WASTE TO ENERGY IN POWER PLANTS; INCREASING THERMAL EFFICIENCY Mohsen Sharifpur

advertisement

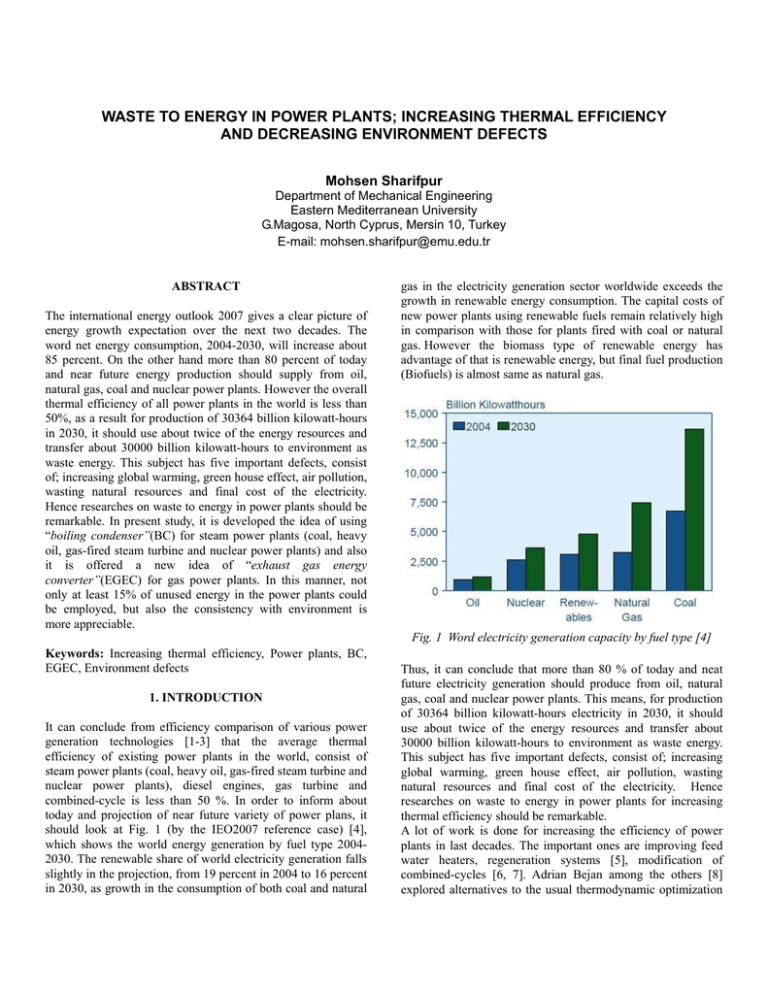

WASTE TO ENERGY IN POWER PLANTS; INCREASING THERMAL EFFICIENCY AND DECREASING ENVIRONMENT DEFECTS Mohsen Sharifpur Department of Mechanical Engineering Eastern Mediterranean University G.Magosa, North Cyprus, Mersin 10, Turkey E-mail: mohsen.sharifpur@emu.edu.tr ABSTRACT The international energy outlook 2007 gives a clear picture of energy growth expectation over the next two decades. The word net energy consumption, 2004-2030, will increase about 85 percent. On the other hand more than 80 percent of today and near future energy production should supply from oil, natural gas, coal and nuclear power plants. However the overall thermal efficiency of all power plants in the world is less than 50%, as a result for production of 30364 billion kilowatt-hours in 2030, it should use about twice of the energy resources and transfer about 30000 billion kilowatt-hours to environment as waste energy. This subject has five important defects, consist of; increasing global warming, green house effect, air pollution, wasting natural resources and final cost of the electricity. Hence researches on waste to energy in power plants should be remarkable. In present study, it is developed the idea of using “boiling condenser”(BC) for steam power plants (coal, heavy oil, gas-fired steam turbine and nuclear power plants) and also it is offered a new idea of “exhaust gas energy converter”(EGEC) for gas power plants. In this manner, not only at least 15% of unused energy in the power plants could be employed, but also the consistency with environment is more appreciable. gas in the electricity generation sector worldwide exceeds the growth in renewable energy consumption. The capital costs of new power plants using renewable fuels remain relatively high in comparison with those for plants fired with coal or natural gas. However the biomass type of renewable energy has advantage of that is renewable energy, but final fuel production (Biofuels) is almost same as natural gas. Fig. 1 Word electricity generation capacity by fuel type [4] Keywords: Increasing thermal efficiency, Power plants, BC, EGEC, Environment defects 1. INTRODUCTION It can conclude from efficiency comparison of various power generation technologies [1-3] that the average thermal efficiency of existing power plants in the world, consist of steam power plants (coal, heavy oil, gas-fired steam turbine and nuclear power plants), diesel engines, gas turbine and combined-cycle is less than 50 %. In order to inform about today and projection of near future variety of power plans, it should look at Fig. 1 (by the IEO2007 reference case) [4], which shows the world energy generation by fuel type 20042030. The renewable share of world electricity generation falls slightly in the projection, from 19 percent in 2004 to 16 percent in 2030, as growth in the consumption of both coal and natural Thus, it can conclude that more than 80 % of today and neat future electricity generation should produce from oil, natural gas, coal and nuclear power plants. This means, for production of 30364 billion kilowatt-hours electricity in 2030, it should use about twice of the energy resources and transfer about 30000 billion kilowatt-hours to environment as waste energy. This subject has five important defects, consist of; increasing global warming, green house effect, air pollution, wasting natural resources and final cost of the electricity. Hence researches on waste to energy in power plants for increasing thermal efficiency should be remarkable. A lot of work is done for increasing the efficiency of power plants in last decades. The important ones are improving feed water heaters, regeneration systems [5], modification of combined-cycles [6, 7]. Adrian