RHOPLEX™ CS-3800

advertisement

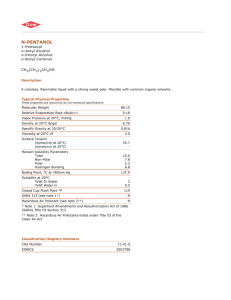

Technical Data Sheet RHOPLEX™ CS-3800 Styrene-Acrylic Copolymer Introduction RHOPLEX™ CS-3800 styrene-acrylic copolymer is designed for use in concrete curing membrane formulations. It provides excellent water retention performance in formulations prepared at low solids level (20% by weight) and a low coalescent level. RHOPLEX™ CS-3800 offers rapid tack-free time in both indoor and outdoor applications. Although optimized for performance in concrete curing membranes, this copolymer also performs well in concrete sealing applications. Advantages • • • • • • • Water-based Rapid tack time Excellent water retention Low VOC levels in formulated product Stain and chemical resistance (as a sealer) Adhesion to concrete substrate (as a sealer) Abrasion resistance (as a sealer) Typical Physical Properties These properties are typical but should not be considered specifications. Solids content, % by weight 44.5-45.5 Brookfield viscosity, cPs 200-2,000 Density wet, lbs/gal (g/ml) 8.60 (1.03) Density dry, lbs/gal (g/ml) 8.93 (1.07) pH 6.5 – 7.5 Glass Transition Temperature (Tg), °C 40 (DSC, midpoint) Minimum film formation 45.0 temperature (MFFT), °C Particle size, micron 0.11 Page 1 of 3 ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow RHOPLEX™ CS-3800 / Dow Construction Chemicals July 2010 Performance Features The following characteristics were identified in Dow laboratories for concrete curing membranes formulated with the RHOPLEX™ CS-3800 copolymer: Excellent Water Retention Concrete curing membranes formulated using RHOPLEX™ CS-3800 provide excellent performance in the water retention section of ASTM C309 (Liquid Membrane-Forming Compounds for Curing Concrete). The excellent performance of RHOPLEX™ CS-3800 is observed in formulations prepared at a low solids level (20% by weight) and a low coalescent level (16% by weight, based on polymer solids) tested under the harshest (earliest) conditioning time allowed by the test method and applied at a 200 ft2/gal coverage rate. Low Coalescent Demand Excellent water retention results are obtained in a concrete curing membrane formulation using 16% propylene glycol phenyl ether on RHOPLEX™ CS-3800 copolymer solids, a lower level than is needed with other commercially available emulsion polymers, resulting in lower formulated product VOC. Rapid Tack-free Time RHOPLEX™ CS-3800 copolymer is designed to give rapid tack-free time in both indoor and outdoor applications. Good Concrete Sealer Performance Although optimized for performance in concrete curing membrane formulations, RHOPLEX™ CS-3800 also can be formulated into and performs well as a concrete sealer when evaluated for stain and chemical resistance, adhesion to concrete substrate and abrasion resistance. Formulation Guidelines Contact your local Dow representative for suggested starting point formulations and related information. Product Specifications Appearance Solids content, % by weight Brookfield viscosity at 25°C, mPa•s LV spindle #3, 60 rpm pH Gel particle on 150 micron, ppm Gel particle on 45 micron, ppm Specification date: July 13, 2006 Page 2 of 3 Off-white fluid, free of coagulated gum and visible impurity 44.5-45.5 100-1,100 CPO 6.50 – 7.50 0 – 50 0 – 100 ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow RHOPLEX™ CS-3800 / Dow Construction Chemicals July 2010 Product Stewardship Dow has a fundamental concern for all who make, distribute and use its products, and for the environment in which we live. This concern is the basis for our product stewardship philosophy by which we assess the safety, health and environmental information on our products and then take appropriate steps to protect employee and public health and our environment. The success of our product stewardship program rests with each and every individual involved with Dow products – from the initial concept and research to manufacture, use, sale, disposal and recycle of each product. Customer Notice Dow strongly encourages its customers to review both their manufacturing processes and their applications of Dow products from the standpoint of human health and environmental quality to ensure that Dow products are not used in ways for which they are not intended or tested. Dow personnel are available to answer your questions and to provide reasonable technical support. Dow product literature, including safety data sheets, should be consulted prior to use of Dow products. Current safety data sheets are available from Dow. Disclaimer NOTICE: No freedom from infringement of any patent owned by Dow or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time, the Customer is responsible for determining whether products and the information in this document are appropriate for the Customer’s use and for ensuring that the Customer’s workplace and disposal practices are in compliance with applicable laws and other governmental enactments. The product shown in this literature may not be available for sale and/or available in all geographies where Dow is represented. The claims made may not have been approved for use in all countries. Dow assumes no obligation or liability for the information in this document. References to “Dow” or the “Company” mean the Dow legal entity selling the products to Customer unless otherwise expressly noted. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED. The Dow Chemical Company www.dowconstructionchemicals.com 215-592-3000 Page 3 of 3 ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow RHOPLEX™ CS-3800 / Dow Construction Chemicals Form No. 832-00114-0710P&M July 2010