8. Waste Minimization

advertisement

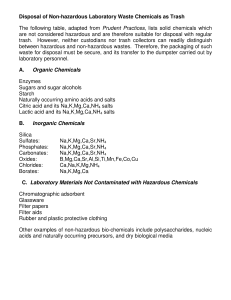

8. Waste Minimization Federal and state law requires all generators of hazardous waste to develop strategies reducing both the volume and the toxicity of hazardous wastes. Please call EHS&RM if you have any ideas on this subject. Also as part of the University agreement with the State of Texas, we must make significant efforts to minimize the amount of waste produced. Some general examples of waste minimization techniques are: Substitution – The best way to minimize hazardous waste is to replace toxic or other hazardous materials with less toxic or non-hazardous substances. An example of substitution includes using Alconox instead of sulfuric/chromic acid glass cleaner and replacing mercury thermometers with less hazardous alcohol thermometers or those with plastic coatings less likely to break when dropped. Recycling/Redistribution – Chemicals that are like new or unopened can often be redistributed to other labs or work areas saving disposal costs for the University and new product costs for the recipient. Reuse chemicals before disposal if possible. Ordering and Procurement Practices – Order only what you will need based on the shelf life of chemical and quantities required. A significant percentage of waste disposed by the University consists of old, unused reagent chemicals. You can sometimes return unused chemicals to the vendor. Even if you are not reimbursed for returning the chemicals, you save disposal costs. Purchase only as much as you need. Bulk discounts may cost more due to eventual removal costs. Micro Chemistry – Use small-scale chemistry instead of traditional methods to reduce the amount of chemicals used in laboratory experiments. Redistilling – Reclaim solvents through distillation processes in laboratories using large quantities of solvents. This is a good way to cut lab costs and drastically reduce the cost of purchasing new solvents. Keep in mind that the residue generated from the re distillation process is hazardous waste. In-Laboratory Destruction – Some chemicals can be neutralized or made exempt from hazardous waste regulations by treatment or alteration in the laboratory. This must be done only as part of the experiment and in accordance with published or recognized methods. Contact EHS&RM prior to performing in-laboratory destruction to confirm the process is safe and meets regulatory requirements. An example would be neutralizing strong acids or bases as the last step in an experiment. All such procedures should be written down as standard laboratory protocols for the particular substance and must be submitted to the EHS&RM for approval. Proper segregation will always save disposal costs. Different treatment procedures have different costs. Proper segregation will allow some solvents to be recycled and thus results in lesser disposal costs.