INDUSTRY TRENDS

The Duck

Author

Bonnie Marini is Director of Product Line

Management at Siemens Energy.

Pond

A Look at Non-Renewable Generation on Grids with A Lot of Renewable Resources

RENEWABLE

DISPATCH AND THE

CALIFORNIA DUCK

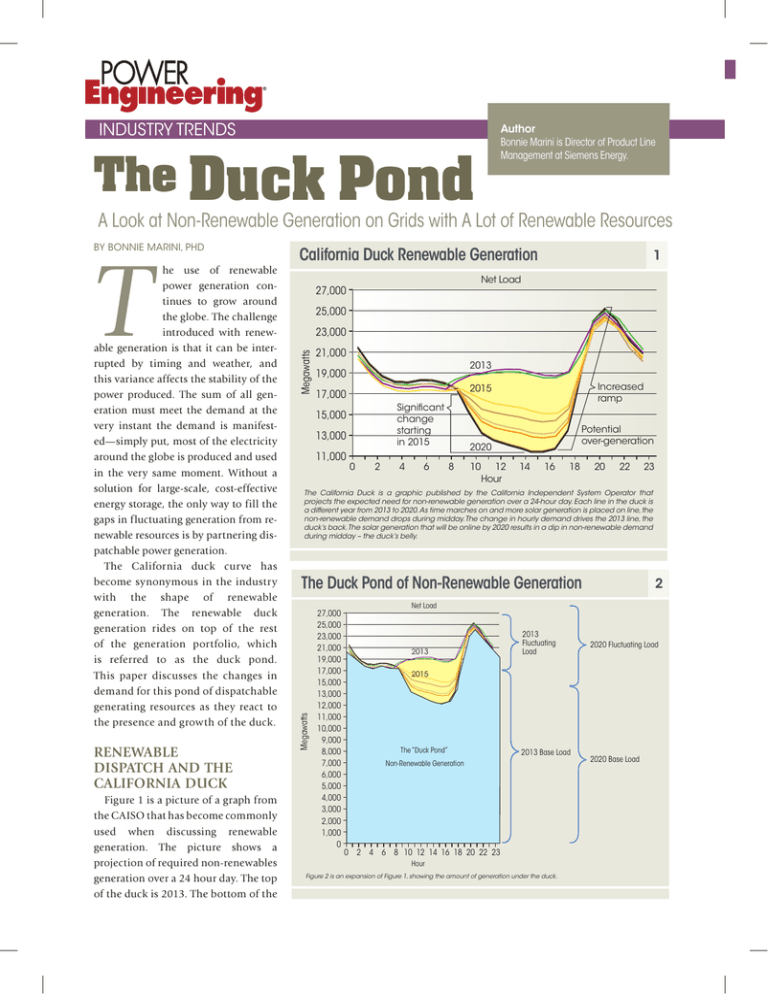

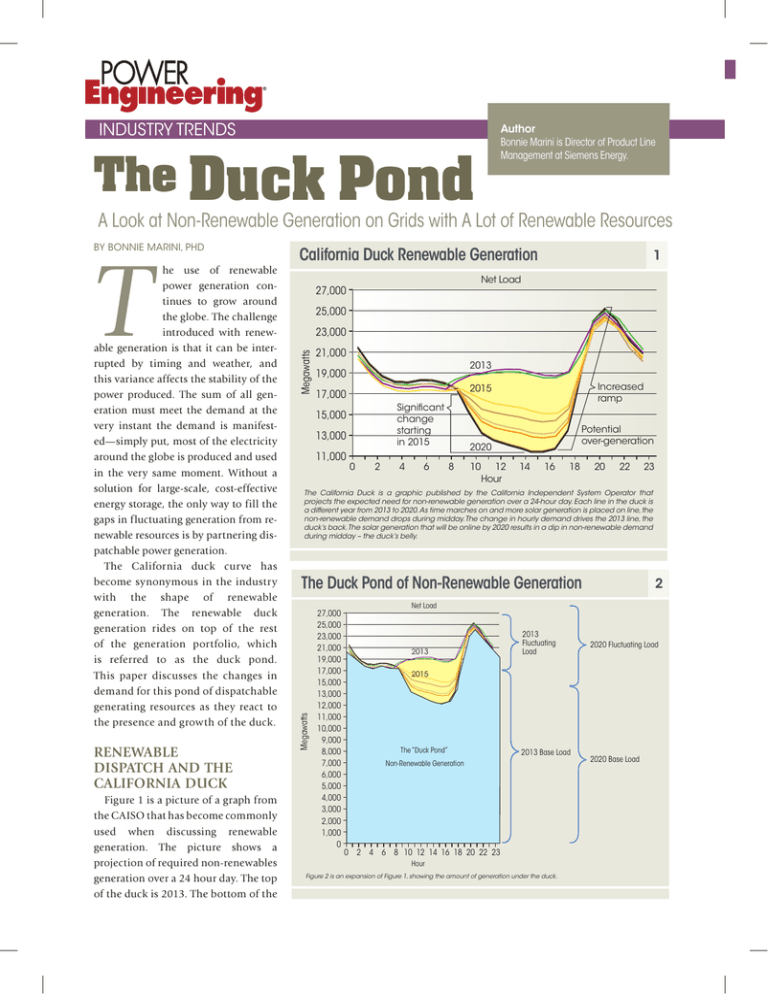

Figure 1 is a picture of a graph from

the CAISO that has become commonly

used when discussing renewable

generation. The picture shows a

projection of required non-renewables

generation over a 24 hour day. The top

of the duck is 2013. The bottom of the

California Duck Renewable Generation

1

Net Load

27,000

25,000

23,000

Megawatts

T

he use of renewable

power generation continues to grow around

the globe. The challenge

introduced with renewable generation is that it can be interrupted by timing and weather, and

this variance affects the stability of the

power produced. The sum of all generation must meet the demand at the

very instant the demand is manifested—simply put, most of the electricity

around the globe is produced and used

in the very same moment. Without a

solution for large-scale, cost-effective

energy storage, the only way to fill the

gaps in fluctuating generation from renewable resources is by partnering dispatchable power generation.

The California duck curve has

become synonymous in the industry

with the shape of renewable

generation. The renewable duck

generation rides on top of the rest

of the generation portfolio, which

is referred to as the duck pond.

This paper discusses the changes in

demand for this pond of dispatchable

generating resources as they react to

the presence and growth of the duck.

21,000

2013

19,000

Significant

change

starting

in 2015

13,000

11,000

Increased

ramp

2015

17,000

15,000

0

2

4

6

Potential

over-generation

2020

8

10

12

Hour

14

16

18

20

22

23

The California Duck is a graphic published by the California Independent System Operator that

projects the expected need for non-renewable generation over a 24-hour day. Each line in the duck is

