Document 10399813

advertisement

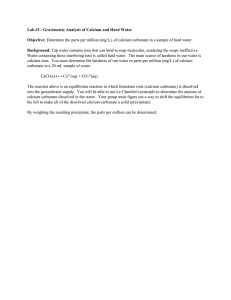

International Flame Research Foundation Finnish-Swedish Flame Days January 28 -29, 2009 Naantali, Finland CO2 EMISSIONS MITIGATION IN FINLAND BY CARBONATION OF SILICATE MINERALS AND INDUSTRIAL WASTES R. ZEVENHOVEN*, J. FAGERLUND, A. WIKLUND, E. NDUAGU, A.-M. FORSMAN, M. FÄLT, H.-P. MATTILA Åbo Akademi University (ÅA), Heat Engineering Laboratory Biskopsgatan 8, FI-20500 Åbo/Turku Finland *Corresponding author: ron.zevenhoven@abo.fi, +358 2 2153223 S. ELONEVA, A. SAID Helsinki University of Technology (TKK), Department of Energy Technology PO Box 4400, FI-02015 Espoo Finland ABSTRACT: Carbon dioxide capture and storage (CCS) technology has to be implemented also in Finland if fossil, carbon-containing fuels are to be used in the future. As underground cavities for geological storage of CO2 appear to be absent in Finland the CO2-producing energy sector seems to aim at carbon dioxide capture and export (CCE) instead. However, as recognised primarily by Finnish pulp and paper industry and metal industries, Finland can make use of its significant resources of magnesium silicates and industrial wastes. Finland’s CO2 emissions in excess of the 1997 Kyoto Protocol commitments are currently 10 – 15 Mt/a (megatons). The carbonation of Finnish magnesium (Mg) silicate resources appears to offer enough capacity for storing at least several Gt (gigatons) CO2, forming a benign carbonate product that doesn’t require post-storage monitoring of the CO2. Besides this, the carbonation of slag by-products from iron- and steelmaking allows for producing many kt (kilotons) of valuable precipitated calcium (Ca) carbonate (PCC) products with applications in paper-making, or for flue gas desulphurisation. Work on CO2 mineralisation has been ongoing at TKK and ÅA for many years, with increasing support from industrial partners from Finland and abroad. In this paper, results and achievements so far are summarised. For long-term storage of large amounts of CO2, a route is being optimised that involves the production of Mg-hydroxide from serpentinite rock material, followed by pressurised fluidised bed (PFB) carbonation to Mg-carbonate. The last (i.e. carbonation) step should give the energy release that must cover for the process’ energy input needs. For the iron-and steel sector, slag by-products are processed in a wet, aqueous process route that involves extraction of calcium followed by carbonation with CO2 and recovery of the solvent chemicals. The gas used may be a flue gas after removal of fly ash and possibly also nitrogen- and sulphur oxides and some trace elements. Process routes and the quality and amounts of carbonate products shall be presented. Keywords: CO2 mitigation, mineralisation, magnesium carbonate, calcium carbonate 1. INTRODUCTION Carbon dioxide capture and storage (CCS) is an important option for mitigating CO2 emissions from human activities (IPCC, 2005). It comprises separation and compression of CO2 from industry and power plants and transportation of CO2 to a storage site followed by long-term storage. The carbonation of natural silicate minerals that contain alkaline-earth oxides like magnesium oxide (MgO) and calcium oxide (CaO) offers a leakage-free alternative to using underground geological formations for the long-term storage of CO2. One of the countries that can make use of this is Finland, where it was assessed that underground storage sites are not available while vast resources of suitable magnesium silicates exist (Koljonen et al., 2004). Finland has emission reduction commitments under the 1997 Kyoto protocol to reduce its greenhouse gas emissions to the level of year 1990 during 2008-2012, while current emissions of CO2 are 10-15 Mt/a above that level. For example, the serpentinite rock formations in Eastern-Central Finland alone could bind several Gt of CO2 (Teir, 2008, Rinne, 2008). Naturally occurring silicate minerals such as serpentine and olivine contain high concentrations of MgO, while pyroxenes and amphiboles are a potential source for both CaO and MgO. Carbonation of these traps CO2 as environmentally stable solid carbonates, which for serpentine (R1) and wollastonite (R2) minerals can be described by the following overall chemistry: Mg3Si2O5(OH)4 (s) + 3CO2 (g) → 3MgCO3 (s) + 2SiO2 (s) + 2H2O (l) (R1) CaSiO3 (s) + CO2 (g) → CaCO3 (s) + SiO2 (s) (R2) Also Mg- or Ca- containing mine tailings and by-products or wastes from industry may be used – see Zevenhoven et al. 2006b, Eloneva 2008, Teir 2008. Only the carbonation of Mg-based material offers the capacity needed for significantly reducing anthropogenic CO2 emissions and this is covered in the first part of this paper. In the second part the production of valuable precipitated calcium carbonate (PCC) from slag by-products from iron- and steelmaking is addressed; this industry sector, the mineral processing sector and the pulp and paper sector have started considering CO2 mineralisation as a route to CO2 emissions mitigation, a route to increases profits from by-products and/or a cheap