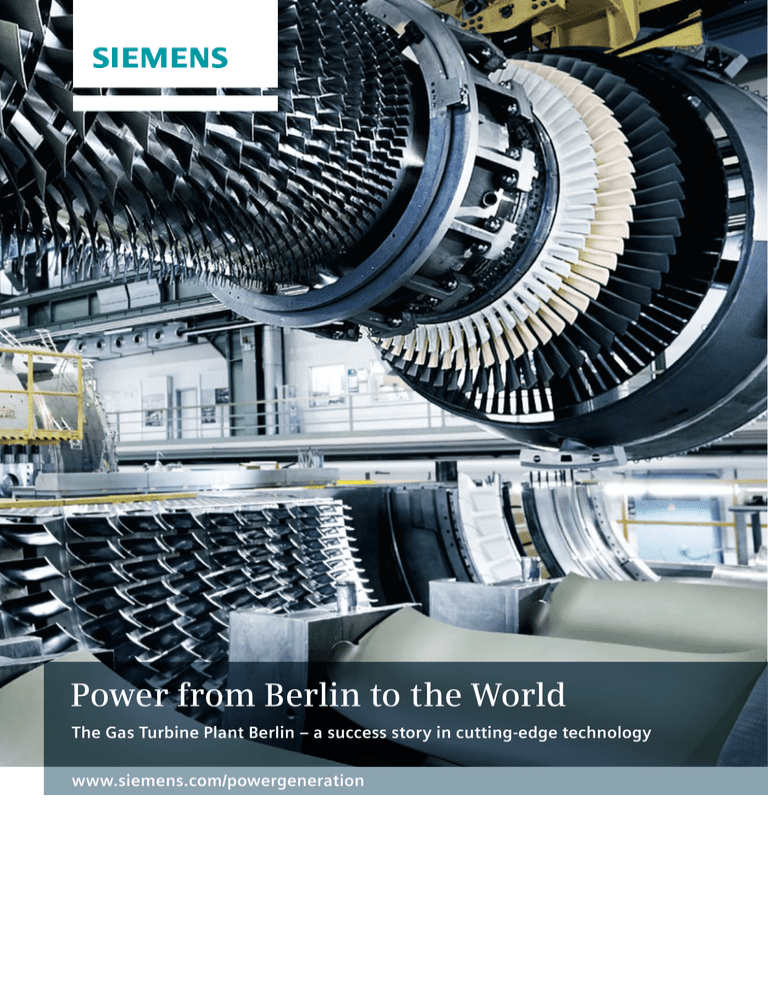

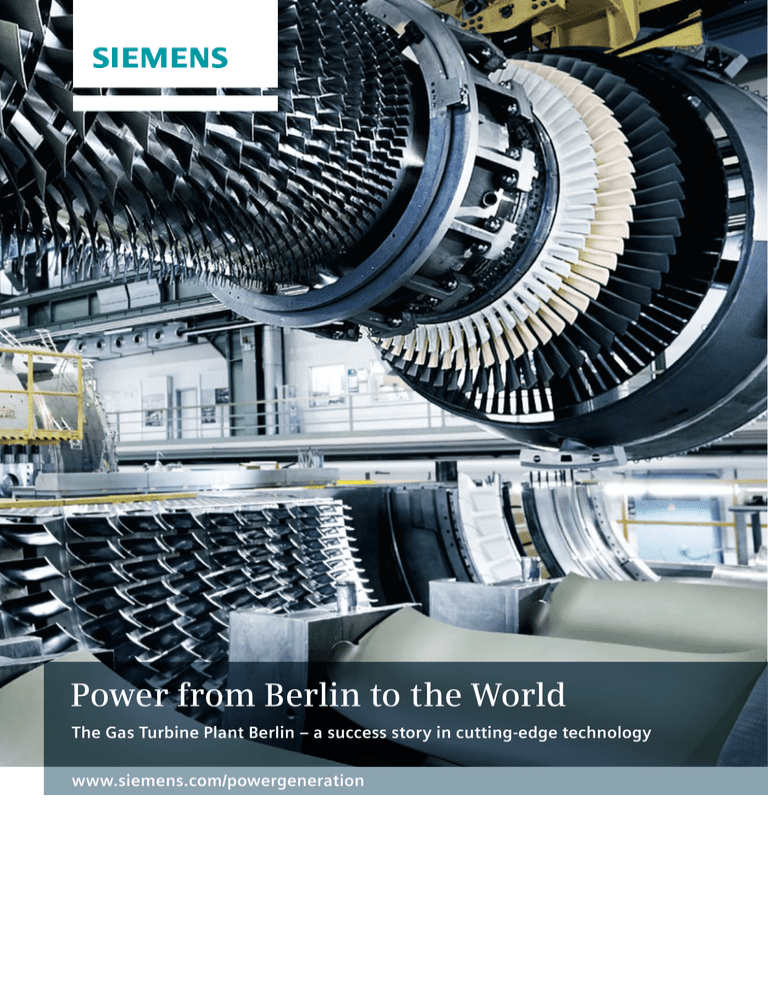

Power from Berlin to the World

The Gas Turbine Plant Berlin – a success story in cutting-edge technology

www.siemens.com/powergeneration

One site,

many

competences

High-tech gas turbines from Berlin Moabit are in

operation in power plants all around the world.

At this traditional location, where turbines have

been manufactured for over 100 years, 3,700

employees work in engineering, on the production line, in test centers, and in service.

02 I 03

Facts, Figures, Data

A bout 3,700 employees from more

than 45 nations

Over 250 technical and commercial

trainees

Over 100 students in dual study

programs

Around 130,000 m2 of facility space

in the Moabit district of Berlin

Further production, testing, service

and storage facilities in Berlin

Siemensstadt, Berlin Tegel and

Ludwigsfelde (Brandenburg)

Co-location of production competency and service expertise

First gas turbine for power plants

delivered in 1972

More than 950 gas turbines sold

in more than 60 countries

Products for the world’s most efficient power plants

More than

100 years of

experience in

cutting-edge

technology

– the success

story continues

Ultimate heavy duty. For over 40 years,

giant rotating machines have been coming off the production line in Berlin Moabit

for operation in simple and combinedcycle power plants. Gas turbine components must withstand an aggressive

operational environment where they are

exposed to extremely high combustion

temperatures and large centrifugal forces

as well as vibration and transient stress.

Customer-focused quality assurance.

The Gas Turbine Plant Berlin has one of

the most modern and highest-capacity

test beds in the world, which allows test

run loads of up to 330 megawatts (MW).

Not only prototypes of next-generation

gas turbines but also advanced designs

of individual gas turbine components

can be tested under realistic conditions.

By virtue of its independence from the

public power grid, the test bed allows

shorter test phases and accelerates

release of prototypes and advanced gas

turbine components for series production and retrofit installation in units that

are already in service.

Intensive research with real prospects.

One of the outstanding projects of the

engineering organization is the operation of a burner test center at Ludwigsfelde in Brandenburg, where combustion

experiments are conducted using natural gas and oil fuels. Synthetic fuels will

also be tested in the future. Current

burner technologies are continuously

being improved and new burner designs

