Impact behavior of parallel strand lumber (PSL)

advertisement

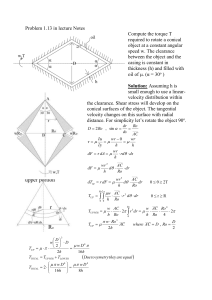

Impact behavior of parallel strand lumber (PSL) P. Sukontasukkul1, S. Mindess2, and N. Banthia3 ABSTRACT In this study, both static and impact behaviors of Parallel Strand Lumber (PSL) was investigated. Series of test were conducted using two types of loading head (tup): blade and circular shape. The use of circular tup as a new testing technique was to reduce the localized damage and to obtain the “true” impact strength of PSL. It was found that PSL tested using circular tup exhibited noticeably less localized damage and more stress rate sensitivity than those tested using blade tup. INTRODUCTION Parallel Strand Lumber (PSL) emerged as a new manufactured wood product with high quality and consistent mechanical properties. Its manufacturing process can be found Wood Reference Handbook (1991). Application of PSL are primarily restricted to static loading conditions. However, the use of PSL can be expanded to consider impact loading if the impact data was available. Mindess et al. (1986) found that wood exhibited very small stress rate sensitivity. However, large amounts of localized damage occurred in the impact tests because their experiments were carried out using a fairly sharp blade-shape tup, which tended to cut through the wood for some distance before the specimen began to fail in flexure. This localized damage is believed to play an important role in their test results, which probably reflect the strength and stiffness of the contact area rather than the real impact strength of the material. In this study, tests on PSL were conducted under similar condition to those used by Mindess et al. (1986). However, two major modifications were made to the impact testing machine: (1) a change in the shape of the loading head, and (2) the installation of a stopping device for the hammer, in order to reduce localized damage. EXPERIMENTAL PROCESS PSL specimens with dimensions of (width x depth x length) 100*100*650 mm were used in this study. Prior to testing, the PSL specimens were conditioned in a controlled temperature and humidity room (20o C and 60% relative humidity) until equilibrium was reached. For both static and impact tests, the specimens were placed on their supports so that the orientation of the ends of wood strands was in the vertical direction as shown in Fig. 1. Section A-A (all measurements in mm) Fig. 1 Orientation in longitudinal and transverse direction of the test specimen 1 PhD Candidate, Dept. of Civil Engineering, University of British Columbia, Vancouver, BC, Canada Professor, Dept. of Civil Engineering, University of British Columbia, Vancouver, BC, Canada 3 Professor, Dept. of Civil Engineering, University of British Columbia, Vancouver, BC, Canada 2 Two series of test were conducted: static and impact, with two different types of loading heads: blade shaped and cylindrical shape (100 mm-diameter); these are shown schematically in Fig. 2. Static testing was conducted on a 1781 kN universal testing machine. The beams were simply supported with a 550-mm clear span. The load was applied at the center of the beam using both shapes of loading head, and the data were collected using a PC-based data acquisition system. For the impact tests, an instrumented drop-weight impact apparatus designed and constructed in the Department of Civil Engineering, University of British Columbia was used. The machine has the capacity of dropping a mass of 578 kg from heights of up to 2500 mm onto the target specimen. The striking tups (both circular and blade shaped) with strain gauges mounted within them, were connected rigidly to the 578 kg drop hammer. The specimens were simply supported on a support anvil using the same span length as in the static tests. The hammer was dropped from three different drop heights 500 and 1250 mm, which provided striking velocities of 3.13 and 4.94 m/s and impact energies of 2832 and 7088 J, respectively. An accelerometer was placed on the underside at the mid-point of each specimen to measure the acceleration. According to the photographic record obtained using a high-speed video camera (1000 frames/second), the deflection of the beam was essentially parabolic prior to the peak and then the deflected shape of each half beam become essentially linear after the peak load. Therefore, the distribution of the acceleration along the length of the beam was assumed to be of a sinusoidal shape during the elastic range and linear from the center to the supports during the inelastic range. The data were acquired using a high-speed PC-based data acquisition system. (a) (b) (all measurements in mm.) Fig. 2 The geometry of the loading head (a) circular tup, and (b) blade tup Impact data analysis True bending load and generalized inertial load (Banthia 1987) The true bending load (Pb(t)) can be obtained by subtracting the generalized inertial load (Pi(t)) from the measured tup load (Pt(t)), which is then given as: Pb (t ) = Pt (t ) − Pi (t ) (1) By assuming the acceleration