125

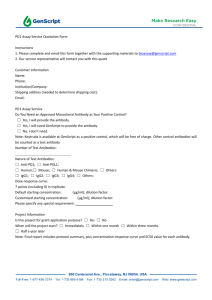

advertisement