are being developed, which will lead to

increased efficiency and will further

reduce emissions from gas turbines.

Competency for the future. Before the

test series, the gas turbines are comprehensively instrumented, which allows

greater quantities of data from more

instruments than is necessary for the

power plant during normal operation.

The various research and development

activities overseen by the Gas Turbine

Plant Berlin – in the test bed, in the

burner test center or during testing at

customer’s plant – lay the foundations

for developing the gas turbines of the

future.

04 I 05

Professional,

global, close to

the customer

The Gas Turbine Plant Berlin serves customers

in more than 60 countries around the world.

Its service experts provide customers with

expert and comprehensive advice throughout

the entire service life of power plants. This

enables more profitable operation of power

plants and, at the same time, prepares customers

to adapt to changing demands in the future.

06 I 07

A worldwide service network exists to

support power plant owners and operators in the drive to sustain the long-term

reliability and availability of assets. Individually-customized long-term maintenance and servicing concepts also ensure

optimum performance of power plants.

Field Service. Siemens’ Field Service organization manages the on-site installation,

commissioning and maintenance of gas

turbines, as well as steam turbines, generators and ancillary systems. Modernization and upgrade solutions can be

integrated into the Field Service scope

of work to allow older plants to profit

from the latest technology, increasing

their output, efficiency, and responsiveness while also reducing emissions. The

benefit for the customers is immense:

power plants can be upgraded to the

state of the art with comparatively little

effort and expense and can thereby be

better equipped to cope with current

and future market demands.

Field Service Training and Repair Center.

Field Service has its own training center

where experts give customers’ and inhouse Service employees basic and

advanced training in the assembly and

installation of gas turbines under realistic conditions.

Ludwigsfelde Logistics Center. The

Ludwigsfelde Logistics Center stocks

more than 30,000 replacement parts for

gas turbines – on call at any time for the

fastest possible delivery. More than two

million spare and replacement parts are

sent to customers every year: from the

smallest items weighing less than an

ounce up to casing sections that each

weigh as much as several hundred tons.

