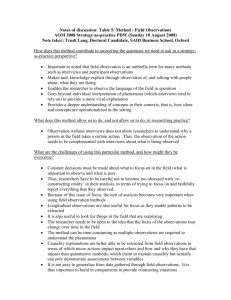

Key insights

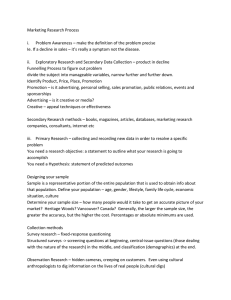

advertisement