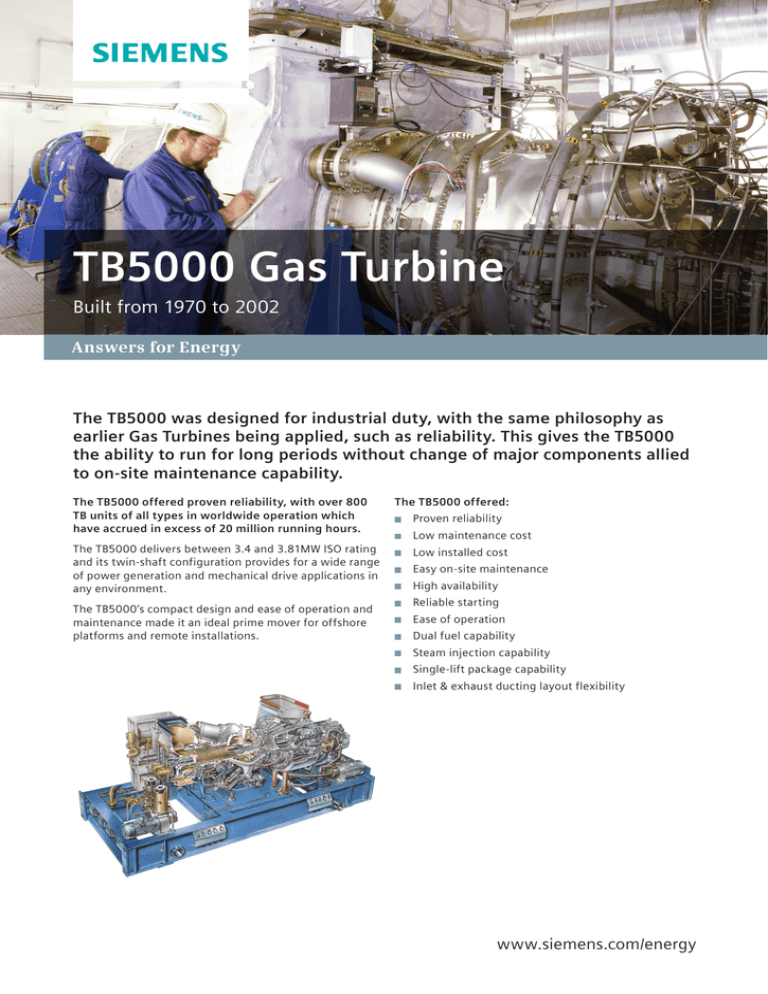

TB5000 Gas Turbine

Built from 1970 to 2002

Answers for Energy

The TB5000 was designed for industrial duty, with the same philosophy as

earlier Gas Turbines being applied, such as reliability. This gives the TB5000

the ability to run for long periods without change of major components allied

to on-site maintenance capability.

The TB5000 offered proven reliability, with over 800

TB units of all types in worldwide operation which

have accrued in excess of 20 million running hours.

The TB5000 delivers between 3.4 and 3.81MW ISO rating

and its twin-shaft configuration provides for a wide range

of power generation and mechanical drive applications in

any environment.

The TB5000’s compact design and ease of operation and

maintenance made it an ideal prime mover for offshore

platforms and remote installations.

The TB5000 offered:

Proven reliability

Low maintenance cost

Low installed cost

Easy on-site maintenance

High availability

Reliable starting

Ease of operation

Dual fuel capability

Steam injection capability

Single-lift package capability

Inlet & exhaust ducting layout flexibility

www.siemens.com/energy

with automatic changeover form primary to secondary

fuel possible across the entire load range.

The two-stage power turbine, with externally air-cooled

discs, is aerodynamically coupled to the gas generator

and provides power for the driven unit. Control System

To maintain alignment between rotating and static

elements, the power turbine stator casing is attached to

the gearbox through air-cooled support struts within the

exhaust elbow. Compactness with rigidity is a feature of

the power turbine assembly.

Flexibility

Texaco‘s Tartan Field platform with 13 Siemens Gas Turbines

installed; five to drive generators, two for main oil line pump drive,

three to drive gas compressors and three to drive water injection

pumps. Exhaust heat from the gas turbines driving the generators

was recovered and used in the processing of the well gas.

