Planned order releases - Ahmad Nazif Bin Noor Kamar

advertisement

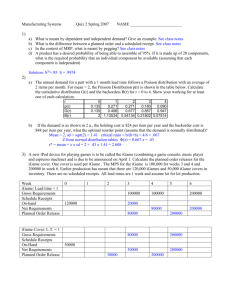

At the end of this chapter, students should be able to: • Understand industrial logistics management concept • Describe the elements and role of logistics in operations • Explain achievement of competitive advantage through logistics • Definition of Logistics • Logistics Management Concepts • The Work / Element of Logistics 1. 2. 3. 4. 5. 6. Order Processing Inventory Management Facility Network Design Materials Handling and Packaging Warehousing Transportation • Logistics and Competitive Advantage Logical Thinking Statistics Logistics “the detailed coordination of a complex operation involving many people, facilities or supplies” [ New Oxford American Dictionary] Logistics concept was introduced due to need for planning and coordinating the materials flow from source to user as an integrated system, rather than managing the flow of goods as a series of independent activities. Materials Flow Suppliers Procurement Operations Distribution Information Flow Customers Objective • The purpose of logistics management is to plan and coordinate all those activities necessary to achieve desired levels of delivered service and quality at lowest possible cost. Scope • From the total systems viewpoint, the scope encompasses management of raw materials and other inputs through the delivery of the final product in order to satisfy a customer. “part of supply chain management that plans, implements and controls the efficient, effective forward and reverse flow and storage of goods, services and related information between the point of origin and the point of consumption in order to meet customer requirements” • Specific customer requirements flow into a firm in the form of orders. • Processing of orders including initial order receipt, delivery, invoicing and collection. • Orders may arrive by phone, mail, fax etc. • Once received, they must be edited and entered into a company’s information system. • Failures and errors in order processing impact the cost of logistics as well as the speed and accuracy of service provided to customers. • Order processing is a key element of order fulfillment. Order processing operations or facilities are commonly called "distribution centers". • Order processing is the term generally used to describe the process or the work flow associated with the picking, packing and delivery of the packed item(s) to a shipping carrier. • The specific order fulfillment process or the operational procedures of distribution centers are determined by many factors. Each distribution center has its own unique requirements or priorities. Example of Order Processing Control System • Inventory is an important element in operational effectiveness and often appears on the balance sheet as the biggest of current assets. • Inventory is created when the receipt of materials, parts or finished goods exceeds their disbursement. • Issues in managing inventory: – How much inventory of each material item to hold? – Where in the system to hold each item and in what form (raw material, work in process, finished goods)? – How often to replenish each item? High inventories will hide problems Less inventories will expose problems Types of Inventory Different inventory control procedures are appropriate depends on the types Functions of Inventory Provide a stock of goods to meet anticipated customer demand and provide a “selection” of goods Provision for fluctuations in sales or production Mistakes in planning Allow one to take advantage of quantity discounts To provide a hedge against inflation To protect against shortages due to delivery variation To permit operations to continue smoothly with the use of “work-in-process” Classification of Inventory • Inventory classification helps allocate time and money . • This system allows firms to deal with multiple product lines and multitude of stock keeping units. ABC Analysis • Based on Pareto principles – created by Juran • The main idea of ABC is to focus resources on the critical few and not on the trivial many. • (Annual Dollar Volume of An Item) = (Its Annual Demand) x (Its Cost per unit) ABC Analysis • Divides on-hand inventory into 3 classes – A class, B class, C class • Policies based on ABC analysis – Develop class A suppliers more – Give tighter physical control of A items – Forecast A items more carefully Class Percentage of Total Items in Inventory Percentage of Total Dollars Tied up in Inventory A 10 70 – 80 B 10 – 20 10 – 15 C 70 - 80 10 - 20 ABC Analysis Example Class A B C % Annual RM Usage 100 80 A 60 40 B 20 % RM Vol. % Items 80 15 15 30 5 55 C 0 0 50 % of Inventory Items 100 Inventory Control • Concerned with achieving a balance between two competing objectives: 1. Minimizing the cost of maintaining inventory 2. Maximizing service to customers • Two different inventory control systems are required: 1. Order point systems – for independent demand items 2. Material requirements planning – for dependent demand items Types of Demand 1. Independent Demand • • Demand or consumption of the item