Bejan among the others [8] explored alternatives to the usual thermodynamic optimization formulation, where the thermodynamic performance of a system is improved subject to physical size constraints (e.g., entropy generation minimization). Kopac and Hilalci [9] investigate about effect of ambient temperature on the efficiency of a power plant. Also, Elzinaty [10] worked on using waste heat for some new purposes, same as desalination. In present study, it is developed the idea of using boiling condenser (BC) [11] for steam power plants (coal, heavy oil, gas-fired steam turbine and nuclear power plants) and also it is offered a new idea of “exhaust gas energy converter” (EGEC) for gas power plants. In this manner, not only at least 15% of unused energy in the power plants could be employed, but also the consistency with environment is more appreciable. However, in this day and age, a lot of efforts are doing for reducing the CO2 emission of power plants in the world. But, usually capturing the CO2 in power generation plants makes reduction of the thermal efficiency about 8 % [12]. Thus by using BC or EGEC it could rectify the efficiency reduction caused by pollution devices. Hence, as a heat exchanger, the steam transfers its latent heat to the working fluid during the path within coming down. Thus, while the condensation happens inside the tubes (for steam), boiling occurs outside of the tube bundles for the working fluid, i.e. inside the channels between the tubes. There are some recirculation pumps those circulate the working fluid among the tube bundles with an accurate control system. Therefore by changing the operating conditions of recirculation pumps, it can control the amount of exchanged heat between steam and the working fluid. The upper parts of the tube bundles are not inside the working fluid, and then it helps to dry (or make superheat) the vapor of the working fluid along the path. This part is the same as chimney in the BWR but heated one. 2. USING BOILING CONDENSER (BC) Boiling condenser (BC) is a new design heat exchanger [11] that could be replaced with typical condensers in the steam power plants (coal, heavy oil, gas-fired steam turbine and nuclear power plants). In the Fig. 2, it is shown a BC with its cycle. A boiling condenser is almost the same as the core of a boiling water reactor (BWR) [13]. Inside a BC consists of some vertical channels which inside the channels are parallel vertical tube bundles. Steam from the power plant turbine exit could enter to the tube bundles of BC (from upward to down). Outside of the tube bundles (between tube bundle and the channel) are almost filled of a proper subcooled working fluid. The BC cycle is working with this working fluid. Fig. 2 Boiling condenser and its cycle Fig. 3 Schematic diagram of Catalagzi power plant in Turkey Fig. 3 shows the Schematic diagram of 154 MW Catalagzi power plants in Turkey [9]. The fuel used in this power plant is low calorific value coal middling with particle size below 0.5 mm. In the Fig. 4 is shown the power output of modified Catalagzi power plant by utilizing BC, is increased to 186 MW. Fig.4 Using BC with some changes to the main cycle The working fluid for BC cycle is chosen R-141b. For comparison of this modified power plant with old one, there are taken the nodes of 5, 14, 31 and 32 as the reference points (i.e. the properties are the same in these points for both). The results confirm that the BC recovers at least 15.2 % of the condenser waste energy of the power plant and the overall thermal efficiency of the power plant increases at least %7.5. 