Air-cooled Footprint ™-Generators for

Industrial Applications

Generator Services

Energy Service, Oil and Gas and Industrial Applications Services

Background

This Footprint-Concept is

applicable for:

Four-pole industrial

generators up to 25MVA

Independent from generator

manufacturer and type

With slip-ring or brushless

excitation

The four-pole industrial generators, built in the

past (before 1990) used for a power range up

to approx. 25MVA, more and more require

extensive reconstruction measures due to the

ageing of the components, e.g. rotor and stator

windings. In many cases, a safe operation of

these generators can no longer be ensured due

to aged insulation.

With frequencies 50Hz and

60Hz

Some of the possible repair measures e.g.

rewinding require a longer outage period.

With voltages 4KV to 16KV

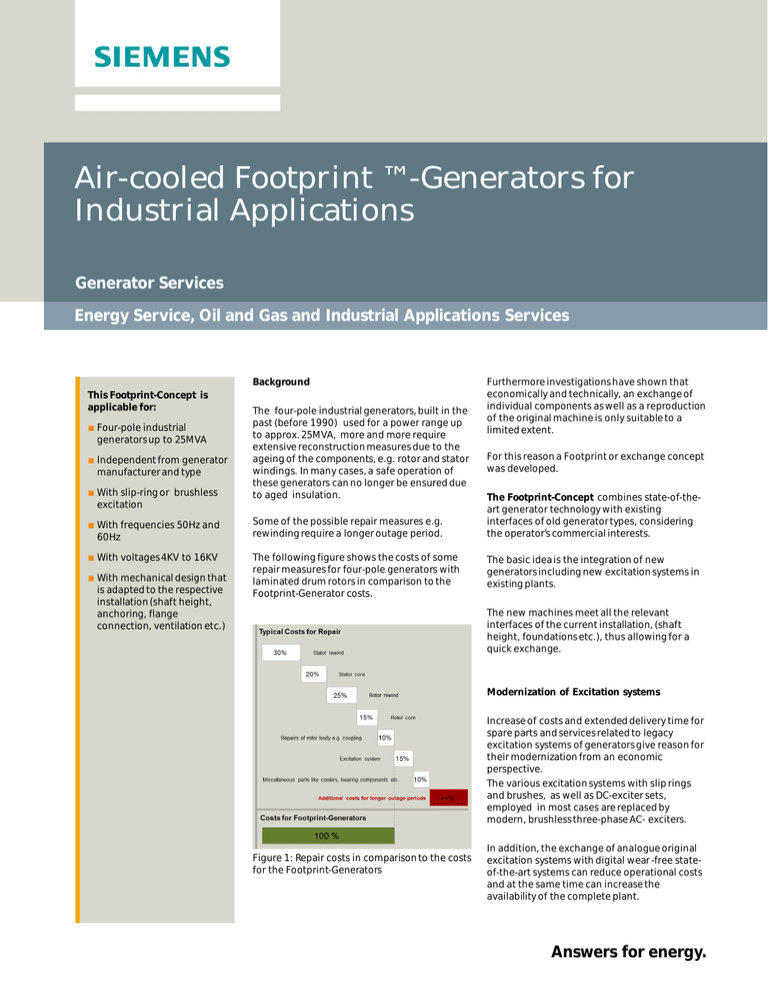

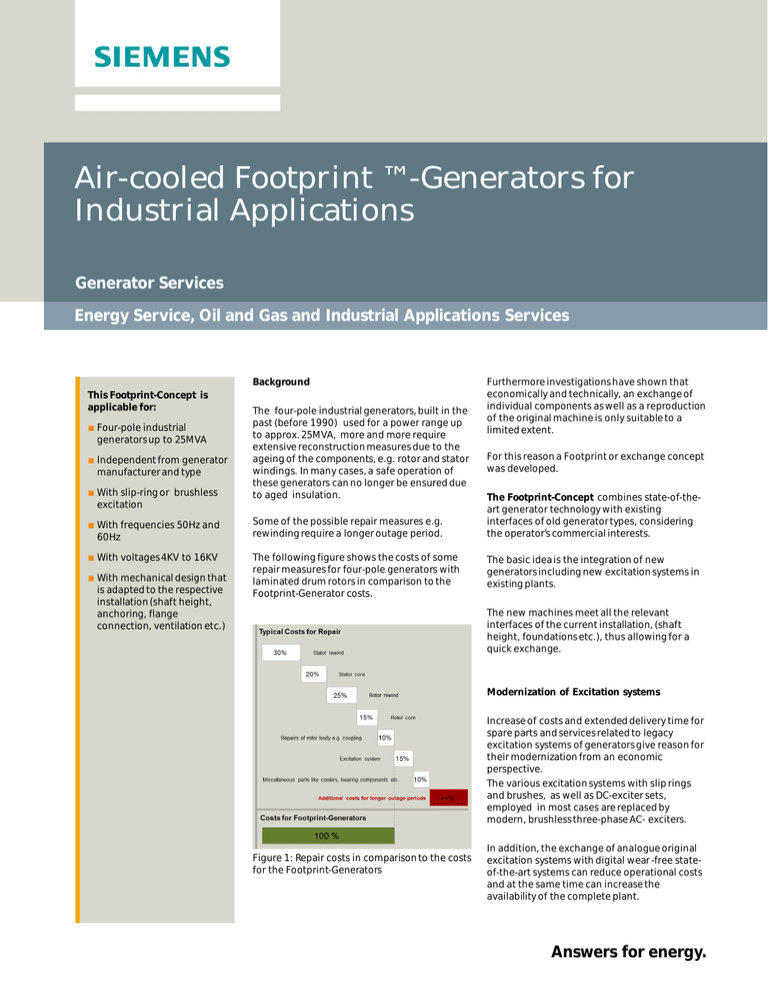

The following figure shows the costs of some

repair measures for four-pole generators with

laminated drum rotors in comparison to the

Footprint-Generator costs.

With mechanical design that

is adapted to the respective

installation (shaft height,

anchoring, flange

connection, ventilation etc.)

Furthermore investigations have shown that

economically and technically, an exchange of

individual components as well as a reproduction

of the original machine is only suitable to a

limited extent.

For this reason a Footprint or exchange concept

was developed.

The Footprint-Concept combines state-of-theart generator technology with existing

interfaces of old generator types, considering

the operator’s commercial interests.

The basic idea is the integration of new

generators including new excitation systems in

existing plants.

The new machines meet all the relevant

interfaces of the current installation, (shaft

height, foundations etc.), thus allowing for a

quick exchange.

Modernization of Excitation systems

Increase of costs and extended delivery time for

spare parts and services related to legacy

excitation systems of generators give reason for

their modernization from an economic

perspective.

The various excitation systems with slip rings

and brushes, as well as DC-exciter sets,

employed in most cases are replaced by

modern, brushless three-phase AC- exciters.

Figure 1: Repair costs in comparison to the costs

for the Footprint-Generators

In addition, the exchange of analogue original

excitation systems with digital wear -free stateof-the-art systems can reduce operational costs

and at the same time can increase the