is unrelated to demand for other items Eg.: end products and spare parts 2. Dependent Demand • • Demand for the item is directly related to demand for something else, usually because it is a component of a product subject to independent demand Eg.: tires on new automobiles Independent Demand • Two related issues encountered when controlling inventories of independent demand items: 1. How much to order - often decided by means of economic order quantity (EOQ) formula 2. When to order - accomplished using reorder points (ROP) Model of inventory level over time in the typical make to stock situation EOQ Assumptions • • • • • • • Demand rate is constant Known and constant lead time Instantaneous receipt of material No quantity discounts Only relevant costs are set-up (ordering) and holding No constraints on lot size Decisions for items are independent from other items Annual cost ($) Total Cost Slope = 0 Holding Cost = (Carrying) Minimum total cost Set-up Cost = (Ordering) Optimal order Qopt HQ 2 SD Q Order Quantity, Q EOQ Cost Model Why Holding Costs Increase? Purchase Order Description Qty. Microwave 1 Order quantity Purchase Order Description Qty. Microwave 1000 Order quantity More units must be stored if more ordered Why Order Costs Decrease? 1 Order (Postage $ 0.32) 1000 Orders (Postage $320) Purchase Order Description Qty. Microwave 1000 PurchaseOrder Order Purchase PurchaseOrder Order Description Qty. Purchase Description Qty. Description Qty.1 Microwave Description Qty. Microwave 11 Microwave Microwave 1 Order quantity Cost is spread over more units S - set-up (ordering) cost H – holding (carrying) cost D - annual demand Q - order quantity 1. Total annual cycle-inventory cost TIC = Holding Cost + Set-up Cost HQ = + 2 2. Economic (Optimal) Order Quantity, EOQ = SD Q 2× D × S H 3. Expected Number of Orders, N = 4. Expected Time Between Orders, T = D EOQ Working Days / Year N EOQ Calculation Example H = $0.75 per yard Qopt = Qopt = S = $150 2SD H 2(150)(10,000) (0.75) Qopt = 2,000 yards No. of orders,N = D/Qopt = 10,000/2,000 = 5 orders/year TIC = TIC = D = 10,000 yards SD Q + HQ 2 (150)(10,000) (0.75)(2,000) + 2,000 2 TIC = $750 + $750 = $1,500 Order Cycle Time,T = 311 days/ N = 311/5 = 62.2 store days Faris Haikal is the logistics executive for the headquarters of a large insurance company chain with a central inventory operation. His fastest-moving inventory item has a demand of 120 units per week. The cost of each unit is RM100 and the inventory carrying cost is RM10 per unit per year. The average ordering cost is RM30 per order. It takes about 5 days for an order to arrive and there are 250 working days per year. Calculate the: a. EOQ b. total cost c. expected number of orders d. expected time between orders e. reorder point Reorder Point System (ROP) • When the inventory level for a given stock item declines to some point defined as the reorder point, this is the signal to place an order to restock the item • Reorder point is set at a high enough level so as to minimize the probability that a stock out will occur during the period between when the reorder point is reached and a new batch is received • Reorder point policies can be implemented using computerized inventory control systems Operation of a reorder point inventory system d = D Working Days / Year ROP = d × L D = Demand per year ; d = Demand per day ; L = Lead time in days EOQ and ROP Material Requirements Planning (MRP) • Computational procedure to convert the master production schedule for end products into a detailed schedule for raw materials and components used in the end products • The detailed schedule indicates the quantities of each item, when it must be ordered, and when it must be delivered to achieve the master schedule • Capacity requirements planning coordinates labor and equipment resources with material requirements • The master schedule specifies the production of final products in terms of month-by-month deliveries • Each product may contain hundreds of components – These components are produced from raw materials, some of which are common among the components (e.g.: sheet steel for stampings) – Some of the components themselves may be common to several different products • These materials and components are called common use items in MRP Lead Times in MRP • The lead time for a job is the time that must be allowed to complete the job from start to finish. • Two kinds of lead times in MRP: – Ordering lead time - time required from initiation of the purchase requisition to receipt of the item from the vendor – Manufacturing lead time - time required to produce the item in the company's own plant, from order release to completion Inputs to the MRP System • For the MRP processor to function properly, it must receive inputs from several files: – Master production schedule – Product design data, as a bill of materials file – Inventory records – Capacity requirements planning MRP Output Reports • Order releases - authorize placement of orders planned by MRP system • Planned order releases in future periods • Rescheduling notices, indicating changes in due dates for