a different year from 2013 to 2020. As time marches on and more solar generation is placed on line, the

non-renewable demand drops during midday. The change in hourly demand drives the 2013 line, the

duck’s back. The solar generation that will be online by 2020 results in a dip in non-renewable demand

during midday – the duck’s belly.

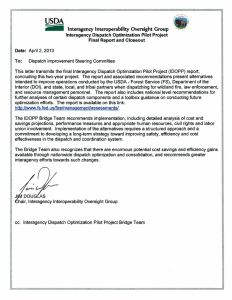

The Duck Pond of Non-Renewable Generation

Megawatts

BY BONNIE MARINI, PHD

27,000

25,000

23,000

21,000

19,000

17,000

15,000

13,000

12,000

11,000

10,000

9,000

8,000

7,000

6,000

5,000

4,000

3,000

2,000

1,000

0

2

Net Load

2013

2013

Fluctuating

Load

2020 Fluctuating Load

2015

The “Duck Pond”

2013 Base Load

Non-Renewable Generation

0

2 4 6 8 10 12 14 16 18 20 22 23

Hour

Figure 2 is an expansion of Figure 1, showing the amount of generation under the duck.

2020 Base Load

Daily Total and Non-Renewable Demand - Load Net Load (2/24/2013)

28,000

3

Load

Net Load

27,000

Load & Net Load (MW)

26,000

25,000

24,000

23,000

22,000

21,000

20,000

19,000

23.00

22.00

21.00

20.00

19.00

18.00

17.00

16.00

15.00

14.00

13.00

12.00

11.00

10.00

9.00

8.00

7.00

6.00

5.00

4.00

3,00

2.00

1.00

0.00

18,000

Figure 3 is another example of total demand and non-renewable demand over the course of a day.

duck’s belly is 2020. What can be seen

from the duck is that the solar power

generated during the day will result in

a need for non-renewable resources to

ramp down in the morning and ramp

up in the evening.

It should be noted that the

California duck curve of Figure 1 is

a picture of one particular day. Since

weather is a big factor, the curve

changes every day.

A glance at any of these curves

can result in an impression that

most of the other generation on the

grid will need to ramp on and off

in order to support the renewables

however in Figure 1 the y-axis is cut

off at 11 Gigawatts. It is interesting to

note that the duck’s belly is marked

“potential over-generation risk”.