route to commercial carbonate materials. Unfortunately, Finland’s energy sector hasn’t yet embraced CO2 mineralisation as the CCS-route to follow and appears to prefer carbon dioxide capture and export, CCE (T&T, 2008). Moreover, a significant renewed effort was started to locate geological sites inside Finland’s borders for carbon dioxide capture and geological storage (further referred to as CCGS1) and according to recent reporting these have not yet been found (Nieminen, 2008). Mapping studies for CCGS “(GeoCapacity”) at the European level are ongoing (Vangkilde-Pedersen et al., 2008), unfortunately Finland’s data is not included here. 1 The recent proposal for an EU directive on geological storage of carbon dioxide (CEC, 2008) confuses this CCS method with CCS in general: “...capture CO2 from industrial installations and store it in geological formations (carbon dioxide capture and storage, or CCS)”. 2/15 This paper is an updated compilation of two papers presented by Zevenhoven and Eloneva at ACEME-08, Rome, October 1-3, 2008 (Zevenhoven et al., 2008b; Eloneva et al., 2008c). Ocean carbon Biomass Atmosphere Annual emissions CARBONATION OF MAGNESIUM SILICATE MINERAL FOR LONGTERM STORAGE OF CARBON DIOXIDE Mineral Carbonates 100 000 Underground injection 10 000 EOR 1 000 Fossil carbon Characteristic storage time (yr) 2. 100 10 1 1 10 100 1 000 10 000 100 000 1 000 000 Carbon storage capacity (Gt) Figure 1. Estimated storage capacities and storage times for various CCS methods. (from Zevenhoven et al., 2006b, after Lackner, 2003) As Figure 1 illustrates, (Mg-based) mineral carbonation gives the highest capacity and longest storage time of all currently known CCS options (Lackner, 2003), and in contrast to CCGS, post-storage monitoring of CO2 will not be needed. Mineralisation of CO2 is attractive especially at locations where absence of underground formations excludes CCGS, the risk of leakage of underground stored CO2 is considered unacceptable, or large resources of material suitable for carbonation are present. Besides this, the deployment of CCGS is progressing rather slowly (current total capacity ~7 Mt CO2/a) and might not offer the necessary capacity soon enough, putting pressure on the development of alternatives. However, no commercial silicate mineral carbonation technology yet exists. Although the overall reactions (R1) and (R2) are exothermic (which implies that proper optimisation and process integration should allow for operation at zero or negative net energy input) the natural carbonation of silicate minerals is very slow. The reaction must be accelerated considerably to be an economically viable large-scale CO2 storage technology. Technology overviews were given by Newall et al. (2000), Huijgen and Comans (2003, 2005), and recently by Sipilä et al. (2008), dealing with Mg-based as well as Ca-based materials. Two problems must be solved to make large-scale mineralisation of CO2 more attractive (Herzog, 2002): • • extracting or activating the reactive component MgO from silicate mineral, and speeding-up the carbonation chemistry kinetics 3/15 A small yet steadily increasing number of countries are looking into technical solutions to perform the carbonation of magnesium with CO2 on a large scale; the most important results were reported from the U.S. since the mid 1990’s. While most research concentrates increasingly on methods using aqueous solutions, research in Finland still addresses gas/solid methods. The reason for preferring a gas/solid route is that aqueous processes have temperatures much lower than, say, 500°C where the rate of the gas/solid carbonation with MgO or Mg(OH)2 appears to become significant. The energy consumption of the “wet” processes is high; it should be much lower (or negative) for a gas/solid process with heat recovery. An important feature of CO2 mineralisation will be solids mining and handling and the question of what to do with the carbonate product material. A metric ton of CO2 will require 2.5-3 tons of magnesium silicate mineral (for coal combustion-derived CO2 this implies ~8 tons of mineral per ton coal). Altogether this will result in a mining activity similar to typical commercial mining of coal or metal-containing ore. In the open literature, hardly any data can be found on the kinetics of chemical reactions between magnesium silicates or oxides with CO2. Since the mid-1990’s many results (mainly qualitative work-in-progress reporting) from mineral carbonation work by U.S. consortia were published. Roughly after year 2000 countries like Finland joined in. 2.1 Gas-phase conversion routes The first experiments reported from the U.S. during the 1990’s showed low levels of carbonation of magnesium silicates even at elevated (supercritical) CO2 pressures and temperatures like 340 bar, 500°C for sub-mm size particles after several hours. This and the results from later work in the U.S. and Finland are summarised in Table 1. Recent tests made in Finland with a serpentinite mine tailing sample (~83 %-wt serpentine + ~14 %-wt magnetite Fe3O4 + 3 %-wt others, size < 75 µm) from the Hitura