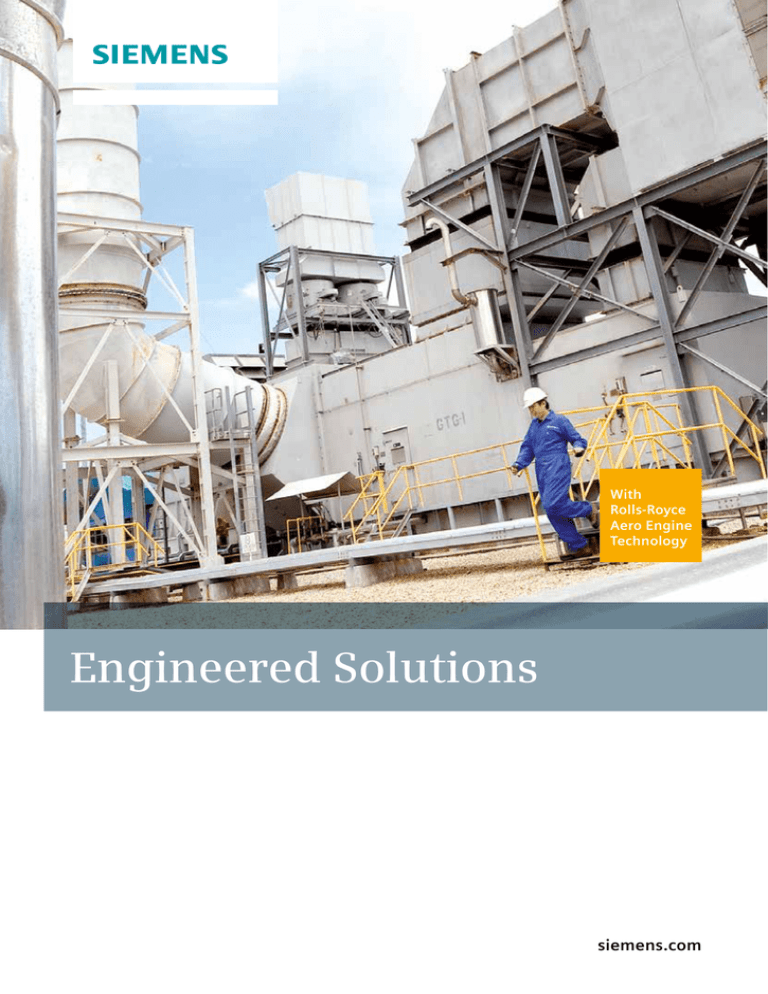

With

Rolls-Royce

Aero Engine

Technology

Engineered Solutions

siemens.com

2 / Engineered Solutions

Major Engineered Solutions

Offerings

Understanding the rapidly-changing nature of today’s

industrial and commercial environment

At Siemens we understand the rapidly-changing nature

of today’s industrial and commercial environment, in

which market requirements and operating conditions

can vary significantly - and often unpredictably. So we

design and shape our products and services to help

ensure Siemens customers maintain and increase

performance and profitability throughout the life of

their power generation or oil and gas project.

The long-term reliability inherent in Siemens equipment

means we have gained unrivalled experience and

knowledge when it comes to developing the engineered

modifications and upgrades that customers need to

sharpen their vital competitive edge by enhancing the

efficiency, environmental performance and profitgenerating potential of their equipment.

These engineered solutions from Siemens enhance your

total package, from the gas generator and its control and

ancillary systems through to the final driven equipment.

Siemens acquired the Rolls-Royce aero-derivative gas turbine and compressor business effective December 1, 2014. References to Siemens

and products are intended to refer to such business as acquired and incorporated into Siemens as from such effective date.

Engineered Solutions / 3

“We design and shape

our products and

services to help ensure

Siemens customers

maintain and increase

performance and

profitability

throughout the life of

their power generation

or oil and gas project.”

The Industrial Avon

The focal-point for three influential engineered solutions

This long-established aero-derivative gas turbine is the

focal-point for three influential engineered solutions

from Siemens, each delivering significant

enhancements to this robust and extensively used

gas generator.

