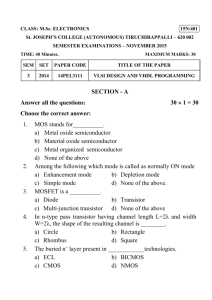

A History of Semiconductors from the Archaic to the Monolithic

advertisement