20110420_Pegylation - International Journal of Advances in

advertisement

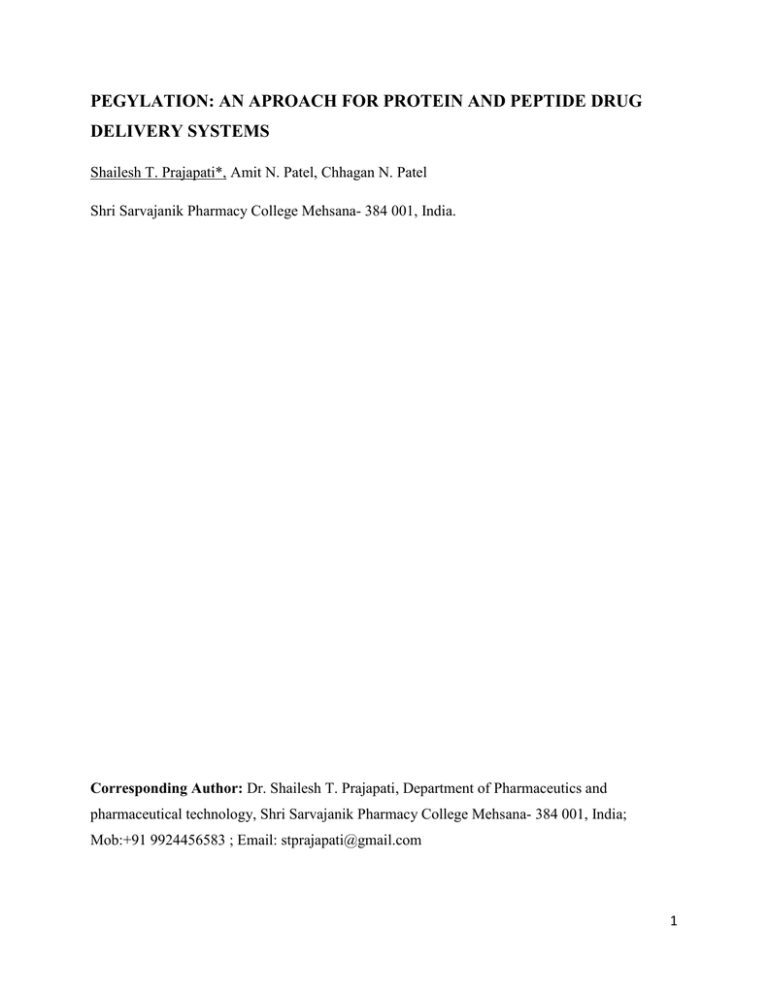

PEGYLATION: AN APROACH FOR PROTEIN AND PEPTIDE DRUG DELIVERY SYSTEMS Shailesh T. Prajapati*, Amit N. Patel, Chhagan N. Patel Shri Sarvajanik Pharmacy College Mehsana- 384 001, India. Corresponding Author: Dr. Shailesh T. Prajapati, Department of Pharmaceutics and pharmaceutical technology, Shri Sarvajanik Pharmacy College Mehsana- 384 001, India; Mob:+91 9924456583 ; Email: stprajapati@gmail.com 1 INTRODUCTION A number of novel drug-delivery mechanisms have been developed to increase the utility of drugs that are otherwise limited by suboptimal pharmacokinetic properties, such as poor absorption, distribution, and elimination. These include continuous-release injectable and liposomal systems, which alter the formulation of the drug, and PEGylation, which alters the drug molecule.[1] PEGylation defines the modification of a protein, peptide or non-peptide molecule by the linking of one or more polyethylene glycol (PEG) chains. This polymer is nontoxic, non-immunogenic, non-antigenic, highly soluble in water and FDA approved. The PEG-drug conjugates have several advantages: a prolonged residence in body, a decreased degradation by metabolic enzymes and a reduction or elimination of\protein immunogenicity. Thanks to these favorable properties, PEGylation now plays an important role in drug delivery, enhancing the potentials of peptides and proteins as therapeutic agents.[2] PEGylation was first described in the 1970s by Davies and Abuchowsky and reported in two key papers on albumin and catalase modification. This was an important milestone, because at that time it was not conceivable to modify an enzyme so extensively and still maintain its activity. Proteins were in fact considered very delicate entities and only few gentle modifications with low molecular-weight products were carried out, mainly to study SARs.[2] PEGylation is a new delivery technology that differs from traditional formulation in a number of ways. For formulated products such as tablets, liquids and capsules, the formulation process is reversible, the drug becomes active after its release from the formulation and the API remains unchanged. In PEGylated products, on the other hand, the API is chemically modified in a durable fashion, and the drug is not released from a formulation but has a permanent action and is in fact classed as a new API. Consequently, PEGylation has to be considered early in the drug development process.[2] The advantages conferred by PEGylation include an increased molecule weight and hydrodynamic volume and a masking of the surface of the molecule with highly mobile PEG chains. PEGylation also reduces the rapid renal clearance of small proteins and makes it possible for liposomes to evade removal from the plasma by lipolytic enzymes and the reticuloendothelial 2 system. As a result, pegylated agents generally have longer plasma half-lives and durations of bioactivity than their nonpegylated counterparts and benefits of pegylated product given in table 1.[1] PROPERTIES OF PEG Polyethylene glycols are pH-neutral, nontoxic water-soluble polymers that consist of repeating ethylene oxide subunits, each with a molecular weight of 44, and two terminal hydroxyl groups. They are either linear (5 to 30 kd) or branched (40 to 60 kd) chain structures.PEG has Polydispersity i.e. Molecular weight distribution is narrow (1.01 – 1.1). The pharmacokinetic properties of PEGs vary according to their molecular weight and site of injection. The area under the time-concentration curve and the half-life of PEGs increase with their molecular weight. For example, after intravenous administration in mice the half-life of 50kd PEG is substantially longer than that of 6 kd PEG (987vs 17.6 minutes); 50kd PEG is also retained longer at the injection site after subcutaneous or intramuscular injection than is 6 kd PEG. Polyethylene glycols appear to undergo oxidation by the cytochrome P450 enzyme system, and lowmolecularweight PEGs are excreted into the bile.