ARRHENIUS EQUATION CONSTANTS AND THERMODYNAMIC ANALYSIS OF CH AND H

ARRHENIUS EQUATION CONSTANTS AND THERMODYNAMIC ANALYSIS OF

CH

4

AND H

2

S PRODUCTION FOR THE VINASSES ANAEROBIC TREATMENT

Alejandra Castro-González*

She obtained the degree Pharmaceutical Biological Chemist at the Facultad de Ciencias Químicas, Universidad Veracruzana in Orizaba, Veracruz,

Mexico City, March 1995; the Master of Science in Chemical Engineering

(Environmenttal Protection) degree was obtained at the Instituto

Tecnológico de Orizaba, in Orizaba, Veracruz, Mexico, May 1997. She is presently finishing the doctoral studies in Chemical Sciences (Chemical

Engineering) to obtain the degree in the National Autonomous University of

Mexico in 2002.

Program for Environmental Chemical Engineering and Chemistry, PECEC (Programa de Ingeniería Química

Ambiental y de Química Ambiental), Facultad de Química, UNAM. Paseo de la Investigación Científica s/n,

Lab. E-301. Ciudad Universitaria, 04510 México D.F. México. Tels. (+52) 55 5622-5300 to 02 and 04, Fax

(+52) 55 5622-5303. alcastro@servidor.unam.mx

María del Carmen Durán-Domínguez-de-Bazúa

Program for Environmental Chemical Engineering and Chemistry, PECEC (Programa de Ingeniería Química

Ambiental y de Química Ambiental), Facultad de Química, UNAM. Paseo de la Investigación Científica s/n,

Lab. E-301. Ciudad Universitaria, 04510 México D.F. México. Tels. (+52) 55 5622-5300 to 02 and 04, Fax

(+52) 55 5622-5303. mcduran@servidor.unam.mx

ABSTRACT

Temperature effects on the methanogenesis and sulfatoreduction was investigated in up-flow anaerobic sludge blanket reactors (UASB) at 35, 45, and 55ºC, adapted to sugarcane alcohol producing wastewaters with an initial organic load measured as soluble chemical oxygen demand (CODs) of 120,000 mg/L. The work was divided in three steps: 1) Adaptation of the anaerobic biomass to vinasses on mesophilic conditions (35ºC); 2)

Adaptation of anaerobic biomass from mesophilic to intermediate mesophilic and thermophylic conditions

(45 and 55ºC, respectively); and 3) Arrhenius equation application on the methanogenesis and sulfatoreduction processes of biomass adapted to vinasses on intermittent tests. The three reactors have a useful volume of 2.6 L with 17 days of hydraulic residence time. When reactors pseudo steady state conditions were reached, CODs percent removal and overall CODs removal were 62, 71, and 78%, and

0.0065, 0.0075, and 0.0082 kgCOD s removal/day at 35, 45, and 55ºC, respectively. The productivity in the gas phase with respect to methane was 0.23, 0.37, and 0.47 m 3 CH

/day, and 0.0099,

S/day, at 35, 45, and 55ºC. Temperature has a positive effect on the generation of methane for the methanogenic bacteria whereas H

2

4

(NPT)/kgCOD s removal at 35, 45, and 55ºC, respectively. The gas composition (gas-liquid equilibria) was 0.066, 0.12, and 0.165 molCH

4

0.0100, 0.0107 mol H

2

S generation remains constant indicating that sulfatoreducing bacteria activity is neither increased nor diminished due to temperature effects. The activation energy for the methanogenesis was 62.86 kJ/kgmol, and for sulfatoreduction, 93.09 kJ/kgmol.

Key words: Vinasses, temperature, methane, H

2

S, anaerobic.

