Document 10414702

advertisement

1058

IEEE TRANSACTIONS ON COMPUTER-AIDED DESIGN OF INTEGRATED CIRCUITS AND SYSTEMS, VOL. 30, NO. 7, JULY 2011

METER: MEasuring Test Effectiveness Regionally

Yen-Tzu Lin, Member, IEEE, and R. D. (Shawn) Blanton, Fellow, IEEE

Abstract—Researchers from both academia and industry continually propose new fault models and test metrics for coping

with the ever-changing failure mechanisms exhibited by scaling

fabrication processes. Understanding the relative effectiveness of

current and proposed metrics and models is vitally important for

selecting the best mix of methods for achieving a desired level

of quality at reasonable cost. Evaluating metrics and models

traditionally relies on actual test experiments, which is timeconsuming and expensive. To reduce the cost of evaluating

new test metrics, fault models, design-for-test techniques, and

others, this paper proposes a new approach, MEeasuring Test

Effectiveness Regionally (METER). METER exploits the readily

available test-measurement data that is generated from chip

failures. The approach does not require the generation and

application of new patterns but uses analysis results from existing

tests, which we show to be more than sufficient for performing a

thorough evaluation of any model or metric of interest. METER

is demonstrated by comparing several metrics and models that

include: 1) stuck-at; 2) N-detect; 3) PAN-detect (physically-aware

N-detect); 4) bridge fault models; and 5) the input pattern fault

model (also more recently referred to as the gate-exhaustive

metric). We also provide in-depth discussion on the advantages

and disadvantages of METER, and contrast its effectiveness with

those from the traditional approaches involving the test of actual

integrated circuits.

Index Terms—Fault models, test effectiveness, test evaluation,

test metrics.

I. Introduction

T

HE MAIN objective of manufacturing test is to separate

good chips from bad chips. Test methodologies continue

to evolve, however, to capture the changing characteristics of

chip failures, and new fault models and test metrics have been

developed to guide the test generation process. Here, we use

the phrase “fault model” in its classic sense, as an abstract

representation of the behavior that results from some type

of defect. A “test metric,” on the contrary, is not necessarily

meant to model defect behavior but instead is a way to evaluate

or measure the quality that a test set would presumably achieve

when applied to failing chips. The stuck-at fault model [1]

has been used as both a model and a metric, and has been

universally adopted as the basis of test generation because of

its simplicity and low cost.

Manuscript received August 26, 2010; revised November 21, 2010; accepted

January 7, 2011. Date of current version June 17, 2011. This work was

supported by the NSF, under Award CCF-0427382, the SRC, under Contract

1246.001, and an NVIDIA fellowship. This paper was recommended by

Associate Editor C.-W. Wu.

Y.-T. Lin is with NVIDIA Corporation, Santa Clara, CA 95050 USA

(e-mail: yenlin@nvidia.com).

R. D. (Shawn) Blanton is with the Center for Silicon System Implementation, Department of Electrical and Computer Engineering, Carnegie Mellon

University, Pittsburgh, PA 15213 USA (e-mail: blanton@ece.cmu.edu).

Color versions of one or more of the figures in this paper are available

online at http://ieeexplore.ieee.org.

Digital Object Identifier 10.1109/TCAD.2011.2113670

Nevertheless, as manufacturing technology continues to

scale and design complexity increases, failure behaviors have

and continue to become more complicated and therefore harder

to characterize [2]. The behavior of even static defects (i.e.,

defects that have no sequence or timing dependency and thus

can be detected by a single test pattern) involves more complex

mechanisms that can no longer be sufficiently dealt with using

just the stuck-at fault model [3], [4]. Various fault models and

test metrics have been developed to ensure test quality, that

include, e.g., bridge [5], [6], transition [7], input-pattern fault

models [8], and test metrics such as gate exhaustive [9], [10],

bridge coverage estimate [12], N-detect [3], [11]–[13], and

physically-aware N-detect (PAN-detect) [14]–[16].

For all existing and newly developed test methods, it is

important to understand their relative effectiveness so that the

proper mix of test approaches can be identified for achieving

the required quality level at an acceptable cost. Traditionally,

test methods have been evaluated empirically. Specifically, experiments involving real integrated circuits (ICs) are conducted

to reveal defect characteristics and for assessing the capability

of various test and design-for-test (DFT) methods to uncover

chip failure. Unique fallouts (i.e., chip-failure detections),

typically shown in the form of a Venn diagram, are considered

to be good indicators of relative effectiveness.

Fig. 1 summarizes some real-chip experiments on test

evaluation that have appeared in the paper over the last 15

years [3], [10], [12], [13], [16]–[30].The y-axis shows various

process nodes and the x-axis is the time. Each circle indicates

the year that the work was published and the process node

used for fabricating the design in the experiment. The size

of the circle reflects the number of test methods evaluated.

Finally, the experiments conducted by the same organization

have the same color. Fig. 1 shows that the evaluation of fault

models and test metrics continues to be of significant interest.

Experiments involving real ICs, however, require a sufficiently large sample in order to produce statistically significant

results. When more test methods are compared, more tests

must be generated and applied in a production environment.

More often than not, generating tests for new, proposed models

or metrics is a significant challenge since the commercially

available test tools are typically hard-coded to handle only a

limited set (e.g., stuck-at, bridge, transition fault, and others).

Conducting real-chip experiments for test evaluation is therefore time-consuming and expensive. An evaluation approach

that is more economical, automatable, and effective is very

much desired.

In this paper, we introduce a general and cost-effective testmetric evaluation methodology, MEasuring Test Effectiveness

Regionally (METER), and show how it can be used to evaluate

c 2011 IEEE

0278-0070/$26.00 © 2011 IEEE. Personal use of this material is permitted. Permission from IEEE must be obtained for all other uses, in any current or future media,

including reprinting/republishing this material for advertising or promotional purposes, creating new collective works, for resale or redistribution

to servers or lists, or reuse of any copyrighted component of this work in other works.

LIN AND BLANTON: METER: MEASURING TEST EFFECTIVENESS REGIONALLY

Fig. 1.

Recent real-chip experiments on test evaluation.

a large variety of fault models and test metrics. METER

analyzes the failure log files that result from the application of

any set of test patterns, i.e., no additional tests are needed. The

cost of this method is therefore low since extra test generation

and test application are completely avoided. Finally, METER

is general since it can be used to evaluate any test metric, or

fault model, or DFT approach that is meaningful within the

environment used for collecting the test data.

The basic idea of METER is to identify the locations (or

regions) of the failure within the bad chip, and then evaluate

the region against the metric/model of concern using the tests

already applied. METER is not perfect, however, since it

relies on the identification of the failure within the bad chip

using diagnosis or other localization techniques. For failing

chips that have some ambiguity in the localization results,

the effectiveness measures must be statistically analyzed. This

shortcoming, however, also exists and is exacerbated in the

traditional evaluation approach. Specifically, tests that target

a particular fault model or test metric that detect a given

failing chip does not necessarily mean that the model or metric

“captures” defect behaviors. In other words, it is possible that

the chip failure is fortuitously caught by the applied tests

but not due to the targeted metric/model. METER instead

precisely addresses this problem by evaluating models or

metrics specifically for possible failure regions.

METER was first introduced in [16] and [31]. This paper

subsumes and extends existing work by:

1) defining new quantitative measures of the effectiveness

and efficiency of various models/metrics over different

products and technology nodes;

2) applying METER to large, industrial designs that include

an NVIDIA graphics processing unit (GPU) and an IBM

application-specific integrated circuit (ASIC);

3) showcasing how METER can be used to select parameters for automatic test pattern generation (ATPG).

The rest of this paper is organized as follows. Section II

provides background on test evaluation and describes related

work. The details of test metric/model evaluation methodology METER are described in Section III. Evaluation

results for several different test metrics are presented in

Section IV. Section V provides a discussion on the applicability of METER, and compares METER with the traditional

1059

Fig. 2. Coverage distribution achieved by a nearly 100% stuck-at test set for

various metrics/models.

tester-based approach. Finally, in Section VI, conclusions are

drawn.

