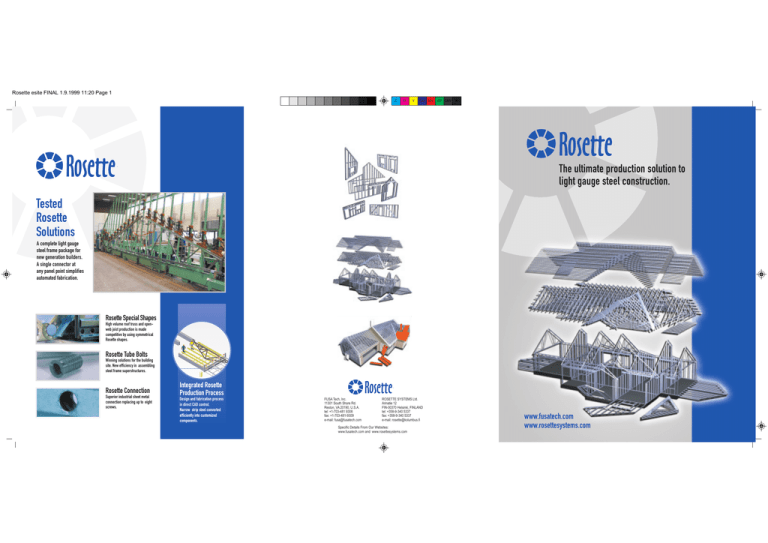

Tested Rosette Solutions The ultimate production solution to

advertisement

Rosette esite FINAL 1.9.1999 11:20 Page 1 C M Y CM MY CY CMY K The ultimate production solution to light gauge steel construction. Tested Rosette Solutions A complete light gauge steel frame package for new generation builders. A single connector at any panel point simplifies automated fabrication. Rosette Special Shapes High volume roof truss and openweb joist production is made competitive by using symmetrical Rosette shapes. Rosette Tube Bolts Winning solutions for the building site. New efficiency in assembling steel frame superstructures. Rosette Connection Superior industrial sheet metal connection replacing up to eight screws. Integrated Rosette Production Process Design and fabrication process in direct CAD control. Narrow strip steel converted efficiently into customized components. FUSA Tech, Inc. 11301 South Shore Rd. Reston, VA 20190, U.S.A. tel: +1-703-481 9308 fax: +1-703-481-9309 e-mail: fusa@fusatech.com ROSETTE SYSTEMS Ltd. Arinatie 12 FIN-00370 Helsinki, FINLAND tel: +358-9-340 5337 fax: +358-9-340 5337 e-mail: rosette@kolumbus.fi Specific Details From Our Websites: www.fusatech.com and www.rosettesystems.com www.fusatech.com www.rosettesystems.com Rosette esite FINAL 1.9.1999 11:20 Page 2 C M Y CM MY CY CMY K THE INTEGRATED ROSETTE PRODUCTION LINE 51 m THE ROSETTE CONSTRUCTION (16 9«) m 10 «) (33 Rosette Symmetrical Roof Trusses and Frame Panels Rosette Pressing Tools and the Rosette Connection THE ROSETTE CONNECTION • total design and production integration • direct-CAD-controlled • high efficiency • low cost materials • high value-add • low space requirements 79 m (26 0«) m 10 «) (33 Years of development Rosette has worked for years to develop a CAD-controlled, integrated light gauge steel building component manufacturing line. The resulting Rosette production system offers a new generation of benefits and solutions. It has a remarkably small footprint, leaving you with ample savings in real estate, and thus securing a feasible total investment. required to assemble any custom-designed component configuration. No members or items need to be kept in inventory. This means that you can dramatically reduce the size of your processing areas. Therefore, you save both in the initial combined investment, and also in continued operating expenses. Direct CAD-control A directly CAD-controlled process has never been quite so accurately put to work as it has been here. The Rosette Line is paperless: computers do the walking and talking, leaving only small snap-on assembly tasks and supervision to be performed by operators. CADcontrol also means high precision products, and especially so in this case, because all the machinery components are made by the leading tool manufacturers of the world. High value-add for less One of the leading ideas behind the Rosette System is the integrated conversion of relatively inexpensive strip coil steel into highly detailed wall frame panels and roof trusses. Automation makes this commodity approach possible and keeps your costs of customized production very competitive. In operating the Rosette System, you pay 40 percent per pound for the raw material compared to your competition. In addition, Rosette offers many important details and capabilities to build added value into the frame components at a fraction of the cost of alternative solutions. Simple mechanics Connecting light gauge steel members has never been this simple. The Rosette connection is created from the two sheet materials to be connected without any need for additional bought-in items. Pressing of the connection takes only a fraction of a second and requires only a vertical move of the Rosette tool; this simplicity in turn makes possible the automation of the customized frame panel fabrication. JIT manufacturing Rosette automation also means that you can modify the production schedule at will and offer the flexibility to keep your customer happy. This is more than ordinary Just-In-Time; Rosette fabrication line produces all the members from a narrow strip in the sequence Mechanized material handling Additional savings in operator resources and labor costs have been achieved by mechanizing material handling. Fast-cycle production and expedited order turnaround are now possible. Specific Details From: www.fusatech.com www.rosettesystems.com Creating the Rosette connection The Rosette connection is produced in three steps. First, a hole is made in the first member and a collared hole is extruded in the other member while the material is still at the flat stage. The second step takes place at the assembly station where the two members that are to be connected are snap-on joined. The snapon assembly is done by the operators. The third phase is the final pressing of the connection at the Rosette Press. Here the proprietary Rosette tool in a single, vertical move penetrates the snap-on assembled hole connection and folds the extruded collar flat around the hole. Strongest connector in the industry The Rosette connection, once formed, is equal in strength to six to eight sheet metal screws. In most panel points there is a pair of Rosette connectors. The connection can be additionally strengthened by using