nickel mine in central Finland with (sub- and) supercritical CO2 involved direct carbonation during 3½h after heat-up and pressurisation to 57-300 bar, 150-200°C gave < 2% carbonation. After efforts to directly carbonate Mg-silicates the U.S. work shifted to MgO extraction from magnesium silicates and the effect of water (released from Mg(OH)2, for example) on carbonation. The carbonation of Mg(OH)2 was soon found to be significantly faster than carbonation of MgO, and the effect of pressure (of H2O and CO2) on carbonation was studied in detail. Increasing pressures above the minimum CO2 pressure for stable MgCO3, slows down the dehydroxylation of Mg(OH)2, generating fewer reactive MgO sites for carbonation (Butt et al., 1996, Béarat et al., 2002, Chizmeshya et al., 2002). Attempts to produce Mg(OH)2 from Mg-silicates resulted in the evaluation of a process using hydrochloric acid (HCl in water) with intermediates MgCl2·nH2O and Mg(OH)Cl, followed by gas/solid carbonation of Mg(OH)2 (see Newall et al., 2000). Due to the complexity and energy consumption of this process route other U.S. researchers proceeded with working on direct routes based on aqueous solutions (see below). 4/15 Table 1. Magnesium-silicate mineral carbonation since the 1990s: gas/solid Mineral Temp. ºC Press. bar Part. size µm Time h Conversion % Where, when Serpentinite 500 340 50-100 2 25-30 US 1997 1, 20 ~ 50 3 negligible Fin 2000 Serpentinite 200, 1000→200 Serpentinite 150-200 57-300 75-125 3.5 <2 Fin 2006 Mg(OH)2 565 52 20 0.5 90 US 1997 Mg(OH)2 375 52 50-100 12 16.5 US 1996 MgO from Mg(OH)2 1000→200 1, 20 ~ 20 3 <5 Fin 2001 2003 Mg(OH)2 370 - 540 1-45 75-125 6 < 60 Fin 2004 2006 200, In Finland, stepwise carbonation initially involved testing with Finnish serpentine and (calcined) magnesium hydroxide Mg(OH)2 powder in a pressurised thermogravimetric analyser (PTGA). Since elevated pressures didn’t give an increase in MgO carbonation rate it was decided to proceed with Mg(OH)2 under test conditions where MgO formation is thermodynamically unfavourable. (Zevenhoven et al., 2002, Zevenhoven and Teir, 2004). Besides the PTGA tests, tests with Mg(OH)2 and MgO in an atmospheric bubbling fluidised bed (FB) reactor were made, with CO2 as fluidising gas. The product of carbonate material that builds up on the reacting particles (eventually slowing down conversion) was noticeably removed from the particles as fines by attrition and abrasion, which were entrained from the reactor with the exit gas flow. These had a considerably higher MgCO3 content (8.1 %-wt) than the material in the bed (4.4 %-wt) after ~11 h. (Zevenhoven and Teir, 2004). Clearly, FB reactors are very suitable here. PTGA tests on carbonation of Mg(OH)2 (97%, 75-125 µm) proceeded with tests at pressures up to 45 bar. These confirmed that Mg(OH)2 can be carbonated faster than MgO. Pressurisation allows for using higher temperatures, but for a given pressure the carbonation rate decreases with temperature as a result of thermodynamic limitations – see Figure 2a. XRD analysis confirmed a significant MgCO3 content in the end product. Conversion at 40 and 45 bar was much faster than at 35 bar at similar or slightly higher temperatures but was slow compared to the aqueous processes used in the U.S. (see below) despite the progress made – see Figure 2b. Unreacted shrinking core (USC) modelling was used to determine rate-limiting steps and rate parameters, showing that after ~5% carbonation, so-called product layer diffusion becomes rate-determining. (Zevenhoven et al., 2006a). This again illustrates that it would be beneficial to use a fluidised bed reactor. 5/15 1000 100 50 10 40 1 Years Carbonation efficiency (%) 60 63 s ar ye 3 ys da 0 20 0.1 30 0.01 20 0.001 s ur ho s s ur ur ho ho 5 6 4< 0.0001 10 2002 2003 0 370 460 495 510 Tempera ture (°C ) 525 2006 h ? 45 ar) b 12 re ( u 1 s s Pre 35 540 2004 2005 Year 1 40 Figure 2a (left) Results of conversion of Mg(OH)2 (75-125 µm) to MgCO3 after 6 h for various temperature/pressure combinations in 99%/1% CO2/H2O (Zevenhoven et al., 2006a) Figure 2b (right) Progress made in Finland as calculated reaction times for full carbonation of Mg(OH)2 under chemical kinetics control (Sipilä et al., 2008) The last PTGA test series made aimed at carbonation of serpentinite rock from the Hitura nickel mine mentioned above (75-125µm) in three steps, producing MgO, hydroxylation of MgO to Mg(OH)2 and carbonation of Mg(OH)2, respectively. It showed that heat-up of serpentinite doesn’t produce MgO but converts serpentine into olivine, water and quartz. Besides this, the dehydroxylation/ hydroxylation of Mg(OH)2 was studied in separate tests, confirming that conversion of MgO to Mg(OH)2 in pressurised steam is very slow. The production of Mg(OH)2 presents yet another challenge. 