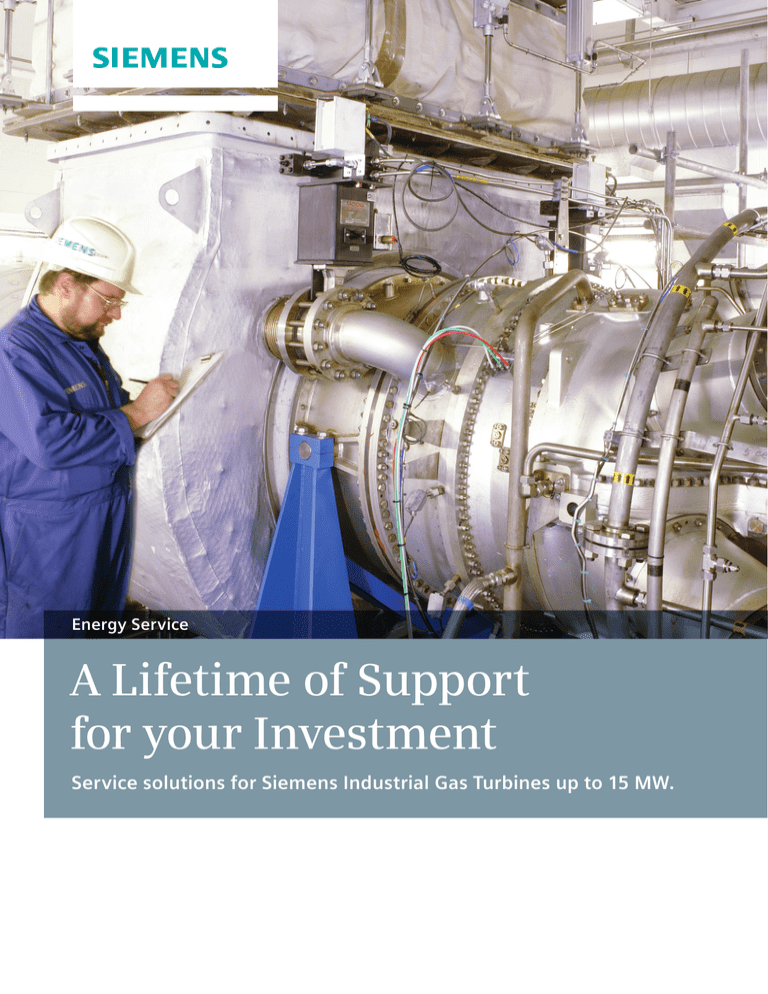

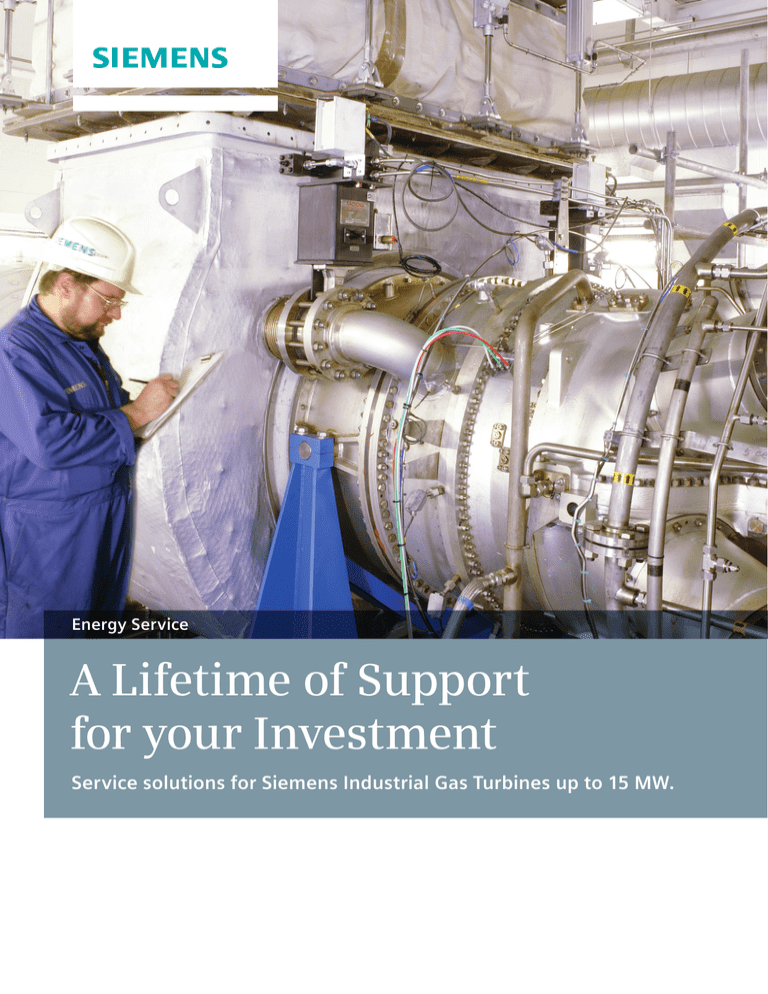

Energy Service

A Lifetime of Support

for your Investment

Service solutions for Siemens Industrial Gas Turbines up to 15 MW.

Get higher re

What do we provide?

Replacement Parts

04 – 05

O verhaul Services

06 – 07

Field Service

08 – 09

Modernization & Upgrades

10 – 11

Long Term Programs

12 – 13

Diagnostics & Monitoring

HelpDesk Support

14 – 15

Customer Training

16 – 17

Health, Safety & Environmental

18

Case Studies

19

es image

Protecting your

investment

In an ever changing business environment a

major challenge is keeping pace with the

number of technical, environmental and

legislative developments.

Siemens offers a range of engineered service

solutions from a comprehensive portfolio,

tailored to the changing needs of global

industries and markets, as well as for the

continued support and optimization of your

asset management.

Replacement Parts

We provide a unique range of support services to

optimize the operation of your gas turbine plant to it’s

fullest capability.

Our replacement parts business

provides coverage 365 days a year,

through established

communication channels and via

local offices.

By opting to purchase parts from Siemens,

you are choosing the reassurance that

the parts are proven capable of meeting

the exacting duty of your engine. All

Siemens parts are also fully warranted by

us as the Original Equipment

Manufacturer (OEM).

Maintenance Kits: comprising

inspection consumables, replacement

and contingency parts for the entire

Small Gas Turbine Range.

We are the only producer of Genuine

OEM core replacement parts for the full

range of small gas turbines, covering all

Ruston / GEC / EGT / Alstom TA, TB, TD

turbines and the later Siemens SGT-100

to SGT-400 turbines (Typhoon, Tornado,

Tempest and Cyclone). Siemens OEM

replacement parts are manufactured to

the same high standard as the originally

delivered equipment, incorporating the