INTRODUCTION

In Mexico, each liter of the alcohol produced generates 12 liters of vinasses. A rough estimate the alcohol production is of 70,000 m 3 /year generating 840,000 m 3 /year of vinasses (Jiménez et al., 1995). An associated problem of these liquid effluents is the sulfate content due to the addition of sulfuric acid to the yeasts culture

media. The anaerobic degradation of the organics present in vinasses is not efficient enough. Some authors think that one of the causes is the sulfate ion presence that promotes the generation of H liquid and gas phases. Serious technical problems arise with the H

2

2

S present in both

S presence in the system, like pipelines corrosion as well as motors impeller damages, and other corrosion problems, as well as obnoxious odors, and the inhibition of anaerobic bacteria including methanogenic, acetogenic, and sulfatoreducing bacteria, affecting the process efficiency. Although the research has been intensive on the last decades, there are still not sufficient data to formulate practical models to reduce the apparent competition between methanogenic and sulfatoreducing bacteria (Lens and Hulshoff Pol, 2000). The sulfatoreducing species activity range and its capacity as competitors for the carbon sources could be limited by temperature increases. In contrast, several methanogenic bacteria are active to higher temperatures. Thus, the hypothesis of this research is that temperature increase has a positive effect on the generation of methane by methanogenic bacteria and that there is an inhibition of the sulfatoreducing bacteria proliferation. To prove it the following experimental work was conducted.

MATERIALS AND METHODS

The adaptation of the anaerobic biomass coming from a beer factory to vinasses at mesophilic conditions

(35ºC) was performed in a 10 Liter up flow anaerobic sludge blanket (UASB) reactor that, after 600 days of operation, became stable (Castro-González and Durán-de-Bazúa, 2001a). Vinasses came from an ethyl alcohol producing plant with an average concentration of dissolved organic and inorganic compounds measured as chemical oxygen demand of 120,000 mgCODs/L. With the adapted biomass, three 2.6 Liter

UASB reactors were inoculated. Each anaerobic reactor was set to a different temperature (35, 45, and 55ºC), to have now the biomass adapted to these temperatures (Castro-González and Durán-de-Bazúa, 2001b).

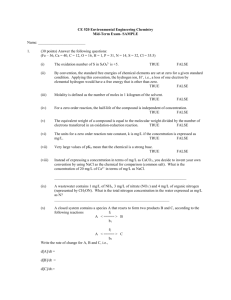

Experiments were then carried out in 30 mL vials inoculated with the temperature adapted biomass to obtain the constants of the Arrhenius equation (activation energy and rate constant). A schematic diagram of the vials is shown in Figure 1.

Figure 1: Schematic diagrams of the vials for the determination of the Arrhenius equation constants

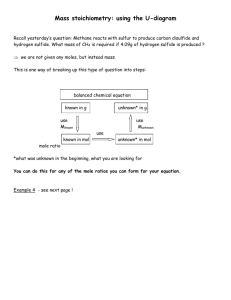

Figure 2 shows the experimental design including the proposed degradation routes considered in this study and the chemical species evaluated (APHA, 1985) techniques. The CODs was evaluated using the APHA technique adapted by Oaxaca-Grande (1997). Biogas analyses were carried out in a Perkin Elmer Autosytem gas chromatograph (GC), using thermal conductivity and flame ionization detectors, designing a complete methodology to separate the peaks for CH

4

, H

2

S, NH

3

, and CO

2

(Castro-González, 2002). To evaluate the elemental analysis considering C, N, and S, a Carlo Erba elemental analyzer Model EA 1110 was used. The gas-liquid equilibria was applied by using the Henry’s law, considering Mexico City total pressure, and the constants found in literature (HCP, 1991; Sander, 1999). All parameters were evaluated by triplicate. All data were calculated at normal pressure and temperature (NPT).

The Arrhenius equation was based on the production rate of CH and H

2

S as the products of the methanogenic

4 and sulfatoreducing reactions, respectively. For finding the constants in the Arrhenius equation, first the reaction order was evaluated from the experimental data gathered in the vials experiments. Results rendered a first order kinetics. Drury (1999) did a work on the modeling of sulfatoreduction on anaerobic reactors for the treatment of mine waste. He did an equivalence to the equation 1 for the sulfatoreduction. Thus, the equations used for methanogenesis and sulfatoreduction were: where

CH

4

(t)=CH

4,max

[1-exp(-K

CH4 t)] ecuación (1)