Industrial Avon 200 upgrade

This modification offering cutting-edge technology

focuses Rolls-Royce Aero Engine technology on the turbine

section of the Industrial Avon. Results provide increased

power, efficiency, component life, reliability and time

between overhauls - without increasing the exhaust gas

temperature.

Swirler burner

This engineered solution enhances combustion stability by

directing compressor delivery air through the burner

nozzle exit faces and flame-tube swirler. This system which is standard equipment on the Industrial Avon 200 focuses on reducing the possibility of liquid hydrocarbon

carry-over from the gas fuel, ensuring smoother

combustion, extended discharge nozzle life and reduced

burner fouling, all of which improve availability. Increased

reliability and reduced overhaul costs also result from the

way this engineered solution minimises the effects of

high-cycle fatigue on turbine blades and discs.

Variable inlet guide vane closed loop control

Advances in materials, sealing, geometry and cooling

technologies deliver enhancements within the high-,

intermediate- and low-pressure turbine sections, while

combustion chamber improvements ensure improved

availability, increased reliability, reduced overhaul costs

and significant reductions in CO and CO2 emissions.

This engineered solution delivers enhanced control of the

Industrial Avon variable inlet guide vane (VIGV) system. It

provides closed-loop control and electronic switching that

exploits latest control technology to replace the current

mechanical system. By eliminating VIGV drift it maintains

gas generator efficiency while removing the possibility of

compressor surge. It also removes the need to check VIGV

position and blow-off valve settings during operation,

enhancing safety, while eliminating time-consuming

regular maintenance and improving reliability

and availability.

4 / Engineered Solutions

The Industrial RB211

The mainstay of a major global range of industrial

applications

With more than 650 Industrial RB211 gas turbine

systems sold worldwide and some 28 million operating

hours logged to date, the Industrial RB211 is the

mainstay of a major global range of industrial

applications - many of which are in remote or offshore

locations where high availability and reliability

are crucial.

Power is increased by up to 13% above -24C base load,

while reduced life cycle costs include reduced fuel burn,

extended time between overhauls and an improved

mechanical design eliminates weaknesses. Significant

reductions in CO2 emissions provide another key benefit.

Industrial RB211 engineered solutions from Siemens

include upgrades based on comprehensive system history

and key performance indicators established in our

technical support networks. These upgrades enable a

retrofit investment that enhances the customer’s

operation in key areas such as improved efficiency,

increased power, extended reliability, and cleaner

environmental performance - one or more of which can

give you that vital competitive edge.

This engineered solution lowers emissions by replacing

the combustor assembly module with nine radial

combustors, fuel valves and associated piping. This

upgrade exploits latest lean-burn combustion technology

and supplies fuel through three manifold systems. Full

low-NOx and low-CO capability is achieved by

this conversion.

Industrial RB211-24C to -24G upgrade

This engineered solution gives the option of increased

power and improved heat rate or increased life when

operating at RB211-24C ratings. Replacement turbine

components feature directionally-solidified blades with

improved cooling, advanced aerodynamics and improved

seals allowing higher firing temperatures, which help

increase power and improve heat rate. If used at -24C

firing temperatures, these materials provide extended

component life.

Industrial RB211-24C/G to 24G DLE upgrade

The success of the Industrial RB211-24G in the market is

emphasised by the presence of nearly 300 units in service

worldwide, with combined operational experience of

nearly 10 million hours - and the lead engine with

100,000 hours. Nearly 60 -24C rated Industrial RB211’s

have received the -24G upgrade, with the lead engine

accumulating more than 70,000 hours since conversion.

Engineered Solutions / 5

“This engineered

solution lowers

emissions by replacing

the combustor

assembly module with

nine radial

combustors, fuel valves

and associated piping.”

Gzero upgrade

Electric start conversion

Up to 10% more power can be achieved by upgrading to a

modified intermediate-pressure compressor equipped

with an extra stage of blades at the front (a zero-stage).

This engineered solution also matches the flow capacity

of the power turbine to the increased gas

generator output.

