Drinking Water

advertisement

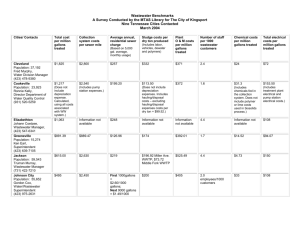

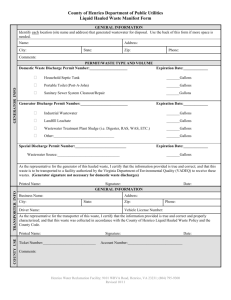

Drinking Water: Challenges and Solutions for the Next Century Mark W. LeChevallier, Ph.D. Director, Innovation & Environmental Stewardship American Water is the largest water and wastewater services provider in North America, headquartered in Voorhees, NJ. American Water provide services to approximately 15 million people in more than 1,600 communities in 32 states and in Ontario, Canada; and employs nearly 7,000 water professionals. American Water owns or operates nearly 400 drinking water systems and 300 wastewater facilities. We treat and deliver over a billion gallons of water daily www.amwater.com The company conducts over one million water quality tests each year for over 100 regulated parameters, and up to 50 types of water-related tests each day. 2 #1. Climate Change • Changing weather patterns • Higher surface air temperatures • Melting of polar ice caps • Longer, more frequent droughts • Shorter, higher intensity rainy seasons • Variation in water quality, pathogen loading • Rise in ocean levels causing salt water intrusion, habitat destruction, and displacement of significant human and animal populations 3 Inventory of AW’s 2007 Green House Gas Emissions Emissions Source Emissions (tons Carbon Dioxide 1 Equivalents) Emissions (%) Direct Emissions Stationary combustion: boilers, generators, … 35,010 3.9% Mobile sources: fleet 27,156 3.1% 56 0.0% 1,754 0.2% 824,779 92.8% 888,755 100.0% Process/fugitive: biogas leakage from WWTPs2 Refrigerant: leakage from A/C units2 Indirect Emissions Electricity Total 1. Emissions in metric tons CO2e includes CO2, N2O and methane emissions 2. Emissions from flared methane gas and HVAC were both <0.5% 4 How Much Electricity Does the Water Industry Use? • Drinking water and wastewater consume: 3% of domestic electricity1 7% of worldwide electricity 19% of California electricity2 1. 2. 3. • Water utility energy use varies widely from 0.25 to 3.5 kWh per 1,000 gallons of drinking water produced and delivered3 • The median 50% of water utilities serving populations >10,000 had electricity use between 1.0 and 2.5 kWh/1,000 gallons3 Electric Power Research Institute (Burton 1996) Energy Down the Drain: The Hidden Costs of California’s Water Supply AwwaRF 91201.Energy Index Development for Benchmarking Water and Wastewater Utilities 5 Emerging Technologies Use More Energy New regulations are increasing the use of the following, energy intensive treatment processes: Added Technology Additional Energy • UV Disinfection • Ozone • Membranes Nano and RO Ultrafiltration Microfiltration 70-100 kilowatt hours/million gallons 170 kilowatt hours/million gallons 1,800 kilowatt hours/million gallons 1,000 kilowatt hours/million gallons 100 kilowatt hours/million gallons 6 Pumping Accounts for the Biggest Energy Use • 85-99% of water treatment plant electric consumption goes to pumping. Raw water & well pumps High service pumps Filter backwash pumps Distribution system booster pumps 7 #2. Infrastructure Integrity American Society of Civil Engineers: Each day, approximately six billion gallons of treated drinking water are “lost” primarily due to system leaks throughout the United States. This is approximately 14% of the nation’s total daily water production. American Water is responsible for 44,000 miles of main. 8 MLOG Acoustic Monitor Installed near a water meter. Easily strapped to service pipe or meter. Maintenance-free, can survive meter pit environment. Battery Life – Radio MLOG 8 years and Fixed Network 15 years. Fixed Network AMR sends data to host, to Website daily. Mobile Units, a separate controller unit acquires up to 11 days of history. Proposed Future Unit –Low Cost Unit at Every Meter 9 10 • A pilot study of 500 MLOG units in Connellsville, PA has reduced 50% of the annual non-revenue water loss within the first few weeks of monitoring. Estimated payback in 6-8 months. • Finding leaks in the City of Connellsville, PA like this pinhole leak in a cast iron pipe under a concrete sewer pipe. • Research will evaluate whether most winter breaks are actually unseen leaks that can be repaired before the disruptive main break event ever begins 11 Infrastructure Assessment • 19 of the 40 leaks were identified by acoustic monitors and repaired in advance of surfacing. Another 6 were MLOG identified before surfacing but appeared before repair made. The remaining 15 surfaced and were repaired. We can higher Definite anticipate noise in leak occurring extremes after of Each point represents the start of a