open orders • Cancellation notices - indicate that certain orders are canceled due to changes in the master schedule • Inventory status reports • Exception reports, showing deviations from schedule, overdue orders, scrap, etc. Dependent Demand A Ladder-back chair F (2) Back legs B (1) Ladder-back subassembly C (1) Seat subassembly D (2) Front legs G (4) Back slats H (1) Seat frame I (1) Seat cushion J (4) Seat-frame boards E (4) Leg supports Bill of Materials Master Production Schedule A part of the material requirements plan that details how many end items will be produced within specified periods of time. April 1 Ladder-back chair 2 May 3 Aggregate production plan for chair family 5 150 6 7 8 150 120 Kitchen chair Desk chair 4 200 200 670 120 200 200 670 Inventory Record Item: C Description: Seat subassembly Lot Size: 230 units Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 0 0 0 0 Projected on-hand inventory 37 Planned receipts Planned order releases Inventory Record Item: C Description: Seat subassembly Lot Size: 230 units Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 0 0 0 0 Projected on-hand inventory 37 Planned receipts Planned order releases Explanation: Gross requirements are the total demand for the two chairs. Projected on-hand inventory in week 1 is 37 + 230 – 150 Inventory Record Item: C Description: Seat subassembly Lot Size: 230 units Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 0 0 0 0 Projected on-hand inventory 37 Planned receipts Planned order releases 117 Explanation: Gross requirements are the total demand for the two chairs. Projected on-hand inventory in week 1 is 37 + 230 – 150 = 117 units. Inventory Record Item: C Description: Seat subassembly Lot Size: 230 units Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 0 0 0 0 Projected on-hand inventory 37 Planned receipts Planned order releases 117 Inventory Record Item: C Description: Seat subassembly Lot Size: 230 units Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 0 0 0 0 Projected on-hand inventory 37 117 Planned receipts Projected on-hand inventory balance Planned order releases at end of week t = Inventory on hand at end of week t - 1 + Scheduled or planned receipts in week t – Gross requirements in week t Inventory Record Item: C Description: Seat subassembly Lot Size: 230 units Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 0 0 0 0 117 117 117 –3 –3 –153 –273 –273 Projected on-hand inventory 37 Planned receipts Projected on-hand inventory balance Planned order releases at end of week t = Inventory on hand at end of week t - 1 + Scheduled or planned receipts in week t – Gross requirements in week t Planned Orders Explanation: Item: C Without a new order in week 4, Description: Seat subassembly there will be a shortage of three units: 117 + 0 + 0 – 120 = – 3 units. Lot Size: 230 units Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 0 0 0 0 117 117 117 –3 –3 –153 – 273 – 273 Projected on-hand inventory 37 Planned receipts Planned order releases Planned Orders Item: C Description: Seat subassembly Lot Size: 230 units Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 0 0 0 0 117 117 117 Projected on-hand inventory 37 Planned receipts Planned order releases Planned Orders Explanation: Item: C Description: Seat subassembly Adding the planned receipt brings the balance to 117 + 0 + 230 – 120 = 227 units. Lot Size: 230 units Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 0 0 0 0 117 117 117 227 Projected on-hand inventory 37 Planned receipts Planned order releases 230 Planned Orders Explanation: Item: C Description: Seat subassembly Adding the planned receipt brings the balance to 117 + 0 + 230 – 120 = 227 units. Lot Size: 230 units Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 0 0 0 0 117 117 117 227 Projected on-hand inventory 37 Planned receipts Planned order releases 230 Planned Orders Explanation: Item: C Description: subassembly Offsetting for Seat a two-week lead time puts the corresponding planned order release back to week 2. Lot Size: 230 units Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 0 0 0 0 117 117 117 227 Projected on-hand inventory 37 Planned receipts Planned order releases 230 230 Planned Orders Explanation: Item: C Description: subassembly Offsetting for Seat a two-week lead time puts the corresponding planned order release back to week 2. Lot Size: 230 units Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 0 0 0 0 117 117 117 227 Projected on-hand inventory 37 Planned receipts Planned order releases 230 230 Planned Orders Explanation: Item: C Seat order subassembly TheDescription: first planned lasts until week 7, when projected inventory would drop to – 43. Lot Size: 230 units Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 0 0 0 0 117 117 117 227 227 77 –43 Projected on-hand inventory 37 Planned receipts Planned order releases 230 230 Planned Orders Explanation: Item: C Description: Seat subassembly Adding the second planned receipt brings the balance to 77 + 0 + 230 – 120 = 187. Lot Size: 230 units Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 0 0 0 0 117 117 117 227 