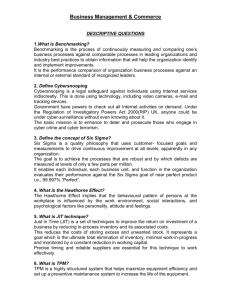

Different techniques for TQM: Benchmarking Chapter – 4: Introduction:

advertisement