Design Features

A heavy duty industrial gas turbine, the TB5000

offered the characteristics of high reliability and long

life associated with well designed turbo machinery.

The TB5000 is a simple-cycle unit which consists of a

12-stage subsonic axial-flow compressor, a two-stage aircooled overhung compressor turbine, four combustion

chambers and a separate two-stage power turbine. The

compressor features variable inlet guide vanes to modulate

airflow and assure fast easy start-up and maximum

efficiency under partial loads. The centre casing is split

horizontally along the centre line providing access to the

compressor with the minimum of dismantling.

The four reverse-flow tubular combustion chambers,

externally mounted around the forward face of the

centre casing assembly, are specially designed for long

life and are readily accessible for inspection purposes.

The flexible fuel system is capable of operating on a wide

variety of gaseous fuels including refinery gas, landfill

gas and high CO2 content as, as well as distillate fuel,

1*013 bar

14*7 psia

15 C

59 F

7*30 bar

105*8 psia

271 C

520 F

6*86 bar

99*5 psia

900 C

1625 F

The highly responsive TB5000 offered unmatched

reliability for base load electrical power generation

and mechanical drive, onshore and offshore. A version

of the TB5000 was also used as a prime mover in the

Nomad 5, a compact, self contained, mobile power

station designed to meet base load and peak electrical

demands up to 3.8MW.

The TB5000 is well suited for cogeneration and combined

cycle power applications. Using exhaust gas to generate

steam for process use or supplementary power

generation significantly increases the system efficiency.

Steam may also be used for injection into the TB5000 to

increase the power output which also reduces heat rate

and emissions. Options exist for emissions control by

primary injection; power enhancement up to 4.2MW

ISO by secondary injection and power enhancement

with emissions control using both injection systems.

A fully integrated Siemens controls package suitable for

all applications is available, offering high reliability and

incorporating features to enhance engine and systems

availability.

Options are available to provide control sequencing and

monitoring of driven equipment and auxiliaries used in

power generation, cogeneration and mechanical drive

applications. The controls package may also be extended

to cover data logging, plant supervisory control and

financial management of complex power systems.

2*43 psia

53*3 ata

663 C

2*43 bar 1225 F

53*3 psia

663 C

1225 F

A Siemens TB5000 gas turbine

driving a 3.3 MW generator at the

pharmaceutical works of the Boots

Company plc at Beeston, near

Nottingham. The exhaust from the

turbine was fed into a boiler which,

with the provision of auxiliary firing,

produced 60,000 lb/hr of process

steam at a pressure of 340 psig. The

installation achieved an efficiency

well over 74%.

Maintenance

Optional Equipment

The TB5000 has been designed for ease of on-site

maintenance thereby maximizing operating

availability and minimizing downtime.

A concept of standard optional equipment provides a

wide range of proven, pre-engineered equipment.

Modular fuel and lubricating oil systems are mounted

away from the hot parts of the engine. Accessibly and

conveniently located on the turbine base are all of the

cable and pipe connections.

Design features included:

On-or-off site maintenance capability

Horizontally split centre casing facilitates easy

inspection of the compressor rotor and stator blades

and turbine inlet support casing and bearings

Using standard roll-out gear, the gas generator is

easily removed from the turbine for blade inspection

and overhaul

Combustion chambers and fuel burners easily

accessible if servicing is required

Gas generator easily transportable by air in a custom

built container

Planned inspection intervals of 8000 fired hours, or

annually, with an intermediate inspection every third

year or 24000 fired hours and major inspection every six

years or 48000 fired hours, give low cost maintenance

and high availability (Note: these inspections are

designated A, B and C).

Servicing

The design of the gas turbine provides operators with the

facility to carry out at site blade inspection and servicing

of the unit or, at the operator’s choice, at a Siemens

approved Service Centre.

Standard roll-out gear enables the gas generator to be

simply removed from the turbine when blade inspection

is due, or when servicing is required. With the gas

generator removed, the rotating assembly is readily

accessible by removing the top half of the stator casing.

Combustion chambers and fuel burners are equally

accessible when servicing is required.

Standard output shaft speeds suit most available driven

machines. A direct drive speed of 7900 rev/min is suitable

for centrifugal pumps and compressors and with an integral

epicyclic or parallel shaft gearbox, shaft speeds within

the speed range of 1500 to 18,000 rev/min are provided.

