Separation and Purification Technology 40 (2004) 123–132

Application of pervaporation and adsorption to the

phenol removal from wastewater

Wojciech Kujawski a,∗ , Andrzej Warszawski a , Włodzimierz Ratajczak b ,

Tadeusz Porȩbski b , Wiesław Capała b , Izabela Ostrowska b

a

Nicolaus Copernicus University, Faculty of Chemistry, ul. Gagarina 7, 87-100 Torun, Poland

b Industrial Chemistry Research Institute, ul. Rydygiera 8, 01-793 Warszawa, Poland

Received in revised form 21 January 2004; accepted 30 January 2004

Abstract

Application of pervaporation and adsorption to the removal of phenol from solutions modeling wastewater from phenol production with

cumene oxidation process was investigated. The transport and separation properties of composite membranes PEBA, PERVAP 1060 and

PERVAP 1070 in pervaporation of water–acetone, water–phenol and water–phenol–acetone mixtures were determined. It was found that all

membranes were selective toward phenol. The PEBA membrane showed the best selectivity. However, this membrane is not actually available

on the commercial scale. Thus, in the practical applications PERVAP-1060 and PERVAP-1070 could be used. Adsorption of phenol on the

different Amberlite resins was also investigated. Among the Amberlite resins of various grades used, the Amberlite XAD-4 had the best

properties in decontamination of aqueous phenol solutions. It was shown that regeneration of the adsorbent bed could be effectively performed

with sodium hydroxide solution.

© 2003 Elsevier B.V. All rights reserved.

Keywords: Phenol; Wastewater treatment; Pervaporation; Adsorption; Hybrid processes

1. Introduction

Phenol is an important raw material in many branches

of industry (e.g. petrochemical, pharmaceutical, plastic and

pesticidal chemical industry). Nowadays, the importance of

phenol is proved by its ever increasing global production

capacity which reached 7.8 million of tonnes in 2001 [1].

Since 1952, the cumene oxidation process, called also

the Kellong, Brown and Root (KBR) phenol process, is a

commonly used technology for the manufacture of phenol

and acetone [2,3]. This process consists in oxidation of isopropyl benzene (cumene) with air, followed by cleavage of

the formed cumene hydroperoxide in the presence of an acid

catalyst. However, the cumene oxidation process is also a

source of wastewater. Depending on the process conditions

up to 0.6 t of liquid wastes is generated per tonne of the phenol produced. The wastewater contains 2–3% phenol, 3–6%

acetone, up to 0.1% aromatic hydrocarbons (mainly cumene

∗ Corresponding author. Tel.: +48-56-611-43-15;

fax: +48-56-654-24-77.

E-mail address: kujawski@chem.uni.torun.pl (W. Kujawski).

1383-5866/$ – see front matter © 2003 Elsevier B.V. All rights reserved.

doi:10.1016/j.seppur.2004.01.013

and ␣-methylstyrene) and 2–3% sodium salts (mainly formate and sulphate). Taking into account the high toxicity

and hazardous character of phenol, the importance of decontamination of these effluents before their discharge into

sewage system and the environment, is obvious.

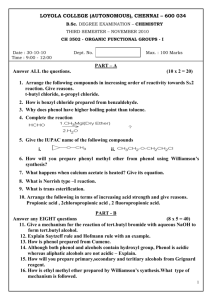

The conventional treatment of the cumene oxidation process effluents is presented schematically in Fig. 1. Generally

it consists of two operation steps: (1) distillation of acetone

and hydrocarbons from raw wastes and (2) phenol adsorption on polymeric resins or phenol extraction with organic

solvent. However, the presently used solution exhibits some

essential disadvantages: (1) distillation is an energy consuming technique, (2) high phenol content in liquors directed to

the adsorption step involves either a frequent regeneration of

the adsorbent bed or the demand of its high capacity, (3) the

use of combustible acetone as regenerant of the adsorbent.

