John Q. Dickmann ESD Symposium March 19, 2004 Leading Systems Architects:

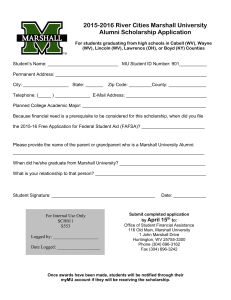

advertisement

John Q. Dickmann ESD Symposium March 19, 2004 Leading Systems Architects: Diverse Problems and Common Patterns Abstract The topic of system architecture is receiving increased attention as technical complexity and social importance of our engineered systems increases. This work proposes and tests a simple framework for study of system architects and their systems. The framework focuses on identifying rule sets chosen by system architects that act as drivers of socio-technical dynamics of their systems. The framework is built on the premise that, in general, development, dynamics and evolution of complex systems are the result of repeated application of relatively few and relatively simple rules that govern interactions between components of the system and between the system and its environment. For four systems –the Toyota Production System, the Marshall Plan, Microsoft Corporation and the Nuclear Navy- this paper identifies rules, highlights system boundary decisions and evolutionary contexts to gain first order understanding of possible connections between rules and system evolution. These systems represent a wide array of technical and social contexts: from government to private enterprise, explicitly technical to technically related, high technology to ‘classic’ industrial. This first order assessment shows that rules are identifiable, openly stated and have common patterns across systems. These patterns are strong focus on both technical excellence of personnel and the human element while emphasizing careful analysis of feedback and attention to information flows, both inside and outside the system. It is argued that system success is strongly dependent on developing an appropriate rule set. Professor Chris Magee of MIT’s Engineering Systems Division provided invaluable guidance and assistance in maintaining focus and clarity in this paper. 1 John Q. Dickmann ESD Symposium March 19, 2004 Introduction and Motivation The topic of system architecture is receiving increased attention as technical complexity and social importance of our engineered systems increases. There is an emerging need to develop better understanding of various aspects of architecture and architecting of large scale engineered systems. A recent review (Whitney 2004) notes the early stages of work in this area. Many treatments of large scale systems and systems architecture, focus on either technical aspects (Maier and Rechtin 2002, Pahl and Beitz 1996, Clark and Baldwin 2000), descriptive historical accounts of system evolution (Thomas Hughes 1998, Knox and Murray 2001), industry level analysis of technology dynamics and evolution (Utterback 1994, Christensen 1997) or case study research to discover best practices (Miller and Lessard 2001). As an additional contribution, the focus of this paper is on a framework for developing better understanding of system architects, their systems and the architecture of forces that most directly influence system evolution. It is designed as an initial investigation of the socio-technical aspects of systems architecture and system architects and to explore whether generalized characteristics might exist among diverse systems studied through one framework. Complex Engineering Systems as viewed by Engineering Systems Division require new mental frameworks and new methods of assessment through which to evaluate their instantiation, performance and evolution. This framework is built on the conception of complex engineering systems articulated by the Engineering Systems Division, summarized below (ESD Symposium Committee 2001, Magee and deWeck 2002, Dodder and Sussman 2002): - Systems are a set of interacting components having well-defined (although possibly poorly understood) behavior or purpose; the precise boundaries of a system can be dependent upon the level of analysis or the specific aspect of the system under consideration; - Complex systems have many components, interconnections, interactions and/or interdependencies; this makes precise prediction and description of behavior difficult in some important circumstances; - Humans design engineering systems; they have purpose, are large in scale, complex and have complex management or social dimensions as well as technical ones. - Additionally, this framework also considers that Complex Engineering Systems are intimately tied to, influence and are influenced by the environment (context) in which they exist and operate. The conceptual foundation for the framework comes from contemporary complex systems research and ESD conceptions. In general, the development, dynamics and evolution of complex systems are the result of repeated application of a limited set of relatively simple rules governing interactions (feedback and feed forward) between system components and cause-effect relationships in these systems are difficult to untangle. As a result, understanding complex systems prioritizes knowledge of (1) interactions and processes within the system over detailed knowledge of internal 2 John Q. Dickmann ESD Symposium March 19, 2004 component characteristics and (2) long-term evolution of the system over static analysis of it. The system architects and systems chosen for study provide a diverse representation of ‘systems’ as contemporary thinking and Engineering Systems Division has come to term them. Spanning a range from government to private enterprise, explicitly technical to only marginally technically related, high technology to classic industrial, they are: 1. Taiichi Ohno (Toyota Production System); 2. Hyman G. Rickover (Naval Nuclear Power Program); 3. George C. Marshall (European Recovery Program (Marshall Plan)); 4. Bill Gates (Microsoft Corporation). Assessment Framework Assessing the effectiveness of systems architects requires a look at the architectural design decisions they made and how the system they designed, built and operated performs against the problem for which it was created and how it interacts with other aspects of its operating environment. The central aspects of this framework are: (1) explicit recognition of the difficulty of precisely connecting every micro-scale interaction to aggregated macro-level effects or behaviors and (2) a consideration of the context in which the system was developed and operated and how context influenced initial development and system evolution over time. Addressing context (external constraints) explicitly creates a focus on decisions about system boundaries, a fundamental issue when assessing system performance or behavior. Macro- versus micro- aspects of systems are considered by highlighting rules used to guide system decisions and evolution and then making inferences regarding connections between rule execution and system evolution. The objective is to see whether a small set of rules, either explicit or implicit, might be a commonly identifiable feature of complex sociotechnical systems and whether, across diverse complex engineering systems, there are commonalities in rules and in the approach architects take in architecting their systems. This line of investigation