Mechanical Engineering Course Module Synopses

advertisement

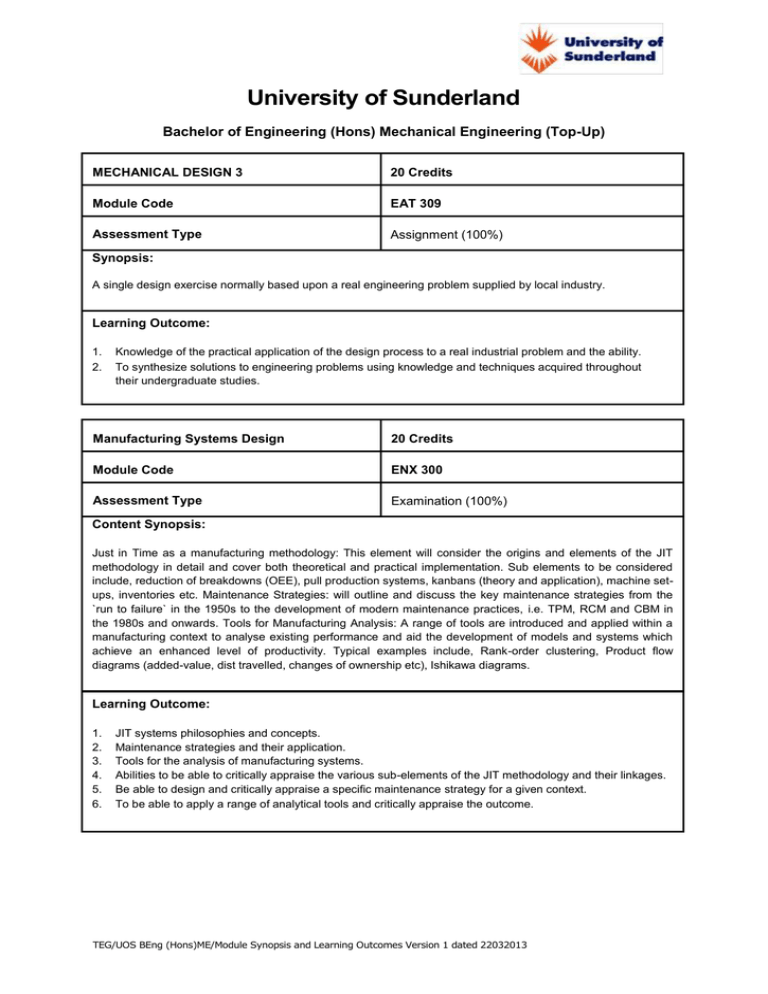

University of Sunderland Bachelor of Engineering (Hons) Mechanical Engineering (Top-Up) MECHANICAL DESIGN 3 20 Credits Module Code EAT 309 Assessment Type Assignment (100%) Synopsis: A single design exercise normally based upon a real engineering problem supplied by local industry. Learning Outcome: 1. 2. Knowledge of the practical application of the design process to a real industrial problem and the ability. To synthesize solutions to engineering problems using knowledge and techniques acquired throughout their undergraduate studies. Manufacturing Systems Design 20 Credits Module Code ENX 300 Assessment Type Examination (100%) Content Synopsis: Just in Time as a manufacturing methodology: This element will consider the origins and elements of the JIT methodology in detail and cover both theoretical and practical implementation. Sub elements to be considered include, reduction of breakdowns (OEE), pull production systems, kanbans (theory and application), machine setups, inventories etc. Maintenance Strategies: will outline and discuss the key maintenance strategies from the `run to failure` in the 1950s to the development of modern maintenance practices, i.e. TPM, RCM and CBM in the 1980s and onwards. Tools for Manufacturing Analysis: A range of tools are introduced and applied within a manufacturing context to analyse existing performance and aid the development of models and systems which achieve an enhanced level of productivity. Typical examples include, Rank-order clustering, Product flow diagrams (added-value, dist travelled, changes of ownership etc), Ishikawa diagrams. Learning Outcome: 1. 2. 3. 4. 5. 6. JIT systems philosophies and concepts. Maintenance strategies and their application. Tools for the analysis of manufacturing systems. Abilities to be able to critically appraise the various sub-elements of the JIT methodology and their linkages. Be able to design and critically appraise a specific maintenance strategy for a given context. To be able to apply a range of analytical tools and critically appraise the outcome. TEG/UOS BEng (Hons)ME/Module Synopsis and Learning Outcomes Version 1 dated 22032013 Engineering Dynamics and ThermoFluids 20 Credits Module Code EAT 339 Assessment Type Examination (100%) Content Synopsis: Thermofluids: First Law analysis of reacting systems: Molar enthalpies; isothermal combustion; enthalpy-temperature plots; enthalpy of formation; enthalpy of reaction; adiabatic flame temperature. Heat exchangers: heat transfer by convection and conduction; the LMTD design method; shell and tube heat exchanger design and analysis; derivation of shell side heat transfer coefficient. Psychrometry : composition of dry and moist air, humidity and the psychrometric chart; heating and cooling of moist air; the quality and quantity of supplied air; heating and ventilation loads; cooling towers, principles of performance and analysis. Transient conduction: finite difference methods; general conduction equation; the Biot number; the Schmidt-Binder method; the Saul’yev method; convective boundary conditions. Engineering Dynamics and Analysis of Materials: Forced vibrations with and without damping. Mathematical modeling and analysis of various dynamic systems and prediction of their response to numerous forms of external loading; non-constant excitation force; vibration transmission and isolation; base excitation (seismic vibration); vibration measurement. Two-degrees-of-freedom systems; definite and semi-definite systems; response to forced excitation;, dynamic vibration absorber; transverse vibration of beams. Vibration of continuous systems using the energy and Dunkerley’s methods; higher order natural frequencies; whirling and rotating shafts; dynamics of rotating shafts; critical speed and whirling characteristics. Strain energy techniques in stress analysis; axi-symmetrical stress systems; thick cylinders, compound cylinders, rotating cylinders and discs; failure of components through excessive deflection; buckling of struts. Learning Outcome: 1 2 3 4 5 6 7 To appreciate the principles underlying a range of engineering applications employing thermodynamics , fluid mechanics and heat transfer theory. To appreciate the significance of different parameters in the performance of thermodynamic systems. To