

500

Polytropic head (kJ/kg)

0

60

REVAMP

50

40

30

ORIGINAL

20

200

Discharge pressure p2 [bar]

2500

Compressor operating envelope: old map versus redesigned

compressor map

Gas power (kW)

Original compressor operating envelope in black, red depicts

compressor map for lighter mol weight

150

145 bar

90%

100

100%

n/n=105%

80%

70%

10

0

0

100

200

300

400

500

600

700

800

50

50

50

75

100

110 Mmscfd

125

150

Flow Rate [Mmscfd]

Suction volume flow (m3/hr)

Upgrade for reinjection

The gas-to-oil ratio of a new unit was much higher than

predicted, with 50 percent more gas than the compressor

was designed for being produced. Revamping possibilities

were evaluated in order to make the compressor train

cope with the additional gas volume and higher temperatures, eventually resulting in an upgraded compressor

design.

However, the drive train, the electric motor, and the

gearbox also required an upgrade due to the higher power

demand of the compressor. Hence, a more powerful

electric motor of equal footprint and a new gearbox were

included in the package.

Redesigned compressor components shown in color

Adaptation to associated gas weight

Due to short remaining reservoir life, the customer

decided to tie-in an additional field and produce the oil

and gas over the existing facility. The reservoir prediction

gave a substantially lower mol weight for the gas from

the new field, and reduced head capacity with the consequence that the compressor operating point moved to the

left of the curve causing the machine not to meet the contractual volume flow. This meant that the customer would

not have been able to meet contractual requirements with

the existing compressor train.

Modifications based on the new operating data included

new compressor internals for the compressor to meet the

new head and flow demand.

Compressor old design (top section) versus new design

(colored bottom section)

7

250

200

Polytropic head (kJ/kg)

REVAMP

150

100

50

ORIGINAL

0

0

500

1000

1500

2000

2500

3000

3500

Suction volume flow (m3/hr)

Initial situation

New design

Cases from refineries and

the chemical industry

Process changes in a refinery

A refinery was upgraded to cope with new low-sulfur

requirements for modern fuels. The existing two-stage

hydrosulfite compressor with a relatively high-flow lowhead design needed to be revamped to a low-flow highhead design. This was achieved by changing the compressor

from a two-stage setup to a four-stage system.

A feasibility study demonstrated that machine redesign

was possible by replacing the internals of the existing

compressor. The new configuration now comprises four

impellers instead of the original two. Moreover, the impeller diameter was increased to ensure the required pressure

ratio can be achieved.

The complete aerodynamic internal compressor design

was changed while the existing casing was retained,

thus meeting the new process requirements at the lowest

cost and lead time.

Redesigned compressor components shown in color

8

Reduction from five to four impellers and respective adaptation

of the feedback stage

Map of predicted performance

Discharge pressure PD (bar)

28

26

24

22

20

6

4

α=65°

α=70°

8

α=30°

10

α=45°

α=60°

α=60°

12

α=45°

14

α=-20°

16

α=0°

α=-15°

α=-10°

α=0°

α=30°

α=15°

18

2

0

Power requirement pcoup (MW)

Original discharge pressure

PD and power

requirement

pcoup (orange)

compared to

predicted performance map (red)

38

36

34

32

30

28

26

24

22

20

18

16

14

12

10

8

6

1

2

3

Mass flow (dry) m L-L (kg/h) *10**-5

Integrally geared compressors in a PTA plant

An STC-GV (125-5) integrally geared compressor was

revamped in order to enable a production increase of

about ten percent. However, the customer demanded

the changes to be kept to an absolute minimum. It

was stipulated that the drive and gear units had to

stay. Therefore, the Siemens engineers used eccentric

bearings to increase the distance of the axis. This resulted

in an improved gear ratio with a higher rotation speed.

Only one rotor had to be changed in addition.

Ethylene machine in a PTA plant

An STC-SV (8-5-A) single-shaft compressor required revamp

to make possible a production increase, which entailed

severe process data changes: volume changed by about

40 percent, drive power demand by about 44 percent.

Replacement parts in red, modified parts in blue

Replacement of the drive motor and the gear unit.

