Home-made Electric Brooders Oregon State System of Higher Education Agricultural Experiment Station

advertisement

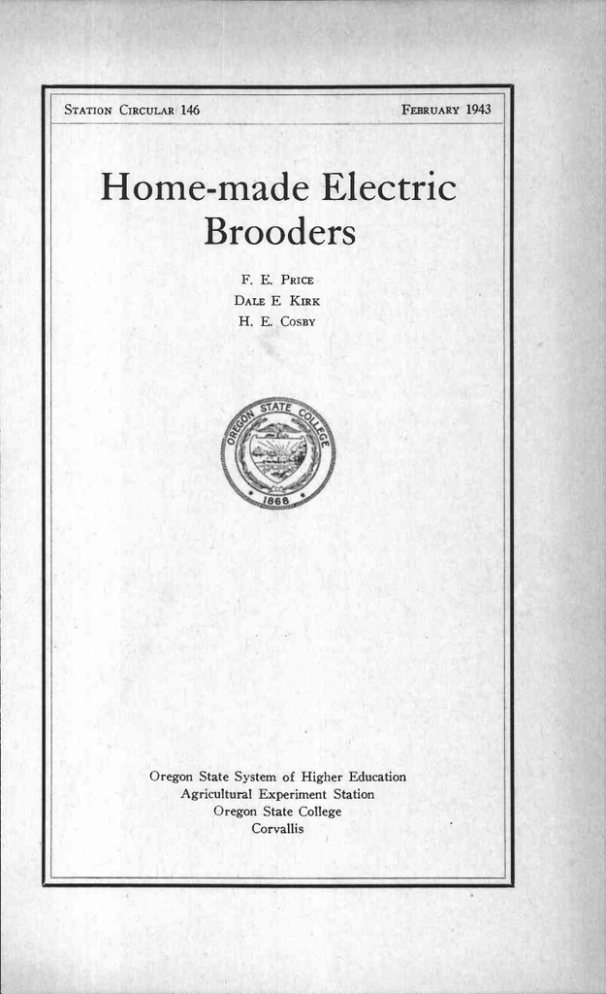

FEBRUARY 1943 STATION CIRCULAR 146 Home-made Electric Brooders F. E. PRICE DALE E KIRK H. E. COSBY Oregon State System of Higher Education Agricultural Experiment Station Oregon State College Corvallis FOREWORD The restrictions on the supply of materials for civilian use caused by the demand for increased production of war materials have created many equipment problems for farmers. The Oregon Agricultural Experiment Station has adjusted its research program in an attempt to solve these problems by new designs that will permit the use of noncritical materials in order to assist producers to increase the food production of our country. Poultrymen are confronted with the problem of obtaining new electric brooders. Electric heating elements and galvanized sheet metal for hovers are no longer available for the manufacture of this equipment for poultry farms. This circular presents plans and instructions so that poultrymen, high school vocational agriculture students, and local shops can build electric brooders from materials that can still be purchased from local dealers. Instructions for proper operation of the brooders and care of the chicks are also included. Dean and Director Home-made Electric Brooders F. E. PRICE, Agricultural Engineer DALE E. KIRK, Research Assistant, Agricultural Engineering H. E. COSBY, Poultry Husbandman INTRODUCTION restrictions on use of critical materials have so limited the supply of THE electric brooders that a strong demand has arisen from poultry producers for plans of an inexpensive, practical, electric brooder that can be made from materials that can now be purchased from local dealers. This circular presents construction plans and instructions for operation and management of three types of homemade electric brooders that have been tested by the Poultry and Agricultural Engineering departments of the Experiment Station. All these brooders use flat-top wood hovers, the material for which should be available in all parts of Oregon. Each of the three brooders has a different type of heating element. One plan is for a small brooder for 50 chicks or less that uses electric lamps as a source of heat with or without a thermostat. This type of heating for small brooders has been used successfully by a number of states. Another plan explains fully the use of iron stovepipe wire as a heating element with a thermostat to control the heat. This brooder is planned for 200 chicks until 8 weeks old. A third type is a 300-chick brooder designed for use with a ready-made kit consisting of a forced ventilation and electric heating unit with thermostat to be installed in a homemade hover. While this type of heating equipment is very limited in quantity, these plans were drawn up to supply information in answer to many requests for such equipment. BROODER CONSTRUCTION Brooder for 50 chicks or less. The brooder shown in Figure 1 has a 2' x 2' plywood top framed by 1 x 8 boards and uses ordinary lamp bulbs for the heating element. The 1 x 8's are nailed together so that the width of the board is the vertical dimension. Inside of this frame 1" x 2" cleats are nailed to form a support for the 2' x 2' sheet of plywood. The 1" x 2" cleats should be placed so that the top edge is 5 inches above the bottom of the frame. The plywood can then be dropped inside the frame from the top where it will rest on the cleats and can be held in place by light nailing. Legs should be placed on the four corners of the frame and should extend 3 inches below the frame of the hover to place the brooder at the proper height to start the brooding season. As brooding progresses, it will be necessary to raise the hover each week as the chicks grow. This can be done by one of the following methods: Block up the legs to the desired height. Install adjustable legs as shown in Figure 2. Attach ropes to the four corners of the brooder that converge at one point over the brooder where they are attached to a single rope with pulley and counterweight. desired height. In this manner the brooder can be set at any X 2 SHEET OF 1/4" PLY-' 1X2- 1 LONG IXB-2 3/4" LONG 1X2-11l 1/4" LONG Figure 1. The SQ-chick electric brooder hover. A jrI1 .1 4 0 N V SECTION A-A A Figure 2. Section view of