Thermometry Cryogenic Instrumentation I OUTLINE

advertisement

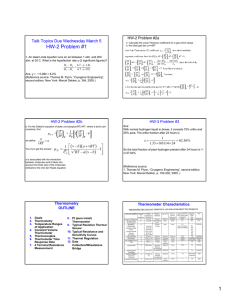

Cryogenic Instrumentation I Thermometry OUTLINE 1. 2. 3. 4. 5. 6. Thermometry Temperature Ranges of Application Constant Volume Thermometer Thermocouples Thermometer Time Response Data 4 Terminal Resistance Measurement 8. Pt (pure metal) Thermometer 9. Typical Resistive Thermal Sensor 10. Typical Resistance and Sensitivity Curves 11. Thermal Regulation 12. Data Collection/Wheatstone Bridge Temperature Ranges of Application Constant Volume Thermometer •Named after Sir Fancis Simon •Helium is an ideal gas down to 5 K •Modern versions use in situ pressure gauges at low T with electrical read-out (no gas line from RT to Low T) RT Gas line Low T Helium gas Thermocouples Wires of 2 different metals (pure or alloy) when joined and connected to a volt meter produce a voltage related to temperature. At right is the sensitivity of various common thermocouples, perhaps the simplest, least expensive, and most common thermometer in use. Usually a reference junction in an ice bath is used to make the measurement absolute. Thermometer Time Response Data Differences between wet and dry can be exploited for level detection Calibrations are tabulated (e.g. type K) Figure adapted from Cryogenic Engineering by Thomas M. Flynn, Dekker:NY (1997), p. 530 Figure adapted from Cryogenic Engineering by Thomas M. Flynn, Dekker:NY (1997), p. 495 1 Pt (pure metal) thermometer 4 Terminal Resistance Measurement •Resistance thermometer—use 4 terminal set-up •R is almost proportional to T: Callender-VanDusen Equation: R(T)=R0[1+AT+BT2+C(T-10)T3] (0 K<T<300K) Other calibrations available down to 20 K •Purity determines calibration (A, B, C)-no individual calibration required •Transfer standard used by NIST Meter at RT must have high input impedance Leads from RT to Low T must have low heat leak (alloy) Thermometer at low T Current source must be stable and reversible. Average of readings with current flowing in opposite directions gives correct voltage drop, canceling thermal emfs. Often, low frequency ac source is used, with lock-in detector as volt meter, to improve sensitivity. Figure adapted from Cryogenic Engineering by Thomas M. Flynn, Dekker:NY (1997), p. 512 Typical Resistive Thermal Sensor Typical Resistance and Sensitivity Curves 106 Cross-section:Details of construction showing strain-free mounting of chip (#4) inside hermetically sealed container Ge on GaAs substrates Produced in development of Maximum sensitivity at 20 K (liquid hydrogen) Resistance () 105 104 TTR-G TTR-D 103 101 0.01 0.1 1 10 100 Temperature (K) Photo of sensor with leads Temp. Monitor Temperature Input-set point TTR-G 3 TTR-D 2 1 0 0.01 0.1 1 10 100 Temperature (K) Data Collection/Wheatstone Bridge Thermal Regulation PID Heater Response Dimensionless Sensitivity (S) 102 Dewar Computer with data acquisition board Computer board Break-out box source detector Resistor Heater Thermometer Computer data acquisition board may be used for all electronics InputCurrent level Temperature sensor Decade Resistor Resistor R Resistor R Temperature Temperature measurement and control is easily automated 2 Cryogenic Instrumentation II OUTLINE 1. 2. 3. 4. Pressure Measurements Pressure Transducers Characteristics Thermal Conductivity Measurements Example: Ortho-Para Ratiometer 5. 6. 7. 8. Level Detection-Point Level Detection-Continuous Thermometer Time Response Data-again Flow Metering Typical Pressure Transducers Pressure Measurement at Low Temperature •Pressure is a force applied to an area, so its measure involves the conversion of a force measurement to some measurable parameter •Converters, or transducers may be: Electrical: Capacitive-diaphragm Inductive-reluctive Resistive-strain gauge Mechanical-spring Piezoelectric-quartz crystal •These devices may often be connected to low temperature volumes using small tubes, avoiding cooling the transducer •Most transducers operate at low temperature, although sensitivity and calibration are usually changed •Low temperature devices often work better than at room temperature because the environment is more controlled Mechanical Pressure Gauge Bourdon Tube Capacitive Inductive Piezoelectric Figure adapted from Cryogenic Engineering by Thomas M. Flynn, Dekker:NY (1997), p. 457 Characteristics of Transducers Figure adapted from Cryogenic Engineering by Thomas M. Flynn, Dekker:NY (1997), p. 458 Temperature Dependence of Transducer Output Figure adapted from Cryogenic Engineering by Thomas M. Flynn, Dekker:NY (1997), p. 459 3 Ultra-sensitive/Low Temperature Pressure Transducer Capacitive Manometer Push Rod Connections to Capacitance Bridge