II. Background

In this paper, we utilize the notion of fault coverage for

an individual line. For instance, a signal line has two stuckat faults and can have a coverage for some set of tests that

is equal to 0%, 50%, or 100%. For a line that has four

“close” neighbors, there are eight possible two-line bridge

faults, where it is assumed each neighbor can impose a faulty0 or faulty-1 value on the targeted line. The possible bridge

coverages for the line are described by the set {1/8 = 12.5%,

2/8 = 25%, . . ., 8/8 = 100%}. Finally, for a line driven by a

two-input gate, the possible gate-exhaustive coverages include

22 = 4 possibilities that lie in the set {0%, 25%, 50%, 100%}.

Sometimes, instead of reporting percentages, we will simply

list the number of detections for a given metric (as will be

seen later in Table II). Extending this notion to N-detect and

PAN-detect is a little more complicated since both usually refer

to one type of fault polarity (either stuck-at-0 or stuck-at-1).

Therefore, the coverage for these test metrics is calculated for

a line with a specific fault polarity.

With this notion of coverage, we show that additional

tests are not really necessary in METER. We have observed

that most test sets inherently achieve high coverage of most

metrics and fault models for a majority of signal lines. In

other words, it is likely that any given circuit region has very

high coverage for any reasonable metric or fault model under

consideration. For example, Fig. 2 shows the distribution of

coverage achieved by the production, stuck-at test set for each

signal line in a test chip (details of the chip are presented in

Section IV) for the bridge fault model, and the gate-exhaustive

and PAN-detect test metrics. We use N = 10 for the PANdetect metric which means 100% coverage is achieved for

some line stuck-at-v (v ∈ {0, 1}) if the fault is detected ten

times with ten different neighborhood states [14]–[16]. Fig. 2

shows that although the stuck-at test set does not directly target

any other models/metrics, 82.8%, 90.11%, and 53.5% of the

signal lines have 100% coverage of the bridge model, and

the gate-exhaustive and physically-aware ten-detect metrics,

respectively. This means that some arbitrary region that is

affected by a defect can likely be used to fully evaluate a fault

model or test metric. Even when the coverage is not 100%, it

1060

IEEE TRANSACTIONS ON COMPUTER-AIDED DESIGN OF INTEGRATED CIRCUITS AND SYSTEMS, VOL. 30, NO. 7, JULY 2011

TABLE I

Comparison Between METER and Other Similar Work on Test

Evaluation

METER [26]

Extra tests

Defect region/location known

Correlate coverage changes

directly with defect detection

No

Yes

No

No

Yes

Yes

[30]

EMD Bridge Intra-Cell

Yes

Yes

No

No

Yes

Yes

No

No

No

Fig. 4.

Fig. 3.

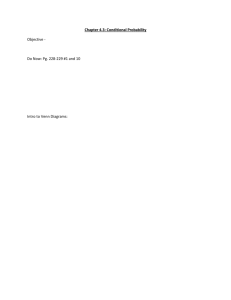

Overview of the test-metric evaluation methodology METER.

is still possible that important information can be derived as

described in detail in Section IV.

Table I compares METER with other similar work on test

evaluation. Specifically, the work in [26] compares several

test metrics by correlating chip failures with metric coverage

achieved by the applied test patterns. These patterns do not

necessarily directly target the considered test metrics, which

means that additional test patterns for different test metrics are

not needed. Nevertheless, in [26], metric coverage is calculated

over the whole design. This means, at a minimum, fault

simulation has to be performed for the entire circuit. Also,

depending on the evaluated metrics, additional logical and

physical information for every signal line in the design may

be needed. In METER, defect detection is better correlated

with metric effectiveness since coverage is limited to the

potential defect regions within the failing chips. Thus, any

need for logical/physical information for coverage calculation

is therefore correspondingly reduced.

On the contrary, the work in [30] used diagnosis to investigate test quality. They however use additional test patterns

to measure the effectiveness of test metrics and fault models

that include, e.g., N-detect [or more specifically, embedded

multi-detect (EMD)] and bridge faults. Reference [30] also

utilized diagnosis to identify failing chips with intra-cell

defects, and examine these chips using the already-applied

test patterns. They however particularly focus on reducing

the mismatch between defect and fault behavior (i.e., the

metric/model behavior outside of the defect behavior) but not

on the effectiveness of the metric/model.

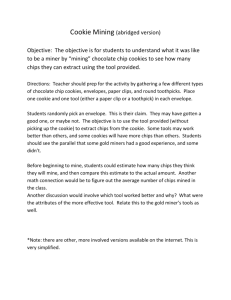

Approaches for identifying suspect regions for test-metric evaluation.

of test metrics and fault models.1 As shown in Fig. 3, METER

consists of four stages:

1) suspect region identification;

2) test selection;

3) failing chip selection;

4) test evaluation.

Specifically, tester-response data that results from the application of any type of test set is collected and analyzed. The test

data may simply include chip pass/fail information, or may

be more comprehensive in the form of full-fail response data.

The collected test data is then analyzed to identify suspect

regions within a failing chip, which are the logical lines that

are believed to cause chip failures. Next, depending on the

objective of the experiment, a subset of test patterns and

some failing chips of interest are selected for further analysis.

Finally, in the test evaluation stage, test metrics are evaluated

for the identified suspects from the failing chips using the

selected test patterns. This is achieved by correlating changes

in metric coverage with defect detection. Details of each stage

are described in the following sections.

A. Suspect Region Identification

III. Test-Metric Evaluation

The first stage of METER is to identify suspect regions

that are believed to cause chip failures. Several approaches

of varying cost and accuracy can be used, as illustrated in

Fig. 4. With the least amount of test data, i.e., only the

pass-fail outcomes of test patterns are recorded, the suspect

regions include all those that are sensitized by the failing

patterns (i.e., test patterns that fail the chip), as shown at

the top level of the reverse triangle in Fig. 4. If additional

information is collected and more comprehensive techniques

are used, higher accuracy is expected but at a higher cost.

For example, if test-pattern failure responses are recorded,

backcone tracing or path tracing [32] from failing outputs

and scan elements can be applied to identify possible defect

regions (the second and third level of the reverse triangle).

Fault simulation can also be performed to identify the fault

sites whose responses are compatible (e.g., match, subsume,

METER is a cost-effective and time-efficient approach for

comparing and evaluating the relative effectiveness/efficiency

1 From this point on, we will not make any distinction between test metric

and fault model.

LIN AND BLANTON: METER: MEASURING TEST EFFECTIVENESS REGIONALLY

and others) with tester responses (fourth level). Alternatively,

diagnosis can be used to identify suspects with higher accuracy

and resolution (fifth level). Diagnosis suspects are very likely

to include the actual defect regions, and are inexpensive to

obtain. If physical failure analysis (PFA) results are available,

test-metric evaluation can be performed on what is presumably

the actual defect region (bottom level).

Among the aforementioned approaches, test-metric evaluation using PFA results is of the highest accuracy but has

an associated high cost. Moreover, the number of failing

chips that have PFA results is typically small. Since more sophisticated region-identification techniques often imply more

assumptions and restrictions, few failing chips can have their

suspects successfully identified. The number of chips available

for evaluation is therefore likely to decrease as more advanced

region-identification approaches are employed as shown in

Fig. 4. Diagnosis, on the contrary, is less expansive since it

mostly involves circuit/fault simulation. Often a decent amount

of failing chips can be diagnosed and used for analysis. In

other words, one is more likely to draw statistically significant

conclusions by analyzing diagnosable failing chips. Circuit

tracing-based approaches require less computation time than

diagnosis, but the number of suspect regions that result is often

much higher. Among the possible techniques for identifying

suspect regions, diagnosis provides very good accuracy at a

reasonable cost, and it often results in a sufficient number of

samples that can be used for analysis. We believe diagnosis

is a good choice since it provides a proper tradeoff between

cost and accuracy.