main or service in Connellsville aheat water and cold. temperature Thereinare drop surface patterns supply that repeat annually. systems. Optimum time for leak detection Water temperature of surface water near plant appears to be the fall. 12 13 #3. Distribution System Integrity • The hydraulic integrity of a water distribution system is defined as its ability to provide a reliable water supply at an acceptable level of service—meeting all demands for adequate pressure, fire protection, and reliability of uninterrupted supply. The most critical component of hydraulic integrity is adequate pressure defined in terms of the minimum and maximum design pressure. A second element of hydraulic integrity is the reliability of supply, which refers to the ability of the system to maintain the desirable flow rate even when components are out of service. 14 Example: Pressures Transient Negative for > 16 sec; as low as –10.1 psi (-69 kPa) Gullick et al. 2005. J. Water Supply & Technol. – AQUA 54(2): 65-81. Separation from Sewer Lines Typical separation distance: 10 feet (3 m) Standards allow for minimum of 18 in. (0.5 m) separation 16 Backflow Sensing Meters – West Virginia Low level event >0.10 gallons of backflow in any 15 minute interval ■ ■ ≥ 0.1 gallons ≥ 10 gallons High level event >10.0 gallons in any 15 minute internal In one 35 day data set there were 199 events (5.1%) in 3900 customers Main Break ─163 locations with low level backflow (4.2%) ─36 locations with high level backflow (0.9%) 17 Field Test Results – Pennsylvania Installed >3,300 meters Found 51 instances of backflow in 1 month 13 instances of >10 gal 38 instances of 1-10 gal Pattern indicative of main break or pump shutdown Several isolated spots warrant further investigation: Possible tampering Private wells 18 Backflow Occurrence Rates New Jersey Month September November December February March April May June July Total # Meters 142 143 147 151 149 150 151 148 195 1,376 # Positive 4 3 2 2 2 2 1 2 4 22 % Positive 2.8 2.1 1.4 1.3 1.3 1.3 0.7 1.3 2.1 1.6 Unique Premises # Positive % Positive 4 2.8 3 2.1 0 0 0 0 0 0 0 0 0 0 1 0.7 2 1.0 10 5.0 19 Backflow Occurrence Rates Pennsylvania # Meters Read # Positive % Positive April 3718 53 1.43% 53 1.43% May 3714 94 2.53% 42 1.13% June 2302 27 1.17% 16 0.70% July 2445 13 0.53% 3 0.12% August 5217 108 2.07% 84 1.61% 17,396 295 1.70% 198 1.14% Month Total Unique Premises # Positive % Positive 20 Backflow Occurrence Rates West Virginia Month # Meters Read # Positive % Positive Unique Premises # Positive % Positive Aug-06 3923 199 5.07% 199 5.07% Jun-08 4265 40 0.94% 38 0.89% Jul-08 4265 23 0.54% 9 0.21% 12,453 262 2.10% 246 1.98% 21 Automating Backflow Alarms As part of our AwwaRF AMI research project, backflow reports are generated from daily reads Backflow events per customer 7/1/08-9/30/08 (4,000 accounts 6-hour time intervals) 45 Number of Backflow Events Advanced Metering Infrastructure (AMI) and metering systems can work together to send backflow alarm immediately after indicator is detected. 40 35 30 25 20 15 10 5 0 1 Over a 3-month period some locations experienced backflow 39 to 41 times 4 7 10 13 16 19 22 25 28 31 34 37 40 43 46 49 52 55 58 61 64 67 70 73 76 Customers 22 #4. Security Since 9/11 there has been heightened interest in how water systems could be compromised through terrorist attack or accident. Collaborative project with the USEPA and the USGS to evaluate multi-parameter on-line sensors. YSI (Yellow Spring Instruments) provided the 6920DW probe that measures temperature, pH, specific conductance, ORP (oxidation-reduction potential), turbidity, and free chlorine. 18 units were deployed in the NJ American, Delran distribution system and linked by telemetry to the SCADA system. Between 110,000 and 220,000 data points collected. 23 Sensor Temp Calibration Frequency Never Typical Variability None SC Never ± 5 μS/cm ORP 3 months Chlorine 4 weeks 0.05 mg/L pH 4 weeks ± 0.1 Turbidity 8 weeks ± 0.5 NTU DO 3 weeks ± 10% 20 mV Comments Stable, reliable, cannot be adjusted. Rarely needed calibration. Stable, reliable and no failures at any site. Rarely needed calibration. Responsiveness declined with time due to platinum electrode oxidation. Rarely needed calibration and no membrane failures. One meter failed (electronic problems) Probes required 0.5-2 hr to stabilize after calibration. About 8 probes failed. Not sensitive in the range (0-1 NTU) for distribution system monitoring. Four probes failed. Membranes failed after 40-60 days, sooner in source water, about 6 probes failed. 