Quality and Durability of ETICS

advertisement

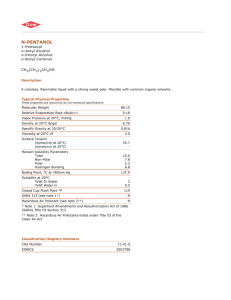

Quality and Durability of ETICS The longevity of building components such as External Thermal Insulation Composite Systems (ETICS)1) is increasingly in focus of both public awareness as well as regulatory bodies when demanding for sustainable solutions in the construction industry. It is generally understood that high quality products can extend the lifecycle of existing and new buildings – thus helping to conserve resources. More stringent energy saving regulations in many countries have become effective and contributed to the rapid growth of ETICS as a façade technology. Today, these systems are being applied on many new buildings as well as in renovation projects world wide. By insulating outside the structure, ETICS reduce air infiltration, stabilise the interior environment and reduce energy consumption. 1) Also referred to as Exterior Insulation and Finish Systems (EIFS) Polymer Additives in ETICS Application 2.15 2.10 2.05 Structural viscosity As mortar layers are an essential part of ETICS, their durability and resistance to a number of factors are key for the longevity of the whole system. The adhesive mortar must provide high tensile bond strength for a reliable adhesion of the insulation board to the wall substrate. The finishing layers have to withstand typical influences resulting from long-term outdoor exposure such as rain water, temperature fluctuations and other environmental effects like air pollution. In addition, they protect the following layers from mechanical impact. 2.00 1.95 1.90 1.85 1.80 1.75 19.0 20.0 21.0 22.0 23.0 24.0 25.0 23.0 24.0 25.0 Water level [%] Dow Construction Chemicals offers a range of cellulose ethers, redispersible polymer powders and liquid latex products as additives for mortar formulations responding specifically to these requirements. 0.15 0.14 Water level [%] Applicators can choose between cementitious and dispersion based adhesives and renders for ETICS. In both cases it is of paramount importance for manufacturers to select additives for the mortar formulations which enable the production of high performance, durable system components thus a sustainable insulation system. 0.13 0.12 0.11 0.10 19.0 20.0 21.0 22.0 Bond strength to EPS [N/mm2] In cementitious systems, cellulose ethers help to control fresh mortar properties like water demand, workability, open time and water retention. The ease of application correlates with the shear thinning of the mortar, expressed as structural viscosity. The higher the water demand of the cellulose ether, the stronger the mortar consistency will depend on the shear rate resulting in pleasant workability. The bond strength of cementitious mortars, however, decreases with higher water levels. This conflicting trend needs to be well balanced by the formulator (see figure 1). Redispersible polymer powders (RDP) are additional binders in dry-mix mortar formulations which make sure that the mineral based mortar adheres to the surface of the polystyrene insulation panel. It also helps to improve the impact resistance of the mortar/polystyrene interface. Figure 2 illustrates the impact of 3 Joules to an ETICS sample with and without the addition of redispersible polymer powders. ETICS mortars need to be hydrophobically modified to repell the water from the system in case of rain. Hydrophobicity is either incorporated in the mortar by accordingly modified redispersible polymer powders or by separate additives wich are either based on alkali salts of fatty acids or by silane based products. Figure 1: Structural mortar viscosity and bond strength controlled by water demand Sample a) Sample b) Figure 2: Impact of 3 Joules to ETICS samples without RDP (sample a) and with 3% RDP (sample b) It is also common to install ETICS with dispersion based mortars and adhesives without using cementitious products at all. These renders, mainly top coats, can be either based on styrene acrylic or pure acrylic polymers. Products based on acrylic emulsions generally enable a very good durability, a high resistance to dirt pick-up and a good workability. Dow is offering a number of APEO free which support these important end-product characteristics. Although top coats produced with styrene acrylic emulsions impart comparable performance in such areas as initial gloss and application properties, pure acrylic emulsions have shown to be superior in terms of their longterm behaviours. In summary, our products help to: – deliver high adhesion strength and reliably adhere the entire ETICS system – make the ETICS system durable by providing resistance to water, UV-light, dirt pick-up and cracking – provide improved water-retention and good workability for efficient application Product Portfolio WALOCEL™ methyl cellulose, DOW™ Latex Powder and PRIMAL™, UCAR™ acrylic emulsion polymers In the region, Dow Construction Chemicals offers a range of products for high-quality durable adhesive, base and top coats. For more information please see the respective brochures, for further requirements please consult the regional Dow sales representative. Dow Construction Chemicals – Where Quality Building Starts With a portfolio of established brands such as PRIMAL™ and UCAR™ acrylic emulsion polymers, WALOCEL™ and METHOCEL™ cellulose ethers, DOW™ Latex Powders, OROTAN™ dispersants, ACRYSOL™ synthetic thickeners and AQUASET™ thermoset binders, Dow Construction Chemicals is a leading supplier to construction product formulators around the world. The business offers broad technology platforms and application know-how in acrylic, redispersible latex powder, and cellulosic technology. Dow Construction Chemicals brings together the combined resources and 40-year industry experience of Rohm and Haas and Dow Wolff Cellulosics to offer in-depth technical knowledge and effective formulation development experience to manufacturers of building and construction products around the world, supported by global research, technical service and manufacturing facilities. The reliability and high-quality of binders and products from Dow Construction Chemicals form the heart of many innovative products that have become industry essentials. Applications range from tile adhesives, renders, plasters, ETICS, self-levelling underlays to repair mortars, waterproofing membranes, roof coatings among others. .do .co &e Note Please follow the instructions indicated on the respective SDS (Safety Data Sheet). The information and data contained in this brochure do not represent exact sales specifications. The features of the products mentioned may vary. The information contained in this document has been provided in good faith, however it does not imply any liability, guarantee or assurance of product performance. It is the pur­chaser’s responsibility to determine whether these Dow products are suitable for the application desired and to ensure that the site of work and method of application conform with current legislation. No licence is hereby granted for the use of patents or other industrial or intellectual property rights. If Dow products are purchased, we advise following the most up-to-date suggestions and recommendations. Dow Chemical IMEA GmbH P.O. Box 7893, Dubai United Arab Emirates Phone +971 4 4537 000 Fax +971 4 4537 117 nl ck in e q ui info m www For more information please send your email to dccinfo@dow.com wcc About Dow Dow (NYSE: DOW) combines the power of science and technology to passionately innovate what is essential to human progress. The Company connects chemistry and innovation with the principles of sustainability to help address many of the world’s most challenging problems such as the need for clean water, renewable energy generation and conservation, and increasing agricultural productivity. Dow’s diversified industry-leading portfolio of specialty chemical, advanced materials, agrosciences and plastics businesses delivers a broad range of technology-based products and solutions to cus­ tomers in approximately 160 countries and in high growth sectors such as electronics, water, energy, coatings and agriculture. In 2011, Dow had annual sales of $60 billion and employed approximately 52,000 people worldwide. The Company’s more than 5,000 products are manufactured at 197 sites in 36 countries across the globe. References to “Dow” or the “Company” mean The Dow Chemical Company and its consolidated subsidiaries unless otherwise expressly noted. More information about Dow can be found at www.dow.com. asy o Version Februrary 2012 ™ Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow. ® 840-01901-0212