CH

CH

4

(t) is the cumulative methane production during time t (in mL at NTP)

4,max

K

CH4

is the maximum methane production (in mL at NTP)

is the first order reaction rate constant for methanogenesis (d t is the time (d)

-1 ) and

H

2

S(t)= H

2

S

,max

[1-exp(-K

H2S t)] ecuación (2) where

K

H2S t is the time (d)

The rates of methanogenesis and sulfato-reduction are represented as a function of temperature by the

Arrhenius equation:

Kv=k o exp -Ea/RT ecuación (3) where:

H

2

H

2

S (t) represents the H

S max

2

S cumulative production during time t (in mL at NTP)

is the maximum H

2

S production (in mL at NTP)

is the first order reaction rate constant for sulfato-reduction (d -1 )

Ea= reaction activation energy, cal/mol

R= gases universal constant, cal/mol K=1.987

Kv=K

CH4 o K

H2S

reaction rate constant for methanogenesis or sulfato-reduction, respectively (d

T=temperature, K

-1 ) k o

= Constant or Frequency factor (d -1 )

The parameters values for CH

4,max

and k were estimated by the minimum square method using the methane cumulative production (Doucet y Sloep, 1992). Linearizing equation 3 renders a simple way for calculating the constants, as shown in Figure 3 and equation 4: lnKv

= −

Ea

R

1

T

+

ln k

O ecuación (4)

Influent Effluent

COD, SO

4

-2 , C, N y S

COD, Methanogenic route

C,

N,

Æ (methanogenic activity)

CH

4

CO

2

(gas)

(gas)

CH

4

(gas) Ù CH

4

CO

2

(gas) Ù CO

2

(liq.)

(liq.)+H

2

O Ù H

2

CO

3

Ù H + +HCO

3

Ù H + +CO

3

= Ù CO

3

S,

SO

4

-2 Æ Sulfatoreducing route

(sulfatoreducing activity)

H

2

S(gas), H

2

S(gas) Ù H

2

S(liq.) Ù H + +HS Ù H + +S = Ù S =

Figure 2: Diagram of the experimental design and proposed degradation routes ln k o

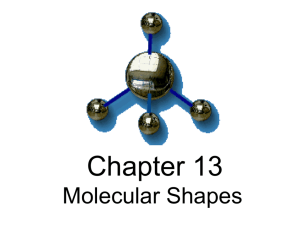

(ordinate to the origin) ln Kv slope= -Ea/R

1/T

Figure 3: Linear representation to obtain the Arrhenius equation constants

RESULTS AND DISCUSSION

Table 1 shows the results of characterization of the vinasses used in this work. Methanogenic ecosystems adaptation to the temperature elevation may be clearly seen. As mesophylic biomass is transformed into thermophylic biomass, at 55ºC, a reduction tendency in CO

Interestingly, H

2

2

is observed with respect to methane.

S production by the sulfato-reducing bacteria, SRB, increases just as well as the methane production by the methanogenic bacteria, MB. Therefore, no SRB inhibición at 55ºC is found. CODs removal is increased since carbon sources are used by both types of communities. Table 2 presents the average values found using the solubilities of the gases generated in the three reactors. The results obtained from the 2.6 liters reactors concerning gas production and using the Henry’s law to evaluate the molar fractions in the liquid phase are shown in Figures 4 and 5. From the three gases found, the most soluble in water is H

2

S>>CO

2

>CH

4

, and methane is the least soluble one. This property is conserved for vinasses (66.7, 60.8, 50.8E-4 for

H

2

S>>20, 17, 13E-4>0.9, 0.8, 0.7E-4 moles/d, for these three gases in the liquid phase, at 35, 45, and 55°C, respectively). In the gas phase, they are exactly opposite: H

2

S<<CO

2

<CH

4

(23, 39, 57E-4 for H

2

S<<198, 266,

323E-4<660, 1240, 1500E-4 moles/d, for these three gases in the gas phase, at 35, 45, and 55°C, respectively).