B. Test Selection

Given a failing chip c and an identified suspect s of c, the

test patterns in the production test set T generated for the

chip design can be classified based on whether they: 1) were

applied to c; 2) sensitized suspect s; and 3) passed or failed

chip c, as illustrated in Fig. 5. METER allows great flexibility

in selecting the test patterns used for analysis, which can be

any subset of T . The only requirement is that for a chip c, at

least one test pattern that failed c needs to be included in the

selected test set Tselc so that we can correlate defect detection

with changes in metric coverage for some identified suspect.

For example, if the test flow stops after the first failing pattern

(FFP), then the subset of test patterns that start from the first

test pattern to the FFP can be used. If more test patterns are

applied, extra information collected from the application of

subsequent test patterns can also be utilized.

Depending on how the test patterns are selected, the subsets

used for different chips may not be the same. For instance,

if the subset of test patterns up to the FFP is used, then the

selected test set for chip 1 can be different from that for chip 2.

This is because the FFPs of chip 1 and chip 2 may be different.

On the contrary, if all the production test patterns are used,

then the test sets selected for different chips will be the same.

It should be noted that in some test flows, such as in adaptive

test or in a stop-on-first-fail environment, some test patterns

may not be applied. These test patterns (Tc ), while no pass/fail

information is available, can still be used for analysis. The use

of selected test patterns will be described in Section III-E.

1061

Fig. 5. Categories of test patterns given a failing chip c and a suspect region

s. The notation in the parentheses denote the set of test patterns in that

category.

C. Failing-Chip Selection

The objective of failing-chip selection is to identify chips

that are suitable for test evaluation and are of interest. The

chip selection process may vary depending on the goal of

the evaluation, evaluated test metrics, adopted suspect-region

identification techniques, and the characteristics of the applied

test patterns. For example, all the failing chips in the failure

logs can be used for analysis if a large sample size is desired.

In the cases where diagnosis is adopted for identifying suspect

regions, diagnosable failing chips are chosen. If test metrics

that target multiple faulty lines (e.g., open, Byzantine bridge,

multiple stuck-at, and others) are to be evaluated, diagnosis

methods such as [33] and [34] can be used to identify chips

that exhibit this behavior. If the considered test metrics target

defects that are not deterministically detected by stuck-at test,

a set of “hard-to-detect” failing chips that do not exhibit stuckat behavior can be selected.

D. Test Metrics for Evaluation

METER can be used to evaluate any test metric, or fault

model, or DFT approach, or their variants, whether they target

static or dynamic defect behaviors. For instance, the inputpattern fault model can be evaluated at the gate level or

higher levels of hierarchy (this will be demonstrated later

in Section IV-E). METER is applicable as long as the test

environment employed and the test approaches applied to the

failing chips adhere to the assumptions of the test metrics

under evaluation. For example, evaluating sequence-dependent

defects for PAN-detect test, although possible, is not reasonable since any detection of sequence-dependent defects is

fortuitous in nature. Similarly, evaluating the transition fault

model for a stuck-at-only test (i.e., no launch-on-shift or

launch-on-capture) would also be inappropriate.

E. Test Evaluation

To evaluate a test metric, we examine whether defect

detection is associated with changes in coverage of some test

metric for the identified suspect regions. This is achieved by

analyzing the selected subset of test patterns Tselc for each

failing chip c. Without loss of generality, we assume here

that all of the test patterns applied to c are selected, i.e.,

Tselc = Tc . (The cases where un-applied test patterns are used,

i.e., Tselc ∩Tc = φ, will be discussed later.) Tc is fault simulated

1062

IEEE TRANSACTIONS ON COMPUTER-AIDED DESIGN OF INTEGRATED CIRCUITS AND SYSTEMS, VOL. 30, NO. 7, JULY 2011

A failing chip may have multiple suspects, each of which by

themselves could alone cause chip failure. For these situations,

the analysis needs to be performed for each suspect. For each

1

2

3

chip c, we sum Xm,

c, s , Xm, c, s , and Xm, c, s over all the suspects

of c as follows:

k

k

Xm,

Xm,

k ∈ {1, 2, 3}

(1)

c =

c, s

s

k

Xm,

c

Fig. 6. Correlation between defect detection and changes in metric coverage

for suspect s of failing chip c.

without fault dropping using stuck-at faults involving the

identified suspect regions only. For each suspect s of chip c,

we identify the set of test patterns in Tc that sensitize s (i.e.,

Tc, s in Fig. 5), and track the changes in metric coverage for

s resulting from the application of each test pattern in Tc, s .

Let Covm, c (s) denote the coverage of metric m for suspect s

of chip c. A test pattern t ∈ Tc, s can be classified into one

of the following categories depending on whether t increases

Covm, c (s) and failed chip c (see Fig. 6):

1)

2)

3)

4)

t increases Covm, c (s) and passed chip c (zone 1);

t increases Covm, c (s) and failed chip c (zone 2);

t does not increase Covm, c (s) but failed chip c (zone 3);

t does not increase Covm, c (s) and passed chip c (outside

the two circles).

Given a test metric, if a failing pattern tf ∈ Tc, s increases

the metric coverage for s, the test metric is considered effective

in detecting chip c. In other words, a test metric is deemed

effective if the metric coverage increases with the application

of the failing pattern tf (which falls into zone 2). If the

coverage does not change with tf (i.e., tf ∈ zone 3), then

it means the test metric was not at all needed to detect the

corresponding chip failure. The chip failed due to other reasons

outside the scope of the metric. Moreover, if the tests before

tf have already achieved “100% coverage” of the test metric,

then it means that the corresponding metric does not guarantee

the detection of the failure.

On the contrary, if a test pattern tp ∈ Tc, s increases coverage

of some metric for suspect s but did not fail chip c (i.e., tp ∈

zone 1), then it means that the metric covers zones outside the

defect behavior. Additionally, in the best case, this means more

test patterns are needed to further improve metric coverage

to eventually detect the defect. But obviously, this may not

be possible if the defect behavior lies outside the metric. Let

1

2

3

Xm,

c, s , Xm, c, s , and Xm, c, s denote the number of test patterns

in Tc, s that falls into zones 1, 2, and 3, respectively, for a

2

metric m. A good test metric should have a large Xm,

c, s and

1

3

a small Xm, c, s and Xm, c, s .

If Tselc includes more than one failing pattern, then each

failing pattern may indict different suspects. For example, a

suspect reported by single location at a time (SLAT) diagnosis [35] may only be associated with some failing patterns

whose tester responses match the suspect’s stuck-at fault

simulation responses. If this is the case, each suspect should

be examined using the corresponding failing patterns.

where

will be used to assess the effectiveness and

efficiency of a test metric.

1) Test effectiveness: to evaluate the effectiveness of a test

metric, we examine how well the metric subsumes defect

behavior using a measure called effectiveness ratio. For

a given metric m and chip c, the effectiveness ratio is

computed as follows:

2

2

3

ERm, c = Xm,

c /(Xm, c + Xm, c ).

(2)

The effectiveness ratio represents how often the coverage

of m is increased for some suspect when the chip

failed. A high effectiveness ratio means that increasing

metric coverage correlates with defect detection for this

2

3

particular chip. If Xm,

c + Xm, c = 1, i.e., chip c has

only one suspect and Tselc includes only one failing

pattern, then ERm, c simply depends on whether the

failing pattern increases metric coverage. If the coverage

2

is increased, then Xm,

c = 1 and ERm, c = 1. Otherwise,

2

3

ERm, c = 0. In other words, if Xm,

c + Xm, c = 1, ERm, c

becomes a binary indicator of whether the test metric is

effective.

2) Test efficiency: another focus in test evaluation is the

efficiency of a test metric. Early detection of failing

chips is desired because it saves test application cost

especially in a stop-on-first-fail environment. Test efficiency has been defined as the ratio of the number of

patterns targeting a specific test metric to the number of

chip failures detected by those patterns. The metric with

a smaller number of “patterns per failure” is considered

more efficient [28].

