SCA Annual Green Bond Letter 2016

advertisement

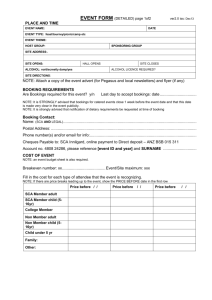

SCA Annual Green Bond Letter 2016 Green bond reporting In March 2014, Svenska Cellulosa Aktiebolaget (SCA) became the first Nordic listed company to issue a green bond. SCA raised SEK 1.5bn, which will be allocated to projects with a positive environmental impact. The bond was oversubscribed and was placed with approximately 30 investors. SCA’s strategy and business model is based on financial, environmental and social value creation. SCA takes a 360degree approach to its environmental impact, with targets in place for reducing carbon dioxide emissions, increasing biofuel and wind power production, achieving water sustainability and preserving biodiversity in its forests. SCA’s production is energy intensive, particularly in its tissue and forest products’ operations, and investments in renewable energy and energy efficiency thus make financial and environmental sense. Use of biofuel, 2006-2015 % 60 50 40 30 06 07 08 09 10 11 12 13 14 15 Air emissions, CO2 fossil ktons 2,000 1,500 1,000 500 0 2013 2014 2015 2013 2014 2015 Air emissions, SO2 tons 800 700 600 500 400 300 200 100 0 Projects financed using proceeds from SCA’s green bond SCA has used SEK 1,173m of its green bond proceeds, of which SEK 144m was allocated in 2015 and SEK 1,029m was allocated in 2014*. Project Total investment, SEKm Investment in 2015, SEKm Biofuel power plant, Nokia, Finland Water treatment, Lilla Edet, Sweden Water treatment, Kunheim, France ESAVE 32.6 21.5 18.7 Ongoing 23.3** 21.5 16.3 82.4 * Details of the 2014 investment can be found in SCA Annual Green Bond letter 2015. ** SEK 14.2m of SCA’s investment in 2015 was allocated for new financing and SEK 9.1m was allocated for refinancing Examples of projects Nokia, Finland In cooperation with local partners, SCA is investing in a new biofuel power plant that will provide SCA’s tissue paper mill in Nokia with a low-cost, renewable and reliable energy supply. The plant will also reduce carbon emissions by almost 40%, equivalent to 20,000 tons per year.The biofuel plant will meet most of the paper mill’s steam requirements, and provide all heating at the SCA facility. Lilla Edet, Sweden An investment of SEK 21.5m will reduce water usage from three million to two million cubic meters annually, corresponding to one billion liters of water, or 30%. At the same time, the mill’s energy consumption will be drastically reduced since smaller volumes of water will need to be heated during the production process. Water treatment will also be improved. Kunheim, France SCA uses one of nature’s own smart systems to treat effluent from the company’s paper mill in Kunheim, France. Since December 2015, reeds growing on four fields around the plant have been used to treat the effluent. The reeds are planted in pools filled with layers of sand and gravel that filter the water naturally. Bacteria living on the roots of the reeds break down the organic matter in the effluent. The combination of bacteria, reeds and filtering layers make it possible to treat water without adding any more chemicals to the process. The process is also cost-effective, energy-efficient and requires little maintenance. ESAVE Since 2003, SCA’s ESAVE energy-efficiency program has contributed to energy savings and improved efficiency in all operational business units. In 2015, 110 ESAVE projects were implemented, resulting in a 0.5% (3.2) reduction in energy used per ton of product produced. The accumulated energy savings in the 2010–2015 period amounted to 8.2%, corresponding to a 1.6 TWh reduction in energy consumption.