2.2 Aqueous phase conversion routes The problems with the U.S. route using MgCl2 as intermediate resulted in the development of a simpler, direct carbonation process using aqueous solutions. Soon after the end of the 1990’s U.S. researchers reported conversion rates such as 65% conversion after 1 h and 80% conversion within ½h after optimisation of solution chemistry, heat treatment and grinding. Currently this method is considered to be the most successful route for mineral carbonation using an aqueous solution of 0.64 M NaHCO3 and 1 M NaCl at 185°C/150 bar (olivine), 155°C/115 bar (heat treated serpentine) or 40 bar/100°C (wollastonite), respectively. The minimum costs for CO2 sequestration would be 54, 78 and 64 US$/ton CO2, respectively. For serpentine, thermal pre-treatment (at 615-630°C) was found more efficient than mechanical treatment (O’Connor et al., 2005, Gerdemann, et al. 2007). Herzog (2002) concludes in his assessment that the reported carbonation levels and rates are obtained only at high energy cost: “a 20% energy penalty for a coal-fired power plant”. Cost levels mentioned 6/15 make this method too expensive at this point – see also (IPCC, 2005). Nonetheless this route still receives attention and improvements are being reported. It has been noted recently, however, that the process costs are overestimated partly due to unrealistic calculation of energy efficiency and energy costs: the costs of process heat input are significantly over-estimated when charged the same way as power input, giving a false impression of overall process economics. (Sipilä et al., 2008, Zevenhoven et al., 2008b). The extensive pre-treatment of feedstock mineral makes the aqueous processes using direct carbonation in fact indirect. As an alternative to energy-intensive pre-treatment research teams worldwide embarked on methods to dissolve or leach Mg or Ca from minerals or industial by-products and wastes using strong or weak acids, alkali solutions or ligands. (See Huijgen and Comans 2003, 2005, Sipilä et al. 2008). For example, Teir and co-workers (2007a,b) dissolved serpentinite from the Hitura nickel mine mentioned above in both weak and strong aqueous solutions of common acids or bases at room temperature during 1 h. It was found that H2SO4 extracted most Mg, followed by HCl, HNO3, HCOOH and CH3COOH. None of the acids extracted Mg selectively, extracting also some Fe and Si. Carbonate precipitation experiments were made with two solutions prepared from serpentinite in strong solutions of HNO3 and HCl, respectively; after filtration and drying, the remaining salts were dissolved in water and iron oxides were precipitated. The magnesium-rich solutions (mainly dissolved magnesium nitrates or chlorides) were used to precipitate magnesium carbonates by exposing each solution to a CO2 flow while regulating pH using aqueous NaOH which was necessary for producing precipitates. Quite pure hydro-magnesite, Mg5(CO3)4(OH)2·4H2O was produced. However, the costs for pH regulating agent NaOH and for make-up acid make this route economically unviable. 2.3 Magnesium carbonate product stability and use Although large-scale mineralisation of CO2 allows for compact storage compared to storage as (super-critical) fluid, the surface disposal of the carbonate material may be problematic and unwanted at certain locations. Using MgCO3-containing material in, for example, building materials or flame retardants may be considered; in paper products however it can’t be used (Zevenhoven et al., 2006b). On the other hand, being also a product of natural weathering of silicate mineral, the carbonate is benign and stable when disposed of in nature. Tests showed that MgCO3 and CaCO3 are stable in rain water and acid solutions down to pH 1 (Teir et al., 2006), but a very slow dissolving in water bodies and streams could in fact be beneficial2. Increasing the concentrations of Mg2+, Ca2+ and HCO3- ions can provide a buffer to the decomposition of solid carbonate material under water, as the equilibrium reactions CaCO3(s) + H2O(l) + CO2(aq) = Ca2+(aq) + CO32-(aq) + H2O(l) + CO2(aq) = Ca2+(aq) + 2HCO3-(aq), with HCO3- being much better soluble than CO32-, will then be pushed to the left side. Thus preferable disposal sites for large amounts of MgCO3 product could be the open sea or ocean. 2 7/15 2.4 Current research in Finland Current work on carbonation of magnesium silicates in Finland focuses primarily on the use of gas/solid fluidised bed (FB) reactors operating at carbonation temperatures and pressures up to 600°C, 100 bar (super-critical conditions for CO2), supported by earlier experiments using (PTGA) and extensive thermodynamic analysis (e.g. Zevenhoven et al., 2006a, 2008). A test facility for this – see Figure 3 – was built and the experimenting has started (Fagerlund et al., 2008). One part of the work involves carbonation of Mg(OH)2 and MgO while at the same time developing methods (aqueous or gas/solid) for producing this from serpentinite rock (Nduagu, 2008). The process as it is currently being optimised at Åbo Akademi University and is shown schematically in Figure 4. Figure 3. Schematic lay-out of the fluidised bed set-up at Åbo Akademi University, showing the (vertical) fluidised bed reactor (i.d. ~1.4 cm, height ~40 cm) and the (horizontal) coil-shape gas pre-heating. In the far right upper corner the cyclone for separating particulates from the gas