[1] PEGylation – MECHANISM OF ACTION After administration, when PEG comes in contact of aqueous environment, ethylene glycol subunit gets tightly attached to the water molecule. This binding to water renders them high mobility and hydration. Hydration and rapid motion causes PEGylated protein to function, as it causes PEG to sweep out a large volume which acts like a shield to protect the attached drug from enzymatic degradation and interaction with cell surface proteins. This increased size also helps to prevent rapid renal filtration and clearance sustaining the drug bioavailability. The high steric hindrance of branched-chain PEGs generally affords greater protection than do linear chain.[1] FACTORS AFFECTING PERFORMANCE OF PEGylated PRODUCT Molecular Weight 3 Molecular weight less than 1000 Da of PEG broken down into sub-units, and have some toxicity, while Molecular weight greater than 1000 Da of PEG: does not demonstrate any toxicity in vivo. Molecular Weight upto 40,000 – 50,000 Da: used in clinical and approved pharmaceutical application. The molecular weight of PEG has a direct impact on the activity; Higher molecular weight PEGs tends to have higher in-vivo activity due to the improved pharmacokinetic profile like increasing half life as earlier discussed.[1] Structure Branched structure has more size than same molecular weight linear structure so; it’s also helps to prevent rapid renal filtration and clearance sustaining the drug bioavailability. The high steric hindrance of branched-chain PEGs generally affords greater protection than do linear chain.[1,4] Number of PEG chains Two or more lower molecular weight chains can be added to increase total molecular weight of PEG complex Specific location of PEG site of attachment to the molecule. Optimal PEGylation is product-specific, and can vary depending on the site of attachment, the chemistry used to create the conjugate, and the characteristics of the PEG used. Effective PEGylation of a drug may be achieved by attaching a single large PEG at a single site, a branched PEG at a single site, or several small PEG chains at several sites.[1] CHEMISTRY OF PEGYLATION To couple PEG to a molecule (i.e. polypeptides, polysaccharides, polynucleotide’s and small organic molecules) as shown in Figure 1, it is necessary to activate the PEG by preparing a derivative of the PEG having a functional group at one or both termini. The functional group is chosen based on the type of available reactive group on the molecule that will be coupled to the PEG. For proteins, typical reactive amino acids include lysine, cysteine, histidine, arginine, aspartic acid, glutamic acid, serine, threonine, tyrosine, N-terminal amino group and the Cterminal carboxylic acid. In the case of glycoproteins, vicinal hydroxyl groups can be oxidized 4 with periodate to form two reactive formyl moieties.[3] The most common route for PEG conjugation of proteins has been to activate the PEG with functional groups suitable for reaction with lysine and N-terminal amino acid groups. Lysine is one of the most prevalent amino acids in proteins and can be up-wards of 10% of the overall amino acid sequence. In reactions between electrophilically activated PEG and nucleophilic amino acids, it is typical that several amines are substituted. When multiple lysines have been modified, a heterogeneous mixture is produced, which is composed of a population of several polyethylene glycol molecules attached per protein molecule (‘PEGmers’) ranging from zero to the number of ´-and a-amine groups in the protein.