Forest certified products from SCA PE FC /05-33-132 Promoting Sustainable

advertisement

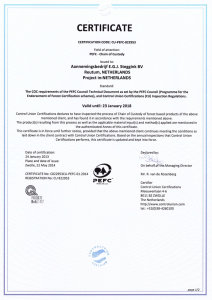

Forest certified products from SCA PE FC /05- 33-132 Promoting Sustainable Forest Management www.pefc.org WH YS HO U LD For i CA est RE? cer pro tific vide atio bet n w sac fore een re redibl e st m s and ana ponsib link t g le h em e of fo c rest onsum ent pro duc ption ts. FSC ® Forest Stewardship Council® (FSC) is an independent, international organisation that promotes the development of environmentally compatible, socially beneficial and financially sound, practices for management of the world’s forests. FSC has established fundamental principles and criteria for responsible forest management. For example these principles call for the protection and preservation of biological diversity and other natural resources, supporting economically sound forestry operations. This contributes to the development of the local community. ASI accredits certification bodies, empowered to ensure that FSC’s standards are met with the auditors granting certificates attesting to their compliance. FSC is supported by major environmental organisations in all parts of the world, among them WWF. Read more on the FSC home page: www.fsc.org PEFC™ PEFC, Programme for the Endorsement of Forest Certification, is an international non-profit, non-governmental organization dedicated to promoting sustainable forest management through independent third-party certification. PEFC promote good practices in the forest and aims to ensure that timber and non-timber forest products are produced with respect for the highest ecological, social and ethical standards. PEFC is based on small-scale family forestry conditions and have national certification standards in line with the international PEFC guidelines. PEFC supports small land owners to gain recognition in the market place thereby making a lasting contribution to livelihoods and rural development. To date, several hundred-thousand family- and community-owned forests have acquired PEFC certification. The demand for PEFC-certified products has risen steadily in recent years. PEFC is the world’s largest forest certification organization with over 240 million hectares of certified forest land. Read more on the PEFC home page: www.pefc.org Similarities and differences Both FSC and PEFC promote responsible forest management, where an active economic management of the forest goes hand in hand with environmental and social responsibility. Certification of forestry endorses marketing campaigns for forest products with more and more businesses and consumers choosing to buy certified products as part of their environmental commitment. PEFC and FSC are not interchangeable. To sell FSC certified products you must hold an FSC Chain-of-Custody (CoC)-certificate and likewise for PEFC. To sell either PEFC or FSC certified products you must hold CoC certificates. In order to use the PEFC logo a license is also required. The FSC standard requires both a license and approval each time the FSC logo is used. There are several differences between the two certification systems and how they are applied in different countries. The General Assembly is FSC’s highest decision-making body. The GA is divided in three chambers for economic, ecologic and social stakeholders respectively, and a decision requires a majority vote in every chamber. The GA adopted a new set of principles and criteria in 2011, which will afford the FSC certification more uniformity between countries. PEFC is an umbrella organisation for national forest certification systems. It works by endorsing national forest certification systems developed through multi-stakeholder processes and tailored to local priorities and conditions. Each national forest certification system undergoes rigorous third-party assessment against PEFC’s unique Sustainability Benchmarks to ensure consistency with international requirements. Both standards give high priority to ecological concerns and require that forests with high conservation values are protected. PEFC emphasises training and workplace safety for forest workers and FSC stresses concern for indigenous peoples and dialogue with local stakeholders. Both FSC and PEFC have a global scope certifiying forest management all over the world, from the management of boreal forests in Northern Europe and North America to the management of tropical rain forests. Source control is required Certified product requires traceability and a certified Chain-ofCustody (CoC) from the forest to the final customer. CoC, as well as the control of uncertified raw material, are audited by accredited certification bodies. In the source control certification process, the entire chain from forestry operations to finished product must be documented. A CoC-certificate is required for every link in the chain, from the forest to the paper mill, from the paper mill to the printing plant, from the printing plant to the finished publication. The same organisations, accredited to certify forestry operations, also oversee certification of CoC. FSC 100%, where all the raw material is FSC-certified. FSC The raw material input is linked with the output of certified products for a specific product line. The producer keeps a record of the volume of FSCcertified timber that is being supplied and a corresponding share of the products may be certified. These are referred to as FSC credits and must be used for the production of FSC-certified products within a 12-month period or they are forfeited. The CoC-standard also demands a strict control of uncertified raw material. All of the raw material fibre for the FSC-certified product line must come from controlled sources. No raw material may come from controversial sources. This means that the FSC’s drive for responsible forest management is being expanded into forests that are not certified. The FSC products from SCA SCA’s pulp, publication papers, sustainable packaging and containerboard are certified as FSC Mix. SCA delivers FSC-certified products only on request and only to FSC-certified printers, converters, publishers and end-users! This is to avoid deliveries of FSC-products outside the CoC, to avoid that FSC is wrongly used as a unique selling