Rosette Tube Bolts in high stress panel points, for example, in double scissor, wide span roof trusses. Versatility of the connection A Rosette connection can be designed to be placed anywhere on the plane of the component. The Rosette tool is automatically directed to the x/y coordinates of the connection and a simple vertical move of the tool will finish the strong connector. Any wall configuration can now be produced, not only rectangular but also rake walls, and the very same connector works for two kinds of Rosette roof trusses and open-web structures as well. Feasibility to serve Rosette capabilities to build added value into the frame components with a fraction of the cost is important in competing to serve the builder customers. First of all, a complete frame package can be manufactured using the same Rosette production technology. In addition, the wall frame panels have drop-down open-web headers, diagonal and lateral bracing can be detailed and fabricated into the structures; even fixture fixing plates can be automatically produced. Precision results The precision of the process and the high quality of steel as the frame material produce building components which are easy and fast to install at the building site. All the Rosette detailing is done at in-line sheet metal machine centers. This will secure consistent industrial quality in member cuttings and detailing. Low cost superior solution Cheap and good quality does not normally come in the same package. With Rosette connector, however, the same package is even better. The Rosette connection is made using the two sheet materials to be connected without any need for additional bought-in items. The Rosette connector does not cost a penny – and it is the best in the industry. The Rosette Site Installation of components has been an important part of research and development. As time has gone by, the Rosette Tube Bolt, specifically developed for the purpose of joining Rosette frame components together, has grown into a product family of its own. It has generated revolutionary new ideas on how to make the site installation safer and faster, with lesser resources, and producing a superior Rosette light gauge steel frame structure. The Rosette Tube Bolt The original goal in designing the Rosette Tube Bolt was to have a simple way of fixing together frame components, even in difficult conditions at the building site. The Tube Bolt has a thread designed to twist into the Rosette connector hole. It is an easy task to fix these bolts, and the installers can keep their gloves on the whole time. The Tube Bolt is again a solution in correct scale and size; it is the Rosette solution designed with lots of experience in site installations. The Rosette Brackets and Other Nice Ideas Put together a bracket and two Rosette Tube Bolts, and a strong connection is made between Rosette frame components in no time. A girder truss can be assembled by fixing two trusses face to face together using a #3 Rosette Tube Bolt driven trough Rosette connector holes – for others a difficult task, a simple one for the Rosette builder. The original Rosette Tube Bolt idea was explored further and male-female ended Rosette Tube Bolts can now be used in precision-installing symmetrical Rosette roof trusses. A continuous tube is formed next to the ridge line running through Rosette connectors. At the same time, a strong temporary and/or permanent lateral bracing of roof structure is formed. Easy and fast installation The Rosette Steel Frame Technology is a complete solution package aiming at easy and fast installation of a light gauge steel superstructures at the building site. The directCAD-control system has measured parts and members, and precision sheet metal work stations have fabricated all the details. Relatively few connection points, Rosette connection holes, and suitable brackets need to be identified at the site, and Rosette Tube Bolts twisted into identified holes. “Simple system” means easy to learn, “strong” means few connectors needed, “few” means fast to install and less resources required; and the combination is called the winning Rosette System. Thermal efficiency Steel as a frame material has some disadvantages compared with wood in thermal conductivity. But we offer a no direct cost solution for this. The slit web thermal stud technology effectively cuts the cold bridge. Originally an American invention, it has been nurtured in Scandinavia, and is now a well tested and established solution even for cold climate steel construction. New Generation solution for Business Success Buying the new-generation Rosette System means buying into the future of light gauge steel construction. By becoming a Rosette License Manufacturer, you will position your business for success. Rosette esite FINAL 1.9.1999 11:20 Page 2 C M Y CM MY CY CMY K THE INTEGRATED ROSETTE PRODUCTION LINE 51 m THE ROSETTE CONSTRUCTION (16 9«) m 10 «) (33 Rosette Symmetrical Roof Trusses and Frame Panels Rosette Pressing Tools and the Rosette Connection THE ROSETTE CONNECTION • total design and production integration • direct-CAD-controlled • high efficiency • low cost materials • high value-add • low space requirements 79 m (26 0«) m 10 «) (33 Years of development Rosette has worked for years to develop a CAD-controlled, integrated