latest technological developments.

Worldwide Locations: Siemens hold

parts in strategic global locations

including Europe, the Middle and Far

East and the Americas.

In addition to core parts, Siemens

supplies genuine OEM package part

replacements, engineered and checked

against our extensive records, to match

the build of your turbine.

Genuine OEM Parts Availability: we

hold approximately 23,000 variants

and over 4 million service parts, in our

Central Parts Warehouse, ready for same

day dispatch*, ranging from individual

components and small assemblies to

gas generators, power turbines and

complete turbine cores.

Parts Options: consisting of repaired

and refurbished components to

complement the supply of new parts.

These parts carry a full OEM warranty.

4

Kits are designed to cover the complete

range of spares required for each

inspection type.

The benefits to you are:

Fully supported OEM replacement

parts.

Complete maintenance kits available

for the full range of engines.

Variety of supply agreements to suit

all customer needs.

Repaired and refurbished parts as an

option to new strategic parts.

Performance guarantees for

replacement core engines.

Web-based ‘Spares Finder’

application.

Rapid dispatch of parts to any

destination in the world.

* Customer Pledge: For OEM parts, same day

dispatch from stock for requests received

before 12.00. Does not apply to configurable

parts / assemblies.

5

Overhaul Services

Siemens have developed a full range of global overhaul

options for all of our industrial gas turbines up to 15MW.

Our extensively equipped regional

workshop facilities are factory

approved and qualified,

guaranteeing the highest levels of

quality and service and are staffed

by approved factory trained

personnel.

Our service exchange units are

backed up with full 12 month

factory warranty as standard.

Factory-based or via fully supported local

service centers, our global overhaul

facilities provide extensive support to

your operations.