stream. CO2 Water Ammonia Ammonia Other gas Serpentinite Mg(OH)2 Ammonium sulphate MgCO3 Water Iron Ammonium sulphate Sillica etc. Figure 4. Schematic of the staged route for magnesium silicate carbonation 8/15 3. CARBONATION OF SLAGS FROM STEELMAKING INDUSTRY FOR PRODUCTION OF SYNTHETIC CALCIUM CARBONATE As the steel industry accounts for approximately 7% of the total anthropogenic CO2 emissions to the atmosphere (Kim and Worrell, 2002), meaningful reductions may be achieved by using steelmaking slags for carbon dioxide mineralisation. Due to a high calcium content, steelmaking slags appear very suitable for this method. The global theoretical CO2 emissions reduction potential of steelmaking slag carbonation is only 170 Mt/year (Eloneva, 2008) but reductions can be significant for individual steel mills. The end product of steelmaking slag carbonation could be quite pure calcium carbonate, if calcium would be extracted from the slags prior to carbonation. Calcium carbonate has wide markets and special precipitated calcium carbonate (PCC) has a price of > 100€/t (Nordkalk Oy, 2004), making the approach presented here an interesting option. By utilizing steelmaking slags for production of marketable calcium carbonate and using it to replace some of the natural and synthetic CaCO3 used in industry, savings in natural resources would be combined with CO2 emissions reduction. While various different mineral carbonation processes have been proposed, an economical and environmentally friendly process that could produce pure calcium carbonate with a low energy penalty has not yet been found. We have previously assessed the possibility to use an acetic acid process route, proposed by Kakizawa et al. (2001) for steelmaking slag carbonation (Teir et al., 2007; Eloneva et al., 2008a, b). It was found that acetic acid is efficient for dissolving steelmaking slags (Teir et al., 2007; Eloneva et al., 2008b), but precipitation of calcium carbonate from the resulting solution required addition of NaOH to allow carbonate precipitation (Eloneva et al., 2008a, b). This made the process too expensive and energy intensive. An effective calciumselective solvent that can be fully recovered and reused seems to be the key issue for developing a feasible process for producing pure calcium carbonate from steelmaking slags. Here, development work on producing pure calcium carbonate from steelmaking slag by carbonation is presented. Selective extraction of calcium from the slag is experimentally investigated using various solvents, and precipitation of calcium carbonate from dissolved calcium was also experimentally studied. 3.1 Dissolution of calcium from steelmaking slags 3.1.1 Solvent selection In order to find a suitable solvent for selective extraction of calcium from the steelmaking slag a range of relatively common (weak and strong) acids, bases and salts, as well as few other solvents were tested. Batches of steel converter slag (74 – 125 µm), provided by Raahe Works, were used for extraction tests; after filtration the concentrations of Ca, Si, Fe, Mg, Al, Mn, V and Cr in the filtered solutions were measured with ICP-AES and AAS. The steel converter slag sample used was also analysed by total digestion, ICP-AES, AAS, XRF and XRD. The results from the XRF and ICP-AES analyses of steelmaking slag are listed in Tables 2a and 2b. The sieved fraction was found to quite well represent the batch. 9/15 According to the XRD analysis, the major phases in steel converter slag are calcium iron oxide (Ca2Fe2O5), larnite (Ca2SiO4), lime (CaO), calcium hydroxide (Ca(OH)2), quartz (SiO2), and wuestite (FeO) (in decreasing order). Table 2a. XRF analysis of the steel converter slag batch, 0-1 mm Units in wt-% (±0.1 %). (elements larger than 1.0 wt-% listed). Ca 32.8 (±0.7) Fe 16.6 (±0.2) Si 6.5 (±0.1) F 6.1 (±0.5) Mg 2.22 (±0.06) Mn 2.3 (±0.1) Al 1.97 (±0.08) V 0.98 (±0.06) Table 2b. ICP-AES analysis of sieved fraction (74-125 µm) of steel converter slag (average of 4 sets, only selected elements measured. Units in wt-% (±0.1 %). Ca 30.1 Fe 14.4 Si 5.0 Mg 2.8 Mn 2.2 Al 1.2 V 1.1 Cr 0.2 As shown in Figure 5, calcium was dissolved efficiently (> 50 %) from the steel converter slag in most of the acids and ammonium salt solutions. 85-100 % of the slag’s calcium dissolved in all these acids with concentration greater than 0.5 M, while the strongest salt solutions were able to dissolve ~70-80 % of the calcium. Acetic acid dissolved calcium most efficiently. Calcium dissolved quite similarly in solutions of ammonium chloride and ammonium acetate, but ammonium nitrate was clearly the most efficient salt solution dissolving ~10 %-units more calcium than ammonium chloride or ammonium acetate. 