might lead to more formal methods of assessment, modeling, and analysis of complex socio-technical systems. For each architect and system, the general historical context will be set and then a specific starting point for the assessment will be defined. This sets the stage for definition of the architect’s problem. Because system boundaries set the scale at which the system operates, attention will be focused on the architect’s definition of system boundaries in terms of objectives and external constraints (context) that drove those choices. We will describe generally how or whether system scale changed over time as the system evolved. Where explicitly stated, the rule sets that the architect’s used in architecting their system will be listed, in other cases, rules will be inferred from an assessment of the architect’s actions and decisions. An overall assessment and comparison of the major characteristics of each system will be made, with emphasis on enduring strengths of the systems, especially as they evolved over time. This assessment will be high level and qualitative, since the four examples are generally acknowledged successes and detailed performance assessment is not the major thrust of this work. 3 John Q. Dickmann ESD Symposium March 19, 2004 The framework consists of five parts: 1. Establishing initial context: Setting general historical background, defining a starting time for assessment of the architect and the system; 2. Stating the goal or purpose of the system; 3. Identifying rules, protocols or principles that guide the growth and evolution of the system; 4. Identifying system boundaries: Initially and as they evolved over time; 5. A brief subjective assessment of overall effectiveness of the created system. Taiichi Ohno and the Toyota Production System Context and Goal Taiichi Ohno is widely known as a visionary leader at Toyota Motor Company and the intellectual creator of the Toyota Production System (TPS). Origins of the TPS can be traced to the particular circumstances of Japan and to the specific goal set for Toyota by its President following World War II.1 Toyoda Kiichiro challenged the Toyota Motor Company the day World War II ended: “Catch up with America in three years. Otherwise, the automobile industry of Japan will not survive.” [Ohno 1988, p. 3] This goal was straightforward and challenging and generated intense activity at all levels of the company [Ohno, p. 9]. As Ohno set about making his contribution to the corporate challenge, he centered his focus on waste elimination. At the time, by standard measures, American productivity greatly exceeded Japanese productivity. The challenging goal and this performance differential with America gave Ohno his initial inspiration for the fundamental governing rule of the Toyota Production System: It [the productivity differential] meant that a job then being done by 100 workers had to be done by 10 workers…But could an American really exert ten times more physical effort? Surely, Japanese people were wasting something. If we could eliminate the waste, productivity should rise by a factor of ten. This idea marked the start of the present Toyota production system. [Ohno, p. 3] The context of post-war Japan is key to understanding the evolution of the Toyota Production System (TPS) and Ohno’s decisions regarding it’s development. Post-war Toyota faced many problems [Womak, Jones and Roos 1990, p. 49-50]: - A small domestic market that demanded a wide array of vehicle types; - A work force that was unwilling to be treated as a disposable part; - Labor laws established by the American occupation force that restricted management’s options with respect to hiring and firing; 1 Ohno traces the intellectual roots of TPS much farther back, to Toyoda Sakichi and Toyoda Kiichiro in the 1920s and 1930s. For purposes of this analysis, the end of WW-II is an appropriate starting point. 4 John Q. Dickmann ESD Symposium March 19, 2004 - Lack of an immigrant population willing to accept lower pay or lower standard working conditions; - A capital starved economy; - Mature and large overseas automobile manufacturers as competition. These were significant constraints, almost all of them pointing to a ‘don’t waste resources’ solution. Recognizing he had to work under conditions that were essentially opposite to those in America and the rest of the global automobile manufacturing industry, Ohno developed an approach that fully considered the unique context of Japan. This approach, Ohno’s basic rule, was: “eliminate waste.” Ohno continuously focused on the goal (“Catch up to America”), always applying this rule. Over time, external context changed; in 1950, there was a large strike, in 1973, there was the oil crisis, the Japanese economy grew. Through all changes, internal and external, Ohno’s response was fundamentally grounded in the basic rule: waste elimination. Solution and Rules Ohno’s solution was not a single technical system, but a set of rules and practices that guided decisions about manufacturing processes and technology choices. These rules did not immediately result in the “Toyota Production System” as we know it today but built it, over time, as they proved valuable through repeated application. [Ohno, p. 33, 35] Though he did not call it a ‘system’ at the beginning, to support the system and its central operating rule of waste elimination, Ohno established two related rules2 that governed subsequent choices over the next 50 years: Just in Time and Autonomation (automation with human touch) [Ohno, p. 4-7]. These three rules became the foundation for the set of practices, subsidiary rules and management tools applied to the Toyota Motor Company’s goal, “Catch up to America”: Rules: 1. Eliminate waste 2. Implement Rule 1 by using Just in Time flow and 3. By meshing human and machine capabilities (Autonomation). System Boundaries and Evolution It is worth noting that Ohno’s initial aim was not to revolutionize Toyota, but to improve existing processes in order to achieve the goal. The System did not spring whole and get implemented across the Toyota Corporation immediately and it does not appear that he had an overarching vision that it would; Just-in-Time production flow were simply his contribution to achieving Toyoda’s goal. Initially Ohno could implement these principles only in the machine shop he managed. So, at first, the system boundaries of what we recognize today as TPS were limited to a single shop in the Toyota enterprise [Ohno, p. 31]. Over time, as effectiveness was proven, Ohno’s responsibilities grew and 2 He calls them principles (p. 4). Dictionary definitions for ‘principles’ and ‘rules’ are very closely related and for the purposes of this framework are synonymous. 