3. EXHAUST GAS ENERGY CONVERTER (EGEC) ability to reuse in the cycle as regeneration. This is due to increasing temperature after compressor (i.e. the temperature of points 10, 2 and 4 are close to each other). But, it can get some parts of this waste energy by using a proper working fluid in an exact thermodynamics cycle (EGEC) which could operate between the exhaust gas temperature (or intercooler temperature) and environment temperature. The power plant (Fig. 5) with applied EGEC is shown schematically in Fig. 7. In this manner some part of waste heat could be converted to work. Usually a significant amount of energy wastes to environment from the exhaust gas (gas turbine exit) of gas power plants. The Exhaust Gas Energy Converter (EGEC) could be an exact thermodynamics cycle, with proper working fluid for recovering some fraction of waste heat from an exhaust gas. It includes boiling heat exchanger, turbine, condenser and a pump with an accurate control system. Fig. 7 A typical gas turbine with EGEC unit It is possible to use the combine form of BC and EGEC in a combined power plant. Fig. 8 shows the application of BC and EGEC to a typical combined power plant, schematically. Fig. 5 A typical gas turbine with regeneration Fig. 5 shows a typical gas turbine with regeneration, intercooler and reheater. The T-s diagram of the cycle is shown in Fig. 6. Fig.6 The T-s diagram of the gas turbine cycle From the T-s diagram, it is clear that the exhaust gas energy (qout) and also the removal heat from intercooler do not have Fig. 7 A typical combined power plant with EGEC and BC 4. RESULTS AND DISCUSSION As it is shown in table 1, the net power of the Catalagzi power plant [9] is 154.144 MW, but after applying BC (theoretically [11]) increases to 186.255 MW (i.e. the net power out increases 20.83 %). The result confirms that the BC recovers at least 15.2 % of condensers waste energy of the power plant and the overall thermal efficiency of the power plant increases at least %7.5. Table 1 compassion of two power plants (with and without BC) Power plant Without BC 35.76 Power plant With BC 43.21 Wnet −total (KW) 154144 186268 Wnet − BC (KW) ― 40151 Wnet − Steam (KW) (KW) Q& 154144 146117 211272 175017 Fuel Energy (KW) Advantage versus Global warming (KW) 431063 ― 431063 32124 ηThermal (%) Condenser However, it must consider that this result notwithstanding some limitations (same as getting nodes of 5, 14, 31 and 32 as the reference points for BC application), the thermal efficiency has had 7.5% increases. Table 2 the thermal efficiency of the EGEC cycle Working Fluid of the EGEC Cycle = R-141b Texh‐gas = 120 °C, Tamb‐ave =20°C, Ttur‐ 141= 110 °C, Tpump‐ 141 = 31.7°C P tur‐ 141= 0.8 Mpa, P con‐ 141= 0.1 Mpa Texh‐gas = 135 °C, Tamb‐ave =20°C, Ttur‐ 141= 125 °C, Tpump‐ 141 = 28.74°C P tur‐ 141= 1 Mpa, P con‐ 141= 0.09 Mpa Texh‐gas = 160 °C, Tamb‐ave =20°C, Ttur‐ 141= 150 °C, Tpump‐ 141 = 31.7°C P tur‐ 141= 1.7 Mpa, P con‐ 141= 0.1 Mpa Texh‐gas = 175 °C, Tamb‐ave =20°C, Ttur‐ 141= 165 °C, Tpump‐ 141 = 31.7°C P tur‐ 141= 2.1 Mpa, P con‐ 141= 0.1 Mpa ηThermal (%) 15.05 16.94 19.21 20.15 Thus for using BC in a new design power plant, it is possible to find more efficiency by finding exact turbine exit condition (for steam cycle) and exact working fluid (for BC cycle). Using BC and its cycle has capability to be utilized for all of the Steam power plants (coal, heavy oil, gas-fired steam turbine and nuclear power plants). This recovering heat of condenser (15%) is due to the latent heat of steam which is too much at low pressure (turbine exit), and then in the BC cycle, it is possible to transfer this heat to boiling another working fluid. A boiling condenser (BC) could be an adaptor between main power plants and environment, i.e. it can design the power plant for maximum output efficiency but independent to environment conditions, and then BC as an interface, could adapt the power plant and environment. For example in Catalagzi power plant [9], the steam at low pressure turbine (LPT) exit has 35.5ºC, because of the average condenser inlet and outlet, are 19ºC