Clearly this “overgeneration” is not

due to the renewables producing

more power than the grid demands.

It is due to the expected behavior of

the resources providing that 12 to

15 GW – the generators that fill the

duck pond. Figure 2 is an expansion

of Figure 1, showing the amount of

generation under the duck.

WHAT CHANGED

AND WHAT DIDN’T

Historically, different types of

power plants were used for different

types of dispatch. Figure 2 shows

how the split between base load and

f luctuating load plants is changing.

Fewer base load plants and more

f luctuating load plants are needed

to integrate with renewables. The

concern is that there are too many

base load plants and not enough

f luctuating load plants. If the base

load plants can’t be turned down or

shut down, there is overgeneration.

Using the same example graph,

moving from the 2013 scenario, the

steady base load was about 18 GW.

In the 2020 scenario the steady load

is about 12 GW, which means that 6

GW of generators had to switch from

being base loaded to f luctuating load.

Looking at the curve, we can see

that it is not just the amount of

f luctuating generation that changes,

it is also the amount of time these

resources are dispatched. In the 2013

scenario, most of this f luctuating

generation is dispatched less than

20 percent of the time. In the 2020

scenario, many of the f luctuating

resources are running more than 60

percent of the time. This changes both

the economic and environmental

impact of these f luctuating resources.

One other factor that has been a

point of discussion with renewable

integration is ramp rate. Figure 3

shows another example of total

demand and non-renewable demand

over the course of a day. The blue line

depicts total demand and the lower

red line depicts the net demand which

in this case is defined as the nonrenewable demand. This shows that

even without renewables, power had

to ramp up and down in order to meet

demand. The difference between the

past and the future is not the existence

or rate of the ramp but simply the

amount of energy that needs to ramp.

The charts illustrate that increasing

renewables:

• will decrease the base load nonrenewable generation

• will increase the amount of fluctuating non-renewable generation

• will increase the amount of

INDUSTRY TRENDS

Megawatts

Dispatch Regimes

27,000

25,000

23,000

21,000

19,000

17,000

15,000

13,000

12,000

11,000

10,000

9,000

8,000

7,000

6,000

5,000

4,000

3,000

2,000

1,000

0

4

Peaking dispatch

2013

Medium dispatch

2015

Base dispatch

The duck pond can be broken into three different kinds of operation: Base load; mid load; and peaking load

Examples of Dispatch on a Grid with Renewables

35,000

Generation (MW)

Wind

Net Demand

Demand

30,000

5

Solar

Simple Cycle

25,000

Combined Cycle

20,000

Hydro

15,000

Gas Fired Steam Turbine

Cogen

10,000

Biomass/Geothermal

5,000

0

Coal Fired Steam Turbine

Nuclear

1

Hour

dispatch of the f luctuating nonrenewable generation

• will require a similar ramp rate

to the f luctuating generation

used in the past

The first reaction to deal with this

non-traditional problem was using a

tradition solution. Some suggested

switching these plants to the types

of plants that had been used for

f luctuating load in the past, for

example simple cycle gas fired power

24

plants, but the change in dispatch

make this solution a less suitable fit

for today’s challenges.

THE RIGHT SOLUTION

FOR FLUCTUATING

GENERATION

The first requirement for a resource

to be used for f luctuating generation

is that it can support f luctuating

operation. For illustrative purposes,

as shown in Figure 4, the duck pond

can be broken into three different

kind of operation:

• Base load = not changing load

frequently

• Mid Load = dispatch for a large

portion of the day, but can reduce

load or shut down for portions

on the day

• Peaking Load = dispatch for

short operational windows and

operate <20% of the time

To support fluctuating load, there are

several types of plants that can be used

• Simple Cycle – Fast start, high

f lexibility, low CapEx, low

efficiency, High LCOE

• Conventional Combined Cycle –

Slow Start, Capable for Fast Load

Changes, Wide operating range,

Higher CapEx, High Efficiency,

Low LCOE

• Flex-Plant Combined Cycle –

Fast start, Capable for Fast Load

Changes, Wide operating range,

Higher CapEx, High Efficiency,

Low LCOE

In addition to technical capability,

the decision between technologies

depends on economics. For a low

dispatch plant, low CapEx is more

critical than low LCOE.

For a high dispatch plant, the

opposite is true. Low LCOE is the

more critical factor. Typically for

plants that dispatch less than 10

percent to 20 percent the economics

favor simple cycles. For plants which

dispatch more, the fuel savings

benefit of the combined cycles results

in better economics for the high

efficiency combined cycles.