Therefore, the present work aimed at developing an

alternative hybrid process (distillation–pervaporation–

adsorption) for the treatment of effluents from the cumene

oxidation process. Pervaporation is an energy saving membrane technique used to separate liquid mixtures [4]. This

technique would allow removal of a considerable part of

124

W. Kujawski et al. / Separation and Purification Technology 40 (2004) 123–132

Nomenclature

List of symbols

BV

volume of resin bed

c

concentration [g dm−3 ]

Ji

permeate flux of species i [g m−2 h−1 ]

k, n coefficients of the Freundlich equation

q

adsorption capacity [g dm−3 ]

Greek letters

α

separation factor

β

enrichment factor

Fig. 2. Scheme of the laboratory scale pervaporation setup.

the organic pollutants, whereas adsorption, the classical

separation technique, would lower the phenol concentration

of the treated effluent to the level acceptable by wastewater

treatment plant. In the present paper, we describe the results

of our studies on the pervaporative removal of phenol using

different hydrophobic membranes and followed by phenol

adsorption on polymeric resins.

2. Experimental

2.1. Pervaporation experiments

Pervaporation experiments were carried out in the

laboratory-scale pervaporation system presented in Fig. 2

[5]. System was composed of a temperature controlled feed

vessel, circulating pump, membrane test cell, cold fingers

and vacuum pump. Feed solution was pump to a membrane

test cell with a membrane area equal to 170 cm2 . The pervaporation system was operated at 333 K (water–phenol mixture) and at 313 K (water–acetone, water–acetone–phenol

mixtures). During experiments the upstream pressure was

maintained at the atmospheric pressure, while the downstream pressure was kept below 1 mbar by using a vacuum

pump. Permeate was collected into cold fingers cooled by

liquid nitrogen. To avoid phenol condensation before the

cold traps, the permeation part of the pervaporation system

was heated to 333 K. Permeation fluxes were determined by

weighing permeate collected over a given period of time in

the cold fingers. Composition of both the feed and permeate mixtures was determined by using gas chromatography.

VARIAN 3300 gas chromatograph equipped with PORAPAC Q packed column and a thermal conductivity detector

(TCD) was used. JMBS BORWIN Software (Le Fontanil,

France) was used to the data acquisition and processing.

Samples were injected by the direct on-column injection

technique. Each sample was analyzed three times.

Performance properties of a given pervaporation membrane were defined by the separation factor ␣ (Eq. (1)) and

permeate fluxes J [4].

αorg/water =

(corg /cwater )permeate

(corg /cwater )feed

(1)

where corg and cwater denote the weight fraction of organic

and water component, respectively.

The experiments were carried out using composite membranes PERVAP-1060, PERVAP-1070 (Sulzer Chemtech

Membrane Systems A.G., Neunkirchen, Germany) and

PEBA (GKSS-Forschungszentrum Geesthacht GmbH,

Geesthacht, Germany). Characteristics of the investigated

membranes are listed in Table 1, and the composition

of investigated water–organic mixtures is presented in

Table 2.

Fig. 1. Scheme of the cumene process wastewaters treatment.

W. Kujawski et al. / Separation and Purification Technology 40 (2004) 123–132

125

Table 1

Characteristics of the investigated membranes, according to the manufacturers’ data

Membrane

Thickness of the

selective layer (m)

Composition of the selective layer

PDMSa

PERVAP-1060

8

PERVAP-1070

10

Zeoliteb filled PDMS

PEBA

80

PEBAc

a

b

c

PDMS–poly(dimethylsiloxane).

Zeolite ZSM-5: Nan [Aln Si(96−n) O192 ] ∼ 16 H2 O, n < 27.

Block copolymer polyether–polyamide (PE–PA).

Table 2

The composition of feed solutions

Mixture

Content of the organic

component (wt.%)

Temperature

(K)

Water–acetone

Water–phenol

water–acetone–phenol

0–8

0–7

0–8

313

333

313

2.2. Adsorption experiments

The Amberlite resins, XAD-4, XAD-7 and XAD-16, manufactured by Rohm and Hass Co. were applied in adsorption

experiments. The properties of the adsorbents are presented

in Table 3. Prior to use, all the adsorbent samples were standardized using the following procedure: the dry resin sample

(100 cm3 ) was placed in a column and the adsorbent bed was

rinsed using distilled water (500 cm3 ), acetone (200 cm3 )

and distilled water (1000 cm3 ) with the volumetric flow rate

200 cm3 h−1 .

Adsorption experiments under static conditions using

three Amberlite resins were carried out by the batch method

[6]. The samples of an adsorbent (0.6–25 g) were shaken

with 100 cm3 of aqueous phenol solution (10 g dm−3 ).

When adsorption reached equilibrium, phenol concentration in solution was determined. The amount of phenol in

adsorbent was calculated from concentrations of solution

before and after adsorption.