100 CH3COOH HNO3 CH3CH2COOH Percent of calcium extracted (%) 80 NH4NO3 NH4Cl CH3COONH4 60 Al(NO3)3 (NH4)2SO4 H2SO4 40 NaCl (NH2)2CO CH3COONa Al2(SO4)3 20 NH4H2PO4 (NH4)2HPO4 NaOH 0 0 0.5 1 1.5 2 Solvent concentration (mol/l) Figure 5. Dissolution of calcium from steel converter slag (1 g) in various concentrations of different solvents (50 ml) at room temperature. Besides calcium extraction the selectivity for this element is important as well. While only weak concentrations of acids seem to be selective for calcium, all concentrations of 10/15 ammonium salt solutions (0.5-2 M) dissolved calcium selectively from the steel converter slag. Finally, besides the ability to dissolve calcium selectively from the slag, the solution should also be favourable for precipitation of calcium carbonate i.e. it should be alkaline before being exposed to CO2. It was found that the solutions that dissolve calcium selectively from the steel converter slag seem to result in an alkaline solution (pH > 7). More detail is given elsewhere (Eloneva 2008 a,b,c). The results given above were obtained at room temperature; testing for the range 30 70°C with aqueous solutions of ammonium acetate and ammonium chloride gave increased extraction with increased temperature. Particle size had an effect as well, with smaller particles giving more extracted calcium for a given time. Besides steel converter slag, also slags referred to as desulphurisation slag and from ladle slag (provided by Raahe Works) were used in extraction tests with acetic acid and ammonium salts at 30 °C. The results are shown in Figure 6. Percent of calcium extracted (%) 100 CH3COOH_L CH3COOH_D 80 CH3COONH4_L CH3COONH4_D 60 NH4NO3_L NH4NO3_D 40 NH4Cl_L NH4Cl_D 20 0 0.0 0.5 1.0 1.5 2.0 Concentration (mol/l) Figure 6. Dissolution of calcium from the ladle slag (pointed by the letter “L” after used solvent) and from the desulphurization slag (pointed by the letter “D” after used solvent) (1 g) in various concentrations of different solvents (50 ml) at room temperature. Thus, the ammonium salts ammonium acetate, ammonium nitrate and ammonium chloride are all three successful in selectively and efficiently extracting calcium from steel slags. The main role of these salts is to increase the solubility of calcium which, in water, would be limited by the solubility of calcium hydroxide. Besides the benefit of selectivity when compared to acetic acid and other acids, the resulting solution does not need the use of (expensive) NaOH or other pH modification chemicals that immediately render the processes uneconomical. One of current activities involves the optimisation of a continuous system – see Figure 7 - with minimum losses of the solvent chemicals used, i.e. the ammonium salt. Some testing with recycled solvent liquid was done, showing that losses of NH3 can be of the order of 10-15% per cycle. This implies that improved recovery of vaporised NH3 is essential or that a make-up stream of NH3 (rather than the ammonium salt itself) is necessary. 11/15 Residue Steel slag Ammonium salt (make-up) Carbonation Extraction CO2 CaCO3 Figure 8. Schematic of a continuous process for CaCO3 production from steel slags. 3.2 Precipitation of calcium carbonate 3.2.1 General Since formation of acid during carbonation of solution produced from the steelmaking slag and acid prevents efficient precipitation of calcium carbonate, ammonium salt solutions seem to be the most promising solvents for dissolving calcium selectively from the steelmaking slags prior to carbonation. For acetic acid another possibility could be the use of for example tributyl phosphate (TBP) for extracting the acid from the water phase as it is produced during carbonation – see Eloneva et al., 2008c. 3.2.2 Carbonation of calcium containing ammonium salt solution Due to promising results with the ammonium salt solutions and the steel converter slag, precipitation of calcium carbonate was tested by carbonating aqueous solutions containing ammonium salts and calcium dissolved from the steel converter slag, at room temperature (~20°C). First, steel converter slag was extracted with the three ammonium salts (ammonium acetate, nitrate and chloride). Then the residual slag was removed and solution samples were taken for Ca analysis (ICP-AES). The filtered solution of ammonium salt and dissolved steel converter slag was carbonated; the precipitate was washed, dried and analysed using XRD, XRF, total carbon (TC) and SEM. The XRD analysis showed that all precipitates consisted of calcium carbonate as calcite. The XRF and TC analysis confirmed that the major elements of the precipitates were Ca and C. The sum of other components identified by XRF amounted only to 0.14–0.21 wt%, indicating that the purity of the calcite produced was 99.8 %. The SEM pictures of the precipitate showed that the precipitates were in the form of rhombohedral calcite with a diameter of about 5–30 µm – see Figure 9. The total conversion of calcium in the slag to calcium in the precipitate was 26-32%. 