Independently and objectively analyze thermo-fluid systems in order to assess their performance. To design from first principles a range of psychrometric and heat transfer systems. To predict failure load and stresses in components due to a range of failure criteria including fatigue buckling. To evaluate the dynamic characteristics of rotating systems and predict instability. To model and analyze various dynamic systems and predict their response to numerous forms of disturbance. TEG/UOS BEng (Hons)ME/Module Synopsis and Learning Outcomes Version 1 dated 22032013 Materials Selection 10 Credits Module Code MEX 312 Assessment Type Assignment (100%) Content Synopsis: METHODOLOGY Materials selection as a multifaceted, iterative exercise. MATERIALS EVALUATION Functionproperty relationships. Assessment of properties - weighted property and target limit approaches. Examples to cover mechanical, electrical, optical, thermal, etc. PERFORMANCE ASSESSMENT Derivation, use and evaluation of Merit indices. Materials selection (Ashby) diagrams. CASE STUDIES IN MATERIALS SELECTION A series of case studies to:- i)illustrate and provide practice in the application of the above principles ii)extend the awareness of the availability of different materials for given applications iii)provide a detailed study of selected materials and/or components and/or areas of application. Learning Outcome: 1. 2. 3. 4. 5. 6. Describe and use systematic approaches to materials selection. Identify and discuss the suitability of materials in terms of their properties. Make critical comparisons of various methods of materials selection and property evaluation. Appreciate materials requirements in the wider engineering context interdependency of design, manufacture, and economics. Describe and identify the characteristic properties of groups and sub-groups of materials and relate to specific areas of application. Select materials for given applications. Project Management Planning and Control 10 Credits Module Code ENX 314 Assessment Type Examination (100%) Content Synopsis: PROJECT APPRAISAL, PLANNING AND CONTROL: Project design. Define project objectives and deliverables. The financial appraisal of engineering and energy projects. Discounted cash flow, net present value, internal rate of return, discounted payback time, discounted unit costs, treatment of inflation - financing of projects and appraisal in different institutional contents, statistical risk assessment. Monte Carlo and Latin Hypercube methods. Create a work breakdown structure. Develop explicit work objectives for team members. Generate PERT task networks and GANTT critical path schedules using PC-based tools. Project control techniques. The establishment of feedback channels to allow the proper monitoring of progress and expenditure. On completion of this module the student should be able to: 1. 2. 3. 4. 5. 6. Define project objectives and deliverables. Compare the economics of competing projects. Use network analysis to determine the best sequence of activities throughout a project. Understand the need for resource scheduling. Make effective use of the software tools available for project management. Understand the need for proper control during the execution of a project and the design of feedback systems. TEG/UOS BEng (Hons)ME/Module Synopsis and Learning Outcomes Version 1 dated 22032013 Final Year Project 40 Credits Module Code ENX 313 Assessment Type Project Brief Report / Project Interim Report / Dissertation and Viva Content Synopsis: The identification of an engineering problem and the construction of a project brief that is submitted to an academic supervisor for approval. Research and preliminary work on the project. The submission of an interim report. The undertaking of a substantial piece of work that must involve the solution of an engineering problem, in addition to a literature survey. The submission of a final report and a project viva. The principal aims of the project are that it will develop the student’s ability to:1. 2. 3. 4. Knowledge of project planning and execution and the ability to: Plan and execute an engineering project. Carry out relevant research and to synthesise a solution to an engineering problem. Accurately and concisely report the work carried out on an engineering project. TEG/UOS BEng (Hons)ME/Module Synopsis and Learning Outcomes Version 1 dated 22032013