The column method [6] was applied to determine adsorption properties under dynamic conditions using the

Amberlite XAD-4 resin. The model feed solutions containing different amounts of phenol (i.e. 3 and 5 g dm−3 )

and sodium sulphate (30 g dm−3 ) were controlled to pass

through the resin bed with volumetric feed rate of 2 BV h−1 .

The symbol BV denotes the volume of resin bed. After

a breakthrough of the column the model solution was removed and resin was regenerated (proportioning rate of a

regenerant was 1 BV h−1 ). The following liquid mixtures

were used as regenerants: water, sodium sulphate solution

(30 g dm−3 ), treated model solution (phenol concentration:

0.08 g dm−3 ) and sodium hydroxide solution (200 g dm−3 ).

Phenol content in the investigated mixtures was determined by spectrophotometric analysis [7].

3. Results and discussion

3.1. Pervaporation

The pervaporation results for water–phenol, water–acetone and water–phenol–acetone mixtures were shown in

Figs. 3–12.

Table 3

Characteristics of the Amberlite resins

Copolymerisate

[m2 g−1 ]

Specific surface area

Porosity [cm3 cm−3 ]

Bulk density [g cm−3 ]

Particle size [mm]

XAD-4 styrene–divinylbenzene

XAD-7 acrylate–divinylbenzene

XAD-16 styrene–divinylbenzene

750

0.65–0.70

0.62–0.63

0.3–1.2

450

0.55

0.62

0.3–1.2

750

0.58–0.63

0.61

0.3–1.2

126

W. Kujawski et al. / Separation and Purification Technology 40 (2004) 123–132

Fig. 3. Separation diagram of hydrophobic membranes investigated in

contact with binary water–acetone mixtures (T = 313 K, permeate pressure <1 mbar).

All investigated hydrophobic membranes were selective

toward the organic component of the mixture, however, the

selectivity was dependent on both the polarity of organic

component and the kind of the membranes used for the

separation.

In case of water–acetone mixture (Fig. 3) the best separation properties were found for PERVAP-1070 membrane,

i.e. the PDMS membrane with zeolite filling, whereas the

PEBA membrane exhibited the lowest selectivity. During the

treatment of wastewater from the cumene oxidation process,

acetone is removed by distillation and its content is usually

low (Fig. 1). The content of acetone could be further diminished by pervaporation.

Fig. 4. Separation diagram of hydrophobic membranes investigated in

contact with binary water–phenol mixtures (T = 333 K, permeate pressure

<1 mbar).

Fig. 5. Enrichment β factor of hydrophobic membranes investigated in

contact with binary water–phenol mixtures (T = 333 K, permeate pressure

<1 mbar).

In contact with aqueous phenol solutions, the PEBA membrane, made of poly(ether block amide) polymer, showed the

highest selectivity. Both PDMS membranes were less selective (Figs. 4 and 5). The high selectivity of PEBA membranes

in contact with water–phenol mixtures have been already

reported by Kondo et al. [8] and Boeddeker et al. [9]. The

enrichment factor β (i.e. a ratio of mass fractions of the component preferentially transported in permeate and in feed,

respectively) [4] found for the PEBA membrane (Fig. 5) was

in the same range as found by Boeddeker et al. [9].

It is worth noting that for both the binary systems investigated, the zeolite filling of PERVAP-1070 membrane improved the membrane selectivity (Figs. 3–5).

Fig. 6. Separation diagram of hydrophobic membranes investigated in

contact with ternary water–phenol–acetone mixtures (T = 313 K, permeate

pressure <1 mbar).

W. Kujawski et al. / Separation and Purification Technology 40 (2004) 123–132

Fig. 7. Permeate phenol flux through hydrophobic membranes investigated

in contact with binary water–phenol mixtures (T = 333 K, permeate

pressure <1 mbar).

127

Fig. 9. Permeate phenol flux through hydrophobic membranes investigated in contact with ternary water–phenol–acetone mixtures (T = 313 K,

permeate pressure <1 mbar).

The selectivity of investigated membranes in contact with

water–phenol–acetone ternary mixture (Fig. 6) showed the

similar trends as for water–phenol binary mixture (Fig. 4).

The selectivity of membrane in contact with a ternary mixture is usually lower than that in contact with a binary one

[10]. This is caused by the additional plasticization effect exerted by the other organic component on the polymeric matrix, resulting in the increase of the water diffusion through

the membrane. The separation coefficients α (Eq. (1)) presented in Table 4 indicated that selectivity of the investigated

membranes decreased with increase of the phenol content

in the feed [7,8].