5 John Q. Dickmann ESD Symposium March 19, 2004 the ‘system’ with them, expanding and maturing over 35 years to include Toyota’s outside suppliers.3 [Ohno, p. 11, 31-36] The net effect of these rules, applied increasingly across the enterprise, was an asymmetric increase in productivity, product quality and responsiveness to market demands compared to the rest of the automobile industry, a competitive advantage recognized by the marketplace [Womak, Jones, Roos 1990, p.62; Womak and Jones 1994, p. 230-31]. Another important boundary feature of TPS is its unique conceptual orientation to the market place. In describing his development of Just-in-Time production flow, Ohno points out how the standard production process results in excess inventory. By focusing on the need to eliminate waste, he decided to stop flowing forward, instead, pulling from prior production steps (solving the problem of inventory pile ups). [Ohno, p. 13] Logically extending this view across the entire manufacturing process results in Ohno’s innovative concept of viewing the production system from the customer back through the manufacturing process to the raw materials. This is one factor among many that generates tight coupling across the boundary between the Toyota Production System and its external environment. In contrast to what he describes as the traditional ‘push’ system, where goods are produced and pushed out the door to be (hopefully) purchased, Ohno’s ‘pull’ system inherently eliminates waste, because nothing is produced “unless it is needed.” [Ohno, p. 5, 33] Since information is needed for people to effectively apply rules, a key to successful evolution of TPS is its extensive reliance on information extraction and flow. The information extraction tool supporting evolution of the system is a subordinate rule set called the ‘5 Whys’. Discussed in Chapter 2 of Ohno’s text, this rule is designed to ensure the multiple layers of causality are probed to discover root causes of any problem. Kanban, a system of information tags linking parts of the process together, enables information flow through the system. Kanban, sitting on top of Just-in-Time, creates a networked ‘nervous system’ for the process, that transmiting signals from the external environment to stimulate action inside the production system. [Ohno, p. xvii, 40-46] Like the flow process, the scale of “5 Whys” and kanban grew as it and TPS demonstrated their ability to improve performance. The TPS boundaries grew over time as worth was proven. Once the system grew to the point of connecting outside suppliers to the process, the system boundaries expanded beyond the Toyota Motor Company. Today, TPS is considered a multienterprise networked system, “a group of roughly 200 companies integrated by their common interest in supplying the Toyota Company.” [Watts 2003, p. 254-55] Net Assessment Ohno’s architecting of the Toyota Production System consisted of a set of basic rules, centered on the elimination of waste, repeatedly and vigorously applied. There were (and are) supporting rules and techniques used to address day-to-day operational issues, but they only reinforce or implement the foundational rules of Waste Elimination, 3 Ohno credits management commitment to his early experiments with kanban and Just-in-Time flow for much of the follow-on success, an indication of what many know as the necessity of top-down commitment to anything ‘new’ in an enterprise. 6 John Q. Dickmann ESD Symposium March 19, 2004 Just-in-Time flow and Autonomation. The system started in a single shop of the Toyota Motor Company, expanding as positive results were achieved and as success was recognized by senior management in the form of Ohno’s promotion. System boundaries evolved, expanding as success was proven, today encompassing multiple enterprises in an extended (global) network of suppliers. At each stage, difficulties arose but were overcome through diligent attention to the fundamental rules and rational assessment of performance, with individuals, groups and the organization learning over time. Overall, Ohno can be assessed as effective in building a system robust to external shocks and highly focused on delivering value. His personal account of the genesis of the system shows him to be a true systems thinker, highly focused on his goal, demanding high standards of him and those who worked for him. [Ohno, p. 5, 17, 35-36, 45-46] His rules generated a tightly coupled system, responsive to external stimulus and proven scalable from shop floor to the multi-enterprise level. The beneficial features of the system are not without hazards; waste elimination can create single point vulnerabilities as the Aisin fire of 1996 demonstrated. [Nishiguchi and Beaudet 1997] As a counterpoint to this vulnerability, the cooperative culture built up around the need to eliminate waste across enterprises can be a key to survival when these ‘single point’ crises occur. Hyman G. Rickover and the Naval Nuclear Power Program Context and Goal The genesis of the U.S. Navy’s nuclear propulsion program, like the origins of the Toyota Production System, can be traced back some years before concentrated effort began. In March of 1939, the Naval Research Laboratory initiated a $1,500 research program on nuclear fission, chartered to investigate new submarine and torpedo power plant technology. In 1944, the Director of the Manhattan Project established a committee to study other uses of atomic energy, including two naval officers in the group. By 1946, there was a formal report, briefed to senior submarine officers, describing the feasibility of a nuclear submarine. [Polmar and Allen 1982, p. 118-123] The relevant historical genesis of the Navy’s nuclear program dates from 1946, when a group of naval officers was sent to Oak Ridge National Laboratory to investigate the application of nuclear energy for naval propulsion, specifically for submarines. Shortly after reporting to Oak Ridge, then Capt. Rickover became convinced that with proper attention and management, a nuclear power plant could be engineered for submarine application. An exceptionally strong personality, with strong views on the proper approach to engineering, he made the goal of putting a nuclear powered submarine to sea for the U.S. Navy a personal mission and convinced his fellow officers at Oak Ridge to join him. During this time, the services were adjusting to the post-war drawdown and the Soviet Union was emerging as an adversarial competitor to the U. S. in world affairs. These were two significant factors, along with the Atomic Energy Act of 1946, which centralized all control of atomic activities in the country with the Atomic Energy 7 John Q. Dickmann ESD Symposium March 19, 2004 Commission (AEC), driving the context in which Rickover would architect his system.4 Initially, and for most of the duration of his tenure as the head of the program, Rickover’s problem was bounded along the two axes of technical and organizational constraints. Technical system constraints were: limited size of submarine hulls, close proximity to crew, a dynamic ocean environment as well as requirements set by military operations. These constraints set the context for engineering and technical development. The Atomic Energy Act of 1946, coupled with the internal structure and processes of the Navy’s Bureau of Ships (BuShips) were the major factors setting constraints for organization design. BuShips contracted for and managed ship construction; the AEC had total control over anything related to atomic energy. Solution and Rules This effort, in contrast to TPS, began as a “blank-sheet.” Neither organization nor technology existed when Rickover