This upgrade replaces existing high-pressure natural gas

starter systems with a simpler, more robust electric motor

that has worldwide voltage capability. Benefits include a

reduced design complexity that delivers a minimum

overhaul/service life of 20 years, better reliability, easier

maintenance, reductions in emissions and noise and

considerable savings in maintenance costs over a 25-year

life cycle of an electric starter.

Dual fuel conversion

This engineered solution increases the flexibility of

Industrial RB211 units operating in power generation and

oil and gas applications. It gives the option of running the

engine on either gas or liquid fuel, while fuels can be

switched during steady-state running of the gas

generator. The upgrade eliminates the risk of interruption

or depletion of the gas generator’s fuel supply. It also

provides a black start capability.

Today more than 80 units are operating with this dual fuel

capability, with combined experience of more than three

million hours.

6 / Engineered Solutions

The Industrial 501

Popular, proven and profitability-enhancing

engineered solutions

Two popular, proven and profitability-enhancing

engineered solutions are available to operators of

Siemens Industrial 501 generating sets worldwide, the

upgrade from KB5 to KB5S standard and the DLE fuel

system upgrade.

Industrial 501-KB5 to KB5S

This superior Industrial 501-KB5S specification improves

the heat rate and increases the output power of the

Industrial 501 package. By replacing the KB5 rear turbine

bearing support and fourth-stage turbine blades, this

engineered solution increases power output by up to 4%

without the need to raise firing temperatures, while the

heat rate can be improved by up to 6%. The work is

undertaken during overhaul of the gas generator.

Dry Low Emissions (DLE) conversion

Advanced lean-burn combustion technology reduces NOx

and CO emissions without the need for water injection.

Available for gas-fuelled Industrial 501 installations, the

dry low emissions engineered solution ensures ignition

and part-power operation is performed by use of the pilot

fuel circuit, while full-power operation is achieved solely

on the main fuel circuit. Emissions levels of 25 vppm of

NOx and 50 vppm of CO are achievable.

More than 100 DLE systems have entered service in recent

years and customers include Triger Cinergy (with five

units), Florida Gas (five units) and Pacific Gas & Electric

(four units). This engineered solution is delivered during

routine overhaul of the Industrial 501.

Engineered Solutions / 7

“With RT48 power

turbines, conversion of

open-bladed stages to

RT48S shrouded blade

design enhances

efficiency and

improves blade

vibration damping.”

Power Turbines

The latest in mechanical and aerodynamic

improvements

Mechanical and aerodynamic improvements, latest

component technologies and refurbishments to ‘as

new’ condition are among the Siemens engineered

solutions aimed at extending the effectiveness of

customers’ power turbines. For example, RT56

packages can be upgraded to RT62 by changing the

power turbine (which shares the same footprint and

centre line) to unlock the existing additional power

available from the same Industrial RB211 engine.

RT48 to RT48S and RT56 to RT62 conversions

These conversions use latest-technology components to

increase power and improve heat rate. They also deliver

the benefit of a ‘zero-hour’ upgrade, in which the unit is

returned to as-new condition. With RT48 power turbines,

conversion of open-bladed stages to RT48S shrouded

blade design enhances efficiency and improves blade

vibration damping. Rated speed can be increased to

realise full efficiency and an increase in power.

RT56 and RT62 T-PIN to curvic rotor upgrade

RT48S/RT56/RT61 zero hour refurbishment

This engineered solution ensures the second-stage disc

rotation is transferred to its shaft by a curvic coupling that

replaces the existing T-pin coupling - an enhancement

that reduces rotor vibration and enhances availability.

RT56 / RT62 hot match conversion

This engineered upgrade replaces first-stage vanes with

new components, increasing the turbine’s throat area and

helping to improve performance in hot conditions.

This engineered solution provides the customer with a

new set of discs and blades that bring the benefits of

running the rotor in ‘as-new’ condition. The RT56 / RT62

upgrade enables the operator to run another 100,000

hours without major overhaul.

8 / Engineered Solutions

Compressors

The focal-point for three influential engineered

solutions

You can match your compressor operation to changes

in operating conditions by undertaking a re-aero of

Siemens pipeline and barrel centrifugal compressors.