light gauge steel building component manufacturing line. The resulting Rosette production system offers a new generation of benefits and solutions. It has a remarkably small footprint, leaving you with ample savings in real estate, and thus securing a feasible total investment. required to assemble any custom-designed component configuration. No members or items need to be kept in inventory. This means that you can dramatically reduce the size of your processing areas. Therefore, you save both in the initial combined investment, and also in continued operating expenses. Direct CAD-control A directly CAD-controlled process has never been quite so accurately put to work as it has been here. The Rosette Line is paperless: computers do the walking and talking, leaving only small snap-on assembly tasks and supervision to be performed by operators. CADcontrol also means high precision products, and especially so in this case, because all the machinery components are made by the leading tool manufacturers of the world. High value-add for less One of the leading ideas behind the Rosette System is the integrated conversion of relatively inexpensive strip coil steel into highly detailed wall frame panels and roof trusses. Automation makes this commodity approach possible and keeps your costs of customized production very competitive. In operating the Rosette System, you pay 40 percent per pound for the raw material compared to your competition. In addition, Rosette offers many important details and capabilities to build added value into the frame components at a fraction of the cost of alternative solutions. Simple mechanics Connecting light gauge steel members has never been this simple. The Rosette connection is created from the two sheet materials to be connected without any need for additional bought-in items. Pressing of the connection takes only a fraction of a second and requires only a vertical move of the Rosette tool; this simplicity in turn makes possible the automation of the customized frame panel fabrication. JIT manufacturing Rosette automation also means that you can modify the production schedule at will and offer the flexibility to keep your customer happy. This is more than ordinary Just-In-Time; Rosette fabrication line produces all the members from a narrow strip in the sequence Mechanized material handling Additional savings in operator resources and labor costs have been achieved by mechanizing material handling. Fast-cycle production and expedited order turnaround are now possible. Specific Details From: www.fusatech.com www.rosettesystems.com Creating the Rosette connection The Rosette connection is produced in three steps. First, a hole is made in the first member and a collared hole is extruded in the other member while the material is still at the flat stage. The second step takes place at the assembly station where the two members that are to be connected are snap-on joined. The snapon assembly is done by the operators. The third phase is the final pressing of the connection at the Rosette Press. Here the proprietary Rosette tool in a single, vertical move penetrates the snap-on assembled hole connection and folds the extruded collar flat around the hole. Strongest connector in the industry The Rosette connection, once formed, is equal in strength to six to eight sheet metal screws. In most panel points there is a pair of Rosette connectors. The connection can be additionally strengthened by using Rosette Tube Bolts in high stress panel points, for example, in double scissor, wide span roof trusses. Versatility of the connection A Rosette connection can be designed to be placed anywhere on the plane of the component. The Rosette tool is automatically directed to the x/y coordinates of the connection and a simple vertical move of the tool will finish the strong connector. Any wall configuration can now be produced, not only rectangular but also rake walls, and the very same connector works for two kinds of Rosette roof trusses and open-web structures as well. Feasibility to serve Rosette capabilities to build added value into the frame components with a fraction of the cost is important in competing to serve the builder customers. First of all, a complete frame package can be manufactured using the same Rosette production technology. In addition, the wall frame panels have drop-down open-web headers, diagonal and lateral bracing can be detailed and fabricated into the structures; even fixture fixing plates can be automatically produced. Precision results The precision of the process and the high quality of steel as the frame material produce building components which are easy and fast to install at the building site. All the Rosette detailing is done at in-line sheet metal machine centers. This will secure consistent industrial quality in member cuttings and detailing. Low cost superior solution Cheap and good quality does not normally come in the same package. With Rosette connector, however, the same package is even better. The Rosette connection is made using the two sheet materials to be connected without any need for additional bought-in items. The Rosette connector does not cost a penny – and it is the best in the industry. The Rosette Site Installation of components has been an important part of