The transport properties of the investigated membranes

in contact with water–acetone, water–phenol and water–

phenol–acetone mixtures were presented in Figs. 7–12.

The permeate flux of the organic component (i.e. phenol

and/or acetone) through the membranes was linearly dependent on the feed composition (Figs. 7,9 and 11). The

highest flux of phenol through the PEBA membrane in

contact with 2 wt.% phenol solution was 150 g m−2 h−1

(Fig. 9). The permeate flux of water was also substantial (around 200 g m−2 h−1 for PEBA and PERVAP-1070

membranes and 600–800 g m−2 h−1 for the PERVAP-1060

membrane) but practically independent on the feed composition (Figs. 8,10 and 12). The detailed comparison

of fluxes of water and organics molecules through both

PERVAP-1060 (i.e. PDMS membrane) and PERVAP-1070

(i.e. zeolite filled PDMS membrane) allowed the expla-

Fig. 8. Permeate water flux through hydrophobic membranes investigated

in contact with binary water–phenol mixtures (T = 333 K, permeate

pressure <1 mbar).

Fig. 10. Permeate water flux through hydrophobic membranes investigated in contact with ternary water–phenol–acetone mixtures (T = 313 K,

permeate pressure <1 mbar).

128

W. Kujawski et al. / Separation and Purification Technology 40 (2004) 123–132

Fig. 11. Permeate acetone flux through PDMS (PERVAP-1060) and zeolite

filled PDMS (PERVAP-1070) hydrophobic membranes in contact with

binary water–acetone mixtures (T = 313 K, permeate pressure <1 mbar).

Fig. 12. Permeate water flux through PDMS (PERVAP-1060) and zeolite

filled PDMS (PERVAP-1070) hydrophobic membranes in contact with

binary water–acetone mixtures (T = 313 K, permeate pressure <1 mbar).

nation of the role of zeolite filling in the separation of

water–acetone and water–phenol mixtures (Figs. 7,8,11

and 12). It can be seen that for both the mixtures the selectivity of the PERVAP-1070 membrane exceeded that

Fig. 13. Phenol content in retentate vs. duration of batch pervaporation

process with hydrophobic membranes investigated (V/S = 2.5).

of the PERVAP-1060 one. In general, a decrease of water

flux would be expected due to the increase in the diffusion pathway in the polymer matrix in the presence of the

hydrophobic zeolite particles. On the other hand, the flux

of organic component can increase or decrease, depending

on the balance between the loss in flux due to the increase

of a tortuosity pathway and augmentation of organic compound sorption in the zeolite particles [5]. In the case of

water–acetone, zeolite fillings caused the decrease of both

water and acetone fluxes (Figs. 11 and 12), but the lowering

of water flux was more pronounced. On the other hand, in

the case of water–phenol mixture, zeolite fillings caused

the substantial decrease of the water flux only (Fig. 8),

whereas the flux of phenol remained practically unaltered

(Fig. 7).

There are several papers dealing with the feasibility of

pervaporation process to recover phenol from wastewater

[8,11–13]. Usually, pervaporation was combined with another technique (both the classical or membrane one) into

a hybrid process. The most work was done with the systems with phenol content in the feed in the range of hundred parts per million. One must remember, however, that

the concentration polarization effects are very strong at this

concentration region, which results in the decreasing of the

Table 4

Selectivity of hydrophobic membranes in contact with binary and ternary water–organics systems

Feed composition

(wt.% phenol)

PEBAX 4033

␣a H2 O/PhOH/Ac

␣b H2 O/PhOH

␣a H2 O/PhOH/Ac

␣b H2 O/PhOH

␣a H2 O/PhOH/Ac

␣b H2 O/PhOH

1

2

4

33.0

22.0

13.5

42.4

41.7

39.0

5.5

5.1

4.5

14.0

13.6

12.3

1.4

1.4

1.3

4.1

3.9

3.5

PhOH: phenol, Ac: acetone.

a Water–phenol–acetone system, T = 313 K.

b Water–phenol system, T = 333 K.