availability of the complete plant.

Answers for energy.

Typical Applications for the FootprintConcept

Some typical industrial generators, which

fit into this concept, are shown in the

following figures.

Figure 2: Generator 4,500KVA, 6,300V,

cos = 0.8, slip-ring excitation 45V, 520A,

1,500rpm

Potential Benefits for the Operator

Altogether, the Footprint-Concept offers

the following benefits:

• Short outage period (resulting from

adapted design to the respective

installation like shaft height, anchoring,

flange connection, ventilation etc.)

• Reduced operational costs (for

maintenance e.g. by decreasing the

maintenance intervals, insurance, etc.)

• Flexible adjustment of design and

cooling system

• Increased operational safety and plant

availability (due to new components)

• Extension of plant life time

• Increased performance (active and

reactive power – possible on demand)

• Increased efficiency respectively

decreased power losses

Additional potential benefits after

exchanging the legacy excitation system:

• Reduced operational costs (also for the

excitation system)

• Reduced contamination (due to carbon

dust)

• Reduced wear parts (stock-keeping)

• Abolition of exciter bearing

References

The Siemens experiences are based on

more than 1,000 air-cooled generators

with laminated drum rotors which are in

operation worldwide.

The Footprint-Concept has already been

implemented in about 30 plants.

For more detailed information

please contact your local Siemens

sales representative or send us an

email to:

support.energy@siemens.com

Figure 3: Generator 18,040KVA, 6,930V,

cos = 0.8, brushless excitation 80/200V,

8/16A, 1,800rpm

Figure 4: Generator 18,000KVA, 6,300V,

cos = 0.8, brushless excitation

113/159V, 3.7/5.2A, 1,500rpm

Figure 5: Side view of Footprint-Generator with brushless excitation (exciter in overhang

without an additional bearing)

Published by and copyright @ 2014

Siemens AG, Energy Sector

Econova-Allee 3

45356 Essen, Germany

Siemens Energy, Inc.

4400 Alafaya Trail

Orlando, FL 32826-2399, USA

For more information, contact our

Customer Support Center.

Phone: +49 180/524 70 00

Fax:

+49 180/524 24 71

(Charges depending on provider)

e-mail: support.energy@siemens.com

Document name: Footprint-Generators for Industrial

Applications

Order no. E50001-G510-A245-X-7600

All rights reserved.

Trademarks mentioned in this document are

the property of Siemens AG, its affiliates, or

their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should

therefore be specified in the contract.