This service assures customers of maximum reliability and availability.

Power Diagnostics Technology Center.

The Power Diagnostics Technology Center

provides remote monitoring of power

plants for customers with long-term

maintenance agreements. This involves

recording and evaluating the on-line

operating data from the plants around

the clock. The benefit for customers is

that any deviations from normal running behavior can be identified quickly

and any necessary repairs can be scheduled and implemented early. The Power

Diagnostics Technology Centers in Berlin,

Erlangen, Muelheim and Orlando keep

a watchful eye on over 600 power plants

around the world.

Innovative

service for

flexibility and

sustainability

08 I 09

Award-winning,

world-recordholding

gas turbines

The Gas Turbine Plant Berlin produces gas turbines

with ratings from 114 to 400 MW for the 50- and

60-Hertz markets. Since the first gas turbine was

delivered to a customer plant in 1972, more than

950 units have been delivered. Continuous evolution of production methods and introduction of

innovative materials ensures that the gas turbines

produced in Berlin meet customers’ high expectations in terms of profitability, flexibility and sustainability. Today, the manufacturing plant produces

award-winning gas turbines, among them the most

powerful gas turbine in the world.

10 I

15

10 I 15

Gas turbines combine traditional

heavy duty mechanical engineering with ultra-modern production

technology in a unique way. They

convert heat from combustion of

liquid or gaseous fuels into rotational kinetic energy. As the core

component of the gas turbine, the

rotor – which turns at 3,000 or 3,600

revolutions per minute depending

on the grid frequency – must transmit this mechanical power to the

generator. Thanks to innovative

designs such as ceramic heat

shields, sophisticated materials

and advanced cooling systems for

turbine blades, temperatures of up

to 1,500 °C can be reached in the

turbine inlet section. Over 60% efficiency can be achieved in combined

cycle operation.

Core competencies and long-term

experiences at a glance

High availability and reliability

High flexibility in operation

Efficient and low emissions

Low lifecycle costs

Easy maintenance

Long inspection intervals

SGT5-2000E

Rated power output: 172 MW / 253 MW*

Efficiency: 35.3% / 52.5%*

Weight: 216 t

Robust design, multi-fuel capability

First commissioned in 1981

> 240

engines sold

> 15,000,000 EOH **

Operating experience

> 260,000 EOH

Fleet leading gas turbine

SGT6-2000E

Rated power output: 114 MW / 171 MW

Efficiency: 34.3% / 51.3%

Weight: 163 t

Robust design, multi-fuel capability

First commissioned in 1989

> 100

engines sold

> 5,900,000 EOH

Operating experience

> 170,000 EOH

Fleet leading gas turbine

SGT5-4000F

Rated power output: 307 MW / 445 MW

Efficiency: 40.0% / 58.7%

Weight: 312 t

F

ast startup and shutdown as well as fast

load changes

12

11 I 12

> 300

engines sold

> 10,000,000 EOH

Operating experience

First commissioned in 1996

> 140,000 EOH

* Configuration combined cycle 1x1

** Equivalent operating hours

Fleet leading gas turbine

SGT6-5000F

Rated power output: 232 MW / 345 MW

Efficiency: 38.8% / 57.6%

Weight: 193 t

V

ery low emissions: NOX and CO emissions

in the single-digit range

First commissioned in 1993

> 350

engines sold

> 9,400,000 EOH

Operating experience

> 170,000 EOH

Fleet leading gas turbine

German Business Innovation Award

2011 Winner in the category: Large enterprises

SGT5-8000H

Rated power output: 400 MW / 600 MW

Efficiency: 40% / > 60%

Weight: 390 t

F

ast startup and shutdown and highly

flexible in operation

First commissioned in 2008

Berlin-Brandenburg Innovation Award

> 10

2008Development of materials and production of

ceramic heat shields for gas turbine combustion chambers

engines sold

> 16,000 EOH

Operating experience

> 16,000 EOH

Guinness Book of Records

Fleet leading gas turbine

2007SGT5-8000H – world’s biggest gas turbine

1996SGT6-4000F – for 38% efficiency

SGT6-8000H

Rated power output: 274 MW / 410 MW

Efficiency: 40% / > 60%

Weight: 286 t

F

ast startup and shutdown and highly

flexible in operation

Fast hot start

First commissioned in 2011

Awards won by the SGT5-8000H

> 25

2011German Industry’s Innovation Award;

prize for the world’s most efficient power

plant (Ulrich Hartmann Power Plant)

engines sold

> 65,000 EOH

2010German Innovation Award for Climate and

Environment

Operating experience

> 7,000 EOH

2010Bavarian Energy Award for the Ulrich

Hartmann Power Plant

Fleet leading gas turbine

2009German Steel Innovation Award for “Climate

Protection with Steel” (special award)

13 I 14

15

Focus

on

people

Our dedicated and creative employees are

the key to our ongoing success. They drive

quality and innovation at the Gas Turbine

Plant Berlin. Their expertise, experience and

inventiveness push our products forward.

