siemens.com/energy/transformers

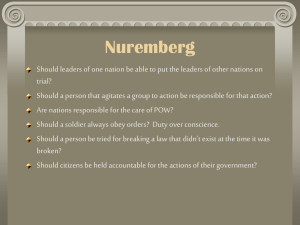

Electrical Research and Testing

Laboratory Nuremberg

Testing and research at the cutting edge of technology

Answers for energy.

The latest methods,

outstanding expertise

The ERT Laboratory Nuremberg offers comprehensive testing and analysis

facilities for energy-related material testing, research, and development.

From general fundamental research using high-voltage

tests with various voltage types to dielectric examinations

and tests using test setups specially designed for use in

electrical components, the Electrical Research and Testing

(ERT) Laboratory Nuremberg is capable of conducting a

wide range of tests and analyses. In addition to precise

replication, modeling, and testing of even the most com­

plex setups, the specific material properties of insulation

components can also be examined.

Materials technology also plays an important role in the

ERT Laboratory. Specially developed devices for oil treat­

ment, drying, and impregnation plus other versatile pro­

cess materials make it possible to consider quality criteria

such as purity, cleanliness, or dryness of the insulants.

This ensures that the study results are meaningful and

precise.

Various test systems are used for electrical investigations,

including a number of independent AC voltage test

systems with a maximum test voltage of 400 kV, an

auto­matically pole-reversible DC voltage test system with

2

up to 400 kV, and a surge generator with a charging

voltage of 1,200 kV for lightning and switching impulse

voltages. In two separate test halls, highly sensitive

measurements can be carried out at an extremely low

noise level of <1 pC.

The services offered by the ERT Laboratory Nuremberg,

however, go far beyond pure electrical testing. Its collabo­

ration with the chemical and physical materials testing

laboratory headed by Dr. Atanasova-Höhlein, which is

located in the same building, opens up a wealth of possi­

bilities for diagnostics and analysis. The materials testing

laboratory fully focuses on the laboratory diagnosis of

oil-filled electrical equipment. The materials that are elec­

trically tested in the ERT Laboratory can then be examined

right down to the tiniest detail. The close cooperation

between the two laboratories creates synergies that ensure

rapid, reliable, and high-quality study results.

Testing tailored to customer requirements: special contract measurements

From test planning to documentation, the outstanding technical equipment

and individual design possibilities make the ERT Laboratory Nuremberg the

first choice for meeting special requirements.

Extensive equipment and the highly qualified staff of

the ERT Laboratory Nuremberg make it possible to fulfill

special customer requests and requirements which go far

beyond the services available in the usual standard

investigations.

Every step can be individually agreed upon and designed

with the customer – including trial planning and prepara­

tion of the specification, planning and production of the

test pieces, test design, as well as conducting the test

series with subsequent evaluation and documentation.

In addition, the ERT Laboratory Nuremberg offers testing

of electrical components within the framework of its

performance class, such as dielectric type and routine

testing of capacitors or bushings.

The services provided by the ERT Laboratory Nuremberg

are rounded out by a wide range of standard electrical

tests for the characterization of insulation materials

in accordance with the established regulations and

standards.

The latest CAD and 3-D software is available for the plan­

ning phase. This allows test assemblies to be designed

using state-of-the-art technology and then simulated with

the corresponding electrical and magnetic calculation

tools in order to find the ideal test design every time.

Range of possible contract measurements

3

Electrical testing of solid insulants for partial

discharge and puncture behavior

Investigation of alternative liquid

insulants and green technologies

Determination of the parameters of electrical

solid insulants

Development and testing of innovative

insulation designs

Investigation and research into the dielectric

properties of liquid insulants

Examination and testing of electrical

components, type and routine tests

Perfect, from preparation

to documentation

Reliable test results ensured by high quality – from test planning

to evaluation

Process technology and sample preparation

Standard material investigations

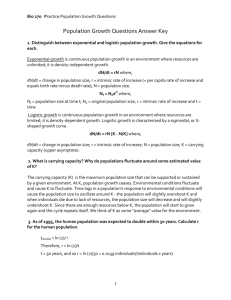

In investigations of insulation materials, the production

and preparation of the samples and test items and com­

pliance with the process parameters before and during the

measurement are of enormous significance. Usable quali­

tative results can only be achieved if all the parameters

are observed exactly. This is why the ERT Laboratory

Nuremberg places such great importance on precision.

In the characterization of insulation materials, there are

various processes for determining the relevant parame­

ters, depending on the material and area of use. These

include determination of the electric puncture strength of

insulating materials of all types – in the case of AC voltage

according to IEC 60243-1 and with DC voltage according

to IEC 60243-2.

All wood and metal treatment processes are carried out

in the ERT Laboratory’s own workshop, which is well

equipped with everything from lathes to belt grinders

and disk sanders.

Another important criterion is the partial discharge behav­

ior of solid insulants. This is investigated in the ERT Labo­

ratory Nuremberg using a specially developed, standard­

ized testing method. The partial discharge behavior of the

test pieces provides information about the quality and

processing of the material.

For preparation work that includes drying and impregnat­

ing, vacuum drying cabinets and specially developed

impregnating cabinets are available. These are used to

precisely regulate and monitor required process parame­

ters such as temperature and pressure.

4

Sample preparation

To characterize the insulation properties with direct

voltage loading, measurements of the specific resistance

according to IEC 60093 or the measurement of polariza­

tion and depolarization currents (PDC measurement using

a step-response measurement) can be carried out. In addi­

tion, dielectric properties such as the loss factor tan δ, the

Equipment for oil preparation

capacities, and the relative dielectric constant of solid

and liquid insulants can be determined according to

IEC 60247. Determining the electric puncture voltage of

liquid insulants according to IEC 60156 and determining

the water content of solid and liquid insulants according

to IEC 60814 enable all the important parameters to be

recorded before, during, and after the measurements.