[3] PEGylation technology is classified into two types: 1. Early PEGylation technology (First generation PEGylation) 2. Advanced PEGylation technology (Second generation PEGylation) 1. First Generation PEGylation First generation PEGylation methods were fraught with difficulties. With first generation PEGylation, the PEG polymer was generally attached to ε amino group of lysine, and gave mixtures of PEG isomers with different molecular masses. The existence of these isomers makes it difficult to reproduce drug batches, and can contribute to the antigenecity of the drug and poor clinical outcomes. In addition, first generation methods mainly used linear PEG polymers of 12 kDa or less. Unstable bonds between the drug and PEG were also sometimes used, which leads to degradation of PEG-drug conjugate during manufacturing and injection Early PEGylation was performed with methoxy-PEG (m-PEG), which was contaminated with PEG diol and which resulted in the cross-linking of proteins to form inactive aggregates. Diol contamination can reach upto 10-15 %.[1] Despite these limitations, several first generation PEGylated drugs receive regulatory approval. Example: Still in use today are Pegademase (ADAGEN®), a PEGylated form of the enzyme adenosine de-aminase for the treatment of Severe Combined Immuno-Deficiency (SCID) and Pegaspargase (ONCASPAR®), a PEGylated form of enzyme asparginase for the treatment of Leukemia.[5] 5 2. Second Generation PEGylation Second generation PEGylation strives to avoid pitfalls associated with the first generation PEGylation. Overall goal of this technology is to create larger PEG polymers to improve the Pharmacokinetics and Pharmacodynamic effects seen with lower molecular mass PEGs. Newer pegylation methods create conjugates with strong linkages that are resistant to sidereactions and are able to withstand purification to remove dio1 contaminants, thereby making it possible to use high molecular- weight PEGs . These methods attach an activated PEG to the drug molecule by incorporating part of the activating group as a link between the two entities. For example, PEGFILGRASTIM® is formed by covalently attaching a 20 kd PEG chain through a stable secondary amine bond directly to the terminal amino group of the filgrastim molecule. In this way, the nitrogen atom to which the PEG chain is attached retains its surface charge, a factor that has been shown to be crucial in conserving the bioactivity of some molecules.[1] Amine PEGylation and N-terminal PEGylation Since most applications of PEG conjugation involve labile molecules, the coupling reaction generally requires mild chemical conditions. In case of polypeptides, the most common reactive groups involved in coupling are nucleophiles with the following decreasing rank order of reactivity: thiol, alpha amino group, epsilon amino group, carboxylate, hydroxylate. However, this order is not absolute, since it depends also on the reaction pH, furthermore other residues may react in special conditions, as the imidazole group of histidine. The thiol group is rarely present in proteins, furthermore it is often involved in active sites. The carboxylic groups cannot be easily activated without having. reaction with the protein amino groups, to yield intra or inter molecular cross linking. Therefore, amino groups, namely the alpha amino or the epsilon amino of lysine, are the usual sites of PEG linking.[4] PEGylating Agents used for amino PEGylation shown in Table 2. Carboxyl PEGylation PEG reagents react with carboxylic acid in the presence of coupling agents such as DCC (N,N'-dicyclohexylcarbodiimide) and EDIC (N-(3-dimethylaminopropyl)-N' ethylcarbodiimide, HCl salt). However, the procedure is successful only when amines are not present in the compound, as for instance in the case of non-peptide drugs. In peptides and 6 proteins the risk of cross-linking is difficult to avoid.[3] PEGylating Agents used for Carboxyl PEGylation are shown in Table 3. PEGylation at the –SH (thiol) groups of Cysteine of polypeptides PEGylation of free cysteine residues in proteins is the main approach for site-specific modification because reagents that specifically react with cysteines have been synthesized, and the number of free cysteines on the surface of a protein is much less than that of lysine residues. In the absence of a free cysteine in a native protein, one or more free cysteines can be added by genetic engineering. PEGylating site specifically can minimize the loss of biological activity and reduce immunogenecity.