Therefore, recruiting qualified, talented and

motivated employees is crucial for the continuing success of our site.

16 I 17

Advantage through know-how. Around

3,700 designers, engineers, technicians

and service experts join forces at the Gas

Turbine Plant Berlin. Their skills, their

creativity and their experience drive innovation and are the key factors for continuing success. Each individual shows

outstanding commitment – and each of

them plays an important role in securing

the future of our site.

Theory and practice. There is a long history of training and promoting young

talents at our site. Every year about 150

talented new employees begin apprenticeships and dual study programs at

the Gas Turbine Plant Berlin. In particular, students of engineering disciplines

gain valuable insights into the design,

manufacturing and service of advanced

gas turbines.

Development and research. We know

that complex technologies call for sound

expertise. Siemens continuously invests

in the development of people and relationships to support our aims. Cooperation with universities and research institutes as well as providing numerous

apprenticeships is the foundation upon

which our continuing success is built.

Benefits for life. Siemens has always

assumed responsibility for its employees

and attaches great importance to their

working conditions. In a constantly

changing working environment, maintaining work-life balance takes high

priority. Siemens takes an active interest

in assisting its staff in balancing work

commitments with their personal and

family lives.

Shaping

cutting-edge

technology of

the future

with leading

specialists

18 I 19

Tradition

and

modernity

Turbines have been built at the Moabit plant since

1904. An era of manufacturing steam turbines for

industrial applications, power plants and for marine

propulsion was followed by a shift to the production of gas turbines for power plants. Then, as now,

these advanced turbines are destined for customers

around the world.

20 I 21

Milestones in

cutting-edge

technology

– more than

one century

of gas turbine

production

in Berlin

The AEG turbine factory. On February 27,

1904, “Allgemeine Elektricitäts-Gesellschaft” (AEG) founded its turbine factory

on the site that is still in operation today.

The facility mainly produced steam turbines for industrial applications, power

plants and for marine propulsion. At

first, the output of the steam turbines

was less than 1 MW – rising within just

25 years to what was then a record value

of 85 MW. In the 1920s and 30s, the

factory also manufactured marine diesel

engines. After the Second World War, the

workforce almost completely rebuilt the

factory for the repair of public transport

vehicles and bridges, before the production of steam turbines and generators

was resumed on a regular basis in 1948.

A cathedral of labor. The Gas Turbine

Plant Berlin is world-famous among architects for its assembly bay. Designed in

1909 by Peter Behrens (1868–1940) on

the basis of structural calculations prepared by Karl Bernhard (1859–1937),

this revolutionary example of industrial

architecture was celebrated by contemporaries as resembling an “iron church”

or a “cathedral of labor”. Protected as a

historic landmark since 1969, the hangarshaped building still serves its original

purpose: the construction of turbines.

Other buildings where high-tech components are still being produced are as well

under protection as historic landmarks.

The Siemens AG Gas Turbine Plant Berlin.

The manufacture of gas turbines at the

Berlin site began back in 1969, when

AEG and Siemens merged their power

plant activities in the subsidiary Kraftwerk Union (KWU). During this merger,

the steam turbine construction was

relocated to Muelheim / Ruhr. Since 1977,

the Gas Turbine Plant Berlin has exclusively been a Siemens site and delivers

cutting-edge technology to customers

worldwide.

22 I 23

Published by and copyright © 2014:

Siemens AG

Power and Gas Division

Freyeslebenstrasse 1

91058 Erlangen, Germany

For more information, please contact our

Customer Support Center.

Phone: +49 180 524 70 00

Fax:

+49 180 524 24 71

(Charges depending on provider)

Order No. E50001-G210-A435-X-7600

Printed in Germany

Dispo 34802, c4bs No. 7448, 7821

hl 1310 8431 WS 14101.0

Printed on elementary chlorine-free bleached

paper.

All rights reserved.

Trademarks mentioned in this document are

the property of Siemens AG, its affiliates, or

their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should therefore be specified in the contract.