Cengage OVERCOMES!

advertisement

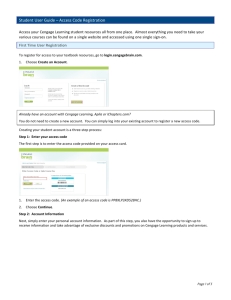

Introduction of Ed Williams Vice President Blue Horseshoe Strategy Division ewilliams@bhsolutions.com @bhsolutions #bhscsummit BHS and Cengage Over a decade of Past Projects @bhsolutions #bhscsummit Cengage Learning https://www.youtube.com/watch?v=Rz4rsh5kyJc @bhsolutions #bhscsummit Doing MORE with LESS : The struggle of ‘right now’ expectations and resource limitations Suzanne Wilsbacher Project Manager Distribution Systems Cengage Learning Suzanne.Wilsbacher@cengage.com @bhsolutions #bhscsummit Tony Hayes Project Manager Distribution Systems Cengage Learning Tony.Hayes@cengage.com Agenda Introduction & Video Get CENGAGED!! Struggles and Challenges Opportunities for improvement at Cengage Attendee Feedback & Discussion @bhsolutions #bhscsummit About Cengage Learning Offering print and electronic learning services Higher Ed, Research & Library, K-12 MindTap ® Aplia ™ Distribution Centers in 6 countries – – – – – – United States Canada Mexico Brazil Argentina England @bhsolutions #bhscsummit “Managers today have to do more with less, and get better results from limited resources, more than ever before.” – Brian Tracy, Chairman and CEO of Brian Tracy International, a leadership and development organization, Full Engagement! Inspire, Motivate, and Bring Out the Best in Your People @bhsolutions #bhscsummit You are about to be CENGAGED! @bhsolutions #bhscsummit Challenges and Obstacles Doing more with less? @bhsolutions #bhscsummit Resource Limitations Bodies Brains Bucks @bhsolutions #bhscsummit Related Fallout Customer Satisfaction Innovation Employee Morale @bhsolutions #bhscsummit Cengage OVERCOMES! T-BOX Packing and Processing @bhsolutions #bhscsummit Cengage OVERCOMES! Tote Prep and Picking PREVIOUS PROCESS NEW PROCESS 8 Parcels to a tote per Totes packed out in LogPRO LogPRO based on Volume/Weight/# Ship label and pick slip printed of Parcels configuration interleaved at plan time in No invoices or labels printed tote groups up front During picking, Picker had to Using voice picking software, find the correct label/invoice Picker picks straight to tote combo each time and rubber with nothing to match up band product to the combo @bhsolutions #bhscsummit Cengage OVERCOMES! Tote Prep and Picking Benefits – Less conveyor traffic • More than 8 shipping parcels per tote when packed by Volume/Weight/# of Parcels • Less conveyor traffic from increased use of totes – Less tote prep time• No more matching up invoices and labels – No handling of invoices or ship/pick labels at all – Pick slip label completely eliminated • Only need to put tote label on the tote – Less pick time• Picker does not need to match up product with correct invoice/label combo @bhsolutions #bhscsummit Cengage OVERCOMES! T-BOX Packaging and Shipping PREVIOUS PROCESS Tote conveyed to Shipping Dock Pallet of totes driven to cold seal machines Two operators package parcels with manual audit of items and invoice/ship label combo Gaylord of packages driven back to the dock and onto a truck @bhsolutions #bhscsummit NEW PROCESS Totes conveyed directly to TBOX packing stations on the dock Parcels packed using LogPro Parcel Audit Ship label and invoice printed Packed parcels taken by conveyor to Gaylord Gaylord driven onto truck Cengage OVERCOMES! T-BOX Packaging and Shipping Benefits – Less double handling• Totes are not stacked and unstacked • Parcels are not driven from the dock and back to the dock – Improved accuracy (aka MORE!!!) • Each item in each parcels is scanned or ISBN typed into Parcel Audit • Invoice is printed only for that parcel • Ship label only printed for that shipping parcel – Less labor• 1 T-box packer vs. 2 cold seal machine operators @bhsolutions #bhscsummit Cengage OVERCOMES! Replenishment to TBOX Packing – Entire case of loose is consumed and packed into TBOX type box PREVIOUS PROCESS RPLN cases conveyed to Picking zones RPLN team performs “Putaway” of cases Picker picks books from cases into totes Tote conveyed to dock and then driven to cold seal machine for packing, etc. @bhsolutions #bhscsummit NEW PROCESS RPLN cases conveyed straight to packing stations LogPro performs “Putaway” at station on conveyor divert Packer scans RPLN label then item Ship label and invoice print F-key for next label and invoice, repeat. Cengage OVERCOMES! Replenishment to TBOX Packing Benefits – Less double handling • RPLN team does not need to handle case • Picking team does not need to pick item – Less conveyor congestion • Cases sent to pack stations during low volume, early morning hours • Items not picked into totes, reducing number of totes on conveyor @bhsolutions #bhscsummit Cengage OVERCOMES! Benefit Review Less double handling of RPLN cases, items, and totes Reduced conveyor congestion Reduced label print Reduced tote prep and pick time Reduced error rate for item and invoice/ship label miss-match Reduced labor Improved error tracking from Parcel Audit stamp of User ID @bhsolutions #bhscsummit Cengage OVERCOMES! T-BOX Processing Stations @bhsolutions #bhscsummit Participation Time! Share what challenges you face, and what you have done to overcome them! @bhsolutions #bhscsummit Cengage OVERCOMES continues!... Daily Staff meeting Cross training Shift timing changes – offer more flexible work hours Combine synergies – Order picking with WO picking – WO module enhancement Work flow management – pick plan organization and timing @bhsolutions #bhscsummit Learning how to do in house what we used to send out to vendor – Specialized label printing Ask HVAC contractor to fix ice machine. Incentive plans for individual contributors Recognition – Bravo system Meeting of the minds – like the Blue Horseshoe Summit!! Always remember… @bhsolutions #bhscsummit Thank You Suzanne Wilsbacher Project Manager Distribution Systems Cengage Learning Suzanne.Wilsbacher@cengage.com @bhsolutions #bhscsummit Tony Hayes Project Manager Distribution Systems Cengage Learning Tony.Hayes@cengage.com