PERVAP 1070

PERVAP 1060

W. Kujawski et al. / Separation and Purification Technology 40 (2004) 123–132

129

Table 5

Efficiency of the phenol removal from wastewater, by using batch pervaporation with different hydrophobic membranes

Membrane

Time of pervaporation (h)

Retentate

Permeate

Fraction of feed

Phenol content (wt.%)

Fraction of feed

Phenol content (wt.%)

PERVAP-1070

PERVAP-1060

PEBA

27

18

8

0.80

0.43

0.92

0.18

0.17

0.17

0.20

0.57

0.08

14.0

5.1

35.2

V/S: 25 kg m−2 , T: 333 K, feed: 3 wt.% of phenol.

efficiency of the process. Application of adsorption would

be much more efficient in this concentration range.

The results obtained on the transport and selective properties of membranes investigated in this work were applied

to the estimation of the efficiency of pervaporation in the

removal of phenol from wastewater. Assuming that the feed

concentration of phenol was equal to 30 g dm−3 (Fig. 1), we

estimated, for each membrane, the time needed to lower the

content of phenol in retentate, down to 2 g dm−3 (Fig. 13).

Additionally, the amount and composition of permeate were

also calculated (Table 5). Calculations were made for the

batch pervaporation and the feed to the membrane area ratio

(V/S) equal to 25 kg m−2 .

Present results proved the high efficiency of the PEBA

membrane in the recovery of phenol. The pervaporation unit

with the PEBA membrane would need about 8 h to decrease

the phenol level in the retentate down to 2 g dm−3 . Moreover,

permeate was only 8% of the beginning amount of the feed

mixture, with the average content of phenol equal to 35 wt.%.

Thus, the phenol content in the treated wastes would be diminished about 15 times. Calculations made for the both

PDMS membranes (i.e. PERVAP-1060 and PERVAP-1070)

showed that time needed for the wastewater treatment would

be longer (Table 5). It is also worth mentioning that time

needed to reach a given dephenolization degree, can be altered by changing the temperature of the system and by

changing the V/S ratio (Fig. 14) [10].

More results on the optimization of the pervaporation process for the phenol recovery from wastewater, based on pervaporation experiments in a larger scale, have been recently

performed in our laboratory [14].

Fig. 14. Phenol content in retentate vs. duration of batch pervaporation

process using PEBA membrane for different V/S ratio.

also the earlier results obtained by Li et al. for sorption of

phenol traces by Amberlite XAD-4 (phenol concentration

below 1 g dm−3 ) [20,21]. Additional experiments, which

were carried out for ternary solutions containing various

amounts of sodium sulphate (up to 50 g dm−3 ) indicated

that phenol sorption on the Amberlite XAD-4 increased

with the increase of Na2 SO4 content in solution (Table 6).

Adsorption equilibria are usually described using various

equations. Among them the Freundlich and the Langmuir

equations are the most frequently used [16,19–21]. In the

case of the investigated Amberlite resins the best fitting was

3.2. Adsorption

3.2.1. Equilibrium adsorption

Sorption isotherms of phenol on the Amberlite resins

(XAD series) plotted in Fig. 15 enabled the comparison of properties of various adsorbents and the choice

of the most efficient one. The Amberlite XAD-4 and

XAD-16 resins made of styrene–divinylbenzene copolymer

showed higher affinity to phenol than the XAD-7 one with

methyl acrylate–divinylbenzene copolymer matrix. The

poly(styrene–divinylbenzene) resins were known as efficient

phenol adsorbent [15]. Amberlite XAD-4 was successively

used for adsorption of various organic compounds [16,17],

among them aromatic ones [18,19]. Our results confirmed

Fig. 15. Adsorption isotherms of phenol on the Amberlite resin of various

grades. Experimental points were indicated, curves correspond to the

Freundlich equation.

130

W. Kujawski et al. / Separation and Purification Technology 40 (2004) 123–132

Table 6

Coefficients of the Freundlich equation for the adsorption of phenol on

the Amberlite resin of various grades

adsorbent

Na2 SO4 content

(g dm−3 )

k

n

r

XAD-7

XAD-16

XAD-4

XAD-4

XAD-4

0

0

0

20

50

16.12

22.47

31.81

34.37

36.97

2.268

2.247

2.326

2.381

2.564

0.9920

0.9999

0.9981

0.9997

0.9994

obtained using the former one. The coefficients k and n of

the Freundlich equation:

q = kc1/n

(2)

where q is adsorption capacity (mass of phenol per unit volume of adsorbent), c the equilibrium phenol concentration in

solution, were listed in Table 6. In all cases, the Freundlich

equation fitted well the experimental data (correlation coefficients r over 0.99). The coefficient k was usually considered as a relative indicator of adsorption capacity. The concave shape of the isotherms and the coefficient n exceeding

unity indicated favourable phenol adsorption [21].