distribution to be sinusoidal prior to the peak load (during the elastic range) and linear after the peak, Pi(t) could be calculated as follows: é l 2π 2 ov 3 ù Pi (t ) = ρAu0 (t ) ê + ú 3l 2 û ë2 é l 8(ov) 3 ù Pi (t ) = ρAu0 (t ) ê + ú 3l 2 û ë3 t < t peak (2) t ≥ t peak (3) where u0 (t ) is the acceleration at the midspan of the beam ρ is the density of the Parallam wood composite A l ov is the cross-sectional area of the beam is the clear span of the beam is the overhang length of the beam The nominal strength and the stress rate The nominal strength and the stress rate were then calculated as: Nominal Flexural Strength ( σ N ) Stress Rate where M c I T (σ ) = Mc I (4) = σN T (5) is the maximum applied bending moment is the distance from the neutral axis to the top fibre is the moment of inertia is the time to failure RESULTS AND DISCUSSION Failure mechanism The failure mechanism of PSL wood is more complex than that of natural (or non-processed) clear wood due to the nature of PSL itself, which is a glued-manufactured product made of long wood strands. The primary failure mode thus may involve not only a flexural failure, but also shear failure and the debonding of the wood strands (Fig. 3a-d). Under static loading, the specimen response consisted of 3 stages: 1) In the elastic stage, the load increased linearly with the deflection; 2) At the beginning of the inelastic stage, the shearing at the mid-section at one end, and the initiation of debonding of wood strand layers at the bottom of the beam, followed by a significant drop in load; 3) Finally, the splitting or debonding of the bottom fiber led to the failure of the specimen. The difference in the shape of the loading tup did not alter the sequence of beam response to the applied static load. However, more localized damage was observed in the tests with the blade tup than with the circular tup. Under the impact loading, the failure mode was affected by the shape of loading head. Two typical modes of failure were observed: flexure and shear-flexure. The flexural mode, accompanied by considerable localized damage, predominated when tested with the blade tup (Fig. 3a and 3b). When using the circular tup, however, the typical failure mode of the beam changed dramatically. The amount of localized damage decreased and the primary failure mode was combined shear-flexure (Fig. 3b and 3c). The failure sequences of PSL under both tups taken by high speed video camera are demonstrated in Fig. 4a-b. In Fig. 4a, the response of the PSL beam under blade tup is shown in 4 millisecond intervals from zero ms to 20 ms. The localized damage began at the very beginning of contact, as the blade tup cut through the surface of the wood. Around 8 ms, the first signs of splitting and fracturing of the bottom fibers occurred, leading to a significant drop in load and failure of the specimen. There was no sign of shear failure at the end of specimen, as was the case in static loading. This is perhaps due to the shape of the blade tup. Because of the contact area of the blade tup was much smaller compared to that of the circular tup; therefore, the forces were highly concentrated at the contact area, resulting in considerable damage at mid-span. The specimen crushed into two straight pieces (V-shape) within a few milliseconds. For the circular tup, the failure of the beam was accompanied by shearing at the mid-section (Fig. 4b) and also debonding at the bottom fiber of the beam. At the very beginning of the contact or during the elastic range, the deflected shape of beam was essentially parabolic. At 4-8 ms, the first sign of shear failure at the end occurred, followed by debonding at the bottom fiber. Unlike the test with the blade tup, damage was not concentrated only in the contact area. Here, the whole beam exhibited damage. However, even though the failures were less localized with circular tup because of the greater contact area and the more distributed damage, the PSL tested under impact loading still exhibited some degree of localized damage due to the relative softness of the wood. (a) (b) (c) (d) Fig. 3 Failure patterns: a) localized damage, and b) flexural and debonding of PSL under impact loading-blade tup; c) decreasing localized damage, and d) shear-flexural failure of PSL under impact loading- circular tup 0 ms 4 ms 8 ms (a) 12 ms 20 ms 0 ms 4 ms 8 ms (b) 12 ms 20 ms Fig. 4 Response of the PSL beam under impact loading up to 20 milliseconds- (a) blade tup and (b) circular tup Flexural strength The typical static and impact load-deflection curves for both tups are compared in Fig. 5a-b. The shape of loading head had a tremendous effect on both static and impact strength of PSL (Table 1 and Fig. 6). Both static and impact strength (at 500 and 1250 mm drop height) of PSL tested with circular tup increased by 31, 65 and 74%, respectively, as compared to those tested with blade tup. When using the blade tup, the tup cut through the top surface of the wood to a considerable depth before the specimen failed by debonding. Thus, the strength results obtained