Prior to the growth of f luctuating

renewables much of the f luctuating

load was low dispatch. The solution

for this demand was simple cycle.

Today’s medium dispatch demands

are different.

To gain a broader understanding

of how future dispatchable resources

will need to behave in order to

accommodate increased renewable

Examples of Dispatch on a Grid with Renewables

12,000

Ramp Rate of

>2,500 MW/hr

10,000

Generation (MW)

6

8,000

6,000

4,000

2,000

0

1

24

Hour

Ramping Support from Combined Cycle Power Plants

CONVENTIONAL

COMBINED CYCLES FOR

FLUCTUATING DEMANDS

Changing load is not only due

to changing dispatch of renewable

generation. It is also due to constant

changes in demand which happen all

of the time. Conventional combined

cycle technology has been used to

meet these changing loads for many

years. As shown in Figure 3, the

Examples of Dispatch on a Grid with Renewables

7

Net Demand

50,000

Demand

45,000

Wind

Solar

40,000

Generation (MW)

generation; data developed in two

recent studies of future dispatch

behavior were evaluated with a

specific focus on what types of plants

will be needed to accommodate

increased renewables.

One study was conducted by the

CAISO1 and the other was conducted

by the Ventyx Corporation.

The results of both studies

indicate that the majority of demand

f luctuations will be supported by

combined cycles.

In a future grid, with an increase

of highly fluctuating renewables,

simple cycles will still support low

dispatch, peaking demands. Whereas,

combined cycles are a better choice for

the rest of the pond if they can meet

the fluctuating demand – and analysis

and history shows that they can.

during the day. The magnitude of the

energy supplied makes it practical to

use large combined cycle plants to

support this need. The red line on

Figure 5 represents the simple cycles.

In this case they are dispatched;

however they are not used to cover the

changes in demand. Their dispatch is

rather f lat, and the amount of energy

dispatched is minimal. It is less costly

and more environmentally friendly

to use the combined cycles to cover

large demand changes so they are

used first.

Figure 7 and Figure 8 show a

Simple Cycle

35,000

30,000

Cogen

25,000

Combined Cycle

20,000

Hydro

15,000

Biomass/Geothermal

10,000

Gas Fired Steam Turbine

5,000

Coal Fired Steam Turbine

0

1

Hour

ramps seen with renewables are not

expected to be faster than the ramps

previously seen in the market – they

are only larger and longer.

Figure 5 is a simulation of a winter

day on the Huntington Beach grid

in California. Many of the plants

modeled are not advanced FlexPlant combined cycles, but are

conventional cycles. Figure 6 focuses

on the energy provided by combined

cycles and shows they are providing

majority of the ramping support. The

power from combined cycles ramps

up and down to cover two peaks

24

Nuclear

projected summer day, in Huntington

Beach. Again, the dispatch of the

simple and combined cycle’s show

that the larger share of demand

change is supported by combined

cycles. In this case, the overall

demand is high, and the simple

cycles are dispatched to meet the

peak in demand. This dispatch order

on a high renewable grid is similar to

the dispatch order on a conventional

grid. Combined cycles dispatch first

because they offer a lower cost of

generation followed by simple cycles

meet peaks in demand. There is no

INDUSTRY TRENDS

Generation (MW)

Generation (MW)

Simple Cycle and Combined Cycle Dispatch

20,000

high ramping capability, they are not

designed to start fast and frequently.

Newer flexible combined cycle plants

can start as fast as a simple cycle while

still maintaining full equipment life,

making multiple restarts viable even

for large combined cycles.

A good example of a f lexible

combined cycle which uses the

advantage of fast start is the Siemens

H-Class power plant which has been

operating since 2012 in Irsching,

Germany. Figure 10 shows an

example of the plant operation as it

starts quickly in the morning, follows

demand during the day, shuts down

in the evening, and repeats this

pattern the next day. With Siemens

8

Gas – Simple Cycle

15,000

10,000

5,000

0

20,000

1

3

5

7

9

11

13

Hour

15

17

19

21

23

9

11

13

Hour

15

17

19

21

23

Gas - Combined Cycle

15,000

10,000

5,000

0

1

3

5

7

40,000

30,000

Wind

25,000

Solar

Hydro

10,000

Gas Fired Steam Turbine

5,000

Coal Fired Steam Turbine

Nuclear

1

Hour

indication of a need for more simple

cycles to support load changes.

Similar data was extracted for a

node in Texas, which has the largest

supply of wind power in the US.