Supports Developed strain-type (similar to UF “Straty-Adams” gauge) in situ capacitive probe with resolution of 1 Pa Requires at least 15 J for 1 measurement (cap(capacitor plate moves 0.01 Å)) Maximum Volume displaced ~1.3 liters 10 cm Membrane which Flexes Under Pressure Capacitor Plates Screen C Differential Pressure Gauge 25 cm C Pressure Transducer Test Apparatus Tested in liquid nitrogen and liquid helium Test Port Reference Port MEMS Technology for Sensor Construction Perfect size range blockkkkkk Design Of Piezo-resistive Pressure Sensors Typical design: 4 piezo-resistors in Wheatstone bridge on a diaphragm diaphragm deflects from applied pressure causing the deformation of the piezo-resistors mounted on the surface Wheatstone bridge Piezo-resistive Pressure Sensor SM5108 Piezo-resistive Pressure Sensor SM5108 Semiconductor resistors joined by aluminum conductors in bridge configuration Resistors placed on diaphragm Two strained parallel to I Two strained perpendicular to I Manufactured by Silicon Microstructures, Inc. 4 Drawbacks of Piezo-resistive Pressure Sensors-Results Relatively low sensitivity Large temperature dependence temperature compensation necessary Voltage vs Pressure for Piezoresistive Transducer at varying temperatures 55 300 K 91.2 K - 94.6 K 64.4 K - 66.0 K 49.8 K - 51.0 K 40.4 K - 43.5 K 29.9 K - 30.4 K 22.9 K - 26.0 K 26.2 K 50 45 Voltage (mV) 40 35 30 Principle of Gas Thermal Conductivity Measurement Regulate the temperature of a pure metal film separated by the H2 gas from a constant T heat-sink Metal film is both heater and thermometer Qtotal=QH2 conduction +Qconvection +Qradiation +Qstructural supports 25 Q H2 gas: ortho-para mixture T T=constant 20 Design makes the hydrogen conduction dominate Planar design—linear heat conduction 15 10 5 0 0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 Q T Pressure (Bar) Conductivity Cell Cross Section Expanded View of Actual Cell Ortho -Para Hydrogen Ratio- Meter Inlet Needle Valve l m Wires & Connector Outlet Needle Valve k S.S. Cap j Inner Wire connec. n d b a g I Cold Cu Plate Nylon Screw c Second Thermal Insulation Layer f LN e In Seal S.S. Can 2 Mylor Spring Pure Ni heater & Thermometer Quartz Spacer (Low Ther. Ex. & low Thermoconductivity Thermal Insulation Electrical Resistance of Nickel micro-ohm-cm 40 60 80 100 120 A Pure Metal Makes a Good Thermometer and Heater Use Feed-back Loop to hold Resistance Constant Heater R R-set R Principle of Ratio Measurement Regulate the temperature of a pure metal film separated by the H2 gas from a constant T heat-sink Metal film is both heater and thermometer Qtotal=QH2 conduction +Qconvection +Qradiation +Qstructural supports Q H2 gas: ortho-para mixture T=constant 20 Our design makes the hydrogen conduction dominate Planar design—linear heat conduction -100 0 100 T(C) 200 T Q T 5 Level Detection-Point Point (discrete) level detectors Any device which changes property when submerged from vapor to liquid (wet or dry) can be a point level detector. • Ex. 1 Device is heated, and the property change (e.g. resistance) is a result of temperature change caused by the large difference in thermal contact and hence heat conduction between the device and its surroundings. • Ex. 2 The Q of a piezo-electric oscillator depends on loading • Ex. 3 Capacitance depends on dielectric between plates • Ex. 4 Motion of paddle or wire depends on viscous drag • Ex. 5 Float and switch Drawbacks •Indication does not change when level is between discrete sensors. • Fluid can not be multiply connected, such as when there is a lack of gravity Thermometer Time Response Data-again Level Detection-Continuous Continuous level detectors Any device which changes property when submerged from vapor to liquid (wet or dry) and can be made long (1dimensional) can be a continuous level detector. •Ex. 1 Resistive strip or Superconducting wire carrying enough current to self heat •Ex. 2 Optical or Acoustic beam which suffers different attenuation in liquid and gas or reflects from interface •Ex. 3 Long tubular Capacitor Drawbacks •May produce unnecessary heat Advantanges • Higher resolution of level determination • Fluid can be multiply connected in Ex. 2, such as when there is a lack of gravity Flow Metering Differences between wet and dry can be exploited for level detection All types of flow meters may be adapted to cryogenic liquids: Positive displacement-measures volume displacement Pressure drop-may cause cavitation Turbine-measures volume displacement Momentum-measures mass directly Vortex shedding-velocity and no moving parts! Doppler shift-difficult Figure adapted from Cryogenic Engineering by Thomas M. Flynn, Dekker:NY (1997), p. 495 6