Weights & Dimensions

Base Engine

Length - 19‘0“ (5790 mm)

Height - 8’0“ (2438 mm)

Width - 8‘0“ (2438 mm)

Weight - 30,000 lb (13,608 kg)

Generator Set

Length - 32‘0“ (9753 mm)

Height - 8’0“ (2438 mm)

Width - 8‘0“ (2438 mm)

Weight - 63,000 lb (28,577 kg)

Pump Set

Length - 26‘0“ (7925 mm)

Height - 8‘0“ (2438 mm)

Width - 8‘0“ (2438 mm)

Weight - 43,000 lb (19,505 kg)

Compressor Set

Length - 26‘0“ (7925 mm)

Height - 8‘0“ (2438 mm)

Width - 8‘0“ (2438 mm)

Weight - 57,000 lb (25,855 kg)

Normal Continuous Ratings

Performance

Altitude Correction Parameter

Power and Specific Heat Input v Speed

2000m

2500m

δ

1.000

Altitude

0ft

0.943

0.888

0.835

0.786

0.739

2000ft

4000ft

6000ft

8000ft

10000ft

δ

1.000

0.930

0.864

0.801

0.743

0.688

9980

Specific Heat

Input Btu/bhp h

0

9750

15

10500

11000

ISO Rating at 15 °C (59 °F) and Sea Level 4900.

BHP output shaft speed 7900 rev/min.

The performance figures given are with zero inlet and

exhaust duct and gearbox losses. Standard gearbox loss for

indirect drive is 1.5%.

30

11500

45

12000

Ambient Temp °C

1500m

5000

1000m

4000

500m

60

3000

0m

Power Output Parameter bhp/δ

Altitude

13000

2000

14000

15000

3000

4000

5000

6000

7000

8000

9000

Power Turbine Speed rev/min

4000

Specific Heat Input is drawn for an ambient temperature of

15°C but is approximately correct for other temperatures.

Direct drive - no output gearbox

Combined Heat & Power Systems

3000

Power Output Parameter bhp/δ

5000

ISO Rating 4900 BHP

-10

0

0

10

20

20

40

30

60

40

80

60 °C

50

100

Generator Drive

120 °F

ISO Rating 4900 BHP

5000

Temperature

Direct drive - no outputAmbient

gearbox

No

48

Co

nti

nu

4000

46

ou

sR

ati

ha

Ex

44

ng

3000

°C

0

50

re

40

38

2000

0

0

40

34

0

0

36

34

0

32

Approximate Region of IGV Change -Over

30

0

38

0

36

0

0

0

32

34

0

30

0

40

1000

0

0

44

36

δ

0

48

46

lb/s

42

Flow

38

t

aus

Exh

ass

M

Gas

0

32

Zero Loss Power Output bhp/δ

0

tu

ra

pe

42

0

30

Since the exhaust gasses are rich in unconsumed oxygen, auxiliary

firing can be employed to increase the heat available by a factor of

up to four or five to one depending on application.

m

Te

Overall thermal efficiencies ranging from 55% to 90% are obtainable

when using a gas turbine as the single power and heat source in an

integrated manufacturing process. The curves show the variation of

exhaust gas mass flow and temperature at sea level and different

ambient temperatures.

52

as

tG

Exhaust temperatures and Mass Flows are typical of current

production engines.

al

us

Inlet and exhaust ducting losses have not been debited. Power

turbine speed 7950 rev/min.

rm

-20

-10

0

0

20

10

40

20

60

30

80

40

100

50 °C

120 °F

Ambient Temperature

Published by and copyright © 2013:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Energy, Inc.

4400 Alafaya Trail

Orlando, FL 32826-2399, USA

For more information, please contact

our Customer Support Center.

Phone: +49 180 524 70 00

Fax:

+49 180 524 24 71

(Charges depending on provider)

E-mail:support.energy@siemens.com

www.siemens.com/energy

Energy Service Division

LCN 2013 - F33.18 LN

Printed on elementary chlorine-free

bleached paper.

All rights reserved. Trademarks mentioned in

this document are the property of Siemens AG,

its affiliates, or their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should

therefore be specified in the contract.