Liquefaction of nitrogen using mixed refrigerant processes G. Venkatarathnam

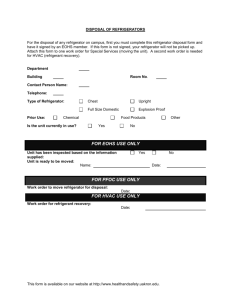

advertisement

Liquefaction of nitrogen using mixed refrigerant processes G. Venkatarathnam∗ Refrigeration and Airconditioning Laboratory Department of Mechanical Engineering Indian Institute of Technology Madras Chennai 600036 Abstract Mixed refrigerant cycle refrigerators and liquefaction systems are under development in our laboratory. The main advantage of these processes is the requirement of low working pressures, typically less than 20 bar. The cost of the system is quite low since single stage traditional refrigeration (R22) compressors can be used in these systems. In case of nitrogen liquefiers, nitrogen pressures of 5 to 6 bar is adequate in many processes. In this paper, we present some results obtained with our mixed refrigerant refrigerator prototypes. Introduction The use of refrigerant mixtures for cryogenic refrigeration was first proposed by Podbielniak in a U.S. patent in 1936 [1]. Kleemenko demonstrated the liquefaction of natural gas using a mixed refrigerant process in 1959 [2]. Most large base load natural gas liquefaction plants operate on processes derived from the basic Kleemenko process, the most popular process being the C3-MR process pioneered by Air Products and Chemicals, USA. Most of the early research on the use of refrigerant mixtures for cryogenic refrigerator and liquefier applications appears to have been done in the former Soviet Union under classified programs. In the mid 90s, DARPA, USA initiated a program for the development of a $1000 cryocooler [3]. Two commercial refrigerators, one by APD Cryogenics (now Polycold) and MMR Inc. resulted from this funding in the 90’s. Praxair has been granted several patents during the last four years on liquefaction of gases and air separation using mixed refrigerant cycles [4-5]. These cycles employ non flammable mixtures. Air Products has patented a hybrid mixed refrigerant and turbine process for liquefaction of nitrogen. Their mixture consists of nitrogen and other hydrocarbon refrigerants [6]. Mixed refrigerant cycle refrigerators have been under development in our laboratory for more than five years. Several undergraduate, postgraduate and doctoral theses have been completed on different aspects of mixed refrigerant cycle cryogenic refrigerators. In this paper we describe the fundamental aspects of mixed refrigerant cycles and the work being done at IIT Madras. ∗ http://mech.iitm.ac.in/faculty/vg.html, Email: gvenkat@iitm.ac.in, phone: 2257-8552, 2257-8581 MIXED REFRIGERANT CYCLE REFRIGERATORS The simplest of cryogenic refrigeration processes is the Linde-Hampson process (Fig. 1). Linde-Hampson refrigerators are also known in literature as Joule Thomson coolers, and are used in a variety of applications including cooling of infra red detectors in missiles etc. In most cases nitrogen is used as the working fluid in these refrigerators. The main drawback of the Linde-Hampson refrigerator is the requirement of a very high operating pressure, typically above 200 bar. The requirement of high pressure limits the use of Linde-Hampson refrigerator to a small number of applications in which the high pressure gas is supplied in a gas bottle. The main advantages of the cycle are its simplicity, absence of any moving components, and fast cool down. Refrigerators such as Stirling, Gifford-McMahon and Pulse-tube refrigerators are not widely used in civilian applications because of the high cost associated with the specialized hardware required in these systems. Stirling refrigerators are used in our country in a number of rural veterinary hospitals and universities for liquefaction of nitrogen. However, their initial cost is quite prohibitive. The working pressure of the Linde-Hampson refrigerator can be reduced to less than 20 bar if the pure working fluid such as nitrogen is replaced by a mixture of gases such as nitrogen, methane, ethane and propane. The small working pressures allow us to use conventional refrigeration compressors (R22), which are built in large numbers. The low pressures also allow us to use regular refrigeration materials such as copper tubes in heat exchangers, and conventional refrigeration compressors. The cost of a Linde-Hampson refrigerator will therefore be only a small fraction of the cost of Stirling, G-M or Pulse-tube refrigerators. The main problem in using conventional oil lubricated refrigeration compressors is that the lubricating oil carried over needs to be removed completely before the refrigerant enters the cold box (cryostat). 5 6 2a 1 . - Wc Co mpressor Evaporator . 