Footprint/substitute generators

for type series FT and FTH

Background

The two-pole generators of the type series

FT (air-cooled) and FTH (hydrogen-cooled),

built in the past up to a maximum capacity

of about 130 MVA, more and more require

extensive reconstruction measures due to

the aging of the components, e.g. rotor and

stator windings. In many cases, a safe operation of these generators can no longer be

ensured due to outworn insulation.

Instead of an expensive rewinding many

operators decode for global upgrades,

resulting in a lasting increase of the plant’s

operating efficiency, considering expenses

and reconstruction period at the same time.

Footprint concept for generators

of type series FT and FTH

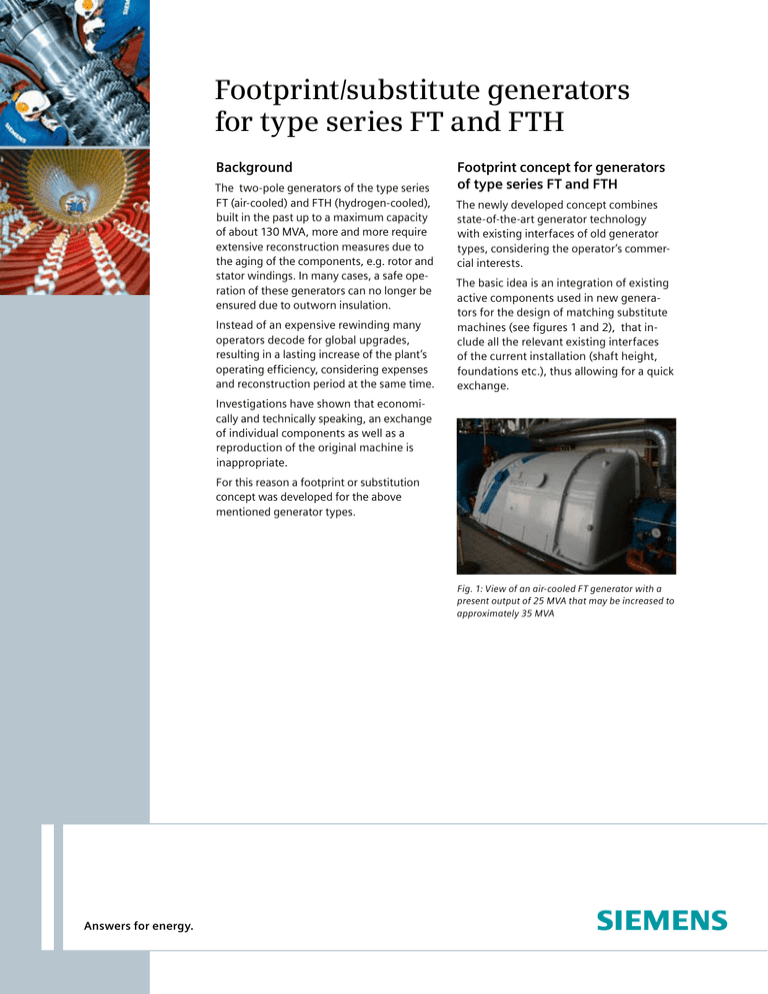

The newly developed concept combines

state-of-the-art generator technology

with existing interfaces of old generator

types, considering the operator’s commercial interests.

The basic idea is an integration of existing

active components used in new generators for the design of matching substitute

machines (see figures 1 and 2), that include all the relevant existing interfaces

of the current installation (shaft height,

foundations etc.), thus allowing for a quick

exchange.

Investigations have shown that economically and technically speaking, an exchange

of individual components as well as a

reproduction of the original machine is

inappropriate.

For this reason a footprint or substitution

concept was developed for the above

mentioned generator types.