Instead, we define the efficiency of a test metric to be

the ratio of zone 2 to the left circle (see Fig. 6). In other

words, we compute the efficiency ratio for test metric m

and failing chip c as follows:

2

1

2

FRm, c = Xm,

c /(Xm, c + Xm, c ).

(3)

A high FRm, c means that zone 1 is smaller compared

to the left circle and that increasing metric coverage

correlates well with defect detection. The test metric

is therefore more efficient in capturing chip failure. If

metric m is not at all effective for a particular chip

2

c, resulting in Xm,

c = 0, then FRm, c becomes zero

by definition. This measure of efficiency is particularly

useful in a stop-on-first fail environment but is also

applicable to cases where information on subsequent

failing patterns are collected as well. It should be noted

that a metric can be very effective in defect detection but

have a poor efficiency. Moreover, a metric that precisely

captures a small portion of some defect behavior may

be ineffective but efficient.

LIN AND BLANTON: METER: MEASURING TEST EFFECTIVENESS REGIONALLY

3) Fault-detection recording: suppose for some metric m,

a failing pattern tf, 1 ∈ Tselc detects some fault involving

suspect s of chip c. If a subsequent failing pattern

tf, 2 ∈ Tselc also detects the same fault, then tf, 2 does not

increase metric coverage. In other words, tf, 2 is placed

3

3

into zone 3. Xm,

c, s (as well as Xm, c ) is increased by 1,

2

2

while Xm, c, s (and Xm, c ) remains the same, which in turn

degrades ERm, c . Nevertheless, it is possible that the fault

captures the behavior of the defect causing chip failure,

and every test pattern that detects this particular fault

fails the chip. The metric m is effective in detecting chip

c, but is not accounted for using the current formulation

of ERm, c .

To prevent underestimating ERm, c , a different faultdetection recording scheme can be used. In the new

scheme, a fault is recorded as detected only if it is

detected by a passing pattern. (This does not affect

whether a test pattern detects the fault; only the detection

status of the fault is changed.) In other words, if a fault

is detected only by failing patterns, each failing pattern

detecting this fault increases the metric coverage (while

the fault is still recorded as undetected). These failing

patterns are therefore classified into zone 2 instead of

2

2

zone 3, and Xm,

c, s as well as Xm, c are increased.

With this new fault-detection recording scheme, ERm, c

will not be underestimated. Nevertheless, we lose the

opportunity to examine whether other faults also detect

chip failures due to the existence of faults detected

only by failing patterns. The original fault-detection

scheme does not have this issue however. Analysis can

be performed using one or both schemes depending on

the evaluation objective.

4) Using un-applied test patterns: in Section III-B, we

mentioned that in some test flows, some production test

patterns may not be applied to a failing chip c (the

subset Tc in Fig. 5). These patterns, if applied, may

further increase the coverage of some test metrics for

some suspects, and may have the capability of detecting

chip failures. METER provides a way to consider the

effect that Tc could possibly have had. Without loss of

generality, assume that all test patterns in Tc are selected

for analysis, i.e., Tc ⊂ Tselc . Specifically, for a suspect

s of failing chip c, test patterns in Tc that sensitize s

3

1

2

(Tc , s ) are used. Let Xm,

c , s , Xm, c , s , and Xm, c , s be the

number of test patterns in Tc , s that could fall into zones

1, 2, and 3, respectively, for a metric m. Again, for each

chip c, we calculate as follows:

k

k

Xm,

Xm,

k ∈ {1, 2, 3}.

(4)

c =

c , s

s

The definition of effectiveness ratio and efficiency ratio

can then be rewritten as follows:

ERm, c =

FRm, c =

2

2

Xm,

c + Xm, c

3

2

2

3

(Xm,

c + Xm, c ) + (Xm, c + Xm, c )

2

2

Xm,

c + Xm, c

.

1

2

1

2

(Xm,

c + Xm, c ) + (Xm, c + Xm, c )

(5)

(6)

1063

Since Tc was not applied, it is unknown whether a test

pattern in Tc , s would pass or fail chip c. The actual

3

1

2

values of Xm,

c , s , Xm, c , s , and Xm, c , s are therefore unknown. However, from fault simulation, we know what

test patterns in Tc , s increase coverage for some suspect

s of chip c (denote the set as Tc+ , s ) and what test patterns

do not (denote the set as Tc− , s ). The number of test

patterns in Tc+ , s and Tc− , s can be used to calculate the best

and worst effectiveness/efficiency ratio that a test metric

could achieve with Tc . Specifically, in the worst case,

chip c passes all the test patterns in Tc+ , s , and fails all

1

+

the test patterns in Tc− , s . In other words, Xm,

c , s = |Tc , s |,

−

3

k

2

Xm, c , s = 0, and Xm, c , s = |Tc , s |. Calculating Xm,

c

and substituting into (5) and (6) provides the worst case

effectiveness ratio and efficiency ratio, respectively. In

the best case, the chip fails all the test patterns in Tc+ , s ,

and passes all the test patterns in Tc− , s . As a result,

3

1

2

+

Xm,c

, s = 0, Xm, c , s = |Tc , s |, and Xm, c , s = 0. The best

case effectiveness ratio and efficiency ratio can then be

derived accordingly.

Actually applying Tc may indict additional suspects that

were not identified previously. When this occurs, further

analysis concerning defect regions or defect detections

may be needed.

F. Metric/Model Case Studies

In the following, we illustrate the detailed procedures

employed for evaluating the effectiveness and efficiency of

the bridge fault model [5], [6], the gate-exhaustive metric [9], [10] (also known as the gate-level input-pattern fault

model [8]), and the physically-aware N-detect test metric [14]–

[16]. METER is not limited however to these test metrics and

can be just as easily applied to various DFT approaches as

well.

1) Bridge fault models: to evaluate various bridge fault

models, we first extract the possible bridge regions for

each identified suspect of a chip c. Specifically, the

physical neighbors that are within a distance d for each

suspect are obtained from the design’s layout.2 A suspect

s and each of its physical neighbors are a possible

bridge defect, and all the bridge defects involving s are

evaluated. Associated with each bridge consisting of a

suspect s and its physical neighbor p are two 2-line

bridge faults: s stuck-at zero when p = 0 and s stuck-at

one when p = 1. Traditional bridge fault models (e.g.,

AND-type, OR-type, dominate, and the four-way bridge

fault models) are all implicitly considered, including

both non-feedback and feedback bridges. M-line bridge

faults can be handled as well but in this analysis we only

consider bridge faults with M= 2.

For each test pattern t ∈ Tselc , we examine the bridge

faults that are detected by t and by Tprev , where Tprev is

the set of test patterns in Tselc that are applied before t.

Whenever a physical neighbor p is driven to the opposite

value of s and a stuck-at fault affecting s is detected, a

2 Physical neighbors can be identified using DRC/LVS [28] or criticalarea [36] approaches or by utilizing parasitic extraction data.

1064

IEEE TRANSACTIONS ON COMPUTER-AIDED DESIGN OF INTEGRATED CIRCUITS AND SYSTEMS, VOL. 30, NO. 7, JULY 2011

bridge fault involving p and s is deemed detected. We

specifically examine whether a particular bridge fault

is detected by t but not by Tprev . If all of the bridge

faults detected by t are detected by Tprev , or if t does

not detect any bridge fault, then t does not increase the

bridge fault coverage for the suspect s of chip c. Test t

will be classified depending on whether t failed chip c

and whether t increases bridge fault coverage for s, as

1

2

described in Section III-E. Quantities XB,

c, s , XB, c, s , and

3

XB,

(where

B

stands

for

bridge

fault)

are

calculated

c, s

based on the classification result, and are used to assess

the effectiveness and efficiency of the bridge fault model.

2) Gate-exhaustive metric: we also evaluate the effectiveness/efficiency of the gate-exhaustive metric [8]–[10].