began. In the early stages of development, there were many uncertainties, technical and non-technical. Addressing them boiled down to two significant architectural issues: building an organizational structure to manage effectively a high technical risk program with unique legal constraints and safety requirements while simultaneously inventing technology, engineering practice and physical system architecture. Rickover’s organizational and technical solution developed as he built the program and as uncertainties became knowledge. It was grounded in fundamental rules built on his personality and operational and engineering experience.5 These were: 1. Personal accountability; 2. Technical excellence focused on reactor safety; 3. Use real data from the technical system operating in the real world to make decisions in pursuit of rule 2. As noted by Robert Pool in Beyond Engineering [p.46-47]: “…[he] demanded complete testing of everything that went into the reactor and was ruthless about reworking things or even starting over, if necessary, when problems appeared…He gave people freedom to do a job the way they thought best, but in return he demanded complete accountability. If something went wrong, there was always someone who bore ultimate responsibility. Rickover’s management style had no room for finger pointing.” This rule of accountability is borne out in his testimony to Congress regarding an accident at an Army research reactor in Idaho [Rockwell 1992]: “You have yet to bring forth an individual in that program who will answer to you “I am responsible.” They rotate people and delegate responsibility in the usual military way. You do not have that problem 5 Duncan 2001 and Polmar and Allen 1982, provide detailed accounts of Rickover’s formative years prior to Navy and of his early career. 8 John Q. Dickmann ESD Symposium March 19, 2004 with my program. I have many people carrying out tasks in the program and I hold them accountable to me for those tasks. But if anything important goes wrong in my program, is there any doubt in your minds who is responsible? I will tell you right now, in case there is any uncertainty about it, I am responsible.” Over time, these principles were codified explicitly and implicitly through reports to Congress, instructions to his organization, training curricula and other communications. In 1982 testimony to Congress, he laid out “important tenets of the program’s engineering philosophy:” [cited in Duncan, 1990, p. 295-96]:6 “Avoid committing ships and crews to highly developmental and untried systems and concepts; “Ensure adequate redundancy in design so that the plant can accommodate, without damage to ship or crew, equipment or system failures that inevitably will occur; “Minimize the need for operator action to accommodate expected transients. If the Plant is inherently stable, the operator is better able to respond to unusual transients; “Simplify system design so as to be able to rely primarily on direct operator control rather than on automatic control; “Select only materials proven by experience for the type of application intended and insofar as practicable, those that provide the best margin for error in procurement, fabrication, and maintenance; “Require suppliers to conduct extensive accelerated life testing of critical reactor systems components to ensure design adequacy prior to operational use; “Test new reactor designs by use of a land based prototype of the same design as the shipboard plant. Prototype plants can be subjected to the potential transients a shipboard plant will experience, so problems can be identified and resolved prior to operation of the shipboard plant; “Train operators on actual operating reactors at the prototypes. Simulators are not an acceptable training device for naval operators; “Confirm reactor and equipment design through extensive analyses, fullscale mockups and tests; “Use specially trained inspectors and extensive inspections during manufacture; accept only equipment that meets specification requirements; concentrate on designing, building and operating the plants to as to prevent accidents, not just cope with accidents that could occur.” System Boundaries and Evolution 6 These tenets were most recently articulated by the current Director of Naval Reactors, Admiral F. L. Bowman in testimony to the House Committee on Science [29 October 2003 testimony]. 9 John Q. Dickmann ESD Symposium March 19, 2004 The two axes of technical and organizational issues are the bounds within which it is most useful to view the impact of Rickover’s rules on system evolution over time. Technical system constraints coupled with the preexisting tendency of submarine officers to demand technical excellence for reasons of survival, were able to set the pattern of technical excellence behavior early. This pattern, once established in the small community of submarine operators and builders, was then more easily transferred when the program expanded to include surface ships [Rockwell 1992, p. 119-120]. Organizational system boundaries did not exist when Rickover began his effort. He had to create the organization and set boundaries with consideration of the constraints of the Atomic Energy Act of 1946 and internal policies and bureaucratic organization of the Navy. Organizational and legal constraints were seemingly in direct conflict with his rule that demanding centralized accountability for management and decision-making in such a complex project. Rickover’s solution was to architect an organization and charter for it that spanned the areas of control necessary to integrate atomic energy with a naval ship. Theodore Rockwell, a long time engineer for Rickover notes, [Rockwell 1992, p. 44-45]: “Rickover spent a lot of time thinking about how the program should be organized, if and when he finally got some money and authority to move on it. “ There is no precedent, or formula, or procedure for what we’re trying to do. We’re on our own, there’s nobody to turn to for advice. We have to think this thing out from basic principles. First, let’s look at the legalities of the matter…We have to be able to do things in the name of BuShips---to sign contracts, spend money and approve ship design features…We need another base of power. And there’s a legal basis for this. I’ve been studying the Atomic Energy Act of 1946. And it’s very clear that responsibility and authority for anything atomic lies with the U.S. Atomic Energy Commission, the AEC. If atomic fuel is to be procured, if it is to be fabricated and reprocessed after use, if reactor safety inspections and evaluations are to be made—all these matters require an AEC base. Only AEC officials can sign contracts and make arrangements to deal with atomic materials and atomic secrets. So I need an AEC hat too…the question is, “How do you set up an organization that operates within two wholly different government agencies?” With this construct, he drafted a Memorandum of Understanding between both agencies chartering the organization that would develop and manage the project. The concrete organizational form evolved over time [Lewis 1980, p. 54-84], but was always working under two different agencies of the government. This