[3] PEGylating Agents used for thiol PEGylation are shown in Table 3. Hydroxyl PEGylation PEG-isocyanate is useful for hydroxyl group conjugation yielding a stable urethane linkage. However, its reactivity may be best exploited for non-peptide moieties such as drugs or hydroxyl-containing matrices to yield biocompatible surfaces. PEG-isocyanate is in fact highly reactive with amines also.[3]PEGylating Agents used for Hydroxyl PEGylation are shown in Table 3. Hetero-bifunctional PEGs As applications of PEG chemistry have become more sophisticated, there has been an increasing need for heterobifunctional PEGs, which are PEGs bearing dissimilar terminal groups. Such heterobifunctional PEGs bearing appropriate functional groups may be used to link two entities where a hydrophilic, flexible, and biocompatible spacer is needed. Heterobifunctional PEG can be used in a variety of ways that includes linking macromolecules to surfaces (for immunoassays, biosensors or various probe applications), targeting of drugs, liposomes and viruses to specific tissues, liquid phase peptide synthesis and many others. Preferred end groups for hetero-bifunctional PEGs are NHS esters, maleimide, vinyl sulfone, pyridyl disulfide, amine, and carboxylic acids.[3] Branched structures Second generation PEGylation uses branched structures of PEG, in contrast to the solely linear structures found in first generation PEGs. Branched PEGs of greatly increased molecular masses – upto 60 kDa or more, as compared with the 12 kDa or less found in the first generation PEGs – have been prepared. A branched PEG ‘acts’ as if it were much larger than a corresponding linear PEG of the same molecular mass. Branched PEGs are also better at cloaking the attached 7 polypeptide drug from the immune system and proteolytic enzymes, thereby reducing its antigenecity and likelihood of destruction.[1,3] Specific PEGylation by enzymes or by reversible protection The specific conjugation of PEG to the amide group of glutamines or to the hydroxyl group of serines and threonines is only possible under mild conditions using enzymes. Sato discovered that glutamine in proteins can be the substrate of the transglutaminase enzymes, if an amino PEG is used as the nucleophilic donor. Through a transglutamination reaction the enzyme links PEG to the protein at the level of the glutamine residue as shown in Figure 2.[2] Now a days, PEG conjugates with different enzyme like arginines n histaminase are also available. LIMITATIONS IN TH USE OF PEG PEG is obtained by chemical synthesis and, like all synthetic polymers, it is polydisperse, which means that the polymer’s batch is composed of molecules having different number of monomers, yielding a Gaussian distribution of the molecular weights. This leads to a population of drug conjugates, which might have different biological properties, mainly in body-residence time and immunogenicity. Polydispersivity problem must be still taken into consideration, especially when dealing with low molecular weight drugs, either peptide or non-peptide drugs, where the mass of linked PEG is more relevant for conveying the conjugate’s characteristics, mainly those related to the molecular size. A second problem for the use of this polymer relates to the excretion from the body. As for other polymers, PEGs are usually excreted in urine or feces but at high molecular weights they can accumulate in the liver, leading to macromolecular syndrome.