227 77 Projected on-hand inventory 37 Planned receipts Planned order releases 230 230 230 Planned Orders Explanation: Item: C Description: Seat subassembly Adding the second planned receipt brings the balance to 77 + 0 + 230 – 120 = 187. Lot Size: 230 units Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 0 0 0 0 117 117 117 227 227 77 187 Projected on-hand inventory 37 Planned receipts Planned order releases 230 230 230 Planned Orders Explanation: Item: C Seat subassembly TheDescription: corresponding planned order release is for week 5. Lot Size: 230 units Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 0 0 0 0 117 117 117 227 227 77 187 Projected on-hand inventory 37 Planned receipts Planned order releases 230 230 230 230 Planned Orders Item: C Description: Seat subassembly Lot Size: 230 units Lead Time: 2 weeks Week 1 2 3 4 5 6 7 8 Gross requirements 150 0 0 120 0 150 120 0 Scheduled receipts 230 0 0 0 0 0 0 0 117 117 117 227 227 77 187 187 Projected on-hand inventory 37 Planned receipts Planned order releases 230 230 230 230 • Determining the number and type of facility required, their geographic locations and the work to be performed at each is an important part of network design • Typical logistic facilities are manufacturing plants, warehouses, cross-dock operations and retail stores • It also determines the inventory type and the quantity to be stocked at each facility and the assigning of customer orders for shipment • The network also must integrates information and transportation capabilities Factors that directly impact the number of facilities and their location in a network: Transportation cost Inventory cost Total network cost • Important factors influence location decisions: 1. Labor (availability and cost) 2. Proximity of suppliers or customers 3. Construction costs 4. Land costs 5. Taxes 6. Regulations 7. Incentive packages 8. Transportation infrastructure 9. Quality of life for employees • The factors influencing modification of network design are: – Change in demand and supply – Product assortments – Changes in suppliers’ supplies – Manufacturing requirements • Managing logistics must plan the best ways to load, offload, move, sort and select products • Work closely with engineers to design or select packaging materials that facilitate materials handling Packaging and materials handling decisions affect value in many ways: • Material handling costs can be substantial, and improved labor and equipment productivities can significantly improve profits • Materials handling is usually the number one cause of product damage and loss in logistics – poor handling practices and improperly packaged items lead to scratched, dented and broken products Packaging Packaging protects the product and facilitate ease of handling in a number of ways: a. Create one large container out of several smaller units (known as containerization / unitization) – Eg.: individual soft drinks are frequently packaged in six-packs b. Packages contain information about the products they contain (useful when sorting products and processing orders) – Eg.: Automated Storage and Retrieval System (AS/RS), Radio frequency identification (RFID) c. Packaging concern is the relationship between the boxes size, order quantity and retail display quantity The determination of final package design requires a great deal of testing to assure that both marketing and logistics concerns are satisfied Materials Handling Principles of Materials Handling 1. 2. 3. 4. 5. 6. Equipment for handling and storage should be as standardized as possible When in motion, the system should be designed to provide maximum continuous product flow Investment should be in handling rather than stationary equipment Handling equipment should be utilized to the maximum extent possible In handling equipment, selection the ratio of dead weight to payload should be minimized Whenever practical, gravity flow should be incorporated in system design Classification of Handling Systems: Mechanized • Lift trucks • Towlines • Tractor Trailers • Conveyors • Carousels • Rider Trucks SemiAutomated Automated • Automated guided Vehicles (AGV) • Robotics • Live Racks • Potential to Automate • Automated Storage / Retrieval (AS/RS) InformationDirected • RF Wireless • Pick-toLight • Nowadays, warehouse are more properly viewed as places where products may be stored and assortments of products created in accordance with customer requirements • Distribution Center term are being used to emphasize the difference between the storage activity and the strategic role of warehouses • For an ideal logistics system – storage is held to a minimum and inventory moves continuously throughout the supply chain on its destination to fill customer needs Primary Functions of Warehousing 1. Trans-Shipment Point – A facility where products are received, sorted, sequenced and selected into loads consistent with the customers’ needs 2. Stockpiling – The storage of inventories in warehouses to protect against seasonality either in supply or demand 3. Production Support – A warehouse dedicated to storing parts and components needed