Condition-based Overhaul Services: for

gas generators, power turbines and

complete engine cores for our entire

range of small gas turbines.

Overhaul Options: focused on

operational demands through in-situ or

factory-based overhauls and/or by

service exchange or lease engines.

Test Facilities: in approved service

centers, with computer controlled test

berths to meet exacting quality

standards and guarantee the

performance of our engines.

Modular Overhauls: either by overhaul

or exchange of rotors and major gas

turbine assemblies.

Overhaul Reporting: detailing all work

carried out, parts fitted and performance

achieved under test.

The benefits to you are:

A global network of company

approved overhaul workshops.

Access to the latest OEM proven

technology for extended economic

viability of the asset.

Quality service and performance

guarantees.

Guaranteed OEM parts for the

turbine build.

Exchange options to minimize

operational downtime, or:

Lease cores, gas generators and

power turbines available for the

duration of the overhaul period.

6

As part of our overhaul options, Siemens

can offer either a service exchange or

lease of major assemblies and full core

engine units, dependent upon suitability

and availability.

Service Exchange

While your gas turbine is undergoing

maintenance, Siemens can relieve the

pressure of production schedules and

minimize on-site disruption by providing

you with a factory built service exchange

core or major sub-assembly. These units

are available for both our current and

some selected mature gas turbine ranges.

Siemens service exchange units are

built to current design standards,

incorporating latest technical

developments and fully tested to

produce power within 5% of original

installed output. Each exchange unit is

configured to match your installation

before being tested and dispatched.

We hold a large multi-engine exchange

fleet which, with sufficient advance

notice, can be made ready for rapid

dispatch following site configuration and

testing.

The benefits of a Service Exchange:

Guaranteed genuine Siemens parts

used for turbine build.

Minimum disruption to your business.

Option of new, repaired or

refurbished components available for

turbine build.

Reduced risk of obsolescence of

spare parts.

All parts and services backed by

Siemens warranties.

Access to and application of the

latest technologies and product

developments.

Global network of Siemens approved

support centers.

Lease Units

If your preference is to have your

engine overhauled, rather than Service

Exchanged, Siemens can supply a lease

unit to reduce disruption and maintain

continuity of operation.

Lease Equipment for Unscheduled

Overhauls: by offering major engine

assemblies, gas generators and power

turbines during unscheduled outage.

Maintenance Programs: with access

to lease equipment, as standard, for

Preventative and Corrective maintenance

programs to reduce any unscheduled

downtime.

Our lease pool of equipment covers

both current and some selected

mature gas turbine ranges, up to

15MW, to ensure that, wherever

possible, items required are

available on the shortest possible

lead times.

The benefits of a Lease Unit:

Whether you have one, or multiple

engines being overhauled consecutively,

we can provide a short or long term

lease of gas generators, power turbines,

major assemblies or complete engine

cores to suit your needs.

Short Term Availability: of major

assemblies during scheduled overhauls

which allow customers to utilize the full

potential of their facility whilst their

own turbine or assembly is away being

overhauled.

Increased uptime during overhaul

periods by scheduling a lease turbine

or assembly.

Reduced impact of unscheduled

maintenance.

Availability of complete packages for

short/ long term leasing where extra

capacity is required.

Flexible response to short term

increased power demands.

Access to lease equipment through

maintenance contracts.

Lease equipment for unscheduled

overhauls.

No major capital outlay.

Esbjerg

Anchorage

Aberdeen

Lincoln

Trenton

Querétaro

Qeshm

Abu Dhabi

Bangalore

SGT Service Shop

Associated Workshop

RNA

North America

RLA

Latin America

REU

Europe / South Africa

RME

Middle East / Central Africa

RAS

Asia Pacific

Bahía Blanca

Adelaide

7

Field Service

We employ a large team of qualified, experienced

engineers and technical personnel to provide you with

world-wide field support.

All Siemens Field Service engineers

are comprehensively trained inhouse, continually assessed, and

are qualified to ISO 9002

standards.

By using the capability of Siemens local

service centers, supported by

strategically located specialists, we are

able to offer a unique level of service, a

service level which is only obtainable

from an OEM, making us your best

choice for long term support.

We have extensive experience, spanning

over 60 years, in the design,

manufacture, operation and

maintenance of our Siemens range of

small gas turbines.