It is understandable then, that not only the temperature is exerting an effect on the desorption (less solubility) but the chemical reactions of conversión of the inorganic and organic disolved compounds by the methanogenic and sulfatorreducing bacteria. For example, for methane, solubility is so low that the controlling mechanism is the chemical reaction, that has an increase of more than 200% by temperature effects between 35 and 55°C (from 0.06609 to 0.14807 moles/d). For the H slight increase. Figures 4 and 5 that show the production of CH

2

S, the phenomenon is different.

The total production on moles/d is 0.00904 moles at 35°C and 0.01075 at 55°C. These data indicate a very

4

y H

2

S, considering the fraction dissolved and the fraction desorbed, give an insight that, for methane, as the gas dissolved is so low kinetics is the controlling factor and most of the methane produced goes to the gas phase. For CO

2

, the two mechanisms

(desorption and chemical reaction) exert an influence on its presence in the gas phase with respect to the fraction dissolved. For the H

2

S, the production is more and less the same to the three temperatures. Here, desorption phenomena are propitiating the gas release depending upon the temperature increase. As mentioned above, at 35°C, there are only 0.0024 moles in the gas phase and 0.0067 in the liquid phase, and at

55°C, there are 0.0057 moles in the gas phase and 0.0051 in the liquid phase. The results of the presence of

H

2

S in the gas phase do not have a significative difference between the value at 35 and at 55ºC although there is a considerable increase in the liquid phase. The amount transferred to the gas phase is 0.00238 moles at

35°C whereas at 55°C is 0.00568, a considerable increase (it should be kept in mind that H

2

S in the liquid

phase is 0.0067 moles at 35°C and 0.0051 in the liquid phase). Thus, solubility is having an effect on the production of H

2

S by the sulfatoreducing bacteria. It is not clear if an inhibitory effect is present but definitely kinetics has an effect, although this is not as marked so for the methanogenic bacteria. An interesting future line of research seems to lay here.

Table 1: Some physicochemical characteristics of the cold-room (4ºC) stored vinasses

PARAMETER Value

Value of pH

Total solids, g/L

Total suspended solids, g/L

4.34

58.45

4.30

Total dissolved solids, g/L

Total volatile solids, g/L

Volatile suspended solids, g/L

Volatile dissolved solids, g/L

Fixed total solids, g/L

Fixed suspended solids, g/L

Fixed dissolved solids, g/L

Chemical oxygen demand total, mg/L

Soluble chemical oxygen demand, mg/L

Nitrogen, mg/mg vinasse

Carbon, mg/mg vinasse

Hydrogen, mg/mg vinasse

54.15

47.25

4.10

43.15

11.20

0.20

11.00

124,428

120,001

0.00124

0.03818

0.04496

M o l o f C H

4

in g a s a n d liq u id p h a s e

0 .2 5

0 .2 0

0 .1 5

0 .1 0

0 .0 5

A v e ra g e

0 .1 6 4 8

0 .1 2 4 0

0 .0 6 5 8

5 5 ºC

4 5 ºC

3 5 ºC

0 .0 0

0 5 0 1 0 0 1 5 0 2 0 0 2 5 0 3 0 0 3 5 0

D a y s

Figure 4: Representation of CH

4 mol in the gas phase + liquid phase at 35, 45, and 55ºC

M o l o f H

2

S i n g a s a n d l i q u i d p h a s e

0 .0 1 4

0 .0 1 2

0 .0 1 0

0 .0 0 8

0 .0 0 6

0 .0 0 4

A v e r a g e

0 .0 1 0 7 5

0 .0 1 0 0 6

0 .0 0 9 9 4

5 5 º C

4 5 º C

3 5 º C

0 .0 0 2

0 .0 0 0

0 5 0 1 0 0 1 5 0 2 0 0 2 5 0 3 0 0 3 5 0

D a y s

Figure 5: Representation of H

2

S mol in the gas phase + liquid phase at 35, 45, and 55ºC

Figure 6 presents the global yield of the 2.6 L reactors in terms of generated biogas per unit CODs removed.

These Y biogás

are 0.38, 0.51, and 0.57 m 3 biogas NPT/kg CODs removed, at 35, 45, and 55°C, respectively.