Figure 9 illustrates that the same

phenomenon can be observed there

as well. The vast majority of load

changes are supported by combined

cycles first. Simple cycles are used

primarily for peak demand and are not

critical for supporting the large ramps

in load that were seen in the past, or

the even larger ramps in load that are

24

Combined Cycle

5,000

0

Combined Cycle

15,000

9

10,000

Simple Cycle

20,000

0

15,000

Generation (MW)

Generation (MW)

35,000

Generation (MW)

A Day in Texas - Simple Cycle and Combined Cycle Dispatch

1,000

800

600

400

200

0

1

3

5

7

9

11 13

Hour

15

17

19

21

23

9

11 13

Hour

15

17

19

21

23

Simple Cycle

1

3

expected in the future. Combined

cycles are able to change load quickly

and ultimately dispatch first due to

the lower cost of generation.

FLEXIBLE COMBINED

CYCLES FOR RENEWABLE

SUPPORT

While conventional combined cycles

offer advantages over simple cycles

for renewable integration, modern

Flex-Plant combined cycles offer

significantly more capability. While

conventional combined cycles have

5

7

Flex-Plants there is no need to trade

efficiency for f lexibility. This plant

exceeds 60% net combined cycle

efficiency and can add 500 MW of

generation to the grid in 30 minutes.

Operating Flex-Plants in the U.S.

include Lodi Energy Center in Lodi,

California and the Temple and

Sherman plants in Texas.

Unlike

most

simple

cycles,

combined cycles often have a very

large load range, enabling them to

ramp up and down without having to

shut down and restart.

Typical Daily Operation at SCC5-8000H

in Irsching Germany

250

Reliable plant startup

200

On Grid

Control

10

Fast, controlled

ramp up & down

MW

150

100

50

0

–50

0:00

4:48

2:24

7:12

9:36

14:24

19:12

0:00

4:48

9:36

14:24

19:12

0:00

12:00

16:48

21:36

2:24

7:12

12:00

16:48

21:36

2:24

Time

ENVIRONMENTAL

CONSIDERATIONS

Today efficiency is not just an economic factor, it is also an environmental consideration. Greenhouse gas production is directly related to efficiency,

and recently issued EPA rules are one

example of the requirements for future

generation. In the EPA’s Carbon Pollution Standards issued this year, in order to manage carbon dioxide production, low efficiency plants are limited

in dispatch based on their efficiency.

For plants with less than 50% efficiency based on LHV, the plant’s dispatch

is limited to its equivalent LHV based

efficiency. For example, a simple cycle

plant with 35 percent net efficiency

may not dispatch more than 35 percent

of the time. Again looking at Figure 4,

it is expected that a large group of fluctuating plants will be needed to dispatch at higher levels, adding another

driver for the use of combined cycles

for renewable integration.

FITTING THE PLANT

TO THE NEED

It seems rare when a choice is

better in functionality, cost, and

environmental footprint, but for

high dispatch plants, combined cycles win in all three areas. Flexible

combined cycle power plants support the renewable concept by being

more efficient, cleaner for the environment and f lexible to meet the

change in demand.

For low dispatch plants, a traditional

approach still makes sense. The lowest

CapEx solution with high flexibility

is a good fit, and this is typically a

simple cycle frame unit.

CONCLUSION

The growing portfolio of renewable

resources has resulted in the addition

of a large demand for high dispatch,

f luctuating generation. This demand

regime is not served by plants which

cannot change load, and is not

served well by low efficiency plants

designed for peaking. This growing

market segment needs a solution

with high operating efficiency, low

LCOE, high ramping f lexibility and

fast start. The new generation of FlexPlant combined cycles offer these

benefits. Use of the right solutions

for these various load regimes will

support the environmental benefit

of renewable generation while

managing the cost of generation

with cost effective, high efficiency

plants.

Electronic and single printed copies or distribution with permission to Siemens Energy from Power Engineering

March © 2016 PennWell Corporation

Siemens’ Flex-Plants™

A trusted partner for renewables

©Siemens, 2016. All Rights Reserved.

The continued growth of renewable energy generation

puts power supply at nature‘s whim. The potential for rapid

fluctuations in generation must be quickly balanced to maintain

a reliable supply of power to the grid. With all of the flexibility

and features of a peaker and the high efficiency of a combined

cycle plant, proven Flex-Plants from Siemens work in harmony

with renewables, providing efficient and reliable electricity

when the wind stops blowing or the sun stops shining.

FlexPlant Ad-Rebranded.indd 1

As you tackle the challenge of ensuring a reliable power

supply while remaining committed to using natural resources

responsibly, Siemens has the solutions that help you do both.

siemens.com/energy

4/19/16 1:22 PM