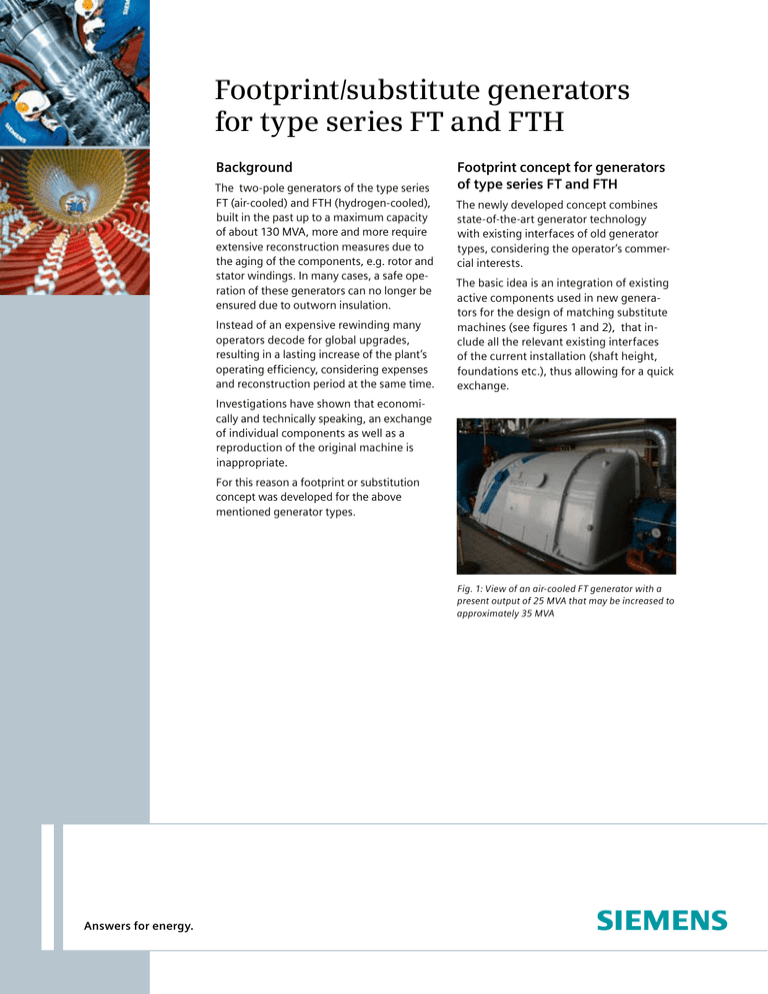

Fig. 1: View of an air-cooled FT generator with a

present output of 25 MVA that may be increased to

approximately 35 MVA

Answers for energy.

Fig. 2: Lateral view of a newly developed generator that is a substitute for the generator shown in fig. 1

The developed footprint concept is applicable for all the FT generators, independent

from design and cooling system, for all

established requirements:

Frequencies 50 Hz and 60 Hz

Voltages 6,3 kV /10,5 kV /13,0 kV

Hydrogen-cooled FTH generators may

optionally be replaced with new, more

efficient, air-cooled machines. Hereby, the

abolition of operational costs for hydrogen

systems effects a significant saving potential for operators.

Excitation system exchange

Increase of costs and extended delivery

time for spare parts and services connected

with legacy excitation systems of FT

generators give economic reason to their

modernization.

Published by and copyright © 2008:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Power Generation, Inc.

4400 Alafaya Trail

Orlando, FL 32826-2399, USA

The exchange of analogue original excitation systems with digital wearless stateof-the-art systems reduces operational

costs and at the same time increases the

availability of the installation.

The direct-current exciter sets employed

in most cases (see fig. 3) are replaced by

modern, brushless three-phase alternatingcurrent exciters.

For more information, contact our

Customer Support Center.

Phone:+49 180/524 70 00

Fax: +49 180/524 24 71

(Charges depending on provider)

e-mail: support.energy@siemens.com

www.siemens.com/energy-support

Altogether, the Footprint concept offers

operators the following benefits:

Generator substitution takes place using

a design that is adapted to the respective

installation (shaft height, anchoring,

flange connection, ventilation etc.),

resulting in short downtime.

If required the nominal output of the

generator can be increased, especially

when considering a future power

enhancement of the entire machine

unit. Based on reduced output power

the operating conditions losses are

decreased, as well as heating of the

components.

An implementation of other cooling

systems and designs is possible, e.g.

a changeover to a closed ventilation

system.

Increased operational safety and

availability by means of component

renewal.

Longer service life.

Additional benefits after exchanging the old

excitation system:

Extension of maintenance intervals

Reduced contamination due to

carbon dust

Separate closed ventilation system

as bypass of the main generator’s

cooling loop

Order No. A96001-G90-B186

Printed in Germany

1386 J DA 0208 1.

Lower operational costs due to

- reduction of wear parts (stock-keeping)

- abolition of exciter bearing

All rights reserved.

Subject to change without prior notice.

Printed on paper treated with chlorinefree bleach.

Trademarks mentioned in this document are the property of Siemens AG,

its affiliates, or their respective owners.

The information in this document

contains general descriptions of the

technical options available, which may

not apply in all cases. The required

technical options should therefore be

specified in the contract.

Benefits

Fig. 3: Excitation set of an FT generator