24 Sensor Location Practical Locations Optimal Locations USEPA TEVA model used Monte Carlo simulations for various scenarios: Contaminant concentration Injection site Duration (or rate) of injection Exposure All non-zero demand nodes assumed to be equally vulnerable to introduction of the biological or chemical contaminants. Time delay from detection to implementation of a mitigation response assumed to be zero. 25 Public Health Benefits with Various Sensor Designs Site Response delay Mean Infections Reduction in Health Risks - 10,427 - 7 practical sites None 7,289 30.1% 7 optimal sites None 1,852 82.2% 9 practical sites None 5,273 49.4% 7 optimal + 2 practical sites None 1,796 82.8% 7 practical sites 12 h 8,642 17.1% 7 optimal sites 12 h 6,148 41% No Sensors 26 #5. Water Quality Risk Modeling • Quantitative Microbial Risk Assessments (QMRA) is a powerful tool for organizing and assessing microbial data. • American Academy of Microbiology Report: The greatest value in microbial risk assessment is in the development of the model – not necessarily in the final answer. Proper application of microbial risk assessments can be valuable in guiding selection and application of treatment processes The microbial risk assessment process is iterative – there is not single start or ending point. 27 QMRA for negative Pressure Transients IDENTIFY INRUSION LOCATIONS Set initial pathogen conc. at intrusion locations Determine pathogen transport Determine combined pathogen concentration at each node Calculate customer’s infection risk 28 Coincidence of Transient and Consumption 1L Intrusion Duration = 16s avg flow before transient period = 36 gpm 38 L People consuming water over 1 hour period, would have a 0.4% (16/3600) probability of drinking contaminated water Therefore, the duration of the transient is important! 29 #6. Wastewater Infrastructure The physical condition of the nation's 16,000 wastewater treatment systems is poor, due to a lack of investment in plant, equipment and other capital improvements. Aging wastewater management systems discharge 850 billion gallons of untreated sewage into U.S. surface waters each year. Sanitary sewer overflows (SSOs), caused by blocked or broken pipes, result in the release of as much as 10 billion gallons of raw sewage yearly The EPA estimates that the nation must invest $390 billion over the next 20 years to replace existing systems and build new ones to meet increasing demands. American Society of Civil Engineers – www.asce.org/reportcard 30 Electroscanning Simplified Electrical System Voltage source Surface Electrode Breaks provides low resistance Pipe full of water Cable Pipe wall provides high resistance Sonde 31 24 0.16in(4mm) wide, 4in long Transverse slot 0.16in(4mm) wide, 8in long 22 Transverse slot 20 0.16in(4mm) wide, 12in long 18 Transverse slot 3.9, 3.1 and 2.4in long 12 14 16 Distance from Center of Start MH(ft) 0.16in(4mm) wide Three transverse slots 4in apart 0.16in(4mm) wide, 2.4in long Two transverse slots 2in apart 0.16in(4mm) wide, 8 in long Longitudinal slot 10 0.16in(4mm) wide, 8 in long 8 Longitudinal slot 6 0.16in(4mm) wide, 4in long 4 Two transverse slots 2in apart 2 Circular hole, diam 0.39in(10mm) 0 Circular hole, diam 0.24in(6mm) Circular hole, diam 0.24in(6mm) Electrode Current 20 Electroscanning Pipe Trace 15 10 5 0 26 32 Electroscanning is more Effective than Conventional CCTV Type of Anomaly (All Materials) Leak Causing Defects Defective Faulty PipeService Manhole Connection Connection Report Joint Defect # CCTV # 82 Electroscanning Longitudinal Crack 488 ft 7 20 Transverse Crack Low Level Corrosion # 103 147 # 19 33 Other Defects 13 487 Protruding Taps Major Structural Damage Sag # # # # 3 63 0 10 9 10 Interpreted Interpreted as corrosion as cracks 34 0 Compared to CCTV, Electroscanning was More effective: Lower cost: Greater productivity: 1.7 to 21 times 50 to 80% less 30 to 50% greater 33 Wastewater Infrastructure Cost Model Cost Effectiveness of I/I Control $30,000,000 $25,000,000 NPV $20,000,000 $15,000,000 $10,000,000 $5,000,000 $0 0 0.5 1 1.5 2 2.5 3 Flow Reduction, MGD Total Cost $ Investment Treatment and Collection 34 #7. Reuse of Treated Wastewater • Water reuse in the U.S. is a large and growing practice • Nationally, an estimated 1.7 billion gallons per day is reused. • Reclaimed water use on a volume basis is growing an estimated 15% per year. • In 2002, Florida reclaimed 584 mgd. California ranked a close second with 525 mgd used daily. • Florida has an official goal of reclaiming 1 billion gallon per day by the year 2010. • Other leaders: Texas, Arizona, Nevada, Colorado, Georgia, Washington 35 Sites 23 and 24 Millennium