leg and hover construction when slotted legs are to be used for adjusting the height of the 50. and 200.chick brooders. P5 HOME-MADE ELECTRIC BROODERS In order to conserve heat, it is always desirable to provide insulation to prevent heat losses through the hover. In this brooder it is done by filling the top of the hover with straw or whatever litter is being used on the brooder floor. This will provide about 2 inches of good insulation on top of the hover and will also serve to keep the top clean. This litter can be changed from time to time as desired. Ordinarily an electric brooder is equipped with a thermostat for automatic heat control. Since the shortage of critical materials may make it impossible to buy a thermostat, plans are shown for wiring this brooder with and without WAFER TYPE ThERMOSTAT WITH SNAP AC11ON SWITCH 1X8 SIDE 1X2 LEG X2 CLEAT cL Gil II 011 6" LI Figure 3. Underside of the 50-chick hover showing wiring layout with thermostat when lamps are used as heating elements. 6 AGRICULTURAL EXPERIMENT STArrON CIRCULAR 146 automatic heat control. Figure 3 shows the location of the lamp receptacles and the necessary wiring when a thermostat is used. The inner receptacle holds the attraction light, which is on continuously. The four outer lights are controlled by the thermostat and go on and off as required to maintain the necessary heat under the hover. Fifty-watt lamps in all five receptacles should provide sufficient heat under ordinary conditions. If this Size brooder is to be constructed without a thermostat, Figure 4 indicates the location of the lamp receptacles and the method of wiring. The total output of heat may be varied by the use of different sizes of lamps, or by partly unscrewing some of the lamps as required. 1X8 BRO'ODER SIDE 1X2 CLEAT PORCLEAN RECEPTACLES 1X2 LEG -* ,OI I N- 0 Figure 4. Underside of the 50-chick hover showing wiring layout without thermostat when lamps are used as heating elements. The 200-chick homemade electric brooder. The brooder illustrated in Figures 5 and 6 has been developed in answer to the wartime need for a plan that would provide for the construction of a poultry brooder with a minimum amount of critical materials and still meet the necessary requirements of a brooder from the standpoint of the poultrymen. 7 HOME-MADE ELECTRIC BROODERS The hover for this brooder is shown in Figure 5 and is built with an outer frame of 1 x 8's with a quarter inch plywood top in the same way that the 50-chick brooder is constructed with two exceptions: First, a 1 x 4 board should be placed on edge ac ross the middle of the hover just above the plywood to help prevent warpage. The plywood should be nailed to this 1 x 4 cross piece from the underside. Secondly, the top of the 1 x 2 cleats nailed to the inside of the frame should be only 3 inches above the bottom of the 1 x 8's 1X8-4 3/4' LONG X44 LONG--, 1X2 I' LONG 1X84 3/4 LONG 4X4' SHEET OF /4' X23' II Figure 5. '4' LONG The 200-chick electric brooder hover. instead of the 5 inches recommended for the 50-chick brooder. This provides greater space in the top of the hover for insulation and still leaves sufficient clearance on the underside of the plywood because of the dilterent type of heating clement used. This brooder is designed for operation without a curtain and was found quite satisfactory in tests at the College in 1942. A thermometer can be passed through a hole cut in the hover and suspended from the cap used to cover the hole. At the beginning of the brooding period the thermometer should be located 21 inches above the litter floor. Electric heating element and temperature control. Nichrome wire is ordinarily used for heating elements in brooders but is difficult or impossible to obtain for this purpose during the war. It has been found by experimental tests that 163 feet of iron stovepipe wire when installed as shown in Figure 6 makes a very satisfactory substitute electric heating element in connection with brooding. This wire is fastened directly against the underside of the plywood hover by single-pointed carpet tacks along the two edges of the hover, and with three rows of double-pointed tacks in the middle area. 8 AGRICULTURAL EXPERIMENT STATION CIRCULAR 146 When selecting the wire be certain it is of the proper size by checking it in at least one of the following ways: Have it measured with a