HMI migration at Amer 9:

Providing modern technology while

preserving the initial investment

Reference – Control System

Instrumentation, Controls & Electrical

HMI migration to SPPA-T3000 Control System

provides Amer 9 with a state-of-the-art HMI,

while at the same time many proven components of the existing DCS are preserved.

The Plant

The Result

■ Smooth migration

to state-of-the-art HMI

technology

■ Investment protection

for key system components

The Amer Power Plant in Geertruidenberg,

Netherlands, is operated by Essent NV. It

consists of two production units that can

supply enough electricity for the power

consumption of 3 million households.

A power generating capacity of 600 MW

and a heat production capacity of 350 MW

make unit Amer 9 the largest biomass co-fired

gas- and hardcoal power plant and one of the

largest CHP units in central Europe (2013).

cabling, key parts of the legacy engineering

and archive data system were preserved,

thus the initial investment was not lost.

Besides that the smooth transition of the

proven HMI engineering was possible due

to the usage of the HMI Migration-Tool.

SPPA-T3000’s HMI comes with a user-friendly

navigation between views and customized

layouts of e. g. displays, trends or bar charts.

Its online configuration makes it possible

to change settings not only from the control

room, which leads to a flexible working

environment.

With this new HMI, the Amer Power Plant

is ready to run smoothly for the coming years.

The Task

Unit 9 and its auxiliary systems were either

running on TELEPERM ME or SPPA-T2000.

As the power plants life cycle promised

another ten years, the possible lifetime

extension for the current DCSs was not long

enough.

Concurrently with the necessary renewal,

Essent NV wanted to protect as much

as possible of its investments and keep

the existing optimized configurations and

settings for the new HMI.

Our Solution

The TELEPERM ME HMI of unit 9 of the Amer

Power Plant and the SPPA-T2000 HMI of the

wood gasification, flue gas densification and

the dry bottom ash handling were migrated

to the modern HMI that SPPA-T3000 offers.

For this migration, new high-performance

HMI components were used. At the same time,

the entire automation level including field

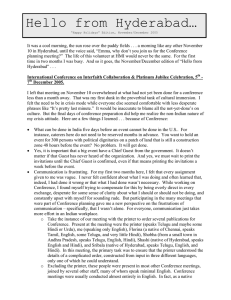

“When part of the installation

is obsolete and still the major

part of the investment can be

preserved, that’s saving money.

For us, this HMI migration was

the best choice.”

Ron van de Korput, Lead Engineer E&I

RWE Generation Hardcoal and Gas Netherlands

Amer Power Station

siemens.com/sppa

Published by and copyright © 2015:

Siemens AG

Power and Gas Division

Freyeslebenstrasse 1

91058 Erlangen, Germany

For more information contact

sppa-t3000.energy@siemens.com

www.siemens.com/energy/sppa-t3000

T3_FR_HMI Migration_Amer9-NL_e_V1-0

Order no. E50001-G230-A416-X-4A00

Printed in Germany

Dispo 05401

Printed on elementary chlorine-free

bleached paper.

All rights reserved.

Trademarks mentioned in this document are

the property of Siemens AG, its affiliates, or

their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should

therefore be specified in the contract.