Taking into account the results concerning equilibrium

phenol adsorption on various grades of the Amberlite resin,

further adsorption experiments under dynamic conditions

were carried out using Amberlite XAD-4 alone.

3.2.2. Adsorption under dynamic conditions

Adsorption under dynamic conditions was performed in

order to investigate properties of the chosen adsorbent Amberlite XAD-4 during adsorption and regeneration steps. The

solutions modelling partially dephenolized wastes contained

phenol (3–5 g dm−3 ) and sodium sulphate (30 g dm−3 ). Four

kinds of incombustible liquors were used to regenerate the

resin bed.

The breakthrough curve for the adsorption step made it

possible to estimate the volume of eluate up to breakthrough

point (Vs ), which corresponded to the volume of decontaminated eluate. On the other hand, the regeneration (elution)

curve indicated the volume of a regenerant (VR ) at which

its concentration decreased to a desired low value. This volume of regenerant was necessary to elute phenol out from

the bed resin. The difference V = Vs − VR was regarded

as a measure of the efficiency of the regenerant used. The

higher V value, the more efficient the regenerant was.

The breakthrough and regeneration curves obtained

at 368 K (95 ◦ C) using water, sodium sulfate solution

(30 g dm−3 ) and treated model solution (with phenol concentration of 0.08 g dm−3 ) were presented in Fig. 16. Phenol concentration in the feed was equal to 5 g dm−3 . It was

found that the highest volume of the treated waste (V

≈ 6 BV) was obtained, when the adsorbent bed was regenerated with hot water. Sodium sulfate solution and treated

model solution were the less efficient regenerants (V

approximately equal to 4 and 1 BV, respectively).

Fig. 16. The breakthrough curve for adsorption and the regeneration

(elution) curve. The Amberlite XAD-4 bed regenerated at 368 K using

water, sodium sulphate solution and treated model solution. The dashed

line indicates phenol concentration in the feed (5 g dm−3 ). The eluate

volume on the abscissa axis is expressed in the volume of resin bed (BV).

Fig. 17. The breakthrough curve for adsorption and the regeneration

(elution) curve. The Amberlite XAD-4 bed regenerated at 333 K using

sodium hydroxide solution (200 g dm−3 ). The dashed line indicates phenol

concentration in the feed (3 g dm−3 ). The eluate volume on the abscissa

axis is expressed in the volume of resin bed (BV).

The regeneration step could be carried out efficiently

with hydroxide solution due to the chemical reaction between phenol and hydroxide. The phenolate formed is not

adsorbed on the resin and as the consequence the low

concentration of phenol in solution changes the equilibrium sorption–desorption enhancing desorption of phenol

from the bed. It is seen from Fig. 17, that about 8 BV

of the model waste solution (i.e. solution containing phenol at the concentration 3 g dm−3 ) could be purified in

one adsorption-regeneration cycle. Moreover, it would be

possible to use sodium hydroxide solution (200 g dm−3 )

several times as an efficient regenerant, which could additionally decrease the total volume of the concentrate. The

breakthrough curves proved also that the repeated usage of

sodium hydroxide solution did not influence the efficiency

of the adsorption of phenol during the next adsorption steps

(Fig. 17).

4. Conclusions

Pervaporation experiments proved that phenol could

be effectively removed from the aqueous solutions using

the appropriate organophilic membranes. All investigated

membranes (i.e. PERVAP-1060, PERVAP-1070 and PEBA)

W. Kujawski et al. / Separation and Purification Technology 40 (2004) 123–132

131

Fig. 18. The proposed hybrid pervaporation–adsorption process for treatment of wastewaters containing phenol. (A) General concept. (B) Pervaporation

part of the hybrid system [14].

showed interesting selective and transport properties in

contact with binary and ternary water–organics mixtures.

In general, the membrane selectivity was smaller in contact

with ternary mixture comparing to the binary one. Although

the poly(ether block amide) membrane (PEBA) possessed

the best separation properties in the removal of phenol, it is

not actually available on the commercial scale. Thus, in the

practical applications PERVAP-1060 and PERVAP-1070

could be used [14]. Partial permeate fluxes of phenol

through both PDMS membranes were practically the same.