unique structure, built to retain fidelity to the rule of central control of and accountability for the program, was formalized by Executive Order in 1982. Relative to traditional government and military organizations, these were very broad “system boundaries.” Legal and institutional issues, combined with technical constraints and Rickover’s “system architecture” rules to mandate this “dual-hatted” approach. Organizationally very small in scale, a few engineers managing the start of a 10 John Q. Dickmann ESD Symposium March 19, 2004 new program, its scope grew over time, extending connections to every site, government or civilian, with any technical or operational connection to the system. Technically, the system boundaries and constraints on a nuclear power system for shipboard use are clear-cut. Physical space is limited, it must “produce enough energy to propel a ship at significant speeds … operate reliably for sustained periods of time, and … be manned by highly skilled Navy enlisted men … the propulsion system had to withstand the shock and motion that were part of the life of any combatant ship.” [Duncan, 2001, p .100] In the early days of the program, there were many unknown technical issues and no nuclear engineering expertise or manufacturing base. This was another significant context factor that drove decisions about technical and organizational system boundaries. Because of these operational and technical constraints, Rickover’s solution, again, was to draw system boundaries broadly. He concurrently explored competing technical alternatives (liquid metal, pressurized water and gas-cooled designs) in parallel with building the operational platform. Full-scale prototypes were used as a learning device to inform design modifications in the shipboard installation. He built tight and carefully controlled alliances with vendors, exerting technical oversight and control over technical (and sometimes personnel) decisions that would have been “provided to the customer by the vendor” in other contexts [Rockwell, 1992, p. 168-171]. Another aspect of system boundaries was the expansion of application of nuclear propulsion plants to other platforms in the Navy. Nuclear surface ship construction programs were started in the late 1950s, after the submarine system had become established and had proven operational utility and safety. These programs grew over time, with the Navy eventually building 9 nuclear powered Cruisers and today’s force of 11 nuclear powered Aircraft Carriers. However, due to the life cycle expense of operating nuclear powered surface ships in comparison to the operational benefit gained by nuclear propulsion, the Navy has decommissioned the Cruisers, maintaining only nuclear powered Aircraft Carriers in its surface force. Net Assessment Through steady, continuous, application of his primary rules, Rickover crafted an organization widely recognized as a standard for technical and operational excellence. The external context changed over time as the military threat evolved, political and service leadership changed and technology advanced but the fundamental rules governing management and operation of the system remained constant. The program has compiled a notable record of safe operations, steaming over 128,000,000 miles (more than 5,500 reactor years) with no nuclear accident or environmentally significant release of radioactivity [CAIB 2003, Bowman, 2003]. Recognizing the effectiveness of this system, the President formalized it in 1982 with Executive Order 12344. It was subsequently codified in law (Public Laws 98-525 [1984] and 106-65 [1999]. There are also some things that can be assessed as negative about this system and its rules. The long tenure of Admiral Rickover may have not been in the best overall interests of the program. While continuity of leadership is a strong positive factor (shared by the Toyota example), ‘forever’ may be too long. Rickover’s longevity and 11 John Q. Dickmann ESD Symposium March 19, 2004 effectiveness was also closely coupled with strong ties to Congressional leaders, ties developed over time. There are also some possible longer term and larger scale negative impacts on institutional innovation in the Navy and in the wider nuclear industry that may have been negatively impacted by Rickover’s longevity and other legal and regulatory structures; exploration of these issues requires more detailed analysis. George C. Marshall and the Marshall Plan Context and Problem The Marshall Plan does not explicitly qualify as a socio-technical system but is an example of an architected large-scale system intended to have socio-technical impact. As with other large-scale systems considered here, its evolution pre-dates the explicit architecting process. The Marshall Plan played a central part in the evolving role of the United States in the post-War geopolitical world order. The most significant factor in this evolution was the emerging competition with the Soviet Union, noted early in the post-War period by many U.S. diplomats and strategists and the weakness of the traditional Great Powers in the aftermath of the War. There were other issues at play during the period that impacted Marshall’s overall approach to architecting a solution to the emerging problem of European recovery [Pogue 1987, p. 213, 215, 196, 241-2 and Acheson 1969, p. 223, 230, 235]: - Domestic political tension regarding over-involvement in the national affairs of others; - Uncertainty regarding the precise amount of aid needed to address the complex issue of world-wide economic and social recovery from the war; - Difficulties surrounding other post- war aid (United Nations Relief and Rehabilitation Administration (UNRRA) and aid to Greece and Turkey); - An upcoming election year; - Added to these was a sense of urgency among the diplomatic community to restore economic and social infrastructures in the face of two especially difficult European winters. Marshall and his immediate staff began laying the groundwork for the proposal of economic aid to Europe months before his famous Harvard speech on June 5, 1947. They continued to evolve the plan as formal legislation worked through the Congress. The basic rules that Marshall laid out at Harvard became the architecture for the evolution of formal legislation for and administration of the aid program. The immediately pressing problem the Marshall Plan intended to address was potential socio-economic collapse of Europe due to widespread physical destruction and economic dislocation (caused by economic exploitation and destruction of capital and capital assets during the War). Though there has been debate about the economic necessity of the Plan, there is little doubt that it provided a stabilizing function during the transition to post war social, political and economic systems in Europe and, with other efforts, established the Transatlantic ties that endured through the Cold War [DeLong and 12 John Q. Dickmann ESD Symposium March 19, 2004 Eichengreen, 1991]. Solution and Rules Marshall’s speech clearly articulated Europe’s problem and its implications for the United States. He then proceeded to state the rules under which an economic aid program should be run: 1. Assistance should be part of a long-term plan: “Such assistance…must not be on a piecemeal basis as various crises develop.” 