At considerably less than the cost of a new compressor,

Siemens can rework the aerodynamic bundle to meet

new site conditions and restore it to full operational

efficiency. Dry Gas Seal (DGS) upgrades bring benefits

too by eliminating problems with the high-pressure

seal oil system. Better operational performance and

higher corrosion resistance add to the value.

Re-aero / aerodynamic / assembly replacement

By upgrading the aerodynamic bundle you can gain

greater operational efficiency and extend the head,

capacity and operating envelope - for considerably less

cost than a new compressor. New components, often steel

machinings to replace castings, deliver significant

improvements. Efficiency improvements of up to four

percentage points can be delivered by better design and

manufacturing techniques.

Dry gas seal conversion

This engineered solution enhances the compressor sealing

system and eliminates problems linked to high-pressure

oil-based sealing systems. It eliminates oil contamination,

saves energy by reducing parasitic losses caused by oil

seal pumps and removes the need to dispose of used oil.

Maintenance costs and downtime are also reduced.

Low leakage wet seal upgrade

This upgrade reduces the potential for oil leaks in

compressors by using wet seals. A Kaydon seal (a liquid

buffered oil bushing seal with low leakage and high

reliability) in a cartridge assembly is fitted to ensure

reduced oil leakage.

Engineered Solutions / 9

“At considerably less

than the cost of a new

compressor, Siemens

can rework the

aerodynamic bundle to

meet new site

conditions and restore

it to full operational

efficiency.”

Controls

Engineered controls solutions improve your equipment’s

reliability

Engineered controls solutions improve your

equipment’s reliability by replacing obsolete controls

with new and improved systems. This enhances system

diagnostic trending and brings benefits of remote

operation and data acquisition.

Option selection based on operational need, equipment

vintage and allowable downtime for replacement.

Quickest replacements are achieved via modular upgrade

and have been completed within 7-9 days with planning

and teamwork between the customer and Siemens field

service teams.

FT125 control system upgrade

This influential engineered solution is ideal for Industrial

501, Industrial Avon and Industrial RB211 packages. Based

on a programmable logic controller with remote I/O’s

(Inputs/Outputs), the FT125 is suitable for both new and

retrofit applications. It can be used as a stand-alone

engine control system, interfaced to a central diagnostic

maintenance system or to a central plant control system.

The FT125 offers the benefit of availability of extensive

information for equipment diagnostics and preventative

maintenance, while protecting your equipment to ensure

improved availability and reliability.

Complementary upgrades to vibration monitoring, surge

control and generator control and protection are

also available.

FT210 HMI and FT310 upgrades

These complementary upgrades along with the FT125

upgrade are also available which bring the software and

hardware of the Health Monitoring Instrumentation

computer and the engineering work station to the latest

standard and configuration.

Fuel control system upgrades

Siemens has developed a variety of control system

solutions. It is important to select the most appropriate

solution for your needs. Three types of upgrades

are available:

•Full panel upgrade

•Sub plate replacement

•Bolt-in/plug-in modular replacement

Siemens engineered solutions can assess your current fuel

delivery system and provide you with the most modern

and robust system updates. For example, our electricallyactuated metering valves meet demands in gas turbine

flow accuracy and are responsive to transient

requirements, including those for low-emission gas

turbine uses.

10 / Engineered Solutions

North America

(NA)

Europe

Russia

& Africa

(ERA)

Middle

East &

Central Asia

(MECA)

Asia-Pacific

(AP)

South America

(SA)

The Package

Engineered solutions deliver a broad range of package

improvements and upgrades

Siemens engineered solutions deliver a broad range of

package improvements and upgrades, including

restoring your power and efficiency in high ambient

temperatures, increasing the functionality and

reliability of your fire and gas protection systems and

improvements to air inlet filtration system to extend

operational life and increase air flow.

vintage Industrial RB211 engines. The scope of supply

involves an on engine hydraulic starter motor plus a

completely independent hydraulic starter skid which has

an electric motor driven pumps and manifold assembly.

Additional pump assemblies rated at 3 x 50% power can

be supplied as an option to increase unit hot sparing and

redundancy.