Gases tend to desorb from liquids at higher rates as temperature increases.

Table 3 shows the results of the data used for the application of the Arrhenius equation, considering methane generation of the vials experiments. Table 4 presents the same information but for sulfatoreduction. From the drawn graphics the values for the constants were obtained (with r 2 = 0.9641 and 0.9718 for methanogenic data and 0.9891 and 0.9643 for sulfatoreduction data). The results indicate that activation energy required for the methanogenic reaction (62.865 kJ/mol) is lower than for the sulfatoreduction reaction (93.088 kJ/mol), corroborating the methane production enhancement over H

2

S production.

Biogas production at NPT

0.70

0.60

0.50

0.40

0.30

0.20

0.10

Average

0.57

0.51

0.38

55ºC

45ºC

35ºC

0.00

0 50 100 150

Days

200 250 300 350

Figure 6: Biogas yields for the 2.6 L reactors at 35, 45, and 55ºC

CONCLUSIONS

Considering the results obtained in this research, the hypotesis stated that temperature has a positive effect on the generation of methane by the methanogenic bacteria in the temperature range studied (35-55°C) was true.

The solubility of the methane in the liquid phase is very low, and due to this, the methane is desorbed as soon as it is generated by the methanogenic bacteria allowing an excelent recovery in biogas.

On the other hand, kinetics of the H

2

S production by sulfatoreducing bacteria, although is also favored by temperature in a global basis, its higher solubility in the liquid phase do not allow its desorption. This phenomenon probably could be acting as an inhibition factor for H

2

S generation by the SR biocommunities that grow in the reactors and its competitivity might be considered somewhat limited within the temperature range studied.

Thus, although competition between sulfatoreducing bacteria and methagenic bacteria for the substrate is not apparent as temperature increases, methanogenic bacteria definitely are favored as temperature increases from

35 to 55°C. Activation energy found demonstrates this.

The activity of SRB is also favored by temperature increase but due to the higher solubility of H

2

S, its desorption does not occurred as readily as for methane, and its presence in the liquid phase might be inhibiting further production as temperature arises, maintaining an almost constant production of H

2 independent of temperature.

S ,

Tabla 2: Average values for gas-liquid equilibria in the 2.6 L reactors at the three working temperatures

Parameter Effluent

Gas flow, L/d

Gas flow, L/d (NTP)

3.33

2.27

5.82

3.85

% CH

4

% CO

2

% H

2

LCH

4

LCO

2

LH

2

CH

4 moleCH

4 moleCH

4

/d (gas phase) mole fraction CH

4

dissolved

/L in solution (liquid phase) moleCH

4 moleCH

4

/d (liquid phase)

/d (gas phase + líquid phase)

0.066

0.00001949

0.00108311

0.00008663

0.06608663

0.124

0.000016507

0.0009171

0.00008049

0.12408049

CO

2

MoleCO

2 moleCO

2

MoleCO

2

/d (gas phase) mole fraction CO

2

disolved

/L solution (liquid phase) mole CO

2

/d (liquid phase)

/d (gas phase + liquid phase) mole CO mole H

2

CO

3

/L solution mole HCO

3

-2 mole H

2

3

-

CO

/L solution mole HCO

3

3

-

/L solution as CaCO mole CO

3

-2 /d as CaCO

3

3

0.01981

0.00045084

0.025048

0.002003

0.0218113

0.00008517

0.000081

0.026627

0.00035094

0.019498

0.001711

0.028338

0.00006629

0.000069

H

2

S mole H

2 mole H

2

S/d (gas phase) mole fraction H

2

S disolved

S/L solution (liquid phase) mole H

2 mole H

2

S/d (liquid phase)

S/día (gas phase + liquid phase) mole HS /d (liquid phase)

0.0023755

0.001499901

0.0833334

0.0066658

0.0090413

0.0039822

0.0012466

0.069266

0.0060794

0.0100616 mole S -2 mole SO

4

-2

/d (liquid phase)

/d (liquid phase)