[2] APPLICATION OF PEGYLATION PEG as Diagnostic Carrier In vivo non invasive diagnosis is done by using tracers detected through magnetic resonance or radioactivity. Usually they are administered in a chelated form using compounds that can give specific biodistribution, stability or targeting. PEGylation increases the body-residence time of paramagnetic chelates that will be cleared more slowly than the unmodified molecules through the kidney or liver, thus allowing more detailed images by magnetic resonance. C225 is a monoclonal antibody directed against the epidermal growth factor receptor, which was 8 conjugated to a heterobifunctional PEG bearing a radiometal chelator (diethylenetriaminepentaacetic acid, DTPA) at one terminus. The conjugate DTPA–PEG–C225 retained 66% of binding affinity, and, more importantly, when labeled with Indium-111 (111In) it showed narrower steady-state distribution than the non-PEGylated 111In–DTPA–C225, because of reduced nonspecific binding. Therefore, in case of protein targeted diagnostic, PEG could help to collect better defined images by limiting the background noise due to nonspecific protein–protein interaction.[2] PEG oligonucleotides Mainly antisense oligonucleotides and are now under active investigation as new potential drugs because of their extremely high selectivity in target recognition. All of them, however, share the problems of short half-life in vivo because of either low stability towards the eso- and endonucleases (present in plasma and inside the cells) or their rapid excretion caused by their small size. Furthermore, their negative charge prevents an easy penetration into the cells. A PEG molecule, bound to the hydroxyl group of a nucleic acid (directly or through a spacer link), was found to increase the stability towards enzyme degradation,prolong the plasma permanence and enhance the penetration into cells by masking the negative charges of oligonucleotides. A PEGylated aptamer, the 28mer oligomeraptanib, has already been approved by FDA for the treatment of age-related macular degeneration of retina. In this product, a branched PEG of 40 kDa was attached to the oligonucleotides through a pentamino linker.[2] PEGylated conjugate as Anticancer agent[7] PEG conjugates with low molecular weight anticancer drugs PEG has been successful for protein modification but in the case of low molecular weight drugs it presents a crucial limit, the low drug payload accompanying the available methoxy or diol forms of this polymer. This intrinsic limitation had for many years prevented the development of a small drug-PEG conjugate. A few studies have been conducted to overcome the low PEG loading by either branching the end chain groups or coupling on them small Dendron structures. Pegamotecan® (Enzon Pharmaceuticals, Inc.) is a prodrug obtained by coupling two molecules of camptothecin to a diol PEG of 40 kDa. The drug is linked through an ester bond involving the 9 C-20 hydroxyl group and a carboxylic group of PEG. The aim of this approach was double, to increase the drug half-life in blood by PEGylation and to stabilize by acylation the active lactone configuration of camptothecin. PEG-irinotecan: The architecture of new multi-arm PEGs was also exploited for the preparation of PEG-irinotecan (NKTR-102) by Nektar Therapeutics. The drug has been covalently bound to a four arms PEG. In preclinical studies NKTR-102 plasma half-life was evaluated in a mouse model taking into consideration the active metabolite SN-38, released from irinotecan. The conjugate showed prolonged pharmacokinetic profiles with a half-life of 15 days when compared to 4 h with free irinotecan. PEG-docetaxel : PEGylated docetaxel (NKTR-105) has been prepared with the same multi-arm PEG technology. The derivative has shown good preclinical activity in colon and lung cancer xenograft models.This product has just entered phase 1 clinical studies enrolling approximately 30 patients with refractory solid tumours who have failed all prior available therapies. PEG-Protein conjugates In PEGylation of protein conjugate two different approaches can be identified based on the type of protein studied: Heterologous protein, Usually the main limit of these proteins is the immunogenicity rather than a short pharmacokinetic. Therefore, both PEG molecular weight and coupling chemistry should ensure a wide shielding of the protein surface or, at least, the immunogenic sites. Basically, in these cases low molecular weight PEGs (5– 10 kDa) and random