Technology Prototypes and Contract Manufacturing UTSA CITE Boot Camp

advertisement

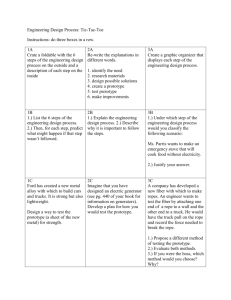

Technology Prototypes and Contract Manufacturing UTSA CITE Boot Camp Fall 2011 Outline !! Technology "!Definition, !! Contract Development, Types, Significance Manufacturing "!Definition, !! Q Prototypes Process, Merits, Company Names &A 2 Technology Prototypes 3 What is a Technology Prototype Prototype is rudimentary model of a design idea, built for a demo purpose or as part of the development process !! Multiple iterations of prototypes are used to progressively refine the product design, by !! "! Exploring design alternatives "! Testing theories "! Confirming performance 4 Product Prototyping Phases Build original prototype Evaluate prototype Abandon project Decide on next step Further revision Prototyping completed successfully Manufacture system from prototype 5 Examples of Technology Prototypes !! Hardware: Concept Cars, Model Airplanes, Breadboards !! Software: Mock-up User Interface, Cockpit Simulators, Alpha-Beta Test Programs 6 Prototype of a Kitchen Appliance 7 Types of Technology Prototypes Role (Establish Use) Integration (Refined Design) Implementation (Working System) Look and Feel (Simulate User Experience) 8 Prototype of a Barcode Scanner 9 Case Study: Prototyping Design of an Enhanced Audio Playback Device !! Embedded Digital Media Player (eDMP) system enhances traditional audio playback devices by adding the ability to play audio from networked digital sources, such as PC files, internet radio, premium audio internet sites and USB storage devices Audio Playback System Embedded DMP System Display & Controls Audio Output System Controller Audio Processor/ Switch SPI / UART Wi-Fi Media Networking Processor Ethernet PHY 10 Prototype of Enhanced Audio Playback Device Host Controller Connector Ribbon Cable eDMP Development Board Model Audio Playback Device LCD 11 Time & Cost to Build Working Prototype !! Time Spent: ~ 1 month "! Research requirements and order parts = 1 week "! Assembly & Software development time = 2 weeks "! Integration & Test = 1 week !! Material costs: ~ $700 "! Development Board = $600 "! Host Controller = $29.95 "! LCD = $39.95 "! Power Supply = $5.95 "! The ribbon cable, connector and USB cable = $15 12 How to Build a Prototype Adequately research requirements Identify parts and steps for assembly Can it be done in-house? No Hire local low volume manufacturer Yes Finished Prototype 13 Rapid Prototyping (RP) !! !! !! !! RP takes advantage of computer technology to turn designs into three-dimensional objects RP can greatly accelerate product development and lead to high-quality, defect-free products by allowing various people to see a model and have input without creating a full-fledged prototype RP has been used by automakers and aircraft manufacturers for several years Newer RP tools are variously known as conceptual modelers, desktop modelers, and 3D printers 14 Significance of Technology Prototypes Shows potential investors and licensees how the proposed product will work without having to rely exclusively on diagrams and description !! Conserves time and resources prior to the commitment of effort to construct a final product !! Refines product design to generate final product specifications for production !! 15 Contract Manufacturing 16 What is Contract Manufacturing? !! An outsourcing agreement where one company custom produces parts or complete products on behalf of their client company. !! As a result, the client does not have to maintain manufacturing facilities, purchase raw materials, or hire labor in order to produce the finished goods. 17 Contract Manufacturing Process Hiring firm sends RFQ to several CMs CMs responds with a Quote All CMs informed of decision Hiring firm decides on a CM Quote revision Hired CM produces/ships products 18 Why Contract Manufacture? !! Benefits "! Lower capital requirements "! Lower labor cost – wages, training, benefits "! CMs have efficient, deterministic and quality production process "! Companies can focus on their core competencies !! Risks "! Costly, if hiring company chooses wrong CM 19 Who obtains any Regulatory Certificates? !! Examples "!FCC, of Regulatory Certifications: UL, Wi-Fi, CE !! Contract Manufacturer may be skilled in these areas and can obtain certificates !! You may have to support regulatory testing, test submission and certificate approval on your own 20 Industries utilizing Contract Manufacturers Aerospace !! Defense !! Computer !! Semiconductor !! Energy !! Medical !! Food manufacturing !! Personal care !! Automotive !! 21 Sample List of Contract Manufacturers Local !! !! !! !! !! !! !! Maxim Integrated Products – San Antonio Pi Circuits – San Antonio D C Electronics – San Antonio ECA Services – San Antonio DPT Labs – San Antonio Benchmark Electronics -Angleton, TX Cypress Industries – Austin High Volume/International !! Foxconn – Taiwan !! Flextronics International Ltd. – Singapore !! Jabil Circuit – St. Petersburg, FL !! Celestica – Toronto, Canada !! Sanmina-SCI – San Jose, CA 22 Questions & Answers 23