The compressor casing remained unchanged, while the

compressor interior and the rotor were modified

Keeping the housing of the old compressor was preferred

in order to keep changes in the process control system

with the feeder lines to a minimum. The feeder lines of

the stator parts were met, and the number of impellers

was reduced from five to four, thus turning the machine

into an STC-SV (8-4-A). Moreover, a new motor and a new

gear unit with diagonal split joint were installed to meet

the higher performance requirements. The diagonal split

joint was required to meet the compressor’s center height

in order to meet the footprint of the original machine.

9

Typical single dry-gas seal layout

Clean buffer gas

Leakage

Process

Atmosphere

Special technologies that

increase reliability

Focus on dry gas seal technology

First introduced in 1987, Siemens dry gas seal technology

has become a proven approach that stands for reliable

operation. Today, a considerable number of compressors

is equipped with dry gas seals, more than 20 percent of

them upgraded compressors of older design. Dry gas seals

not only eliminate the particular challenges associated

with wet-seal systems, they also help reduce seal exchange

time, power losses, and maintenance costs, and improve

the overall operating health of turbomachinery.

Convincing advantages

Dry gas seal upgrades stand for proven technology, reliable operation, and reduced plant downtime. The system

is designed in accordance with API 614 and even exceeds

the requirements of this standard. It reduces maintenance

effort, bearing inspections and instrumentation repairs can

be performed considerably easier. The oil itself remains

cleaner, and oil leakages into processes become a thing

of the past. All instrumentation is valved and arranged to

permit on-line testing without upsetting the operation

of the compressor.

10

State-of-the-art lubrication oil system

Focus on oil system revitalization

Siemens provides a targeted solution that addresses the

common reliability problems of older oil systems, their

increased maintenance requirements resulting from damaged components, and the consequential resource drain

and loss of profits.

Substantial increase of reliability and availability

New strategies in system design, engineering progress

in component technology, and new approaches in operational philosophy are the basis for oil systems that are

more reliable, functional, and ergonomic than currently

common systems.

Upgrade options comprise packages for pumps, filters,

and coolers, and the installation of a continuously

coalescing oil filter to remove free water. Along with the

replacement of a considerable number of parts, system

piping and component placement are reconfigured

and optimized to obtain a more ergonomic design that

supports easy operation and maintenance.

Such an upgrade results in improved reliability of the

entire system, as the ability to maintain proper oil pressure and temperature, as well as high cleanliness levels,

help minimize outage risks and translate into increased

bearing and seal life. An upgraded system is even capable

of performing cold oil startups without problems.

Focus on air trains

Air compressors are used in air separation plants, for the

production of compressed air, in the steel industry, in the

fertilizer and chemical industry, and in many other fields

of application. In most cases, integrally geared compressors and axial-flow compressors are used for these tasks.

These two compressor types are traditionally characterized by high efficiency.

Volume increases of up to 15 percent can be obtained

through the modification of flow-guiding components,

the exchange of the impellers, or the exchange of the

rotor blades. Structural changes are kept economically

justifiable in such cases, and suitable studies allow the

definition of possible increases and the precise estimation

of required structural changes beforehand.

Focus on control system modernization

While compressors themselves have relatively long life

cycles, many control system components become obsolete

or discontinued within a comparatively short period of

time. In such cases, optimizing the control system hardware using the modular Siemens compressor automation

system SCAUT can ensure reliable performance upgrades

of the plant and machinery for years to come. Depending

on individual factors, a partial exchange or a total optimization of the controls may be advisable. Both can be performed by Siemens experts, who also have the know-how

and experience to handle and integrate third-party devices.

11

Published by and copyright © 2011:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

For more information, please contact

our Customer Support Center.

Phone: +49 180 524 70 00

Fax:

+49 180 524 24 71

(Charges depending on provider)

E-mail: support.energy@siemens.com

Service Division

Order No. E50001-W510-A208-X-4A00

Printed in Germany

Dispo 34805, c4bs No. 7817

fb 3366 WÜ WS 09113.0

Printed on elementary chlorine-free

bleached paper

All rights reserved.

Trademarks mentioned in this document

are the property of Siemens AG, its affiliates,

or their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should therefore

be specified in the contract.