amine coupling are used. It is important to note that all the enzymes studied possess small substrates; these can cross the PEG layer, around the protein, and easily reach the active site. Conversely, active site approach of large and hindered substrates would be prevented this compromising the enzyme activity. This would suggest that PEGylation may be not a suitable approach for immunogenic enzymes having big substrates. Endogenous protein, For these biopharmaceutical drugs the prolongation of body circulation half-life is the driving force in seeking for a polymer conjugate. Most of the endogenous proteins act through a receptor-mediated activity. This dictates the strategy for an optimum PEGylation approach, namely a site specific conjugation to generate monoPEGylated isomers. In particular 10 the site of polymer attachment must be far from the receptor recognition area. In this case, it is mandatory the use of high molecular weight polymers to reach the PEG mass for the desired half-life prolongation. PEG-antibody fragment angiogenesis inhibitor (CDP791) Vascular endothelial growth factor receptor-2 (VEGFR-2) is involved in the formation of new blood vessels in tumours (angiogenesis), allowing cancer cells to receive nutrients and to maintain growth. Therefore, a molecule able to block VEGFR-2 can interfere with the development of tumour vasculature. CDP791 is a PEGylated diFab antibody that binds the VEGFR-2, with a Kd of 49pM, preventing the activation by VEGF ligands. The unconjugated CDP791 antibody fragment is affected by a too fast in vivo clearance, because it has a reduced mass due to the absence of Fc region. This problem was overcome by PEGylation of the cysteine present at the C-terminus. PEG-interferon-alpha conjugates Several clinical studies are evaluating the effectiveness of PEGinterferon-α2b (PEG-INTRON®), presently used for the treatment of hepatitis B and C, as adjuvant therapy in certain anticancer protocols. The native interferon-α2b is one of the most studied agents for adjuvant therapy in stage IIb and stage III melanoma. Improvements in the recurrence-free survival have been shown when interferon- α2b therapy was prolonged for 12–15 months. This long therapy, consisting in a daily drug administration, can particularly compromise the patient compliance. This can be highly improved using the PEGylated form of interferon-α2b, a monoPEGylated derivative obtained by conjugating the protein with a linear 12 kDa amino reactive PEGylating agent. The conjugate maintains the therapeutic level of interferon-α2b by a weekly, self administered, dose schedule and its safety has been studied in several cancers. PEG-Interferon-α2a, a conjugate obtained by linking a branched PEG 40 kDa to the protein and marketed as PEGASYS®, is used in clinic to treat hepatitis as PEG-INTRON®. The higher polymer molecular weight of PEGASYS® (40 kDa versus 12 kDa of PEG-INTRON®) and the higher stability of the PEG-protein linkages (i.e. His residues are involved in this case) allowed for the prolonging of the in vivo half-life to 65 h with respect to the 27–37 h of PEG-INTRON®. 11 PEGylation: the in vitro activity is reduced to about 7% of that of native interferon, this being the weakness of stable polymer conjugation, but this limitation is more than counterbalanced by the enhanced in vivo half-life of the conjugate. PEG-granulocyte colony stimulating factor Granulocyte colony stimulating factor (G-CSF) is used as adjuvant therapy to treat granulocytes depletion during chemotherapy. The fast blood clearance of the free drug was addressed by PEGylation. Different PEG coupling approaches were conducted but the most successful one consisted of a reductive alkylation with PEG aldehyde performed at acidic pH. Under this condition, a monoPEGylated conjugate was preferentially obtained in which the polymer was linked to the protein N-terminal α amino group. The PEG 20 kDa conjugate showed an improved pharmacokinetic profile as consequence to the reduced kidney excretion. The PEG-G-CSF