and 39ºC respectively. In the case of EGEC cycle, Table 2 offered the thermal efficiency of the EGEC cycle for some different exhaust gas temperatures. The average ambient temperature (Tamb-ave) in a year is assumed to be 20 ºC. For deriving this data it is used EES software [14], by using R-141b as working fluid and also pump and turbine efficiency of 90 %. The results confirm that by using EGEC, not only at least 15% of unused energy from exhaust gases of gas turbine power plants could be employed, but also it has more consistency with environment. Table 2 is a sample calculation of converting some part of exhaust gas energy to work. Hence in an actual situation, with exact information of the exhaust gas temperature, it could design accurate EGEC cycle with proper working fluid for more efficiency. However, it can use this system for anywhere that needs to remove some energy of high temperature gases, same as intercoolers. 5. CONCIUSION Because of overall thermal efficiency of world power plants is less than 50 %, thus for producing 30364 billion kilowatt-hours electricity in 2030, it should use about twice of the energy resources and transfer about 30000 billion kilowatt-hours to environment as waste energy. In this work for reducing this problem is developed the boiling condenser (BC) for steam power plants (coal, heavy oil, gas-fired steam turbine and nuclear power plants) to recover at least 15 % of the waste energy in the condensers. Also for gas turbine power plants is offered to use exhaust gas energy converter (EGEC) to recover at least 15 % of the exhaust gas energy. Using BC and EGEC in power plants have five important advantages, consist of; decreasing global warming, green house effect, air pollution, saving natural resources and reducing final cost of the electricity. 6. REFERENCES [1] [2] [3] [4] [5] [6] [7] Janos M. Beer, “High efficiency electric power generation: The environmental role”, Progress in Energy and Combustion Science, Vol. 33, 2007, pp. 107–134. Kiarash Dorry, “A thermodynamic and economic design/optimization of gas turbine power plants”, Master Thesis, Mechanical engineering department, Eastern Mediterranean university, 2005. Steven E.K., “Advancing Gas Turbine Technology: Evolution and Revolution”, Power Engineering, 1995, Vol. 99, No. 5, pp. 25-28. EIA Report No.: DOE/EIA-0484, International Energy Outlook2007, http://www.eia.doe.gov/oiaf/ieo/electricity.html, 2007. Cengel Y.A., Boles M. A., “Thermodynamics an Engineering Approach”, McGraw-Hill, 2006. Stefano Consonni, Paolo Silva, “Off-design performance of integrated waste-to-energy, combined cycle plants”, Applied Thermal Engineering, Vol. 27, 2007 pp. 712– 721 Chuang C.C., Sue D.C., “Performance effects of combined cycle power plant with variable condenser pressure and loading”, Energy, Vol. 30, 2005, pp. 1793– 1801 [8] [9] [10] [11] [12] [13] [14] Bejan A., “Thermodynamic optimization Alternatives: Minimization of Physical Size Subject to Fixed Power”, International Journal of Energy Research, Vol. 23, 1999, pp. 1111-1121 Mehmet Kopac, Ayhan Hilalci, “Effect of ambient temperature on the efficiency of the regenerative and reheat Catalagzi power plant in Turkey, Applied Thermal Engineering, Vol. 27, 2007, pp 1377–1385. Rami Elzinaty, “Design of a desalination system using waste heat of power plant”, Master Thesis, Mechanical Engineering department, Eastern Mediterranean university, 2003. Mohsen Sharifpur, “Designing Boiling Condenser for more efficiency in power plants and less environment defects”, ASME POWER 2007, July 2007, USA. John Davison, “Performance and costs of power plants with capture and storage of CO2”, Energy, Vol. 32, 2007, pp. 1163–1176. El-Wakil M.M., “Nuclear Heat Transport”, American Nuclear Society, 1981. Engineering Equation Solver (EES), Educational version distributed by McGraw-Hill, 2007.