Extraction of Phenolic Antioxidant Compounds from Peanut Skins Project Overview: Economic Feasibility:

advertisement

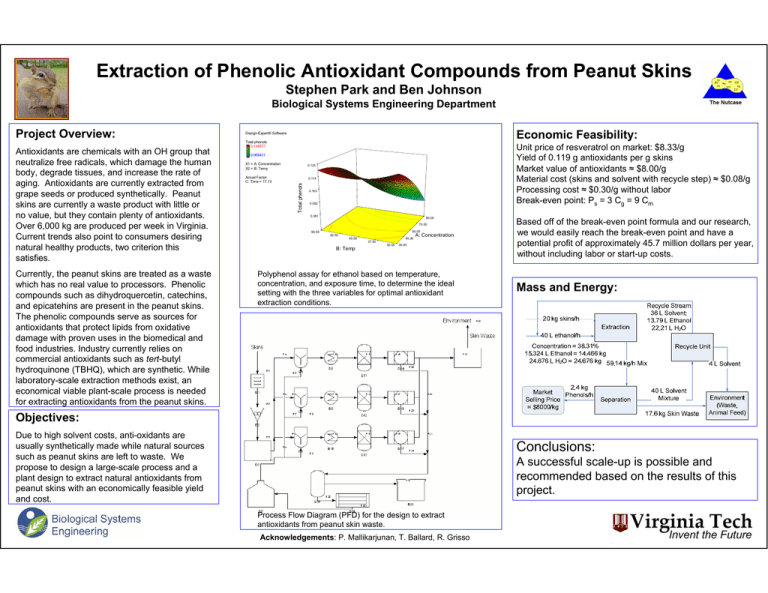

Extraction of Phenolic Antioxidant Compounds from Peanut Skins Stephen Park and Ben Johnson Biological Systems Engineering Department Antioxidants are chemicals with an OH group that neutralize free radicals, which damage the human body, degrade tissues, and increase the rate of aging. Antioxidants are currently extracted from grape seeds or produced synthetically. Peanut skins are currently a waste product with little or no value, but they contain plenty of antioxidants. Over 6,000 kg are produced per week in Virginia. Current trends also point to consumers desiring natural healthy products, two criterion this satisfies. Currently, the peanut skins are treated as a waste which has no real value to processors. Phenolic compounds such as dihydroquercetin, catechins, and epicatehins are present in the peanut skins. The phenolic compounds serve as sources for antioxidants that protect lipids from oxidative damage with proven uses in the biomedical and food industries. Industry currently relies on commercial antioxidants such as tert-butyl hydroquinone (TBHQ), which are synthetic. While laboratory-scale extraction methods exist, an economical viable plant-scale process is needed for extracting antioxidants from the peanut skins. Economic Feasibility: Design-Expert® Software Total phenols 0.116977 Unit price of resveratrol on market: $8.33/g Yield of 0.119 g antioxidants per g skins Market value of antioxidants ≈ $8.00/g Material cost (skins and solvent with recycle step) ≈ $0.08/g Processing cost ≈ $0.30/g without labor Break-even point: Ps = 3 Cg = 9 Cm 0.069431 X1 = A: Concentration X2 = B: Temp 0.125 Actual Factor C: Time = 17.13 0.114 Total phenols Project Overview: 0.103 0.092 0.081 90.00 75.00 60.00 60.00 52.50 45.00 45.00 A: Concentration 37.50 B: Temp 30.00 30.00 Polyphenol assay for ethanol based on temperature, concentration, and exposure time, to determine the ideal setting with the three variables for optimal antioxidant extraction conditions. Based off of the break-even point formula and our research, we would easily reach the break-even point and have a potential profit of approximately 45.7 million dollars per year, without including labor or start-up costs. Mass and Energy: Objectives: Due to high solvent costs, anti-oxidants are usually synthetically made while natural sources such as peanut skins are left to waste. We propose to design a large-scale process and a plant design to extract natural antioxidants from peanut skins with an economically feasible yield and cost. Conclusions: A successful scale-up is possible and recommended based on the results of this project. Process Flow Diagram (PFD) for the design to extract antioxidants from peanut skin waste. Acknowledgements: P. Mallikarjunan, T. Ballard, R. Grisso