to support a plant’s operations 4. Break-Bulk – Splitting a large shipment into individual orders and arranging for local delivery to customers 5. Warehouse Consolidation – Combining shipments from a number of sources into one larger shipment going to a single location 6. Cross-Docking – Combines break-bulk and consolidation warehouse activities 7. Reverse Logistics Support – The logistics needed to send products or packaging materials back to disassembly, reclamation or disposal sites – Returned products can be remanufactured or updated for resale 8. Value-Added Services – Any work that creates greater value for customers – Services may change the physical features or configuration of products so they are presented to customers in a unique or customized manner Warehouse Operations 1. Receiving and Unloading – Inbound shipments must be received and unloaded from the transportation vehicles – Part of this activity may also involve checking the shipment for the correct quantities and for potential damage to products 2. In-Storage Handling – Once unloaded the goods must be moved to the desired destination within the facility, whether this is an actual storage location or a shipping area in the case of a crossdock facility 3. Storage – Products are held, even if for only a few minutes in a storage area 4. Order-Picking – The products are removed from storage and assembled into appropriate quantities and assortments to fill customer orders 5. Staging – The assembled orders are moved to an area in the warehouse in readiness for loading into a transportation vehicle bound for customer locations 6. Shipping – Involves verifying that the assembled orders are correct and the actual loading of the transportation vehicles Warehouse Ownership 1. Private Warehouse – Facility that is owned and operated by the firm that own the products 2. Public Warehouse – A firm that offers warehouse services to the public for a fee based on the amount of spaced used and the number of shipments into or out of the facility 3. Contract Warehouse – Companies offer to build, own and operate warehouse facilities for the benefit of clients who do not want to undertake those responsibilities themselves Transport Functionality Product Movement • Basic value provided by transportation is to move inventory to specified destination Product Storage • While a product is in a transportation vehicle, it is being stored – storage at shipment origin or destination Transport Principles There are 2 fundamental economic principles that impact transportation efficiency: 1. Economy of scale – is the cost per unit of weight decreases as the size of a shipment increases 2. Economy of distance – refers to decreased transportation cost per unit of weight as distance increase – Eg.: a shipment of 800km will cost less to perform than 2 shipments of the same weight each moving 400km • Consolidation is one of the strategy used by logistics management to reduce transportation cost by combining small orders or shipments into one larger shipment. 1. Market Area Consolidation – combining several small shipments from one shipper that are going to the same market area into one shipment 2. Pooled Delivery Consolidation – combines small shipments from different shippers that are going to the same market area; normally handled by independent transportation companies 3. Scheduled Delivery Consolidation – establishing specific times when deliveries will be made to customers Modes of Transportation Rail Highway Water Pipeline Air Truck Rail Water Pipe Air Speed 2 3 4 5 1 Availability 1 2 4 5 3 Dependability 2 3 4 1 5 Capability 3 2 1 5 4 Frequency 2 4 5 1 3 Cost to Shippers** 2 3 4 5 1 Typical Uses medium & light mfg.; wholesale & retail distribution heavy bulk commodities bulk commodities; agriculture products petroleum; natural gas small shipments; emergency shipments Operating Characteristics* * 1 = best; 5 = worst ** 1 = highest cost; 5 = lowest cost Carrier Types 1. Common carriers – transportation companies that provide service to the public 2. Contract carriers – carriers that have specific contracts with a limited number of shippers 3. Private carriers – companies that own and operate transportation equipment to transport their own products The success in the marketplace is based around the triangular linkage of the company, customers and its competitors. Customers Seek Benefits at Acceptable Cost Value Asset Utilization Value Cost Differential Asset Utilization Commercial Success Cost Advantage Value Advantage • Logistics management provides for the flow and storage of information and products between the firm and its suppliers (inbound), the firm and its customers (outbound) and the various plants, divisions and units of the firm. • The objectives of logistics management is to provide customers with their required service benefits at the lowest total logistics cost • A complete logistics management system comprises 6 major decision areas: facility network design, inventory management, order management, transportation management, warehousing management and packaging and materials handling management.