2. Recipients should be integral to building the plan: “The initiative … must come from Europe. The role of this country should consist of friendly aid in the drafting of a European program and of later support of such a program so far as it may be practical for us to do so.” 3. The plan administrator should be independent, isolated from political interference. This rule was not explicitly articulated in the speech, but arose as Marshall and the Executive worked with Congress on the formal legislation that became the Plan. System Boundaries For the socio-economic problem that Marshall addressed, system boundaries can be characterized in terms of nations, political constituencies and characteristics of candidate projects for Plan aid. The boundaries of the Marshall Plan were not specifically known when it was articulated, but were defined, as legislation was developed and as European nations joined. Marshall drew the “upper boundary” of the plan explicitly by leaving it open to any nation choosing to cooperate under the framework. Openness was explicitly part of Marshall’s decision calculus: “Any government that is willing to assist in the task of recovery will find full cooperation, I am sure, on the part of the United States Government. Any government which maneuvers to block the recovery of other countries cannot expect help from us. Furthermore, governments, political parties, or groups which seek to perpetuate human misery in order to profit therefrom politically or otherwise will encounter the opposition of the United States.” Though not specifically named, the increasingly adversarial Soviet Bloc was the intended audience for this comment. Conceivably, the Plan could have included all of Eastern Europe and the Soviet Union. [Pogue, p. 196, 204] There were other significant boundaries drawn by Marshall. The first was the ‘lack of a boundary’ between the aid plan and its intended recipients. Marshall made the Plan explicitly contingent upon participation by the countries receiving aid. This served two functions, related to previously defined context: it appeared less like interference in the affairs of others and forced stronger administrative ties between the governments of Europe and the U.S [DeLong and Eichengreen]. The second boundary of importance was temporal; he convinced Congress to commit to a four and a half year aid period, to ensure that it could be effectively applied to the problem. [Pogue, p. 241] He also worked with Congress to make sure that an appropriate administrative boundary was drawn between 13 John Q. Dickmann ESD Symposium March 19, 2004 the Plan administrator and undue political influence from the State Department, President or Congress [Pogue, p. 241-2, 254-56] Net Assessment: The Marshall Plan was the concrete instantiation of a clear set of rules set up to address a compelling national security problem. As architect, Marshall skillfully walked the space between grand abstraction when articulating the problem and its importance and practical execution when working with Congress to craft a concrete Plan. A case has been made that the outcome of the Marshall Plan was not the economic recovery of Europe but the instantiation and strengthening of U.S/European ties and redirection of European governments toward democratic infrastructures [DeLong and Eichengreen]. In many ways, the Economic Cooperation Administration set the stage for a strong U.S.European economic and political relationship during the Cold War. This set of relationships facilitated effective opposition to totalitarian forces by encouraging appropriate structural changes in European economies and governments toward open markets and away from command economies. Bill Gates and Microsoft Corporation Background and Goal The roots of Microsoft Corporation, like the other cases, predate the relevant time frame of this analysis. The context of the development of Microsoft was the early period of microprocessor and personal computer development the late 1970s and early 1980s. During this time frame, there were many different computer operating systems, a wide array of computers and a high rate of change in them. There was great debate among software writers at the time over the future direction of their profession, namely whether software should be free or should be sold for profit. Computer manufacturers were trying to understand the impact the personal computer would have on their business. This was a time of high uncertainty regarding future economic value for computer and software firms. From very early stages, Gates defined Microsoft’s problem very succinctly: “Compete and win in the IT industry by focusing on writing and selling software”. Because of the uncertainty surrounding the future direction of software at the time, Gates' business model, concentrating only on software, was a risky one. Software is a product highly dependent on individual human knowledge and skill; it is easily transported and copied. It also has unique economic characteristics: once the first copy is produced, subsequent copies are very inexpensive to manufacture, so profit margins can be very large. In addition, the rapid rate of change in computer hardware capability drives similar rates of change in the needs and desires of customers. As these capabilities became available, market success was and remains intimately tied to deep connections with and understanding of customer value equations and the aggregated dynamics of them. Solution and Rules Gates’ rules, similar to Rickover’s and Ohno’s are clear and unambiguous: commit to technical excellence; hire intelligent, dedicated people; challenge and trust them. In their 1995 work Microsoft Secrets, Michael Cusumano and Richard Selby listed the rules that guide the management of Microsoft. It is remarkably consistent with lists 14 John Q. Dickmann ESD Symposium March 19, 2004 compiled by other authors who have studied Microsoft. The list, taken from Cusumano and Selby: 1. Hire a CEO with deep understanding of the technology and the business 2. Organize flexibly around product markets and business functions 3. Hire smart people with a deep understanding of the industry and the business. In addition to these rules, there are several subsidiary ones, again, found in numerous books and articles, but Cusumano and Selby’s [p.26-7] capture them well: - “Smart people and small teams; - A development process that allows large teams to work like small teams; - Product architectures that reduce interdependencies among teams; - Nearly all-new product development done on one site; - People working on the same machines the build products for; - A single main development language; - Large capital investments to support people; - Internal use of their own engineering tools; - More than one person who understands the product details; - Managers who both create the product and make the technical decisions; - Quick decision making on technical versus business tradeoffs; - An enormous feedback loop from customers; - Deliberate efforts to learn from past projects” These rules are not earth shattering, as Cusumano and Selby point out. It is in execution and in the leadership of the system architect (Gates) that the separation from companies occurs and performance differentials arise.7 System Boundaries and Evolution As in any entrepreneurial business, the scale of Microsoft began very small, both in size and scope. Starting in an apartment, moving to small rented offices with only a few people using purchased computer time at schools and governments, the physical size of the enterprise has grown to encompass several sites and a dedicated campus in Redmond Washington. Product-wise, scale began with BASIC, a software set that allowed compiling of programs on various hardware systems, growing, as computer hardware capability grew, to include an operating system (MS-DOS to Windows) then application software (Office). More recently, growth has been in the direction of webbased services and applications. 