GG Lube Oil System Upgrade

Inlet fogging system upgrade

The GG Lube Oil system upgrade is applicable to all

Industrial RB211 and Industrial Avon gas generators

model. This upgrade provides the latest standard lube oil

system design for Oil and Gas and Power Generation

customers with a free standing state-of-the-art lube oil

console. The new Lube Oil System can be an external skid

mounted next to the Gas Turbine package or alternatively

integrated within the package itself. Various retrofit

solutions such as sharing of the same oil reservoir for the

Hydraulic Start systems for Industrial RB211 to the new

Lube Oil Console is available to maximizes your unit

availability and reliability.

This system comprises a pump unit with dispensing

nozzles placed in the combustion air inlet duct

downstream of the air filter. It provides up to 14ºC of

cooling effect thus providing a power boost on hot

ambient days. Its demineralised water supply is available

from an optional water treatment skid. This upgrade is

installed at your site.

Hydraulic Start System Upgrades

The Hydraulic Start System Upgrade is applicable to all

Industrial RB211 gas generators models. This upgrade

provides a completely new close loop hydraulic start

system that incorporates the latest technology in the

market today and also addresses the older obsolete

components of the hydraulic starter systems on all older

Fuel metering valve and motor controller upgrade

The old standard hydraulic fuel valves and motor

controllers can be upgraded to the latest standard and are

offered as an optional complementary upgrade to the

FT125 controls system upgrade.

Fire and gas detection/suppression system upgrades

This engineered solution uses latest technologies in fire

and gas detection. It revises your package’s suppression

system to conform with local environmental regulations.

Engineered Solutions / 11

“The old standard

hydraulic fuel valves

and motor controllers

can be upgraded to the

latest standard and are

offered as an optional

complementary

upgrade to the FT125

controls system

upgrade.”

Machinery protection, availability and reliability is

improved and systems have on-board diagnostics.

Inlet air filtration upgrade

Multiple filter options extend operation life and increase

air flow. Replacement units for normal unit operation,

plus enhanced systems that cope with rapid

contamination in harsh environments are the available

options. This engineered solution provides high protection

from fine particles and extends unit performance by

preventing environmental deposits on the inlet housing

and compressor rotor. Low-cost turbine protection is

gained while compressor fouling and erosion is reduced,

increasing your unit’s availability and its mean time

between overhauls.

Regional Sales Offices

Europe, Russia & Africa

The Iceni Centre, Warwick Technology Park

Warwick CV34 6DA, United Kingdom

Tel: +44 (0) 1926 306000

Tel: +44 (0) 1926 306000

South America

Av. Almirante Barroso 52, 9th Floor,

20031-000, Rio de Janeiro, Brazil

Telephone: +55 21 2277 0100

Fax: +55 21 2277 0168

Middle East & Central Asia

Siemens Energy

Ground Floor, Block 6, SAF 2, Masdar City

Abu Dhabi

United Arab Emirates

Tel : +971 2 616 5100

North & Central America

Asia, Far East & Australasia

8303 McHard Road

Houston, Texas 77053 USA

Telephone: +1 281 436 6700

Fax: +1 281 436 6777

Singapore Siemens Pte Ltd

The Siemens Center

60 MacPherson Road

Singapore 348615

Tel : +65 6490 6000

Published by and copyright © 2014:

Siemens AG

Power and Gas

Freyeslebenstrasse 1

91058 Erlangen, Germany

For more information, please contact

our Customer Support Center.

Phone: +49 180 524 70 00

Fax: +49 180 524 24 71

(Charges depending on provider)

E–mail: support.energy@siemens.com

Order No. E50001-G510-A250-X-4A00

WS 1114

Printed on elementary chlorine-free

bleached paper.

All rights reserved. Trademarks

mentioned in this document are the

property of Siemens AG, its affiliates, or

their respective owners. Product Mark

501 is a trademark of and used under

license from Rolls-Royce plc.

Subject to change without prior notice.

The information in this document

contains general descriptions of the

technical options available, which may

not apply in all cases. The required

technical options should therefore be

specified in the contract.