With the assumption that only a single gate is faulty,

gate-exhaustive testing requires each gate output to be

sensitized for all possible input combinations.

The procedure for evaluating the gate-exhaustive metric

is similar to the one used for the bridge fault models. For

each suspect s of a failing chip c, we identify the inputs

of the gate that drives the suspect, i.e., the driver-gate

inputs. The set of logic values applied to the driver-gate

inputs of s by a test pattern t that sensitizes s is defined

as a driver state of s. We next track the driver state

established by each test pattern t ∈ Tselc , and examine

whether t establishes a new driver state and sensitizes

s, thereby increases the gate-exhaustive coverage. In the

case where s is a branch, the coverage of the downstream

gate driven by s is calculated. Based on the zone that

3

1

2

t falls into (see Fig. 6), XG,

c, s , XG, c, s , and XG, c, s

(G stands for gate-exhaustive) are calculated.

3) Physically-aware N-detect metric: the physically-aware

N-detect (PAN-detect) metric exploits physical information to generate test patterns capable of improving defect

detection for modern designs [14]–[16]. The metric

defines the neighborhood of a suspect as the set of signal

lines surrounding the suspect. Three types of signal lines

are considered in the neighborhood of a suspect [16]

that include: 1) signal lines that are within a distance

d of the suspect in the layout (physical neighbors);

2) inputs of the gate that drives the suspect (driver-gate

inputs); and 3) side inputs of the gates that receive the

suspect (receiver-side inputs). The set of logic values

established by a test pattern t on the neighborhood

lines of a suspect s when s is sensitized is called the

neighborhood state. PAN-detect test requires a targeted

signal line be sensitized with at least N neighborhood

states.

To evaluate the effectiveness of PAN-detect, we extract

the neighborhood for each suspect. We next track the

neighborhood states established by test pattern t ∈ Tselc

and by Tprev for each suspect s. If t establishes a new

neighborhood state that has not yet been established by

Tprev , then t increases the PAN-detect coverage for the

suspect. Test t is then classified into the appropriate

zone based on the rules described in Section III-E, and

1

2

3

XP,

c, s , XP, c, s , and XP, c, s (P stands for PAN-detect) are

calculated.

IV. Experiments

We apply METER to evaluate the bridge, gate-exhaustive,

and PAN-detect metrics. Failure logs from LSI test chips

fabricated in a 110 nm process are utilized. The test chip

design consists of 384 64-bit arithmetic-logic units (ALUs),

where each ALU has ∼3000 gates. The stuck-at test of

an ALU consists of approximately 260 scan-test patterns,

achieving >99% stuck-at fault coverage. In this experiment,

signal lines within 0.5 µm of the targeted line are deemed as

physical neighbors, which are used for evaluating both bridge

and PAN-detect. We have data for over 2500 failing chips.

For an assumed yield of 95%, this means our analysis here

is equivalent to a chip test experiment involving more than

50 000 chips.

In the following, we describe the procedures used to select

failing chips and identify suspects for subsequent analysis

(Section IV-A), and present the results in great detail (Sections IV-B–IV-E). While the test patterns up to and including

the FFP are used in Sections IV-A–IV-E, we demonstrate in

Section IV-F how test metrics can be evaluated using all the

applied test patterns and different suspect-region identification

techniques.

A. Diagnosable and Hard-to-Detect Chip Selection

In this experiment, we use diagnosis to identify suspect regions that cause chip failure. The three test metrics evaluated,

namely, bridge, gate-exhaustive, and PAN-detect, target defects

not deterministically detected by stuck-at test patterns. A set

of diagnosable and hard-to-detect failing chips are therefore

selected for analysis. Here, diagnosable means that a suspect

region that leads to the FFP can be pinpointed by diagnosis,

while “hard to detect” means that the failing chip would not

be necessarily detected by tests aimed only at stuck-at faults.

Hard-to-detect chips are the target of bridge, N-detect, and

PAN-detect test, and therefore are the subject of our analysis.

Of the 2533 chips in the LSI failure logs, 720 chips are

diagnosable and 87 of 720 are hard-to-detect.3 The 87 chips

are partitioned into two categories: 28 chips having only one

suspect and 59 having two or more suspects, each of which

alone could cause the chip’s FFP. The 28 failing chips are

of particular interest since we have significant confidence in

the failure region identified by diagnosis. Test metrics can

be easily evaluated for the single suspect of each chip. For

the remaining 59 chips, resolution for the FFP is degraded,

meaning that there is more than one single-region candidate

that could cause the FFP. For these cases, test-metric evaluation is performed and analyzed over all the suspects of a chip

(Section IV-C).

B. Single-Suspect Failing Chips

Table II shows the results of applying METER to the 28

single-suspect LSI failing chips. Column one gives the chip

index. Columns two to six show the total number of physical

neighbors of the suspect (Nbrs), the number of test patterns

3 All the 2533 chips, including those that are disregarded here, are analyzed

later when all the failing chips are examined using all the applied test patterns

and less-restricted suspect-region identification techniques.

LIN AND BLANTON: METER: MEASURING TEST EFFECTIVENESS REGIONALLY

1065

TABLE II

Test-Metric Evaluation Results for Single-Suspect Failing Chips

Chip

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Nbrs

14

18

18

5

10

32

12

12

8

24

7

14

14

11

5

13

8

15

11

8

18

13

6

14

16

11

32

32

Nd,B

3

6

8

19

3

2

3

12

16

3

4

4

9

9

6

5

5

19

2

10

42

2

17

5

3

4

2

2

Bridge

Bprev

14

28

31

10

12

13

7

22

14

14

10

12

25

18

5

10

9

29

7

15

36

6

11

18

19

15

13

17

1

XB,c

2

5

4

6

2

1

1

6

4

2

3

3

5

4

4

3

4

9

1

8

12

1

5

3

2

3

1

1

BFFP

0

1

1

0

3

10

1

0

0

2

1

0

1

1

2

1

2

0

2

0

0

5

0

4

3

1

10

6

Gate inputs

2

1

3

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

3

1

2

1

1

2

2

2

(including the FFP) that sensitize the identified suspect (i.e.,

Nd, B ), the number of unique bridge faults detected by the

patterns before the FFP (Bprev ), the number of test patterns

1

before the FFP that detect new bridge faults (XB,

c ), and the

number of new, unique bridge faults detected by the FFP

(BFFP ), respectively. Similarly, for gate exhaustive, columns

seven to ten give the total number of gate inputs driving the

suspect (Gate inputs), the number of test patterns that sensitize

the identified suspect (Nd, G ), and the number of unique driver

states (of the suspect) that are established before the FFP

(Gprev ) and by the FFP (GFFP ). The last four columns show

the numbers for PAN-detect, including the number of signal

lines in the neighborhood of the suspect (Nbrhd), the number

of test patterns that sensitize the identified suspect (Nd, P ), and

the number of unique neighborhood states established before

the FFP (Pprev ) and by the FFP (PFFP ).

For gate-exhaustive and PAN-detect, the number of test

patterns that passed the chip and increase metric coverage

1

1

for the suspect (i.e., XG,

c and XP, c ) is equal to the number

of states established by the patterns before the FFP. In other

1

1

1

1

words, XG,

c = Gprev and XP, c = Pprev . XG, c and XP, c are

therefore not listed explicitly.