As the on-site representative of our

business, the Field Service Engineer is

key to the success of the Siemens service

support team. They are fully backed by

the engineering support group and

design teams in Lincoln. Additionally

they can call on the wealth of resources

available in our manufacturing plant.

Only Siemens employed Engineers are

provided with a ‘capability passport’ that

records all of the training, qualification

and competency skills that the individual

has successfully completed during their

career with Siemens. The ‘capability

passport’ is your assurance that the

Engineer we send to your site is fully

conversant with your engine type and

has the necessary up to date skill-set to

properly maintain your turbine.

Many of our field staff are qualified

across engine types and technical

disciplines, with extensive experience in

the maintenance of your particular type

of installation. We also ensure that they

continue to receive technical updates,

improvement bulletins, refresher courses

and new product training.

8

Available Expertise:

Supervision: or full installation of new

or relocated equipment.

Short or Long Term: operation and

maintenance services.

Routine Service Work: for all scheduled

inspections.

Speed of Response: through local

service personnel.

Troubleshooting: on-site and remotely

for problems or unscheduled outages.

Emergency: 24/7 call out services 365

days per year.

Hands-on Site Training: for users’

operators and maintenance personnel.

The benefits to you are:

A source of OEM supported field

service technicians.

Provision of the latest technical

updates.

All of our work is covered by OEM

warranties.

We offer a high quality and reliable

service.

Our field service engineers specialize

in your product.

We cover a range of services including

operation and maintenance,

installation, commissioning, troubleshooting and operator training.

9

Modernization & Upgrades

Life extension of your existing installation is the most

cost efficient means of continued operation.

Modernization and Upgrades

provide the latest technology

enhancements to all of our existing

industrial gas turbine fleet up to

15MW and enable you to extend

the working life of your asset.

Keeping our customers up to date with

the latest developments in gas turbine

technology is the key to the Siemens

customer support philosophy.

Utilizing the latest technical benefits

derived from our extensive new turbine

development programme, Siemens has

produced a wide variety of

modernization and upgrades for existing

installations. These include the latest in

emissions reduction technology,

availability improvements and control

system upgrades, as well as power and

efficiency improvements for the current

range of industrial small gas turbines.

Power Enhancements: through engine

hardware replacement, or by secondary

means, such as filtration efficiency

improvements.

Emissions Reduction: to meet demands

for cleaner energy through the

company’s award winning DLE (Dry Low

Emissions) combustion system, or more

traditional techniques such as steam or

water injection.

Availability Enhancements: to lower

cost of ownership through updated

control and package systems.

Efficiency Improvements: through

upgraded hardware design to reduce fuel

usage and improve environmental

impact, resulting in lower operating costs.

10

The benefits of modernization and

upgrades are:

Access to the latest OEM proven

technology for extended economic

viability of the asset.

Reduced operating costs through

efficiency gains.

Increased power, with greater

availability and efficiency.

Reduced emissions with lower

environmental impact.

Obsolescence

Cost

Reduction

Health &

Safety

Benefit by

Mods & Ups

Reliability

Performance

Environment

11

Long Term Programs

With a Siemens support contract, you can be confident of

a high level of plant availability.

Siemens LTPs offer customer

satisfaction, increased reliability

and increased availability.

We offer years of experience,

technical back-up, original spare

parts and a dedicated Customer

Support Manager.

In the late 1980s we recognized that, for

our newer industrial or utility based

customers, there was a need to provide a

different type of maintenance support.

In recognizing that need, we were one of

the first companies to develop the long

term service agreement, or ‘Long Term

Program’ (LTP) solution, to provide

support for our range of Industrial Gas

Turbines. Over the years the types and

durations of the service contracts have

varied, in line with Customer’s

requirement. While we still provide

tailored LTP solutions for total coverage

of the long-term maintenance needs of

your gas turbine installation, the

standard support packages are as

follows:

Support LTP - Provides basic cover,

annual ‘A’ type Inspection, parts and

manpower plus emergency support.

Preventative LTP - Covers all scheduled

and unscheduled maintenance, plus loan

unit, frontline stock of parts and STA-RMS.*

Corrective LTP - Provides a

comprehensive contract for total

maintenance coverage and availability.

Additionally, we offer further options to

any standard LTP:

Resident engineer based at

Customer’s site.