research and development. As time has gone by, the Rosette Tube Bolt, specifically developed for the purpose of joining Rosette frame components together, has grown into a product family of its own. It has generated revolutionary new ideas on how to make the site installation safer and faster, with lesser resources, and producing a superior Rosette light gauge steel frame structure. The Rosette Tube Bolt The original goal in designing the Rosette Tube Bolt was to have a simple way of fixing together frame components, even in difficult conditions at the building site. The Tube Bolt has a thread designed to twist into the Rosette connector hole. It is an easy task to fix these bolts, and the installers can keep their gloves on the whole time. The Tube Bolt is again a solution in correct scale and size; it is the Rosette solution designed with lots of experience in site installations. The Rosette Brackets and Other Nice Ideas Put together a bracket and two Rosette Tube Bolts, and a strong connection is made between Rosette frame components in no time. A girder truss can be assembled by fixing two trusses face to face together using a #3 Rosette Tube Bolt driven trough Rosette connector holes – for others a difficult task, a simple one for the Rosette builder. The original Rosette Tube Bolt idea was explored further and male-female ended Rosette Tube Bolts can now be used in precision-installing symmetrical Rosette roof trusses. A continuous tube is formed next to the ridge line running through Rosette connectors. At the same time, a strong temporary and/or permanent lateral bracing of roof structure is formed. Easy and fast installation The Rosette Steel Frame Technology is a complete solution package aiming at easy and fast installation of a light gauge steel superstructures at the building site. The directCAD-control system has measured parts and members, and precision sheet metal work stations have fabricated all the details. Relatively few connection points, Rosette connection holes, and suitable brackets need to be identified at the site, and Rosette Tube Bolts twisted into identified holes. “Simple system” means easy to learn, “strong” means few connectors needed, “few” means fast to install and less resources required; and the combination is called the winning Rosette System. Thermal efficiency Steel as a frame material has some disadvantages compared with wood in thermal conductivity. But we offer a no direct cost solution for this. The slit web thermal stud technology effectively cuts the cold bridge. Originally an American invention, it has been nurtured in Scandinavia, and is now a well tested and established solution even for cold climate steel construction. New Generation solution for Business Success Buying the new-generation Rosette System means buying into the future of light gauge steel construction. By becoming a Rosette License Manufacturer, you will position your business for success. Rosette esite FINAL 1.9.1999 11:20 Page 1 C M Y CM MY CY CMY K The ultimate production solution to light gauge steel construction. Tested Rosette Solutions A complete light gauge steel frame package for new generation builders. A single connector at any panel point simplifies automated fabrication. Rosette Special Shapes High volume roof truss and openweb joist production is made competitive by using symmetrical Rosette shapes. Rosette Tube Bolts Winning solutions for the building site. New efficiency in assembling steel frame superstructures. Rosette Connection Superior industrial sheet metal connection replacing up to eight screws. Integrated Rosette Production Process Design and fabrication process in direct CAD control. Narrow strip steel converted efficiently into customized components. FUSA Tech, Inc. 11301 South Shore Rd. Reston, VA 20190, U.S.A. tel: +1-703-481 9308 fax: +1-703-481-9309 e-mail: fusa@fusatech.com ROSETTE SYSTEMS Ltd. Arinatie 12 FIN-00370 Helsinki, FINLAND tel: +358-9-340 5337 fax: +358-9-340 5337 e-mail: rosette@kolumbus.fi Specific Details From Our Websites: www.fusatech.com and www.rosettesystems.com www.fusatech.com www.rosettesystems.com Rosette esite FINAL 1.9.1999 11:20 Page 1 C M Y CM MY CY CMY K The ultimate production solution to light gauge steel construction. Tested Rosette Solutions A complete light gauge steel frame package for new generation builders. A single connector at any panel point simplifies automated fabrication. Rosette Special Shapes High volume roof truss and openweb joist production is made competitive by using symmetrical Rosette shapes. Rosette Tube Bolts Winning solutions for the building site. New efficiency in assembling steel frame superstructures. Rosette Connection Superior industrial sheet metal connection replacing up to eight screws. Integrated Rosette Production Process Design and fabrication process in direct CAD control. Narrow strip steel converted efficiently into customized components. FUSA Tech, Inc. 11301 South Shore Rd. Reston, VA 20190, U.S.A. tel: +1-703-481 9308 fax: +1-703-481-9309 e-mail: fusa@fusatech.com ROSETTE SYSTEMS Ltd. Arinatie 12 FIN-00370 Helsinki, FINLAND tel: +358-9-340 5337 fax: +358-9-340 5337 e-mail: rosette@kolumbus.fi Specific Details From Our Websites: www.fusatech.com and www.rosettesystems.com www.fusatech.com www.rosettesystems.com