Åbo Akademi Process Chemistry Centre Mikko Hupa

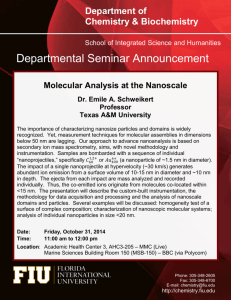

advertisement

Åbo Akademi Process Chemistry Centre Mikko Hupa ÅA PCC • Chemistry-oriented chemical engineering research centre at Åbo Akademi University • Centre of Excellence in research appointed by the Academy of Finland (2000-2005; 2006-2011) ÅA-PCC Scientific Advisory Board by the Academy of Finland • Jean-Claude Charpentier, CNRS, Lyon, France • Jiri Janata, Georgia Institute of Science and Technology, Atlanta, USA • Douglas Reeve, University of Toronto, Canada ÅA PCC - Industrial Advisory Board 2006Örjan Andersson, Swedish Polytechnic – Finland Kenneth Sundberg, Top Analytica Håkan Gros, Danisco Hannu Toivonen, Kemira Lars Gädda, M-real Kari Toivonen, Elomatic Markku Karlsson, UPM-Kymmene Harri Turpeinen, Neste Oil Bertel Karlstedt, Nordkalk Petri Vasara, Pöyry Eeva-Liisa Lakomaa, Vaisala Hannu Vornamo, Chemical Industry Federation of Finland Ismo Reilama, Metsä-Botnia ÅA PCC Mission Detailed understanding of physico-chemical processes in environments of industrial importance in order to meet the needs of tomorrow’s process and product development. ÅA PCC Mission Detailed understanding of physico-chemical processes in environments of industrial importance in order to meet the needs of tomorrow’s process and product development. We call our approach Molecular Process Technology Molecular Process Technology • Parallel to other “molecular sciences”, Molecular Biology, Molecular Medicine • Molecular Process Technology should work on: – chemical phenomena and mechanisms at the molecular level – elementary reactions and interactions in complex industrial processes – process models based on detailed physico-chemical understanding – relevant molecular structures for industrial products – environmentally significant components discharged from processes Åbo Akademi Process Chemistry Centre 2006Wood and Paper Chemistry Combustion and Materials Chemistry Prof. Bjarne Holmbom Prof. Mikko Hupa Wood Chemistry Fibre and Pulping Chemistry Combustion Chemistry Materials Chemistry Paper Chemistry Process Analytical Chemistry Kinetics and Catalysis Prof. Ari Ivaska Prof. Tapio Salmi Chemical Sensors Heterogeneous Catalysis Electroactive Materials Chemical Kinetics Environmental and On-line Analysis Chemical Reactor Modelling Åbo Akademi Process Chemistry Centre 2006 Senior researchers Doctoral Thesis works Other research MSc Thesis works Other support and visitors Total Participation 2006 4 + 22 39 9 25 40 139 ÅA PCC Research Areas 2006Metals in Wood and Fibres Biofuels & Bioenergy Chemicals from Wood Functional Inorganic Materials Intelligent Electroactive Materials New Functions for Paper Chemicals and Fibres Catalysis & Molecular Engineering Reaction Intensification Ionic Liquids ÅA PCC Research Areas 2006Metals in Wood and Fibres Biofuels & Bioenergy Chemicals from Wood Functional Inorganic Materials Intelligent Electroactive Materials New Functions for Paper Chemicals and Fibres Catalysis & Molecular Engineering Chemistry in Forest Biorefineries Reaction Intensification Ionic Liquids Chemistry in Forest Biorefineries BIORAFF 1.1.2006 - 31.12.2008 Åbo Akademi Forest biorefinery Optimum use of biomass raw material in an integrated process to produce: - Chemicals to process industry Chemicals to pharmaceutical industry Liquid and solid fuels Pulp and paper Heat and power Goal of the program Chemistry in Forest Biorefineries • Identify new products as well as separation and conversion technologies • Focus on chemistry • Value-added use of trees as raw material • Evaluate environmental effects Partners involved Kraft Pulp Mill pulp pulping chemicals stemwood round wood forest chipping chips pulping black liquor debarking harvesting pulp bark heat & power combustion emissions pulping chemicals ash Kraft Pulp Mill & Biorefinery WP5 round wood pulp pulping chemicals stemwood chipping chips knots extraction debarking WP1 extraction forest harvesting bark extraction WP5 pulp conversion pulping P WP3 black liquor P P P residues WP 4 P P WP2 separation residues heat & power WP6 pulping chemicals recycling combustion ---gasification WP8 emissions WP7 synthesis gas ash WP6 biofuels (l) synthesis P Projects 1. 2. 3. 4. 5. 6. Polysaccharides from wood -R&I Sugar based fine chemicals –I Cellulose derivatives –R Polyphenols from knots and bark –I Metal ions and functional groups in trees and pulp –R&I Fuel analysis and presence of trace elements in biofuels –R&I 7. Options for catalysts in production of bio based liquid fuels R&I – Influence of the impurities on the catalyst behavior 8. Gasification of biorefinery streams for synthesis and energy –I 9. Biorefinery and FTP - I (KCL) What Happens in a Black Liquor Gasifier? Product gas Moisture Char gasification Pyrolysis Drying Droplet H2, CO Volatiles, tars Solids Char CO2, H2O Smelt Gasification Reactors • The gasification reaction can be made happen in a variety of reactors • Challenges: - complete carbon conversion - behavior of the inorganics (solid or molten) - gas cleaning and emissions Major BLG Development Projects Today • MTCI fluidized bed steam reformer • Chemrec entrained-flow gasifier