0.006065

0.000521

0.0042

Table 3: Arrhenius constant obtained for the production of methane in vials

0.005532

0.000457

0.0033

Average 1

Temperature (TºC)

Reaction velocity K

CH4

(d -1

Arrhenius constant, k o

)

Average

Activation energy (kJ/mol)

7.29

4.67

0.148

0.000014043

0.00078022

0.000067345

0.148067345

0.032318

0.00027073

0.0150418

0.00129834

0.03361634

0.00005114

0.000052

0.0056814

0.0010584

0.058807

0.0050759

0.0107573

0.004619

0.000298

0.0017

Average 2

35 45 55 35 45 55

0.0313 0.0528 0.1397 0.0305 0.0533 0.1380

1.179x10

9 1.464x10

9

1.321x10

9

62.56546 63.1647

Table 4: Arrhenius constant obtained for the H

2

S production in vials

Average 1

Temperature (TºC)

Reaction velocity K

H2S

(d -1 )

Gas constant

Arrhenius constant

Average

Activation energy (kJ/mol)

Average 2

35 45 55 35 45 55

0.0040 0.0179 0.0476 0.0097 0.0191 0.0679

2.342x10

15

0.00813141 kJ/mol

5.945x10

11

1.171x10

15

104.6018 81.57391

ACKNOWLEDGEMENTS

First author acknowledge Conacyt doctoral scholarship. Helpful advise from Dr. Enrique Bazúa on the thermodynamic analysis is also acknowledged by authors.

REFERENCES

APHA, 1985. Standard Methods for the Examination of Water and Wastewater. 16th Ed. American Public

Health Association. Washington, DC, USA.

Castro-González A. 2002. Estudio del efecto de la temperatura en la actividad metanogénica y sulfato-reductora de consorcios microbianos en condiciones anaerobias. Doctoral Thesis (in review). Programa de Maestría y Doctorado en

Ingeniería, UNAM. Mexico City, Mexico.

Castro-González A. and Durán-de-Bazúa C. 2001a. Adaptation of anaerobic biomass to a new substrate in an upflow anaerobic sludge blanket reactor. Tecnol. Ciencia Ed. (IMIQ, Mexico), 16(1):49-55.

Castro-González A. and Durán-de-Bazúa C. 2001b. Temperature effects on the microbial activity in an anaerobic upflow reactor during the treatment of sugarcane ethyl alcohol wastewaters treatment. Presented at IWA

Congress 2001. Berlin, German Federal Republic.

Doucet, P. and Sloep, P.B. 1992. Mathematical modelling in the life sciences. The Ellis Horwood Ltd.

Chichester, England.

HCP. 1991. Handbook of Chemistry and Physics. 42th Ed. Chemical Rubber Pub. Co. Cleveland, Ohio, USA.

Jiménez R., Martínez M., Espinoza A., Noyola A., and Durán-de-Bazúa C. 1995. La caña de azúcar, su entorno ambiental. Parte II. Tratamiento de vinazas en una planta piloto en México en un reactor anaerobio de lecho de lodos.

Informe técnico de proyecto VIN-01-95. GEPLACEA, CNIIAA, PIQAYQA-FQ-UNAM. Pub. Facultad de Química,

UNAM. Mexico City,. Mexico.

Lens P. y Hulshoff Pol L. 2000. Environmental Technologies to Treat Sulfur Pollution: Principles and

Engineering. IWA Edition, London, England.

Oaxaca-Grande A. 1997. Estudio comparativo para la determinación de la demanda química de oxígeno entre el método estándar de reflujo abierto y el método colorimétrico (rápido) de reflujo cerrado. Professional Thesis. Instituto

Tecnológico de Orizaba. Orizaba, Veracruz, Mexico.

Sander, R. 1999. Non commercial reproduction. Air Chemistry Dept. Max Planck Institute of Chemistry. Mainz,

German Federal Republic. www.mpch-mainz.mpg.de/ sander.

Veeken A. and Hamelers B. 1999. Effect of temperature on hydrolysis rates of selected biowastes components.

Biores.

Technol.

.

69:249-254.