Emergency back-up spares.

Guaranteed availability

Special tools and instruments.

Condition monitoring on driven unit.

Provision of operational

consumables.

Customer Support Manager based at

your office location.

12

The benefits to you are:

High quality maintenance by OEM

trained maintenance staff.

Cap on costs by fixed term contract

and use of agreed financial indices.

Scheduled payments to smooth out

cash flows and aid financial planning.

Long term security with maintenance

levels to suit your requirement

through the term of contract.

Maximizes availability with

availability guarantees where

appropriate.

Response times give guaranteed

mobilization times through all levels

of contract.

Reduced inventory through

management of scheduled activities

and access to emergency parts.

Planning of outages where all

scheduled outages can be tailored to

suit your plant requirement.

Protection of your investment

with the addition of our remote

monitoring system, STA-RMS.*

Penalties for non-performance

if we fail to meet our contracted

obligations.

24hr Telephone Help-line, freely

available to all LTP customers.

Access to the latest OEM proven

technology.

Quality, service and performance

guarantees.

Guaranteed OEM parts for all turbine

servicing.

* Siemens Turbomachinery Applications Remote Monitoring System (STA-RMS).

Framework / Call Off

These products are tailored specifically and give the flexibility to the customer to decide when they want to perform maintenance under a set

of pre-agreed prices, terms and conditions.

Remote Diagnostic Service

These products tend to be offered to those customers with restrictions or accessibility issues. However we encourage all customers to obtain

it, as the Siemens RDS allows us to remotely detect potential issues.

This includes:

Production of either basic or advanced reports

Provision of 24/7 hotline support with technical specialists.

Supportive LTP

Offered to operators who are capable and confident in operating and maintaining their Gas Turbine Package, but recognize the benefit of

having easy access to technical support and priority services.

Includes:

Parts and manpower for annual scheduled ‘A’ type inspections

Priority service

Emergency call out service

Guaranteed mobilization times

Basic hand tool kit and delivery.

Preventative LTP

Typically offered to operators who would like the costs associated with all scheduled maintenance to be known and fixed for a period of time.

In addition to all items from the Supportive LTP, this includes:

Parts for scheduled ‘B’ and ‘C’ type maintenance inspections

Manpower for scheduled maintenance inspections

Service exchange unit at ‘C’ type inspection

Gearbox inspection / overhaul

Access to spares held within territory

STA-RMS (Remote monitoring / diagnostics system)

Access to 24hr global help desk service

Corrective LTP

Offered to operators who would like the benefit associated with a fully inclusive type of contract with costs for all technical support,

scheduled and unscheduled maintenance to be known and fixed for a period of time.

In addition to all items from the Preventative LTP, this includes:

Parts for unscheduled maintenance

Manpower for unscheduled maintenance

Emergency back-up stock holding

Guaranteed availability and access to loan unit

Annual availability guarantee*

Agreed annual downtime*

* Optional Corrective LTP with Availability Guarantee

Siemens Maintenance

Products allow you to

concentrate on your core

business activities.

13

Diagnostics & Monitoring

Remote data access to provide information and reports,

helping to effectively manage your turbine.

* Siemens Turbomachinery

Applications - Remote Monitoring

System (STA-RMS).

Our latest remote monitoring system,

STA-RMS*, ensures maximum machine

availability by monitoring either

individual units or the complete power

train, including driven units, in either

power generation or mechanical drive

applications.

Using STA-RMS, Siemens can provide

various levels of remote services, from

basic reporting and support (office

hours), to full 24 hour, 7 day service and

either comprehensive thermodynamic

and/or rotor dynamic analysis of your

asset. Whichever service level you

choose, all can be tailored to suit your

specific requirements.

STA-RMS utilizes the experience that we

as the OEM have accumulated from our

operating fleet of over 350 installed RMS

units, coupled with the extensive

knowledge of both our field and service

engineering teams, to advise you in all

aspects of our product range, tailored to

the specific requirements of your Oil &

Gas or Power Generation application.

STA-RMS can be offered both as part of a

Long Term Programme (LTP) or as a

stand alone Service Support Agreement.

14

The benefits to you are:

Fast, secure online help and

advanced troubleshooting.

Proactive recommendations.

Increased production through

maximum train performance,

availability and reliability.

Outage optimization and reduction of

overhaul costs, through trending and

root cause analysis.