12/15 However, conversions of calcium from calcium containing solutions to calcium in the precipitate were much higher (~50-70 %), indicating that the calcium extraction had not been as efficient as with the dissolution experiments. This is probably due to the low stirring speed during calcium extraction and could be solved by using better equipment for stirring. Also, as mentioned above, the losses of NH3 from the process lead to significant amounts of dissolved calcium in the liquid after the carbonation step. Figure 9. SEM pictures of the precipitates produced from the solution of ammonium salt and dissolved steel converter slag. 4. CONCLUSIONS Mineralisation of CO2 is an interesting (due to its enormous potential at very many locations) and urgent (due to the slow deployment of geological storage of CO2) option for CCS that appears to have great potential for countries like Finland where this appears to be the only CCS option. An overview was given of methods and procedures for magnesium silicate carbonation, with emphasis on processes that involve a gas/solid route for the carbonation step, preferably using Mg(OH)2. Based on that, a stepwise process using a high pressure high temperature fluidised bed is being developed for carbonation at up to 600°C, 100 bar (allowing for super-critical conditions for CO2). Besides this, a production route for Mg(OH)2 from serpentinite rock is being optimised. Also reported here was the production of pure calcium carbonate from steelmaking slags by carbonation. The key issue is to find a solvent that would dissolve calcium selectively and efficiently and could be fully recovered and reused. It was found that acetic acid dissolved calcium most efficiently (~100 %), while ammonium nitrate was clearly the most efficient salt solution (~ 80 %). The ammonium salt (ammonium acetate, ammonium nitrate and ammonium chloride ) solutions were found to dissolve calcium selectively from the steel converter slag and resulted in an alkaline solution, likely favourable for precipitation of calcium carbonate. It was found that the higher the solution temperature, the higher was the ratio of dissolved calcium and the smaller the slag’s grain size distribution, the higher was the calcium extraction. These results are in a good agreement with results by Kodama et al. (2008), who also studied experimentally the dissolution of steel converter slag in ammonium chloride solutions followed by precipitation of calcium carbonate. Precipitation experiments were carried out with solutions containing ammonium salt and dissolved steel converter slag as well as with the solution of acetic acid and dissolved steel converter slag. It was found that calcium carbonate precipitated as rhombohedral calcite from the solution containing 13/15 ammonium salt and dissolved steel converter slag. Calcium conversion from the solution into the precipitate was 50-70 %, while the purity of the precipitate was 99.8 %. The next task is to find out which solvent gives the cheapest and most efficient route to produce pure calcium carbonate from the steelmaking slags. 5. ACKNOWLEDGEMENTS The work on magnesium silicate reported here was done under Ekokem Oy support funding (2000); the Finnish National research programmes ClimTech (1999-2002) and ClimBus (2004-2008) by the Finnish Funding Agency for Technology and Innovation Tekes; Nordic Energy Research (2003-2007); KH Renlund Foundation (2007,2008); and the Academy of Finland research programme Sustainable Energy (2008-2011). The work on steel slag carbonation was done under Tekes’ research programme ClimBus (2004-2008), projects Slag2Pcc (2005-2007) and Slag2Pcc+ (2007-2009). 6. REFERENCES BÉARAT, H., MCKELVY, M.J., CHIZMESHYA, A.V.G, SHARMA, R., CARPENTER, R.W. (2002) Magnesium hydroxide dehydroxylation/carbonation reaction processes: Implications for carbon dioxide mineral sequestration. J. Amer. Ceram. Soc. 85(4), 742-748 BUTT, D.P., LACKNER, K.S., WENDT, C.H., CONZONE, S.D., KUNG, H., LU, Y.-C., BREMSER, J.K. (1996) Kinetics of Thermal Dehydroxylation and Carbonation of Magnesium Hydroxide. J. Amer. Ceram. Soc., 79(7), 1892–1898. CEC (2008). Commission of the European Communities, Proposal for a Directive of the European Parliament and of the Council on the Geological storage of carbon dioxide and amending council directives, COM(2008)XXX, 23.1.2008 CHIZMESHYA, A.V.G., MCKELVY, M.J., SHARMA, R., CARPENTER, BEARAT, H. (2002) Density functional theory of the decomposition of Mg(OH)2: a lamellar dehydroxylation model. Mat. Chem. & Phys. 77, 416-425 ELONEVA, S. (2008) Co-utilisation of CO2 and steelmaking slags for precipitated calcium carbonate production. Lic. tech. thesis, Helsinki Univ. of Technol., Espoo Finland ELONEVA S., TEIR S., SALMINEN J., FOGELHOLM C.-J., ZEVENHOVEN R., (2008a) Fixation of CO2 by carbonating calcium derived from blast furnace slag. Energy, 33, 1461-1467 ELONEVA S., TEIR S., SALMINEN J., FOGELHOLM C-J., ZEVENHOVEN R., (2008b) Steel converter slag as a raw material for precipitation of pure calcium carbonate. Ind. & Eng. Chem. Res. 47, 7104-7111 ELONEVA, S., TEIR, S., SALMINEN, J., REVITZER, H., FORSMAN, A.-M., ZEVENHOVEN, R. FOGELHOLM, C.-J. (2008c) Pure calcium carbonate product from the carbonation of steelmaking slag. Proc. of ACEME-08, Rome (Italy) October 1-3, 2008, 239-248 FAGERLUND, J., TEIR, S., NDUAGU, E., ZEVENHOVEN, R. (2008) Carbonation of magnesium silicate mineral using a pressurised gas-solid process presented at GHGT-9, Washington (DC), November 16-20, 2008 GERDEMANN, S.J., O’CONNOR, W.K., DAHLIN, D.C., PENNER, L.R., RUSH, H. (2007) Ex Situ Aqueous Mineral Carbonation Environ. Sci. Technol. 