micrometer. diameter. It should be 0,0348 inch in Check it on a Washburn & Moen Wire Gauge. It should be size No. 20. Check it on an American Standard (Brown and Sharpe) wire gauge. It should be smaller than No. 20 and larger than No. 19. In case of doubt as to whether the wire is of the proper size, send it to the Agricultural Engineering Department at Oregon State College and it will be checked and promptly returned free of charge. The arrangement and spacing for installing exactly 163 feet must be followed as shown in Figure 6. The three middle rows of double-pointed tacks are very necessary in order to keep the wire from sagging below the hover. This is particularly important because of the expansion of the wire when the electricity is turned on and it begins to operate as a heating element. The 163 L 4 - _Pv Figure 6. Underside of the 200.chick electric brooder showing proper wiring installation to use 163 feet of iron stovepipe wire as a heating element. Note that the stovepipe wire is tacked and stapled against the wood hover. 9 HOME-MADE ELECTRIC BROODERS feet of iron stovepipe wire will make a 9(10-watt heating element on 120 volts, which is adequate for this size of brooder. The wire operates at sufficiently low temperature so that it will not in any way cause a fire hazard by being in contact with the plywood hover. It is imperative, however, that the wire be of the type, size, and length specified to operate with safety. To prevent rusting of the element when not in use, the iron wire should be protected by a thin film of oil. This can be easily applied with a paint brush without removing the wire from the hover. Rusty wire should never be used as a heating element. The wire should be inspected at the beginning of each brooding season and if found to be rusting it should be replaced with a new wire of the same type, length, and size. The electric service is brought into one corner of the brooder through the top or the side, depending upon the most convenient arrangement for the thermostat used. The porcelain receptacle shown in Figure 6 is for the installation of an attraction light and must be so wired that it is on at all times. As the brooding season progresses the operator may turn this light off by unscrewing the bulb, if he so desires. Poultrymen who have operated electric brooders that are equipped with a pilot light that signals the on and off position of the thermostat may wonder why none is provided for this brooder. It is unnecessary in this brooder because the wire used for the heating element makes a sufficiently loud humming noise to indicate easily to the operator the on and off position of the thermostat. The only specialized piece of poultry brooder equipment required in this plan is the thermostat. Fortunately most poultry equipment supply houses are now standardizing on a snap-action thermostat that is operated by an ether wafer and is very much superior to the old type of slow breaking thermostats that were common on all of the earlier makes of electric brooders. Homemade hover for fan-type electric brooder, 300-chick capacity. Dtiring the last few years the fan-type forced ventilation electric brooder has become quite popular throughout the Pacific Northwest area. These brooders include a very small electric fan that draws fresh air in through the center and top of the hover and discharges it downward against a baffle, which deflects the air horizontally in all directions under the hover. As the air leaves the fan it passes across an electric heating element and this warm air then moves to all ADJUSTMENT SCREW AND AIR INTAKE I X 12, 5 LONG I. 2 LAYERS OF I4' PLY WITH INSULATION BETWEEN LOOSE PIN HINGES FOR EASY REMOVAL OF WINGS FOR STORAGE 1X4, B' LONG 1X4, 1' II I/4LONG 2X2 LEGS 10' LONG CANVAS CLTAIN IXI2, I0LONG 1X2 AIR SEAl. Figure 7. The 300-chick forced ventilation electric brooder with hLnged wings extended to show method of construction. This brooder requires a special electric kLt including a fan, heating unit, and thermostat. 