Help Desk

24/7 Hotline Support with duty CSM

and technical specialists.

The 24/7 Hotline Support can ensure

help is there when you really need it,

either by telephone or through secure

online connection.

Our help desk is available to assist you

with any kind of technical issue, as part

of an LTP or Service Support Agreement,

whether it is for performance fine tuning

or breakdown assistance.

15

Customer Training

The most cost effective way to maximize your operation.

Our Product Training Facility is

located within the University of

Lincoln Engineering School. This

was part of a ground breaking

collaboration between Siemens

and the University, to open the

first, purpose built, School of

Engineering to be created at a UK

University for more than 20 years.

The focus of the School of

Engineering is industrial power and

energy; a sector that has a huge

global significance and one in

which Siemens specializes.

In addition to being a cutting edge

teaching facility, the building hosts

extensive research laboratories,

contributing to the school’s ethos

of ‘research led teaching’ enabling

a new generation of ‘industry

ready’ graduates.

Customer training is provided to enable

customer engineers to operate

equipment in a safe and competent

manner, which combined with regular

maintenance, results in reduced

operating costs.

In order to achieve the most effective

training for our customers, we have

developed a range of Standard Courses.

These have been divided into two levels

and associated disciplines:

Level 1: Operations & Maintenance

Courses.

Level 2: Controls Courses.

Associated Disciplines.

Operation & Maintenance (O&M)

These courses provide customer

personnel with an insight into the

design, major components, auxiliaries,

applications and principles of operation

of their turbines.

We offer a 5 day course, designed to

provide you with an understanding of

the principles of gas turbine operation

and specific knowledge of the gas

turbine, computerized control and

associated systems. A combination of

theoretical and practical training is

provided in classrooms with state-of-theart training aids and in our extensively

equipped training workshop.

16

Controls System

The courses cover detailed training on

the recent PLC based systems, installed

on the SGT-100 to SGT-400 fleet, as well

as the various control systems used on

the mature engine fleet, such as the Mk2

Control system. We also cover TCM

configuration, maintenance, monitoring

and governing controls and the testing

and calibration of the control system.

The use of the integrated system

simulators within the ‘Control Room’

provides unique access to your original

controls software to ensure that the

hands-on practical training is both

realistic and relevant to your installation,

as well as providing a practical means of

assessing a delegate’s system

knowledge.

During the courses, much emphasis is

placed on practical exercises to increase

the delegate’s familiarity with the

system. In order to maximize the ‘hands

on’ approach, course numbers are

restricted to ensure that one simulator is

provided per delegate.

Training is given on the use of the

programming language and commands

to enable first level analysis and fault

finding.

Associated Disciplines

Our Associated Discipline courses provide

valuable extra skills and knowledge that

help with fault finding and the overall

understanding of your equipment.

With our ‘Vibration Fundamentals’

training course, we teach the basics of

vibration theory as it applies to our

machinery and the skills required to

carry out trim balancing, hand held

surveys and spectrum analysis. Courses

on ‘Generation and Generator Control

Panel’, ‘Laser Alignment’ and the

‘Integrated Fuel Valve’ add further skills

and understanding and the equipment to

create highly skilled and motivated staff.

All courses incorporate a high level of

hands-on work to ensure the skills are

transferred effectively.

Alignment Training: Provide the course

delegate with an understanding of the

principles of alignment, the operation of

the alignment equipment and experience

of practical aligning of Turbomachinery.

Vibration System Training: Provides an

understanding of the fundamental

principles of rotating machinery

vibration theory, together with an

in-depth view on the techniques

necessary, for solving basic out-of-balance

problems, through a combination of

theoretical and practical training.

Fire & Gas Training: Provides an

understanding of the control principles

of the fire and gas protection systems

used on SGT equipment. Delegates will

learn how to operate, maintain and

commission control system components

and instrumentation.

Special One-off Training Courses: With

the ability to offer training on gas

turbines produced over the past 60 years,

unique training courses can be designed

to meet your specific requirements.

All courses follow a ‘tell me, show

me, let me have a go’ methodology

with hands-on work, and the

application of skills and knowledge

learnt being key in the delivery of

the training.

We constantly review our training

courses and their content to ensure

they provide the information that

front-line staff require.

