NBER WORKING PAPER SERIES ANALYZING COMPENSATION METHODS IN MANUFACTURING:

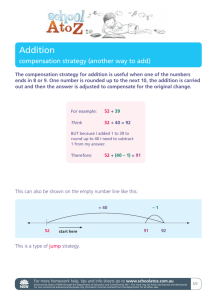

advertisement