Research and development projects

The ERT Laboratory Nuremberg provides the best possible

conditions for electrotechnical research and development.

The excellent equipment in the laboratories and work­

shops makes it easy to carry out customer-specific exami­

nations. The experts at the ERT Laboratory Nuremberg are

also happy to provide assistance in the development of

concepts, and they can be helpful in planning the tests or

carrying them out on behalf of the customer. When the

tests are actually conducted, it is possible to react flexibly

and unbureaucratically to technical idiosyncrasies, for

example with modifications to the test design or test

pieces. Moreover, it is also possible to react spontaneously

Air-conditioned measuring and test cell

to effects during the course of the test series. What is

important is the scientific character of the investigations.

Because the ERT Laboratory Nuremberg has enough room

to maneuver, it can offer a wide range of options to spe­

cifically pursue any phenomena that might arise.

All work stages can be swapped on short notice and

through direct communication. It goes without saying

that the client can be present at every test and investiga­

tion and make resulting modifications to the test item.

To ensure full reporting, all process stages and measure­

ment results are documented and reported with absolute

precision.

Sample inside the test container

5

Cutting-edge testing technology

for precise, reliable results

Technical data for the test areas and material equipment of the

ERT Laboratory Nuremberg

High-voltage laboratory

400 kV AC test system with 200 kVA (50 Hz)

150 kV AC test system (50 Hz)

Impulse generator with 1,200 kV charging voltage for

lightning (1.2/50 μs) and switching impulse voltages

(250/2,500 μs)

Multiple chopping gap for chopped impulse voltages,

e.g. for measurements according to IEC 60076-3

400 kV DC test system, automatically pole-reversible

(for measurements according to IEC 61378-2)

Screened high-voltage laboratory, background noise

level < 1 pC

Crane capability 1 t

Air cushion system up to 7.5 t

Air-conditioned test cell

Screened measuring cell, background noise level ≤ 1 pC

High-voltage module (AC 100 kV/DC 140 kV/LI 140 kV)

Precision high-voltage system device, 60 kV

(electrically pole-reversible)

Fully air-conditioned measuring cell, temperature range

–40 °C to +180 °C, ambient humidity 10% to 98% rH

Measuring cell to determine dielectric parameters of

solid and liquid insulation materials (tan δ, capacity,

dielectric constant)

Process technology

Oil preparation unit (300–700 l/h), which can also be

used for other liquids

Vacuum drying cabinets

Special vacuum impregnation chambers

Determination of the water content of liquid and solid

insulation materials (Karl Fischer titrator)

Determination of oil puncture voltage according

to IEC 60156

Workplace for hazardous materials

Workshop for test piece preparation and modification

of test designs

PDC measurement system for conductivity investiga­

tions of individual materials or components

Mobile 150 kV AC test system

Workshop equipment

6

A long tradition of research and development

In the 1920s, the transformer plant systematically expands

its research and development capacities, adding the most

modern equipment. The development of transformer tech­

nology makes great progress. Oil transformers are moni­

tored for the first time with a Buchholz relay, an electrical

safety device. In 1923, the first five-limb cores are produced

for high-capacity 3-phase AC current transformers. 1927

sees the start of the manufacture of transformers with step

switches for uninterruptible voltage adjustment under load.

After the war, the research facilities are built up again and

systematically expanded. The investigations made possible

as a result lay the foundations for the steady growth of the

Nuremberg transformer plant.

The new ERT Laboratory Nuremberg

The laboratory building for the newly established ERT

Laboratory Nuremberg is completed in December 2011.

After the installation and commissioning of the electrical

components, the ERT Laboratory Nuremberg starts work

in July 2012. The new facilities set a new quality standard

in the testing of insulants. One of the special features of

the ERT Laboratory Nuremberg is its close cooperation

with the chemical and physical test laboratory housed in

the same building, which creates unique synergies for

development projects and quality testing.

A comprehensive test portfolio

The ERT Laboratory has a testing hall and an airconditioned measurement cell. Both can be operated in

parallel or independently of each other. This facilitates

flexible workflows and operating sequences and enables

unconventional studies to be carried out. In addition to

the standard test voltages such as AC, DC, and impulse

voltages, polarity reversal tests (DC) can also be carried

out and chopped impulse voltages can be generated. In

parallel, partial discharge analyses can be conducted and

dielectric measurements (e.g. loss factor and capacity

measurements) can be carried out in defined climatic

conditions.

New opportunities in diagnosis and analysis

Factors such as humidity and temperature play a crucial

role in the electrical characterization of insulants. In the

ERT Laboratory Nuremberg, both the characteristic para­

meters of the test pieces and the ambient and process

parameters can be precisely monitored with the latest

measuring and testing equipment. This means that the

empirical investigations can be statistically analyzed so

that the right conclusions can be drawn for the object

under investigation.

7

Published by and copyright © 2014:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens AG

Energy Sector

Power Transmission Division

Transformers

Katzwanger Strasse 150

90461 Nuremberg, Germany

For more information, please contact

our Customer Support Center.

Phone: +49 180 524 70 00

Fax:

+49 180 524 24 71

(Charges depending on provider)

E-mail:support.energy@siemens.com

Order No. E50001-G640-A234-X-4A00

Printed in Germany

Dispo 19200

fb 5802 WÜ 472764 02141.0

Printed on elementary chlorine-free

bleached paper.

All rights reserved.

Trademarks mentioned in this document

are the property of Siemens AG, its affiliates,

or their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should therefore

be specified in the contract.