Bridge faults involving a suspect include the cases where

the suspect fails with a faulty-0 or faulty-1. Similarly, for

gate exhaustive, considering all possible driver states implicitly

takes into account both stuck-at faults. The analyzed test

patterns therefore include those that sensitize the suspect to

Gate-Exhaustive

Nd,G

Gprev

3

1

6

2

8

4

19

3

3

2

2

1

7

3

12

2

16

4

3

1

4

2

5

2

9

2

9

2

6

2

6

2

5

3

19

3

2

1

10

4

42

6

2

1

17

3

5

2

3

2

4

2

2

1

2

1

GFFP

0

0

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

Nbrhd

15

19

21

7

12

32

13

14

8

25

9

15

15

12

7

14

9

16

13

10

21

14

8

15

16

12

32

32

PAN-Detect

Nd,P

Pprev

3

2

4

3

7

6

10

8

2

1

2

1

3

1

9

7

10

8

3

2

2

1

4

3

5

3

3

2

4

3

5

4

2

1

9

8

2

1

6

5

30

29

2

1

7

5

2

1

2

1

2

1

2

1

2

1

PFFP

1

1

1

1

1

1

1

1

1

1

1

0

1

1

1

1

1

1

1

0

1

1

1

1

1

1

1

1

either logic zero or logic one up to and including the FFP.

In cases where the suspect is a branch, the downstream gate

g driven by s is analyzed, and the considered test patterns

include those that sensitize the output of g. Since there can

be more test patterns that sensitize g compared to s, Nd, G

can be larger than Nd, B . For PAN-detect, on the contrary, a

neighborhood state is associated with a specific stuck-at fault

involving the suspect. Only the test patterns sensitizing the

suspect with the required stuck-at fault polarity is considered.

Therefore, Nd, G ≥ Nd, B ≥ Nd, P .

Analysis of Table II reveals that nine of the 28 singlesuspect chips have BFFP = 0. This means that for these nine

chips, tests aimed at bridge faults do not guarantee failure

detection. Specifically, for chips 4 and 21, all the bridge faults

involving the identified suspects are detected by the patterns

before the FFP (i.e., 2 × Nbrs = Bprev ). In other words, the

bridge coverage for the suspects of these two chips is 100%,

which indicates that the use of typical bridge models does

not guarantee detection of these failures. Moreover, chips 8,

9, 18, 20, and 23 have a bridge coverage of over 80%. For

these cases, it is possible that additional bridge coverage could

have detected the failure but obviously was not necessary since

BFFP = 0 for each of these failing chips.

For the gate-exhaustive metric, only three of the 28 chips

have increased coverage due to the FFP (i.e., GFFP = 1).

The gate-exhaustive coverage appears to be low for many of

these chips, which is surprising given Fig. 2. There could be a

1066

IEEE TRANSACTIONS ON COMPUTER-AIDED DESIGN OF INTEGRATED CIRCUITS AND SYSTEMS, VOL. 30, NO. 7, JULY 2011

Fig. 7. Venn diagram showing the number of single-suspect failing chips

whose FFP increases coverage for the bridge, gate-exhaustive, and PAN-detect

test metrics.

number of reasons why coverage is low however that include,

e.g., only tests before the FFP are examined, and that some

gate-input patterns may not be possible due to circuit structure.

In any event, it is not the case that a particular driver state alone

is needed to detect a large majority of these single-suspect

failures. For the PAN-detect metric, the FFPs of all but two

failing chips (chips 12 and 20) establish new neighborhood

states for the identified suspects.

Because single-suspect failing chips are considered here and

2

3

Tselc includes only one failing pattern (the FFP), Xm,

c +Xm, c =1,

where m ∈ {B, G, P}. For chips whose FFP increases some

metric coverage (i.e., chips with BFFP > 0, GFFP > 0, or

2

3

PFFP > 0), Xm,

c = 1 and Xm, c = 0. The effectiveness ratio for

these chips for the corresponding metric is therefore equal to

2

3

one. Otherwise, Xm,

c = 0 and Xm, c = 1, and the effectiveness

ratio becomes zero. For example, the effectiveness ratio of

chip 5 in Table II for bridge, gate-exhaustive, and PAN-detect

is one, zero, and one, respectively. The efficiency ratio of a

1

chip, on the contrary, can be calculated using (3) with XB,

c,

1

1

XG, c = Gprev , and XP, c = Pprev for bridge, gate-exhaustive,

and PAN-detect. For instance, the efficiency ratio of Chip 5

for bridge, gate-exhaustive, and PAN-detect is 1/(2+1)=0.33,

0/(2+0)=0, and 1/(1+1)=0.5, respectively.

The Venn diagram in Fig. 7 summarizes the outcome of

effectiveness evaluation for single-suspect failing chips. Each

integer in the diagram is the number of chips whose FFP

increases coverage of the evaluated metrics for the suspect

regions. Fig. 7 shows that one chip is captured by all three

metrics, while five chips are uniquely caught by PAN-detect.

Note that the FFP of chips 12 and 20 do not increase the

coverage for any of the three metrics, implying that the chips

failed in a way that cannot be captured by any of the three

metrics, at least for the metric parameters used. These chips

are further discussed in Section IV-E.

Fig. 8. Distribution of the effectiveness ratio ER for the multiple-suspect

failing chips.

Fig. 9.

chips.

Distribution of the efficiency ratio FR for the multiple-suspect failing

(i.e., ER = 100%). The bridge fault coverage is not increased

for any of the suspects for nine of the 59 failing chips,

implying that the bridge effectiveness and efficiency ratios for

these chips are zero.

For gate exhaustive, no chip has ER = 100%, but 48 of the

59 chips have ER = FR = 0. For PAN-detect, the FFP of 39

failing chips each establishes a new neighborhood state for all

suspects (ER = 100%). The FFP of the remaining 20 chips

each establishes a new neighborhood state for at least one

but not all of the suspects. Since the suspects of these chips

have failed with Nd > 1, each suspect is sensitized by at least

1

one passing pattern, i.e., Xm,

c ≥ 1. As a result, the efficiency

ratio can be at most 50%. Note that the trend of test-metric

effectiveness observed from the multiple-suspect failing chips

is inline with what we observed from the single-suspect failing

chips presented in the previous section.

D. Average Efficiency and Effectiveness

C. Multiple-Suspect Failing Chips

We apply METER to the 59 failing chips with multiple

suspects. Specifically, for each suspect of a multiple-suspect

failing chip, we apply the same analysis described in Section IV-B. Results for all the suspects are then collected, and

the effectiveness ratio and efficiency ratio are calculated.

Figs. 8 and 9 show the distribution of the effectiveness

and efficiency ratio for the 59 multiple-suspect failing chips,

respectively. For the bridge fault model, the FFP of 11 failing

chips each detects some new bridge fault for all the suspects

Using the data from the 28 single-suspect chips in Table II,

an average effectiveness and efficiency ratio of bridge, gate

exhaustive, and PAN-detect for the 28 single-suspect and hardto-detect failing chips can be calculated and compared. Here,

we adopt a visual approach to compare the effectiveness and

efficiency for these metrics. For each metric m and each failing

1

2

3

chip c, we calculate the ratio of Xm,

c , Xm, c , and Xm, c to their

sum as follows:

k

k

1

2

3

Fm,

c = Xm, c /(Xm, c + Xm, c + Xm, c )

k ∈ {1, 2, 3}.

(7)

LIN AND BLANTON: METER: MEASURING TEST EFFECTIVENESS REGIONALLY

Fig. 10. Likelihood that a test pattern failed a chip and/or increases coverage

for (a) bridge, (b) gate-exhaustive, (c) PAN-detect, and (d) N-detect for the

28 LSI failing chips.

The ratios for a zone are averaged over all of the 28 failing

chips as follows:

k

Akm =

Fm,

k ∈ {1, 2, 3}

(8)

c /|C|

c

where |C| = 28 is the number of chips considered. Note that

A1m + A2m + A3m = 1. The averaged effectiveness ratio and

efficiency ratio are calculated as follows:

ERm = A2m /(A2m + A3m )

(9)

FRm = A2m /(A1m + A2m ).

(10)

For each evaluated test metric, we re-plot Fig. 6 and make

the area of zones 1, 2, and 3 proportional to A1m , A2m , and

A3m , as shown in Fig. 10(a)–(c).4 It can be observed that PANdetect has the largest zone 2 (0.31) among the three evaluated

metrics, and also has the largest average effectiveness and

efficiency ratios. The gate-exhaustive metric, on the contrary,

has the smallest zone 2 (0.03), which leads to the lowest

effectiveness and efficiency ratios among the three metrics.