The benefits of Siemens Training:

Well trained personnel increase a

plant’s operating efficiency, reduce

down-time and service call-outs,

resulting in reduced operating costs.

Only source of approved Product

Training Courses.

Courses are conducted at our Product

Training Centre in Lincoln or at your

own onshore premises.

A range of standard courses are

held at our Product Training Centre

throughout the year, allowing

economic training of new personnel.

Uniquely tailored one-off training

courses.

Courses can be provided

at our purpose built

Product Training Facility

in Lincoln, UK, or at the

customer’s own premises.

17

Environmental,

Health & Safety

The health and safety of our employees and the

protection of our environment are vital issues to which

Siemens is totally committed.

We pride ourselves on meeting

your high standards.

“We only have one life and we only

have one planet to live on so,

together, we must take good care

of ourselves and our planet and

create a sustainable environment

for the generations to come”

Andreas J Goss,

UK Chief Executive

Zero Harm

Employee Well Being

With strict EHS policies, risk assessments,

employee training and protective

equipment, we actively promote a

culture of Zero Harm across all our

businesses.

Lifestyles in the 21st century present

new challenges for health that affect our

whole life. Health challenges stem from

choices we make in the way we travel,

what we eat, how we live and work.

If something looks wrong or feels

unsafe, then it probably is.

Well being at Siemens is about providing

our employees with information on

health and wherever practical, making

healthy choices easier.

We encourage everyone to look at what

they do with fresh eyes, challenge the

status quo and re-engineer how they do

things to eliminate risks, even if it comes

at a cost to our organization.

We can be open and honest about safety

at Siemens, and will always listen and

take appropriate preventative actions.

Those who work for us and with us have

the right to expect nothing less.

18

Sustainable Future

At Siemens, sustainability is embedded

in our values and we are committed to

continually improving the integration of

sustainability into our business processes

and decisions.

We strive to identify means to prevent

pollution and reduce harmful impacts on

the environment.

Case Studies

Customer: Single Buoy Moorings (SBM)

Engine: SGT-400

History

Service Solution

Customer Benefits

FPSO Serpentina, belonging to Single Buoy

Moorings (SBM), located offshore Equatorial

Guinea, required assistance during a re-start of

the SGT-400 gas lift compressor package.

SGT Lincoln successfully connected FPSO with

shore bases, colleagues in Hengelo and SGT

engineers via STA-RMS / RDS and established a

Live-Meeting link to share the Control System

Intelligent Display Screen (IDS), on the FPSO to

observe the re-start and driven unit vibration

levels.

The local operator was guided

through several changes during the

start sequence, enabling them to

successfully put the engine back

into service.

The Live-Meeting was made available for SBM

and their client Exxon-Mobil to join, along with

a number of their employees from various

worldwide offices, to observe the re-start.

“We really appreciated to be able to

attend the compressor re-start,

and to share it with Siemens

Lincoln and Hengelo. We found this

very useful as everybody was on

the line...” Delphine Malenfant,

SBM Offshore.

Customer: Boots Plc

Engine: SGT-100

History

Service Solution

Customer Benefits

When Boots Plc experienced an unexpected shut

down of their SGT-100 engine, operations staff,

unable to restart the gas turbine, contacted the

SGT Lincoln Helpdesk for assistance.

The SGT Lincoln Helpdesk utilized STA-RMS /

RDS* to perform a detailed remote investigation

to determine and resolve the problem.

Increased availability through 24/7

Siemens Remote support. On this

occasion, the engine was up and

running within the same day.

19

Energy Service Division

Order No. E50001-E510-A206-X-7600

Printed on elementary chlorine-free

bleached paper.

Published by and copyright © 2013:

Siemens Plc

Faraday House

Frimley, GU16 6QD

United Kingdom

Siemens Industrial Turbomachinery Ltd.

Ruston House, Waterside South

Lincoln LN5 7FD

United Kingdom

www.siemens.co.uk/energy

Siemens Energy, Inc.

4400 Alafaya Trail

Orlando, FL 32826-2399, USA

All rights reserved. Trademarks

mentioned in this document are the

property of Siemens AG, its affiliates, or

their respective owners.

Subject to change without prior notice.

The information in this document

contains general descriptions of the

technical options available, which may

not apply in all cases. The required

technical options should therefore be

specified in the contract.