10 AGRICULTURAL EXPERIMENT STATiON CIRCULAR 146 parts of the brooder and is discharged under the curtain surrounding the hover. Some manufacturers have offered the electric fan, heating element, and thermostat in a compact, completely assembled unit, which could be mounted in a homemade hover. While the supply of these fans will undoubtedly be very limited for the duration of the war, the following plans are offered for those who are interested in this type of brooder and may be in a position to obtain the necessary fan, heating unit, and thermostat assembly for a homemade hover. A hover of the type shown for the 200-chick brooder, Figure 5, could be used with a forced ventilation kit by moving the 1 x 4 that is installed on the top of the plywood so as to permit the installation of the ventilator and fan in the center of the hover. If this type of hover is used as a force ventilated brooder a curtain must be used. The plans presented in Figure 7 show a method of building a homemade 5' x 5' hover for a force ventilated brooder in which the center section is stationary and the two side sections are hinged so that each can be easily raised for inspection of the chicks under the hover. The center section is made of a 1 x 12 with the top piece 5 feet long, supported by two end pieces 10 inches in length. The intake for the fan is usually a round pipe about 2f or 3 inches in diameter that would require a hole of the same size through the center of the 1 x 12 board. To the center section are hinged the two side wings. The wings are usually made of two layers of f-inch plywood with corrugated cardboard or f-inch insulation board between for insulation. The plywood is supported on three sides by a 1 x 4 frame. The 2 x 2 legs and canvas curtaincomplete the hover. MANAGEMENT AND OPERATION Improper heat, brooding more chicks than either the brooder or brooder room will accommodate, soil contamination, and faulty nutrition are the most common hazards to guard against in brooding chicks. Temperatures. The empty brooder should be regulated to a temperature of 92° to 95° Fahrenheit at a height of about 2f inches above the floor litter level before the chicks are put under the brooder. The thermometer may be placed on a block 2f inches above the floor or may be suspended from the hover to the proper height above the floor. To keep the chicks from wandering away from the brooder until they have learned where to go for heat and how to eat and drink, an enclosure wall made of cardboard, fine-mesh wire, or hinged boards should be set up around and a few inches from the brooder. As brooding age advances, the temperature under the brooder should be gradually reduced. The operator soon learns from observing the chicks whether or not they are comfortable. Too much heat will drive them out from under the brooder while too little heat will cause them to crowd the center of the brooder. Brooding capacity. If all the day old or started chicks placed under the brooder are to use the brooder as long as artificial heat is needed, allow at least 12 to 14 square inches of heated area under the brooder for each chick. Brooder room capacity. If all the chicks brooded are to remain in the brooder house with or without access to a small natural yard or artificial porch for a period of 8 weeks, 1 square foot of floor space should be allowed per HOME-MADE ELECTRIC BROODERS bird. 11 The number of chicks to be purchased should be determined by which- ever has the least capacity, the brooder or the room in which it is to be operated. Soil contamination. When chicks are brooded year after year on the same limited ground area the soil becomes infested with filth, parasite eggs, and disease organisms. Under contaminated conditions many poultry enterprises are short lived. Unless brooding equipment can be moved to clean soil, it is well to consider the use of an artificial yard. The most common type used in Oregon is the wire porch, the floors of which are made of 1-inch mesh number 18 gauge wire. Nutrition. The chick develops rapidly and failure to provide it with the proper nutrients cannot be corrected later in its life. Many of the ingredients normally used in poultry feeds are not generally available. It will probably be much safer to purchase prepared mashes and grain feeds from reputable feed agencies than to attempt home mixing of feeds under present conditions. References. More complete information on chick brooding, brooder houses, feeding, and management may be obtained from the following bulletins available from the office of the county agricultural agent or the Poultry Department of Oregon State College: Extension Bulletin 511, O.S.C. Brooder Houses. Extension Bulletin 549, Chick Brooding and Rearing.