E. Test Metric Generalization

Results of METER described in Sections IV-B and IVC show that the FFP of a chip may not improve the

coverage of a metric. These chips failed due to defects

that have activation conditions that are outside these metrics.

Of the three evaluated metrics, PAN-detect increases coverage

4 Using the data in Table II, we can also evaluate traditional N-detect, and

the result is shown in Fig. 10(d). Specifically, Nd, P is the number of times a

suspect is sensitized with the required stuck-at fault polarity, i.e., the stuckat fault involving the suspect region of a failing chip has been N-detected

with N = Nd, P test patterns when it fails. When a chip fails, the coverage

for N-detect for a suspect region is always increased since Nd, P increases

(unless a hard threshold of N is used). In other words, N-detect can never be

ineffective. This is reflected in the perfect ER and the high FR for N-detect,

and is also shown in Fig. 10(d) where zone 3 is empty and the left oval

completely subsumes the right one. While the proposed measures reveal the

characteristics of N-detect, using these measures to judge the effectiveness of

N-detect is inappropriate. This holds for any test metrics that can never be

ineffective. Later in Section, we demonstrate how to better compare N-detect

and PAN-detect by utilizing METER in a different manner.

1067

for the FFP for most failing chips. Nevertheless, PAN-detect

does not capture two single-suspect failing chips and may fail

to capture 20 multiple-suspect failing chips in the worst case

(as shown in Figs. 7 and 8, respectively). In our analysis

thus far, we included physical neighbors, driver-gate inputs,

and receiver-side inputs in the neighborhood for each suspect

signal line. In the diagnosis procedures described in [37],

[38], other types of neighbors are used as well, including

the driver-gate inputs of physical neighbors since it is known

they affect drive strengths [6]. If the driver-gate inputs of

physical neighbors are included in the neighborhoods instead

of the physical neighbors, the FFPs of all the hard-to-detect

chips (with either single or multiple suspects) establish new

neighborhood states for all the suspects of these chips. Because

the neighborhood encompasses all the localized influences on a

suspect line, it is not surprising that PAN-detect performs well.

However, there is danger that having a neighborhood

too large creates a situation where the metric becomes too

general. Exploring the tradeoff between including additional

types of signal lines in the neighborhood and increasing the

distance d used for physical neighbor extraction, and the

mismatch between defect behaviors is needed to efficiently

generate effective test sets. METER can be easily used to

meet this objective by analyzing and guiding the selection of

parameters used in ATPG.

Bridge fault models focus on unintended connections among

wires. Use of bridge fault models is typically limited to defects

involving only two lines, that create no structural feedback,

and ignore cell-drive strengths. But they can be generalized

in several ways, e.g., by including more than two lines, and

more complex contention functions. The gate-exhaustive test

focuses on problems at the transistor level. It too, however,

can be generalized to higher levels of the hierarchy or to

include groups of cells or gates [8], [39]. Both bridge and

gate-exhaustive metrics are subsumed however by PAN-detect

with a neighborhood that includes physical neighbors, drivergate inputs, and receiver-side inputs.

F. Utilizing All Test Patterns

We further apply METER using all of the applied test

patterns for each of the 2533 available failing chip logs. In

addition, we demonstrate different methods for identifying

potential suspects. In the first method, any region that is

sensitized by a failing pattern is deemed a suspect region. In

the second method, the stuck-at fault response of a sensitized

region (for at least one failing pattern) must exactly match the

failing-pattern tester response to be deemed a suspect. For the

bridge fault model, and the gate-exhaustive and PAN-detect

metrics, we plot the effectiveness ratio ER for all 2533 chips

against the total number of unique suspects identified across

all failing patterns. Specifically, Fig. 11(a) shows the result

for selecting suspects using only pass-fail test data,5 while

Fig. 11(b) shows the result for SLAT regions. Each failing chip

has three points plotted, one that indicates the effectiveness

5 The analyzed ALU has 5110 signal lines, i.e., a failing chip has at most

5110 unique sensitized regions. The maximum occurs when a failing chip has

many failing patterns where the union of the sensitized regions is the set of

all the signal lines.

1068

Fig. 11.

IEEE TRANSACTIONS ON COMPUTER-AIDED DESIGN OF INTEGRATED CIRCUITS AND SYSTEMS, VOL. 30, NO. 7, JULY 2011

Effectiveness ratio for the 2533 chips. (a) Calculated for all regions sensitized by the failing patterns. (b) Calculated for the SLAT regions.

ratio for PAN-detect (triangles), one for bridge (circles), and

one for gate-exhaustive (squares).

Fig. 11(a) and (b) reveals that there is significant range

in the ER values which is expected since many of the

suspects, of course, have nothing to do with the defect. Also as

expected, the scatter along the ER axis does reduce however as

the suspect-identification procedure improves as demonstrated

when moving from the sensitized regions [Fig. 11(a)] to

the SLAT regions [Fig. 11(b)]. Finally, it is clear that the

effectiveness of the metrics follow the same trend observed

as the hard-to-detect chips, i.e., PAN-detect is most effective

followed by bridge and then gate exhaustive.

V. Discussion

In this section, we demonstrate the applicability of METER

to large designs, and discuss applications of the methodology.

We also compare and contrast METER against the traditional

tester-based approach for evaluating test metrics.

A. Applicability to Large Designs

METER can be easily applied to large, industrial designs

since it simply analyzes failure logs from already applied tests,

and only requires fault simulation of stuck-at faults involving

suspect regions. In other words, only a small portion of the

circuit has to be analyzed and existing fault simulation tools

can be utilized. METER is therefore scalable to large designs.

To demonstrate applicability, we apply METER to an

NVIDIA GPU. The GPU has ∼10M gates, and is fabricated

using 90 nm technology. The bridge fault model, the gateexhaustive and PAN-detect metrics are evaluated. Diagnosis is

performed using Synopsis TetraMAX [40] to identify suspect

regions within failing chips. For each failing chip, the test

patterns up to and including the chip’s FFP are used for

analysis.

Of the 4000+ failing chips in the stuck-at failure logs, we

focused on the 33 chips that have a single suspect reported by

diagnosis and are hard to detect (Nd > 1). We perform fault

simulation on these suspects over the selected test patterns

using TetraMAX, and examine whether a chip’s FFP increases

the coverage of any metric for the suspect. The outcome is

summarized in the Venn diagram shown in Fig. 12. Each

integer in the diagram represents the number of chips whose

FFP increases the coverage of the evaluated metric(s) for the

Fig. 12. Venn diagram showing the number of single-suspect failing chips

whose FFP increases coverage for bridge, gate-exhaustive, and PAN-detect for

NVIDIA GPUs.

suspect regions. The evaluation results are consistent with the

previous experiments that use the LSI test chips. Specifically,

PAN-detect uniquely captures five chip failures, while bridge

test is found to be much more effective than gate-exhaustive.

There are two chips whose FFP does not increase coverage

of any of the three metrics. It is likely that PAN-detect

test can capture these two chips if the driver-gate inputs of

physical neighbors are included in the neighborhoods instead

of the physical neighbors, similar to the case discussed in

Section IV-E.

Similar to the experiment using the LSI test chips, we

calculate the average ratios Akm , ERm , and FRm , using (8)–

(10), respectively, for the three evaluated metrics (as well as

N-detect) for the 33 selected NVIDIA GPUs (see Fig. 13). It

can be observed that for these GPUs, PAN-detect test is most

effective and efficient in defect detection, followed by bridge

and then gate-exhaustive.

Our measure of effectiveness and efficiency provides a

manner to evaluate and compare test metrics over different

manufacturing technologies and products. For example, by

contrasting Figs. 10 and 13, it can be observed that gateexhaustive test becomes more effective for the NVIDIA 90 nm

GPUs than for the LSI 110 nm ALU chips. On the contrary, the

ratio for the bridge fault model remains virtually the same. The

PAN-detect metric becomes even more effective and efficient

for the NVIDIA GPUs. To be conclusive, however, much more

data from failing chips should be analyzed.