point and door-opener and to reduce the risk of misusing the FSC label in the market. FSC alternatives FSC Mix, where the input of FSC-certified raw material equals the output of FSC-certified products, while the uncertified raw materials are strictly controlled in order to avoid timber from controversial sources. Recovered fibre may also form part of the basis for this label. FSC Recycled, where all of the raw material is recovered fibre. Options for Chain-of-Custody For FSC Mix there are two options for certification: • The minimum share system – The fibre material in the product contains more than 70% FSCcertified fibre (and the rest of the fibre material meet the requirements in the standard for Controlled Wood). • The volume credit system – The producer holds a volume credit account where the input of FSCcertified fibre is documented. A corresponding share of the production may then be certified. Both systems may be applied in the same CoC and the FSC share need to be recalculated in a corresponding way. As with other FSC-standards, the CoC-standard is applied by an accredited auditor. The Controlled Wood-standard contains minimum requirements for fibre raw material that is not FSCcertified. No fibre in an FSC-certified product may come from controversial sources. Material in the product that is not fibre, such as fillers and coating, is not part of the calculations. PEFC The traceability standard is international and therefore common to all national PEFC certification systems. Two different methods are used to follow wood raw materials through the supply chain from forest to end user. Chain-of-Custody certificate is required from all companies involved in the chain. In one method the company separates certified raw material and products from non-certified material by the use of different storage places. In the other method the company calculates the share of certified wood or products in a purchased lot. SCA applies the latter method. For the labelling the product must contain at least 70% certified wood. PEFC logo options Different options are available to label products, depending on the tracking method used and the share of certified raw material. A minimum content of 70% of PEFC certified material from PEFC certified forest and/or recycled sources, as well as wood from controlled sources as prescribed by the PEFC due diligence-system. The PEFC Recycled Label indicates that the product contains at least 70% PEFC-certified material from recycled sources or wood from recycled sources. The Möbius loop is an optional element for this label only. The different options may be accompanied by option specific claims. The logo can be used optionally, on or off product, under licence from PEFC. Certified forests are the start of the chain of custody and each subsequent link must have a chain of custody certificate to allow forest-based products to be traced from the forest to the finished product. Percentage based claims This method, that SCA is using, allows the mixing of certified and non-certified raw material in the production or trading process. However the share of PEFC-certified raw material must be known and communicated to the company’s customers (average percentage method calculates the average share of certified material that is included in a product group). As an alternative, the company can sell a share of PEFC-certified products that corresponds to the share of PEFC-certified raw material used (the share is documented in a volume credit account). Eco lifecycle Forests play a crucial role in the cycles affecting the climate. Through photosynthesis growing trees sequester an enormous amount of carbon dioxide from the air. The forests as they grow release oxygen in the process. The carbon in the wood of the trees is stored and kept out of the atmosphere until the wood fibre have decomposed or burned. Timber from a tree becomes wood and paper products that continue to hold stored carbon. Wooden houses, for example, may store carbon for centuries. And when eventually the tree, the house or the paper decays and the carbon becomes carbon dioxide once more and will be the same amount of carbon dioxide as the tree sequestered when growing. If the fibre is used for fuel and is substituting fossil fuels such as oil or coal, the positive effect on the climate is even greater. Growing forests are one of the most effective means to reduce carbon dioxide levels in the at- mosphere. SCA’s well managed forests (2.6 million hectares) are the biggest asset in our environmental work, but also provide an important strategic resource to secure the raw material supply to our pulp and paper products. SCA’s various production plants for sawn timber, pellets, pulp and paper involves the efficient usage of the whole tree. About 100 million seedlings are grown each year to produce new forests. The standing volume of living, growing trees has grown from 130 million m³ in 1947 to over 200 million m³ today and is forecast to grow to 250 million m³ by year 2035. The growth rate in our forests is more than 30 per cent higher than the felling and as a result our forests are net sequestering 2.5 million tonnes of carbon dioxide every year. That is more than the total fossil carbon dioxide emissions from our forestry, our production processes and our transport of both raw materials and products in all of SCA Forest Products. The interest in forest certified publication papers is growing; therefore SCA Ortviken achieved PEFC certification for their paper products in 2012. Since 1999, the mill has offered FSC certified products. The combination of TCF (Total Chlorine Free), FSC, PEFC and uniquely low carbon footprints has given SCA Östrand a leading position among kraft pulp mills with the lowest environmental impact. The interest in sustainability and forest certification for packaging products grows and now SCA Containerboard offers all of its products as FSC and PEFC. We also have a totally chlorine-free process for the production of our white products. Layout: Originaldesign Sweden Print: Tryckeribolaget, May 2014. Both the paper and the printer are FSC certified. Part of the SCA team For more information please look at: sca.com/publicationpapers | sca.com/pulp | sca.com/sp | sca.com/containerboard