UNIVERSITY ISSUE

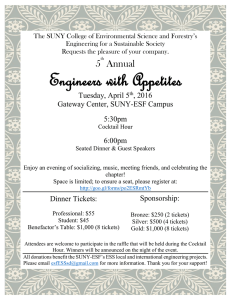

advertisement

UNIVERSITY ISSUE SUNY-ESFSolidifiesLinkswith Radiation-CuringIndustry NovelOrganic-InorganicHybrid NanocompositeCoatingsby UV-InitiatedSol-GelProcess Self-InitiationofPhotopolymerization ReactionsUsingHalogenated(Meth) Acrylates FromGasBarrierstoHighGasFlux Membranes:UV-CuredThiol-ene NetworksforTransportApplications ControlofFree-RadicalReactivityin PhotopolymerizationofAcrylates IUCRCPromotesWorld-ClassResearch AcademicListingofUniversities PRSRT STD US POSTAGE PAID CINCINNATI OH PERMIT NO 7312 with Radiation-Curing Industry By Rosanna Stoutenburg T he State University of New York College of Environmental Science and Forestry (SUNY-ESF) in Syracuse, N.Y., is a unique university community with a specialized mission— to promote the leadership necessary for the stewardship of both the natural and designed environments. As such, technologies that promote a healthier environment (i.e., radiation-curing technologies) fall squarely within this mission and allow SUNY-ESF to provide unique educational opportunities that have limited availability elsewhere. As part of SUNY-ESF’s Institute for Sustainable Materials and Manufacturing (ISMM), the Ultraviolet Light/Electron Beam (UV/EB) Technology Center was recently established. It is funded, in part, by a New York State Energy Research and Development Authority (NYSERDA) grant and works in concert with RadTech International North America (RadTech). The SUNY-ESF UV/EB Technology Center participates in research and development of low- and no-emission manufacturing of inks, coatings, paints and resin binders for composite materials. The center enables industries in New York to pilot these technologies before investing in equipment. “The center is an excellent opportunity for SUNY-ESF’s students, faculty and technical staff to work closely with New York State manufacturers on energy-efficient curing and manufacturing processes,” said Dr. Cornelius B. Murphy Jr., president of SUNY-ESF. “The college will help develop and transfer the latest in energy-efficient UV and EB technologies to the coating, adhesive and composite industries in New York State. These new technologies will help New York State-based companies be more competitive by reducing costs and marketing more environmentally friendly products.” Research The center was established in May 2011 and is co-directed by Dr. Mark Driscoll and Dr. Jennifer Smith. In addition to NYSERDA’s The SUNY-ESF Campus in Syracuse, N.Y., is home to the ISMM’s UV/EB Technology Center. ISSUE 4 2012 RADTECH REPORT 5 RadTech News SUNY-ESF Solidifies Links RadTech News involvement, the center has a number of industrial partners and collaborators, including: • IBA Industrial (Edgewood, N.Y.) • Knowlton Technologies (Watertown, N.Y.) • Manufacturers Association of Central New York (Syracuse, N.Y.) • MAS Associates Inc. (Indian Lake, N.Y.) • Rapid Cure Technologies Inc. (Syracuse, N.Y.) • Transparent Materials (Rochester, N.Y.) The center continues its industrial collaborations and is involved in numerous research efforts, including the use of pretreatment chemicals and EB to dimensionally stabilize natural fibers; the development of natural adhesives using UV/EB; and the use of EB for processing agricultural wastes for biofuel production. Educational Opportunities A recent development entails the center’s collaboration with SUNY-ESF’s Office of Outreach, RadTech and 10 other partners to provide nationally available educational opportunities in radiation curing. The partners include the Manufacturers Association of Central New York (MACNY), New York State Department of Labor, Rapid Cure Technologies, The Manufacturing Institute, Onondaga County Workforce Investment Board, Central New York Technology Development Organization, CenterState Corporation for Economic Opportunity, New York Academy of Sciences, Partners for Education and Business, and NYSERDA. The program is funded, in part, by a U.S. Department of Labor Employment and Training Administration H-1B Technical Skills Grant—Enhancing American Jobs and Global Competitiveness: A Collaborative Initiative in Sustainable Materials 6 RADTECH REPORT ISSUE 4 2012 and Manufacturing. The program will provide radiation-curing professional development opportunities and includes: • post-baccalaureate online courses in radiation curing of resins; and • an industry-recognized (by the Manufacturing Skills Standards Council) Certified Production Technician credential (led by MACNY). Programs are expected to be offered online beginning January 2013. Webinar Series This educational initiative in radiation curing includes a professional webinar series—The Future of UV/EB Advanced Manufacturing: Trends, Strategies and Applications. Offered by SUNY-ESF in collaboration with RadTech, the webinar series began in September 2012 and is presented on a monthly basis. Webinars focus on relevant and timely topics and trends pertinent to the radiationcuring industry and its development. Topics include an introductory overview; comparisons of UV and EB technologies; equipment; government regulations; and applications, including food packaging and metal substrates. This highly specialized educational initiative aims to encourage environmentally conscious advanced manufacturing through the use of UV/EB curing; professional development for those in or interested in the curing industry; and the cultivation of technical skills in radiation curing for United States citizens. w For more information about this program, please visit www.esf.edu/ outreach/projects/sustainus. —Rosanna Stoutenburg is a graduate assistant at SUNY-ESF Outreach and is a doctoral candidate in the department of Environmental and Forest Biology at SUNY-ESF in Syracuse, N.Y. Author Guidelines RadTech Report publishes technical and non-technical articles related to UV/EB curing. Before submitting material, authors should: • Contact the managing editor to determine appropriate timing and deadlines for articles. • Submit a 50- to 100-word abstract highlighting the key findings of the paper/article. All submissions must include: • Author’s complete name, telephone, mailing address and email address; • Name and address of the organization where the work was performed; and • Author’s job title and company name. Feature articles range from 1,500 to 4,000 words in length. Digital art is to be provided by the authors. Articles/papers should avoid excessive promotion of commercial products. Technical papers will be reviewed for scientific validity and, where appropriate, revisions will be requested. Authors should submit electronic abstracts, articles and summaries via email. Layout proofs will be emailed to authors for approval prior to publication. Submissions should be directed to: Angela Osborne Managing Editor, RadTech Report RightSource Communications P.O. Box 36164 Cincinnati, OH 45236-0164 aosborne@rightsourcecomm.com Phone: 513.731.4332, ext. 11 Fax: 513.297.7568