7 None of the other system architects in this study have been formally designated or studied as architects. Only Gates, in a recent corporate reorganization, carries a formal designation: Chief Software Architect. 15 John Q. Dickmann ESD Symposium March 19, 2004 This growth in system boundaries is in direct correlation to business success and a result of the highly effective execution of the business rules noted above. As the external market for software and related computer products has changed, the business (system) rules have helped to steer Microsoft in response. The evolution of the product line of Microsoft can be seen as the result of successful execution and successful execution can be traced directly to the application of the rule set articulated by Gates. In terms of organizational design, Cusumano and Selby document numerous organizational changes over the years, changes that reflect the continual evaluation of current organizational state versus other possible states, while using the rule sets fed information from inside and outside Microsoft to make organizational decisions. Net Assessment The results of this rule set put into practice are similar to that of Rickover’s program, though measures of success are different. Corporate performance is well known, Microsoft is the most highly valued corporation in the world and its products are highly successful. On non-monetary measures, performance is similarly different from others in most of commercial industry: employee turnover at Microsoft is among the lowest in its industry8 Negative perspectives about Microsoft abound, from anti-trust, quality of code, philosophical perspectives of the IT marketplace. These issues are all debatable and the eventual success of Microsoft over the long term is an open question. That said, few people would argue that their ability to sense and respond to a market place driven by technology with extremely high rates of change is not exceptional. Summary and Overall Assessment This study aims to test a conceptual framework that views repeated application of a limited set of rules as the fundamental guide of system evolution over time, that these rules can be identified and at first order linked to system performance. By reviewing histories and other literature on four large-scale systems, this study has shown that decision-making rules are used by system architects to guide evolution of their systems, sometimes very clearly and forcefully, and that, at the highest scale, there are a very limited number of them. Though factors leading to success of each of these systems are numerous, the effectiveness of each system can be inferred to be at least partially attributable to the rule sets put in place by the system architects. Table 1 summarizes the results of this review. In considering these four systems and architects, common themes emerge: (1) A well defined problem or goal for the enterprise or system to measure progress against; (2) A core set of rules governing routine (day-to-day) decisions in pursuit of the goal; 8 Based on data from Directions on Microsoft, provider of independent analysis of Microsoft at: http://www.directionsmicrosoft.com/sample/DOMIS/update/2001/02feb/0201mamt_ch.htm , accessed 12 Feb 2004. 16 John Q. Dickmann ESD Symposium March 19, 2004 (3) Strong enforcement and reinforcement of rules through feedback and leadership. (4) Goals, rule sets and system boundaries together might be central factors in successfully understanding system evolution Further work using this lens to focus on the evolution of large scale systems may be able to yield more generalizable knowledge for understanding of growth and dynamics of other complex engineering systems as well as the role that system architects and their rule sets play in setting conditions and guiding that evolution. System Architect/System Clearly articulated goal Ohno Toyota Production System 4: Catch up to America in Automobile Production Explicit recognition of system boundaries and constraints 4: Japanese Market; Labor relations; Limited physical resources; Large competitors; import restrictions; Rule Evolution over time Rules Rickover Naval Nuclear Propulsion 4: Harness nuclear energy for naval combatants 4: Compete and win in computer software industry 4: Domestic political constraints; Soviets as adversaries 4: Technical: physical constraints of ships and ocean environment; organizational: AEC/Navy interface 4: Computer software and software enabled capabilities; technical capability of processors; intellectual capability of people; 4: One shop, growing over 35 years to encompass enterprise and partner suppliers 7: Limited time horizon program; but integral to 50 year alliance evolution 4: Technology evolved inside strict boundaries; Organization institutionalized by E.O. 12344 and Pubic Law 4: Computer operating systems, growing to encompass applications, web services; Organization evolves continually to adapt to changing market 4: Eliminate Waste; Just-in-time; Autonomation; 4: Long term commitment; Autonomous Administrator; Strong input from Europe 4: Technical excellence focused on safety; decentralized control with personal accountability and review 4: Technical excellence; Extremely intelligent people; decentralized control with “detailed” review Marshall Marshall Plan 4: Provide economic aid to Europe Gates Microsoft Table 1. It is also possible to look at these systems and see common patterns in the character of the rule sets, in the evolution of the systems and the actions of the architects: 9 (1) Strong emphasis on technical excellence9; (2) A strong, technically competent personality in the leadership position for an extended period of time10; Marshall Plan is an exception, because of the nature of the system. 