from these tests cannot really be considered as the “true” bending strength; they are more a reflection of the interactions between the steel striking tup and the much softer wood in the contact region. With the 100 mm diameter circular tup, the localized failure was reduced significantly. A much greater volume of the beam became involved in reacting with the applied load. In order to cause failure, the force had to overcome not only the bending and crushing strength of the wood, but also the shearing and debonding strength of wood strands. Unlike the tests with the blade tup, the results obtained from tests with the circular tup provided a much better representation of the “true” impact bending strength of the PSL. In addition, PSL also did not exhibit significant rate sensitivity when testing with blade tup. The average impact strength of the specimens tested with the blade tup was not much different from their static strength, the strength increased by only 1% and 15% (Table 1 and Fig. 6) at the hammer drop height of 500 and 1250 mm, respectively. However, when using the circular tup, PSL exhibited distinctly rate sensitive behavior. The measured impact strength at 500 and 1250 mm drop height increased dramatically by about 27% and 53%, respectively, over the static strength (Table 1 and Fig. 6). This may be attributed in large part to the influence of the shape of the tup itself. 100 100 Blade Tup Circular Tup Blade Tup-Impact 500 mm 80 Load (kN) Load (kN) 80 60 40 20 Circular Tup-Impact 500 mm 60 40 20 0 0 0 5 10 15 20 Deflection (mm) 25 30 0 5 10 15 20 25 Deflection (mm) (a) 30 35 (b) Fig. 5 Typical load deflection curve of PSL under (a) static and (b) impact loading using different tup Table 1 Static and impact strength of PSL Type of Loading head Blade Tup Circular Tup Static Strength (MPa) Mean S.D. 47.84 2.17 62.85 2.81 S.D: Standard deviation Impact Strength at 500 mm Impact Strength at 1250 mm (MPa) (MPa) Mean S.D. Mean S.D. 48.15 6.09 55.12 6.29 79.60 7.11 95.95 10.75 Strength (MPa) 100 80 60 40 20 - Blade Tup Circular Tup Shape of Loading Head Static Impact at 500 mm Impact at 1250 mm Fig. 6 Effect of loading head tup on static and impact strength Relationships between nominal strength and stress rate. The relationship between the nominal bending strength and the stress rate (Fig. 7) can be expressed as follow: For PSL tested with circular tup For PSL tested with blade tup σC σB σ is the impact strength of PSL tested with circular tup (MPa) is the impact strength of PSL tested with blade tup (MPa) is the stress rate (MPa/sec) 120 100 Strength (MPa) where σ C = −2 × 10 −13 σ 3 + 2 × 10 −8 σ 2 − 10 −4 σ + 62.93 σ B = −10 −11 σ 3 + 4 × 10 −7 σ 2 − 2.5 × 10 −3 σ + 47.96 2 80 R = 0.9114 60 2 40 R = 0.5689 20 - 20,000 40,000 60,000 Stress Rate (MPa/Sec) Circular Tup Blade Tup Fig. 7 Relationship between strength and stress rate 80,000 It was found that PSL tested with the blade tup exhibited only a very small rate sensitivity, which is not consistent with our knowledge of wood behavior (e.g. Mindess et al 1979). By changing to a circular tup, the strength did become rate sensitive, as expected. In addition, the impact strength obtained from testing the blade tup was always lower than that obtained with the circular tup at the same rate of loading. At the stress rate of 104 MPa/sec, the blade tup impact strength was about 45 MPa, compared to the circular tup impact strength of 65 MPa (Fig. 7). CONCLUSIONS 1. A mixed mode of failure (shear and flexure) was found in PSL subjected to static and impact loading. 2. Similar to most materials, PSL exhibits at least some strain rate sensitive behavior. The increases in strength were in the range of 5-30%, depending on the type of test setup. 3. A circular striking tup considerably reduced the amount of localized damage. However, the occurrence of localized damage was still totally unavoidable in the impact tests. 4. The rate sensitivity of PSL is very much dependent on the test setup and procedure (i.e. the shape of loading head). 5. With the circular tup, PSL exhibited more rate sensitivity and less localized damage. The strength results obtained were higher than those obtained from the blade tup and better represented the real impact bending strength of the material. ACKNOWLEDGEMENTS The authors would like to thank Trus-Joist MacMillan Co. Ltd. for providing the test materials, and also David Mak, a grade-eleven student from Killarney Senior Secondary School, Vancouver, for his assistance during the experiments. REFERENCES Banthia, N. P., 1987. Impact Resistance of Concrete. Ph.D. Thesis. University of British Columbia. Canada. Canadian Wood Council. 1991. Wood Reference Handbook. pp. 161-164. Mindess, S., Barrett, J.D., and Spencer, R.A. 1979. Time-Dependent Failure of Wood. Proceedings 3rd International Conference on Mechanical Behavior of Materials. Cambridge. England. Pergamon Press. Vol. 3. pp. 319-328. Mindess, S., Madsen, B. 1986. The Fracture of Wood under Impact Loading. RILEM Materials and Structures Research and Testing. pp. 49-53.