B. Applications

METER has been demonstrated by comparing the effectiveness and efficiency of several metrics. Measures of test-

LIN AND BLANTON: METER: MEASURING TEST EFFECTIVENESS REGIONALLY

Fig. 13. Illustration of chances that a test pattern failed a chip and/or

increases coverage for (a) bridge, (b) gate-exhaustive, (c) PAN-detect, and

(d) N-detect for the 33 NVIDIA GPUs.

metric effectiveness and insufficiencies learned from tester

data provide guidelines for developing new fault models,

test metrics, and DFT methods. The information can also be

used to select a proper mix of tests to guarantee a certain

level of quality as described in [38] and [41]. Specifically,

the work in [38] and [41] derives a defect type distribution.

METER can be used in conjunction with these other papers

to determine which metrics and models are best at detecting

the derived defect types, thus enabling custom test, i.e., a test

that matches the defect-type distribution for a given design.

Other applications of METER include guiding the selection of

parameters used in ATPG, such as selecting the distance for

bridge extraction and neighbor identification for PAN-detect,

and others.

In the following, we demonstrate how METER can be

applied to select a proper value of N for both N-detect and

PAN-detect. As N increases, it is expected that the defect

coverage of an N/PAN-detect test set would increase [3], [11],

[14]. The improved test quality however comes at the cost of

a higher pattern count and test application cost. Selecting an

appropriate value of N therefore requires a tradeoff between

cost and quality. Common practice is to choose N based on

available test resources (i.e., tester memory, test time, and

others). Here, we use METER to demonstrate how the test

quality can be examined as a function of N.

For choosing N, we use failure logs of another large design,

an IBM ASIC. The IBM chip has nearly a million gates,

fabricated using 130 nm technology. Physical neighborhood

information includes all the signal lines within 0.6 µm of the

targeted line. The stuck-at test set applied during wafer test

consists of 3439 test patterns that achieve 99.51% stuck-at

fault coverage. Among the 606 chips in the stuck-at failure

logs, the 304 chips that failed scan chain flush test are

disregarded. The remaining 302 chips are diagnosed to identify

the suspects using Cadence Encounter Diagnostics [42]. Each

suspect is fault simulated using all test patterns up to and

including the chip’s FFP. For the stuck-at fault involving the

suspect, we record the number of times the fault is detected

(i.e., the number of N detections, Nd ) and the number of

neighborhood states established for the fault (i.e., the number

1069

of PAN detections, Ns ).

Because 284 of the 302 diagnosed failing chips have more

than one suspect, we take the following approach to handle

multiple-suspect chips. For each failing chip, we record Nd

and Ns of the suspect that is ranked highest in the diagnosis

report, as well as the maximum/minimum/average Nd and Ns

over all the suspects of the chip. The diagnosis tool employed

reports a score for each identified suspect, where the score

measures the similarity between suspect behavior and failingchip behavior. The best-ranked suspect is the one that has the

highest score, and is considered more likely to be the actual

location of the failure. Using the Nd and Ns for the bestranked suspect, as well as using the max/min/average Nd and

Ns , constitutes a variety of options for obtaining Nd and Ns

values for a multiple-suspect failing chip.

Fig. 14(a) and (b) shows the histograms of the number

of N and PAN detections, respectively. The bars indicate the

number of chips that are N/PAN detected, and the table in

each plot reports the tail data. For example, seven of the

302 failing chips have their best-ranked suspect N-detected

four times before the corresponding chip failed. For one

chip, the best-ranked suspect was sensitized 33 times with

a different neighborhood state before it finally failed for the

34th state. Using Fig. 14, the number of possible test escapes

when different values of Nd and Ns are chosen can be easily

determined. For instance, if the best-ranked suspect region

is the actual defect region, then applying Nd =10-detect test

to that region only would lead to three test escapes. On the

contrary, applying physically-aware Ns =10-detect test would

result in one test escape. Given enough chips to analyze and

a threshold on the defect parts per million, this analysis can

be used to select the value of N for ATPG.

C. Comparing Test-Metric Evaluation Methods

Table III compares METER with the traditional approach

involving application of extra test patterns generated specifically for the metrics under evaluation. Both approaches require

the analysis of the chip’s design information (e.g., netlist

and layout) for identifying fault characteristics that include,

e.g., physical neighbors and driver-gate inputs. Tester-based

evaluation, however, typically requires the generation and fault

simulation of extra test patterns in order to isolate the detection

characteristics of each metric. Furthermore, new, powerful

ATPG and fault simulation tools need to be developed, or

existing tools have to be tricked, to generate tests for new test

metrics since tests are needed for the entire design. METER,

on the contrary, fault simulates only a small subset, albeit

without fault dropping, of the existing test patterns against

suspect failing regions identified from failing chips. Given the

NP-complete nature of ATPG, limited fault simulation of just

a portion of the design without fault dropping is a significantly

less-intensive task.

METER can be easily applied to large designs, as demonstrated in Section V-A, since current tools for stuck-at fault

simulation can be utilized and the analysis only requires some

script writing. This is not scalable for traditional tester-based

evaluation approach where the entire design is considered.

More significantly, analysis of existing fail data is a much more

1070

IEEE TRANSACTIONS ON COMPUTER-AIDED DESIGN OF INTEGRATED CIRCUITS AND SYSTEMS, VOL. 30, NO. 7, JULY 2011

Fig. 14.

Histograms showing the number of (a) N detections and (b) PAN detections for the 302 IBM failing ASICs.

TABLE III

VI. Conclusion

Comparison of Test-Metric Evaluation Techniques

A general and cost-effective test-metric evaluation methodology, METER, was described and demonstrated. METER

provided a novel approach for analyzing the effectiveness and

efficiency of new and existing test and DFT methods, which

traditionally relied on empirical data from expensive and timeconsuming chip experiments. METER analyzed failure log

files from tests already applied, and did not require additional

tests. Although only test data from failing chips were analyzed,

it was equivalent to chip experiments with a large sample size.

The time and cost for test generation and test application for

test-metric evaluation were therefore completely avoided.

One problem of METER is that test metrics are evaluated

under the environment that was employed (e.g., temperature, voltage, test clock rate, and others) since existing testmeasurement data is utilized. As test environment changes,

the relative effectiveness of the evaluated test metrics may

change as well. Test-measurement data collected under a different environment is needed to evaluate metrics for different

conditions. Moreover, the test approaches applied to the failing

chips should adhere to the assumptions of the test metrics

under evaluation. Otherwise, the evaluation is not reasonable

although possible.

METER has been demonstrated by comparing the effectiveness and efficiency of several metrics that include bridge,

gate-exhaustive, and PAN-detect using the stuck-at failure logs

from actual fabricated and tested ICs. With this approach, test

metrics can be easily evaluated and compared over different

manufacturing technologies and products. The resulting information provides guidelines on how to select the best mix of

test methods. It can also be used to guide the development of

new test metrics, fault models, and DFT methods, as well as

the selection of parameters used in ATPG.

Tester-Based Evaluation

METER

Netlist analysis (−)

Netlist analysis (−)

Layout analysis (−)

Layout analysis (−)

ATPG/fault sim. (×)

Limited fault sim. w/o fault dropping (✓)

New ATPG/fault sim. tools (×) Existing fault sim. tools (✓)

Tester use (×)

Analysis of fail data (✓)

Controllable test environment (✓) Test environment not controllable (×)

Controllable coverage (✓)

Coverage not controllable (×)

Gross (×)

Fine-grained (✓)

*

✓: good; −: tie; ×: bad.

cost-effective activity as compared to the tester time needed to

apply extra patterns to tens or hundreds of thousands of chips.

However, since METER utilizes existing test patterns, the

test environment (e.g., temperature, voltage, test clock rate,

and others) cannot be changed. In other words, test metrics

are evaluated under what was employed. Moreover, as already