2 (m) . Qo Af tercoo ler 3 He at exchanger . Q 4 Expansio n valve 450 2 1 6 Temperature 200 bar 1 bar 3 2a Mixture 20 bar 2 bar 350 Temperature (K ) Nitrogen 400 300 Ambient temperature 2 6 1 250 200 150 45 f Entropy 100 3 4 5 -300 -280 -260 -240 -220 -200 -180 -160 -140 -120 -100 Entropy (J/mol.K) Figure 1 : Linde-Hampson cycle refrigerator working with pure nitrogen and mixtures REFRIGERANT MIXTURES Our own research in mixed refrigerant cycles has shown that nitrogen-neonhydrocarbon mixtures such as nitrogen/neon/methane/ethane/propane are most suitable for obtaining temperatures from 70 K to 120 K. Nitrogen-hydrocarbon mixtures such as nitrogen/methane/ethane/propane are excellent for temperatures in the range of 90-120 K, where as Argon-hydrocarbon mixtures such as argon/methane/ethylene/propane are excellent for temperatures in the range of 120-150 K. We’ve also tested mixtures such as argon-nitrogen-helium-methaneethane-propane mixtures, which have been found to be excellent for operation in the 80-120 K temperature region. The composition to be used depends on a variety of factors including the type and size of the heat exchanger used, type of compressor used, the desired amount of refrigeration etc. There’re no known rules for choosing the mixture composition. Dozens of patents exist on the “best” composition to be used. Several patent applications have also been filed by us during the last one year, and one patent has already been granted. 60 Heat load (Watts) 50 40 30 b 20 a N2-Ar-He-HC mixture b b 10 a a N2-Ar-HC mixture Ar-HC mixture 0 75 80 85 90 95 100 105 110 115 120 125 130 135 140 145 150 Refrigerant temperature at evaporator outlet (K) Figure 2: Heat load characteristics with different refrigerant mixtures with a power input of 900 to 1100 Watts 45 Heat load (Watts) 40 35 30 25 20 mixture 1 mixture 2 mixture 3 15 10 5 0 90 100 110 120 130 140 Refrige rant temperature at evaporator exit (K) Figure 3: Heat load characteristics of our most recent prototype with power input of 600-750 Watts Figure 2 shows the performance of our third generation refrigerator with a power input of 900 to 1100 Watts. Figure 3 shows the performance of our most recent prototype with a power input of 600 to 750 Watts using nitrogen hydrocarbon mixtures. The exergy efficiency of our refrigerator is close to that of commercial Gifford-McMahon cryogenic refrigerators at 100 K. The main advantage with our refrigerator is the low cost, because of the use of refrigerant compressors used in domestic air conditioners and off the shelf components. Warm end temperature difference (K) 5.0 mixture-1 mixture-2 mixture-3 4.5 4.0 3.5 3.0 2.5 2.0 1.5 1.0 0.5 0 0 10 20 30 Load (Watts) 40 50 Figure 4: Warm end temperature difference in the heat exchanger in our most recent prototype with different nitrogen hydrocarbon mixtures The excellent performance of our system is largely due to the very small temperature approaches or high effectiveness of the heat exchanger in our refrigerator, and the mixtures tested. It can be seen from Fig. 4 that the warm end temperature approach between the streams is only 1 to 4.5 K, corresponding to a temperature change of about 180 to 210 K for the cold stream. A single refrigerator prototype costs us less than Rs. 50,000 to build (with out the cryostat), with the cost of the imported oil filters being about half that price. Figure 5 shows the pictorial view of our refrigerator. Compressor, aftercooler Cold box Figure 5 : Pictorial view of our cryogenic refrigerator showing the compressor and cold box. A 1.0 TR R22 Window air conditioner compressor is used in the system. The system has been tested in the temperature range of 80-120 K with working pressures of 15-20 bar. LIQUEFACTION OF GASES USING MIXED REFRIGERANT CYCLES Mixed refrigerant cycles are used in very large natural gas liquefaction plants (up to 5 MMTY). However, there is considerable interest worldwide in using them for liquefaction of other gases such as nitrogen, air etc. The simplest cycle that can be used for the liquefaction of gases is shown in Fig. 6. In this cycle a mixed refrigerant is pressurized to about 15-20 bar in the refrigeration system. The refrigeration system provides all the refrigeration necessary for cooling nitrogen at 5 to 6 bar pressure to saturated or even subcooled liquid. In large systems the refrigeration available with the flash gas can also be used to improve the liquid yield. The system has high efficiency and can compete with turbine based plants. The cost, however, would be much smaller because of the use of low pressure compressors and absence of turbine. Air products and chemicals have recently patented a hybrid mixed refrigerant-turbine cycle for the liquefaction of nitrogen. LN2 Mixed refrigerant cycle nitrogen in Figure 6 : Simple mixed refrigerant cycle nitrogen liquefaction cycle Small nitrogen liquefaction cycles based on mixed refrigerant processes are very ideal for our country and can compete effectively with small Stirling cycle liquefiers. A small nitrogen liquefier prototype is currently under development in our laboratory, the results of which will be shared with this august audience in the future AIIGMA meetings. References [1] W.J. Podbielniak, Art of Refrigeration,U.S. Patent 2,041,725 (1936) [2] A. P. Kleemenko, One flow cascade cycle, Proceedings of the 10th international congress of refrigeration, Vol. 1, 34-39 (1959) [3] M. Nisenoff, F. Patten and S.A. Wolf, ...And What about Cryogenic Refrigeration, Proc. of International Cryocooler Conference, June 25-27, 1996, Waterville, USA [4] A. Bayram, W. J. Olszewski, J. A. Weber, D. P. Bonaquist. A. Acharya and J. H. Royal, Multicomponent refrigerant cooling with internal recycle, US Patent 6,065,305 (2000) [5] B. Arman, D. P. Bonaquist, J. A. Weber, J. H. Ziemer, A. Acharya and M. A. Rashad, Cryogenic rectification method for producing nitrogen gas and liquid nitrogen, US Patent 6,125,656 (2000) [6] A. A. Brostow, R. Agrawal, D. M. Herron, and Mark Julian Roberts, Process for nitrogen liquefaction, US Patent 6,298,688 (2001)