Towers Tribeca Green Visionaire Solaire River House 36 Tribeca Green 19B The Solaire Site 18A Visionaire Site 3 Sites 23 & 24 Riverhouse 16/17 Millennium Tower Site 2A 37 Sewer Mining: Immediate Benefits • Enhances collection system capacity • Increases drinking water supply reliability • Minimizes infrastructure requirements Reclaimed water distribution requirements kept at a minimum Saves on pumping costs of reuse water • Enhanced Sustainability • Waste Activated Sludge to collection system • Improves odor control In-pipe treatment Provides planning, operating and capital investment flexibility Tailored Treatment 38 #8. Desalination • Worldwide, the desalination market soared from $ 2.5 bn in 2002 to $ 3.8 bn in 2005 with a growth rate over 15% per annum. • Over 50% of the US population live in coastal areas. • Frost & Sullivan reports that the "U.S. Desalination Pretreatment Market" will double from $184.0 million in 2005 to $399.6 million in 2012 • Key issues: Brine Disposal Pretreatment (biofouling) Energy Conservation Productivity Operational Experience 39 And California too… Moss Landing, Monterey Carlsbad Desalination Plant 40 Control of Membrane Fouling • In drinking water the presence of assimilable organic carbon is known to be associated with growth of biofilms • Development of a bioluminescence AOC test has permitted rapid, low cost, measurements Development of a salt-water test can evaluate the effectiveness of desalination pre-treatment processes Comparison: Multiple substrate model & actual data (NOX) 10,000,000.0 1,000,000.0 Luminescence • Application for reclaimed waters 100,000.0 10,000.0 1,000.0 100.0 0.0 10.0 20.0 30.0 40.0 Time (hours) 50.0 60.0 70.0 80.0 41 #9. Energy – Water Nexus The U.S. Energy Policy Act of 2005 established the DOE’s role in energy and water related issues. The DOE’s Sandia National Lab states that: Energy and Water are inextricably linked That link is vital to U.S. security and economic health The nation’s ability to continue providing both clean, affordable energy and water is being seriously challenged by a number of emerging issues 42 Water Use for Mining of Oil, Gas, and Coal Mon River quality up after limits on drillers By The Tribune-Review Thursday, January 22, 2009 State concerned about waste water from new gas wells Sunday, December 21, 2008 By Don Hopey, Pittsburgh Post-Gazette 43 Canal Road Solar Array, NJ 590 kW ground-mounted photovoltaic system Produces 687,000 kilowatts of energy / year Eliminates 493,835 pounds (224 metric tons) of CO2e per year 44 Bioenergy Recovery • Widely used with natural gas • Increased number of applications for Digester Gas • Typical Applications for Digester Gas Power to the Electric Grid (Green Power- RECs) Heat to heat digestion process And Building HVAC Documented case studies for: Fuel Cells, Microturbines, Combustion Engines 45 Co-Location with Landfill Biogas Raw Water Pump Station • Landfill located two (2) miles from water pumping station • The landfill currently is flaring its methane • The pump station uses close to 500 kW of electric power • The pump station has an emergency power generator to run on natural gas • Easy conversion of generator to biogas • Landfill has 10x more gas than needed to run the generator Landfill 46 #10. Alternative Delivery Systems • In 100 years will anyone drink piped water? • In a hydrogen economy water will be a by-product of energy production Drinking water is already produced on the space station • Water companies will be stewards of the water cycle and protectors of the environment Transition from public health protection to environmental protection Communicate the value of water 47 Conclusion • This is an exciting time to work in the water industry • Challenges provide opportunities for innovative solutions • The aging water industry workforce will require new professionals 10-15% of engineering and other technical and scientific professionals will retire in the next 5 years • Students should consider an exciting, challenging, and immensely rewarding career in the water industry • The work that you will do will save lives, protect public health, and protect the environment; at same time as providing a vital and necessary service. • Maybe that’s the final challenge! 48 Thank you for your attention! Acknowledgements Support was provided by the utility subsidiaries of American Water Contact Information Mark W. LeChevallier, Ph.D. Director, Innovation & Environmental Stewardship American Water 1025 Laurel Oak Road Voorhees, NJ 08043 USA phone: (856) 346-8261 fax: (856) 782-3603 e-mail: mark.lechevallier@amwater.com 49