A Batch Processing Module Thomas F. Edgar Department of Chemical Engineering

A Batch Processing Module

Thomas F. Edgar

Department of Chemical Engineering

University of Texas

Austin, TX 78712

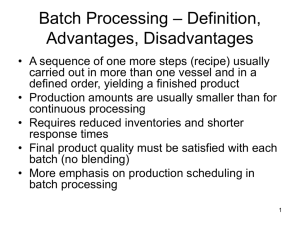

Batch Processing – Definition,

Advantages, Disadvantages

• A sequence of one more steps (recipe) usually carried out in more than one vessel and in a defined order, yielding a finished product

• Production amounts are usually smaller than for continuous processing

• Requires reduced inventories and shorter response times

• Final product quality must be satisfied with each batch (no blending)

• More emphasis on production scheduling in batch processing

Other Advantages

• Batch time can be adjusted to meet quality specs

• Repetition is conducive to continuous improvement in product

• Slow dynamics permit real-time calculations

• Greater agility

Batch Processing Used in

Manufacturing

• Electronic materials

• Specialty chemicals

• Metals

• Ceramics

• Polymers

• Food and agricultural materials

• Biochemicals

• Multiphase materials/blends

• Coatings

• Composites

Representative processing steps in a semiconductor wafer fab

(Deposition, Patterning, Etching, Doping, etc)

Unit operations in microelectronics manufacturing are characterized by:

1. Physical/chemical complexity

2. Inability to measure directly many process variables

3. High sensitivity to process changes

4. Multiple inputs/multiple outputs

CD Variation Effects in Pattern Transfer

Wafer

Flatness

Reflectivity

Topography

Reticle

CD

Defects

Edge Roughness

Proximity Effects

Stepper

Aberrations

Lens Heating

Focus

Leveling

Dose

Etch

Power

Pressure

Flow rates

Refractive Index

Thickness

Uniformity

Viscosity

Contrast

Resist PEB

Temperature

Uniformity

Time

Delay

Time

Temperature

Dispense Pattern

Rinse

Develop

Amines

Humidity

Pressure

Environment

Why Control Critical Dimension (CD)?

• Small changes in CD distribution = Large $ values lost

Higher speed

210

3 σ = 36nm

3 σ = 12nm

230 250

Gate CD (nm)

270

290

Control Hierarchy in Batch

Processing

1. Sequential control to step the process through a recipe

2. Logic control to deal with device interlocks

3. Within-the-batch control to make set point changes and reject disturbances

4. Run-to-run control to meet final quality constraints

5. Batch production control to maximize utilization of equipment and minimize cycle time

Figure 22.19 Batch control system – a more detailed view

Within-the-Batch Control:

Operational Challenges

• Time-varying process characteristics (no steady state)

• Nonlinear behavior

• Model inaccuracies

• On-line sensors often not available

• Constrained operation

• Unmeasured disturbances

• Irreversible behavior

Run-to-Run (RtR) Control

• Keeps batch process product on target by using feedback to manipulate batch recipe for consecutive batches

• Required due to a lack of in situ, real-time measurements of product quality of interest

• Extremely useful where initial conditions or tool states are variable and unmeasurable

• Supervisory controller determines optimal setpoints for real-time control loops (typically

PID)

STI

Application: Resist etch process

SiON

Linewidth

Trimmed

Resist

Poly Silicon

Gate Oxide

Silicon Substrate

STI

• The incoming pattern is masked with linewidths greater than required.

• An additional step is added to the etch process which etches the resist pattern.

• The resist etch step trims the lines to the proper resist linewidth.

• The rest of the etch transfers the resulting mask pattern into the polysilicon, creating the poly gate structures.

30

40

Results – Increased C

pk

Prior to APC Implementation

With Automated Run-to-Run Control

20

10

0

-1 -0.9 -0.8 -0.7 -0.6 -0.5 -0.4 -0.3 -0.2 -0.1

0 0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

Normalized Deviation From Target

Metric

Mean Deviation From Target

Standard Deviation

Cpk

Uncontrolled

-0.201

0.254

1.05

Controlled

0.045

0.188

1.7

% Change

-77%

-26%

+62%

Figure 22.17 Multiproduct batch plant

Characteristics of batch scheduling and planning problems (Pekny and Reklaitis)

DETERMINE

What

Product amounts: lot sizes, batch

Sizes

When

Timing of specific operations, run lengths

Where

Sites, units, equipment items

How

Resource types and amounts

GIVEN

Product requirements

Horizon, demands, starting and

Ending inventories

Operational steps

Precedence order

Resource utilization

Production facilities

Types, capacities

Resource limitations

Types, amounts, rates

A

Multi-Product Processing Overview

B B A A B

Fab Tool

Process 1

A A A A

A B B A A B

Fab Tool

Process 1

Process 2

Fab Tool

Process 1

Process 2

2

1.8

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

0

A B

Metrology Variations

4

3.5

3

2.5

2

1.5

1

0.5

0

Process

Correct Metrology

Ordering

A B C D E

4

3. 5

3

2. 5

2

1. 5

1

0. 5

0

Incorrect Metrology

Ordering

E D C B A

C D E

4

3.5

3

2.5

2

1.5

1

0.5

0

C D A E B

Incorrect Metrology

Ordering

Integration Across Standard

ChE Courses

• discrete logic in process operations

• design for safe operation

• measurement strategies (e.g., end point)

• batch vs. semibatch (bioreactors)

• use of fundamental (nonlinear) models

• numerical methods, statistics

• population balances

• case studies