17 John Q. Dickmann ESD Symposium March 19, 2004 (3) Rational evaluation of data and information transmitted by feedback loops with the goal of reducing uncertainty to the maximum extent possible; (4) Strong emphasis on the human element, especially notable in the technically oriented systems—both attention to their value and to the critical need to continually refresh technical knowledge. These patterns and other common characteristics among the systems are summarized in Table 2. Ohno Marshall Rickover Gates TPS ECA NNPP Microsoft Clear Goal 4 4 4 4 Strive for technical excellence 4 4 4 People are key to success 4 4 11 4 4 Rationally assess feedback 4 4 4 4 Draw system boundaries 4 4 4 4 Continuity of Leadership 4 4 4 4 Intense focus on goal and rules12 4 4 4 4 Class of rule Table 2 As noted in the discussion of each, these systems are all generally considered successes. Nonetheless, the success record of each system and, in many cases, the architects remains open to debate or still is unfolding—success is often ‘in the eye of the beholder’ and is very dependent on the time period of evaluation.13 Although these systems appear to be successful over the timeframe of decades, all may be further questioned as evaluation time increases and more knowledge is gained: - For Toyota: the degree of adaptability and flexibility of TPS in the face of unforeseen turbulence is not well known; 10 Again, Marshall Plan is an exception, though the head of the Economic Cooperation Administration was specifically chosen for his competence as a businessman. [Pogue, p. 255] 11 For the Marshall Plan, the participation of Europeans in the Plan captures this aspect. 12 This can also be viewed as ‘reduction of noise’ to the system. The ability to focus only on what moved the organization closer to its goal. 13 It can also be argued that traditional, technically oriented, success measures are becoming insufficient to effectively judging ‘success’. 18 John Q. Dickmann ESD Symposium March 19, 2004 - The centralization of control in atomic matters with the AEC coupled with the dominance of Rickover in that arena may have inhibited wider industrial activity in nuclear technology; - In hind sight, the Marshall Plan may have been unnecessary for the economic recovery of Europe, but may have served other important purposes in the Post-War period; - Microsoft Corporation, its products and Bill Gates are the subject of often contentious debate on the subjects of innovation, competition, and quality in the computer software (and, more frequently, internet) industry. Other questions about the effective architecting of complex sociotechnical systems are highlighted by this initial exploration: - Role of a strong leader compared to more diffuse decision-making structures in generating exceptional performance (comparing, for example nuclear submarines with other large system development programs); - What rules best match external contexts for long term system or enterprise survival?; - Effectiveness is a ‘value judgment’, generally either a subjective evaluation of qualitative data or a subjective choice of a quantitative metric. Can a set of common success metrics be identified for large-scale systems so that better generalizations regarding effective architecture rules may be made, ex ante? - It is difficult (at present) to judge effectiveness of rules a-priori; can models be built to help forecast or guide the evolution of complex largescale systems? With increasing scale and complexity of our engineered systems, risks of all types of failure (safety, financial, political, performance) grow and our ability to microscopically control these systems for risk mitigation becomes untenable. A closer look at foundational rules governing system behavior and evolution as well as architecture of processes built on them might guide us toward generation of tools that can better assess system performance potential, risk and possibly provide better on-line diagnostic tools as well as better up front enterprise level design information. 19 John Q. Dickmann ESD Symposium March 19, 2004 References: Acheson, Dean (1969), Present and the Creation, W.W. Norton & Co., New York, NY. Baldwin, Carliss and Clark, Kim (2000), Design Rules: The Power of Modularity, MIT Press, Cambridge, MA. Bar-Yam, Yaneer (1997), Dynamics of Complex Systems, Perseus Books, Reading, MA. Bowman, Frank L., ADM, 2003, Statement before the House Committee on Science, 29 October 2003. Christensen, Clayton (1997), The Innovator’s Dilemma, Harvard Business School Press, Boston, MA. Columbia Accident Investigation Board (CAIB) Report, (2003) Chapter 7. Cusumano, Michael and Selby, Richard (1995), Microsoft Secrets, The Free Press, New York, NY. DeLong, J. Bradford and Eichengreen, Barry (1993), "The Marshall Plan: History's Most Successful Structural Adjustment Programme," in Dornbusch, Nölling, and Layard, eds., Postwar Economic Reconstruction and Lessons for the East Today, M.I.T. Press, Cambridge, MA, pp. 189-230. Dodder, R. and Sussman, J (2002), “The Concept of a CLIOS Analysis Illustrated by the Mexico City Case”, MIT Engineering Systems Division Working Paper 2003-01.07. ESD Symposium Committee (2001), “ESD Terms and Definitions (version 12)”, MIT Engineering Systems Division Working Paper 2002-01. Duncan, Francis (2001), Rickover: The Struggle for Excellence, , Naval Institute Press, Annapolis, MD. Duncan, Francis (1990), Rickover and the Nuclear Navy: The Discipline of Technology, Naval Institute Press, Annapolis, MD. Hughes, Thomas (1998), Rescuing Prometheus, Vintage Books, New York, NY. Lewis, Eugene (1980), Public Entrepreneurship, Indiana University Press, Bloomington, IN. Magee, C. L. and deWeck, O. L. (2002), “An Attempt at Complex System Classification”, MIT Engineering Systems Division Working Paper 2003-01.02. Maier, Mark and Rechtin, Eberhardt (2000), The Art of Systems Architecting, CRC Press. Marshall, George C. (1947), Speech given at Harvard University, June 5, 1947, State Department version referenced at: http://www.marshallfoundation.org/about_gcm/marshall_plan.htm. Miller, Roger and Lessard, Donald, 2001, The Strategic Management of Large 20 John Q. Dickmann ESD Symposium March 19, 2004 Engineering Projects: Shaping Institutions, Risk and Governance, MIT Press, Cambridge, MA. Nishiguchi, Toshihiro and Beaudet, Alexandre (1997), “Self-Organization and Clustered Control in the Toyota Group: Lessons from the Aisin Fire, MIT International Motor Vehicle program Working Paper #W-0167a. Ohno, Taiichi (1988), Toyota Production System: Beyond Large Scale Production, , Productivity Press, Portland, OR. Pahl, G.. and Bietz, W. (1996), Engineering Design: A Systematic Approach, Springer, New York. Pogue, Forrest C. (1987) George C. Marshall, , Viking, New York, NY. Polmar, Norman and Allen, Thomas (1982), Rickover: Controversy and Genius, , Simon and Schuster, New York, NY. Poole, Robert (1997), Beyond Engineering, Oxford University Press, New York, NY. Rockwell, Theodore (1992), The Rickover Effect: How One Man Made a Difference, , Naval Institute Press, Annapolis, MD. Stross, Randall (1996) The Microsoft Way, Addison-Wesley, Reading, MA. Utterback, James (1994), Mastering the Dynamics of Innovation, Harvard Business School Press, Boston, MA Watts, Duncan J. (2003), Six Degrees, , W.W. Norton & Co. New York, NY. Whitney, Daniel, 2004, “System Architecture and Complexity”, paper prepared for ESD Symposium, 29-31 March 2004. Wolfram, Stephen (2002), A New Kind of Science, Wolfram Press, Chicago, IL. Womak, James, Jones, Daniel and Roos Daniel (1990), The Machine That Changed the World, HarperCollins, New York, NY. Womak, James and Jones, Daniel (1996), Lean Thinking, Simon and Schuster, New York, NY. 21