41, 2587-2593 HERZOG, H. 2002. Carbon sequestration via mineral carbonation: overview and assessment, MIT Laboratory for Energy and the Environment, Cambridge (MA) U.S., March 14, 2002 HUIJGEN, W.J.J., COMANS, R.N.J. (2003) Carbon dioxide sequestration by mineral carbonation. Energy Research Centre of the Netherlands (ECN), Report ECN-C--03-016 HUIJGEN, W.J.J., COMANS, R.N.J. (2005) Carbon dioxide sequestration by mineral carbonation – Literature Review Update 2003-2004. Energy Research Centre of the Netherlands (ECN), Report ECNC--05-022, Report 2005/11. IEA Greenhouse Gas R&D Prog. IPCC 2005. Special Report on Carbon Dioxide Capture and Storage. Metz, B., Davidson, O., de Coninck, H.C., Loos, M., Meyer, L.A. (Eds.) Cambridge University Press, U.K. 14/15 KAKIZAWA M., YAMASAKI A., YANAGISAWA Y. (2001) A new CO2 disposal process via artificial weathering of calcium silicate accelerated by acetic acid. Energy 26, 341-354. KIM Y., WORRELL E. (2002) International comparison of CO2 emission trends in the iron and steel industry. Energy policy 30, 827-838. KODAMA S., NISHIMOTO T., YAMAMOTO N., YOGO K., YAMADA K., (2008). Development of a new pH-swing CO2 mineralisation process with a recyclable reaction solution. Energy 33, 776-784. KOLJONEN, T., H. SIIKAVIRTA, R. ZEVENHOVEN, I. SAVOLAINEN (2004), CO2 capture, storage and reuse potential in Finland, Energy 29, 1521-1527. LACKNER, K. S. (2003) A guide to CO2 sequestration. Science 300, 677-1678. NDUAGU, E. I. (2008), Mineral carbonation: preparation of magnesium hydroxide [Mg(OH)2] from serpentinite rock. MSc (Eng) thesis, Åbo Akademi Univ., Heat Engineering Lab., Turku, Finland NEWALL, P.S., CLARKE, S.J., HAYWOOD, H.M., SCHOLES, H., CLARKE, N.R., KING, P.A., BARLEY, R.W. (2000) CO2 storage as carbonate minerals, Report PH3/17 IEA Greenhouse Gas R&D Prog. NIEMINEN, M. (2008) Carbon dioxide capture and storage (CCS) possibilities in Finland (in Finnish), Energiakongressi 2008, October 29, 2008, Tampere Finland NORDKALK OY (2004) Price data supplied by Nordkalk Oy, June 2004. O'CONNOR, W.K., DAHLIN, D.C., RUSH, G.E., GERDEMANN, S.J., PENNER, L.R., NILSEN, R.P., (2005) Aqueous mineral carbonation: Mineral availability, pretreatment, reaction parametrics, and process studies, Report DOE/ARC-TR-04-002, Albany Research Center, Albany (OR) U.S. RINNE, J. (2008). CO2 sequestration potential of industrial by-products and waste materials in Finland. MSc (Eng) thesis, Helsinki Univ. of Technol., Espoo Finland SIPILÄ3, J., TEIR, S., ZEVENHOVEN, R. 2008. Carbon dioxide sequestration by mineral carbonation – Literature Review Update 2005-2007, Åbo Akademi Univ., Heat Engineering Lab. report VT 2008-1. URL: http://web.abo.fi/~rzevenho/MineralCarbonationLiteratureReview05-07.pdf TEIR, S., ELONEVA, S., FOGELHOLM, C.-J., ZEVENHOVEN, R. 2006. Stability of calcium carbonate and magnesium carbonate in rainwater and nitric acid solutions. Energy Conv. & Manage. 47, 3059-3068. TEIR, S., REVITZER, H., ELONEVA, S., FOGELHOLM, C.-J., ZEVENHOVEN, R. (2007a) Dissolution of natural serpentinite in mineral and organic acids. Int. J. of Mineral Proc. 83, 36-46 TEIR, S., KUUSIK, R., FOGELHOLM, C.-J., ZEVENHOVEN, R. (2007b) Production of magnesium carbonates from serpentinite for long-term storage of CO2. Int. J. of Miner. Proc. 85, 1-15 TEIR S., ELONEVA S., FOGELHOLM C-J., ZEVENHOVEN R., (2007c) Dissolution of steelmaking slags in acetic acid for precipitated calcium carbonate production. Energy 32, 528-539 TEIR, S. 2008. Fixation of carbon dioxide by producing carbonations from minerals and steelmaking slags. PhD (Eng) thesis, Helsinki Univ, of Technol., Espoo Finland T&T (2008) Tekniikka & talous, January 18, 2008. VANGKILDE-PEDERSEN, T. (2008) Assessing European Capacity for Geological Storage of Carbon Dioxide - the EU GeoCapacity Project. Presented at GHGT-9, Washington (DC), November 16-20, 2008 ZEVENHOVEN, R., KOHLMANN, J., MUKHERJEE, A.B., (2002) Direct dry mineral carbonation for CO2 emissions reduction in Finland Proc. of 27th Int. Conf. on Coal Utilisation and Fuel Systems, Clearwater (FL) U.S., March 2002, 743-754 ZEVENHOVEN, R., TEIR, S., 2004. Long term storage of CO2 as magnesium carbonate in Finland, Proc. of Third Ann. Conf. on Carbon Capture and Sequestration, May 2004, Alexandria (VA), U.S., ZEVENHOVEN, R., ELONEVA, S., TEIR, S., 2006a, A study on MgO-based mineral carbonation kinetics using pressurised thermogravimetric analysis, Proc. of GHGT-8, June 2006, Trondheim, Norway, paper P02_01_09. ZEVENHOVEN, R., ELONEVA, S., TEIR, S., (2006b), Chemical fixation of CO2 in carbonates: routes to valuable products and long-term storage Catal. Today, 115, 73-79. ZEVENHOVEN, R., TEIR, S., ELONEVA, S. (2008a). Heat optimisation of a two-stage gas/solid mineral carbonation process for long-term CO2 storage. Energy 33(2), 362-370 ZEVENHOVEN, R., SIPILÄ3, J., TEIR, J. (2008b) Motivations for carbonating magnesium silicates using a gas-solid process route Proc. of ACEME-08, Rome (Italy) October 1-3, 2008, 45-54 3 Nowadays: Fagerlund, J. 15/15