It means that the presence of zeolite filling of PERVAP-1070

membrane did not influence the phenol transport. On the

other hand, flux of water was much smaller through the

PDMS membrane with the zeolite filling (PERVAP-1070)

compared to the pure PDMS membrane (PERVAP-1060).

The enhancement of transport in the presence of zeolite

was observed in the case of acetone transport.

The static adsorption experiments proved that the Freundlich equation described well the sorption phenomena in

all systems. The best sorption properties were found in the

case of the Amberlite XAD-4. Using this adsorbent, made

of cross-linked styrene–divinylbenzene copolymer, the removal of phenol from model solution containing phenol

(3–0 g dm−3 ) and sodium sulphate (30 g dm−3 ) was carried

out by the column method. Non-combustible liquors: distilled water, sodium sulphate solution (30 g dm−3 ), eluate

and sodium hydroxide solution (200 g dm−3 ) were used to

regenerate the sorbent bed. The breakthrough curve and the

regeneration (elution) curve were determined. It was found

that the regeneration of the sorbent bed using NaOH solution enables the most effective removal of phenol from low

concentrated solution.

Pervaporation and adsorption results obtained with

water–phenol mixtures suggest that the hybrid system could

be used to the efficient decontamination of the effluents

from the cumene oxidation process. The scheme of such

hybrid process was presented in Fig. 18 [14].

References

[1] Anonymus, Phenol, Chem. Week 164 (2002) 31.

[2] P. Wiseman, An Introduction to Industrial Organic Chemistry, Applied Science Publishers Ltd., London, 1979.

[3] W. Jordan, H. van Barneveld, O. Gerlich, M. Kleine-Boymann, J.

Ullrich, Phenol, in: B. Elves, S. Hawkins, W. Russey, G. Schulz

(Eds.), Ullmanns Encyclopaedia of Industrial Chemistry, vol. A19,

VCH Publishers, Weinheim, 1991, pp. 299–312.

[4] W. Kujawski, Polish J. Environ. Stud. 9 (2000) 13.

[5] W. Kujawski, Sep. Sci. Technol. 35 (2000) 89.

[6] M. Marhol, Ion Exchangers in Analytical Chemistry. Their Properties

and Use in Inorganic Chemistry, Academia, Prague, 1982.

[7] T. Nowicka-Jankowska, E. Wieteska, K. Gorczyñska, A. Michalik, Spektro-fotometria UV/VIS w Analizie Chemicznej, PWN,

Warszawa, 1988.

[8] M. Kondo, H. Sato, Desalination 98 (1994) 147.

[9] K.W. Boeddeker, G. Bengston, E. Bode, J. Membr. Sci. 53 (1990)

143.

[10] W. Kujawski, R. Roszak, Sep. Sci. Technol. 37 (2002) 3559.

[11] C.C. Pereira, A.C. Habert, R. Nobrega, C.P. Borges, J. Membr. Sci.

138 (1998) 227.

[12] M. Benett, B.J. Bridson, R. England, R.W. Field, J. Membr. Sci. 137

(1997) 63.

[13] P. Wu, R.W. Field, R. England, B.J. Bridson, J. Membr. Sci. 190

(2001) 147.

[14] W. Kujawski, A.Warszawski, W.Capała, R.Ratajczak, Application of

pervaporation to treatment of wastewater containing phenol, Przem.

Chem. 83 (2004), in press.

132

W. Kujawski et al. / Separation and Purification Technology 40 (2004) 123–132

[15] C. Klampfl, E. Spanos, J. Chromatogr. A 715 (1995) 213.

[16] D.S. Grzegorczyk, G. Carta, Chem. Eng. Sci. 51 (1996) 807.

[17] J.L. Martı́nez Vidal, F.J. Egea González, C.R. Glass, M. Martı́nez

Galera, M.L. Castro Cano, J. Chromatogr. A 765 (1997) 99.

[18] W.-L. Song, Z.-L. Zhi, L.-S. Wang, Talanta 44 (1997) 1423–

1433.

[19] Z. Xu, Q. Zhang, J. Chen, L. Wang, G.K. Anderson, Chemosphere

38 (1999) 2003–2011.

[20] A. Li, Q. Zhang, J. Chen, Z. Fei, C. Long, W. Li, React. Funct.

Polym. 49 (2001) 225–233.

[21] A. Li, Q. Zhang, G. Zhang, J. Chen, Z. Fei, F. Liu, Chemosphere

47 (2002) 981–989.