Industrial Catalysis Inorganinic Synthesis Nikodem Kuźnik

advertisement

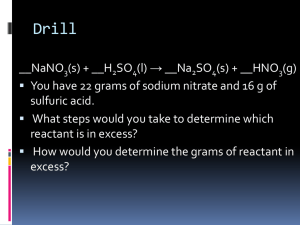

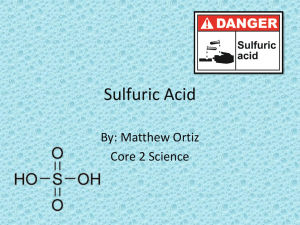

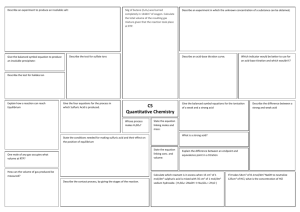

Industrial Catalysis Lecture for Makrokierunek Lecture 8 Heterogeneous catalysis Inorganinic Synthesis Nikodem Kuźnik Silesian University of Technology Gliwice, Poland Scope of the lecture • Synthesis of ammonia • Synthesis of nitric acid • Synthesis of sulfuric acid Introduction of ammonia synthesis Bond energy – 944.7kJ/mol N N Ionisation energy 1503 kJ/mol - order of Ar, greater than O2 Haber, Mittasch, 1909 Fe NH3 Dissociation on Fe, Cu, Ag, Pt, Au known since 1813 Fe N2 + 3H2 2NH3 Bosch designed reactor for 900K, 200 bar Production of ammonia Catalytic system Active phase (real catalyst) Promotores: -donate electrons -suppression of S adsorption Promotore: avoid Fe sintering Fe3O4 K2O Al2O3 heated powders at 1873 K On surface: Fe4N Fe N N Production of ammina Industrial solutions Uses of Ammonia and Nitric acid Amonia NH3 Nitric acid HNO3 World annual production appr. 140 million tonnes World annual production appr. 60 million tonnes Production of nitric acid 90%Pt, 10% Rh 4 NH3 + 5 O2 2 NO + O2 3 NO2 + H2O 760oC 4 NO + 6 H2O 2NO2 N2O4 2HNO3 + NO Industrial system types: signle- and dual-stage pressure Nitric acid cataylst Electron micrograph of platinum/rhodium catalyst showing large surface area of gauze. Nitric acid Ostwald method Nitric Acid Dual-pressure process CW = Cooling water, WB = Boiler water / feedwater History of sulfuric acid production Old names for sulfuric acid: oil of vitriol, spirit of vitriol Ibn Zakariya al-Razi, 9th century, Albertus Magnus: FeSO4 • 7 H2O → n H2SO4 + m Fe2O3 green vitriol CuSO4 • 5 H2O → n H2SO4 + m CuO blue vitriol J. Glauber, Roebuck 17-18th century, lead chamber process: S + O2 + KNO3 + H2O (steam) → H2SO4 + .... Gay-Lussac, Glover, 18th century, 78% acid: FeS2 (pyrite) + O2 → FeSO4 → Fe2(SO4)3 → Fe2O3 + SO3 Sulfuric acid production Mechanism 1. Solid sulfur, S(s), is burned in air to form sulfur dioxide gas, SO2 S(s) + O2(g) → SO2(g) 2. The gases are mixed with more air then cleaned by electrostatic precipitation to remove any particulate matter 3. The mixture of sulfur dioxide and air is heated to 450oC and subjected to a pressure of 101.3 - 202.6 kPa (1 -2 atmospheres) in the presence of a vanadium catalyst to produce sulfur trioxide, SO3(g), with a yield of 98%. Exrotermic reaction! Catalysts: Pt, V2O5, NO2 2SO2(g) + O2(g) → 2SO3(g) 4. Any unreacted gases from the above reaction are recylced back into the above reaction Sulfuric acid production Absorption of SO3 5. Sulfur trioxide, SO3(g) is dissolved in 98% (18M) sulfuric acid, H2SO4, to produce disulfuric acid or pyrosulfuric acid, also known as fuming sulfuric acid or oleum, H2S2O7. SO3(g) + H2SO4 → H2S2O7 6. This is done because when water is added directly to sulfur trioxide to produce sulfuric acid SO3(g) + H2O(l) → H2SO4(l) the reaction is slow and tends to form a mist in which the particles refuse to coalesce. 7. Water is added to the disulfuric acid, H2S2O7, to produce sulfuric acid, H2SO4 H2S2O7(l) + H2O(l) → 2H2SO4(l) SO3 in H2SO4: oleum, fuming sulfuric acid, Nordhausen acid Sulfuric acid production Obtaining sulfur Sulfuric acid production Contact Process Sulfuric acid production Lead Chamber Process Uses of Sulfuric Acid •Fertilizer production – fluoroapatite is treated with sulfuric acid to produce superphosphate •Paper production •Ore processing •Wastewater processing •Nitration – production of explosives •Acid batteries •Dehydrating agent