conjugate (Pegfilgastrim, Neulasta®) was approved for human use in 2002 for the first and subsequent cycleadministration against febrile neutropenia in patients with nonmyeloid malignancies receiving myelosuppressive chemotherapy associated with a 30%– 40% risk of febrile neutropenia. PEG conjugates with enzymes PEG conjugated Asparaginase several leukemic lymphoblasts cells rely on the serum supply of asparagine, for their growth, because they lack the enzyme asparagine synthetase. Asparaginase, the enzyme that converts asparagine into aspartate and ammonia, has therefore been proposed as a therapeutic agent for acute lymphoblastic leukaemia (ALL). FDA approval for PEG-asparaginase (Rhone-Poulenc Rorer as Oncaspar®) was granted in 1994 for treatment of patients with ALL who are hypersensitive to the two native isoforms of the enzyme. PEGylated asparaginase has been used in combination with several traditional anticancer molecules, often in a multiagent regimen, including for example one or more of the following drugs: cyclophosphamide, daunorubicin, vincristine, cytarabine, prednisone, etc. In these studies the PEGylated enzyme was well tolerated, showing hyperbilirubinaemia and hyperglycaemia as the most common adverse effects. 12 Arginine deiminase and Arginase In literature two types of arginine degrading enzymes are reported, and both have been suggested as antitumour agents: citrulline i) arginine deiminase (ADI), which degrades arginine in and ammonia, ii) arginase (ARG) that catalyses the conversion of arginine in ornithine and urea. This enzyme was shown to be even more powerful than asparaginase in killing human leukaemia cells. arginine depleting enzymes can be useful in treating these tumours. Indeed, arginine deficiency inhibits tumour growth, angiogenesis and nitric oxide synthesis. Chitosan–PEG nanocapsules as new carriers for oral peptide delivery Chitosan–PEG nanocapsules and the control PEG-coated nanoemulsions were obtained by the solvent displacement technique. Their size was in the range of 160–250 nm. Their zeta potential was greatly affected by the nature of the coating, being positive for chitosan–PEG nanocapsules and negative in the case of PEG-coated nanoemulsions. The presence of PEG, whether alone or grafted to chitosan, improved the stability of the nanocapsules in the gastrointestinal fluids. Using the Caco-2 model cell line it was observed that the pegylation of chitosan reduced the cytotoxicity of the nanocapsules. Finally, the results of the in vivo studies showed the capacity of chitosan–PEG nanocapsules to enhance and prolong the intestinal absorption of salmon calcitonin. Additionally, they indicated that the pegylation degree affected the in vivo performance of the nanocapsules. Therefore, by modulating the pegylation degree of chitosan, it was possible to obtain nanocapsules with a good stability, a low cytotoxicity and with absorption enhancing properties.[8] Gene Delivery Polyethyleneglycol modified polyethylenimine for improved CNS gene transfer One problem of using polycation DNA complexes, especially in an in vivo study, is their poor solubility. They may immediately precipitate out of a solution when prepared at a higher concentration. Polyethylene glycol (PEG) modification (PEGylation) often can improve the solubility of macromolecules, minimize aggregation of particulates and reduce their interaction with proteins in the physiological fluid. PEGylation of PEI reduced surface charge of PEI/DNA 13 particles, increased their dispersion ability at high concentrations, decreased plasma protein binding and erythrocyte aggregation, prolonged blood circulation and reduced systemic toxicity & increased invivo transgene expression of PEI. The study provides the in vivo evidence that an appropriate degree of PEG modification is decisive in improving gene transfer mediated by PEGylated polymers.[9] Small interfering RNA (siRNA) delivery Small interfering RNA was conjugated with poly(ethylene glycol) (PEG) at four different terminal ends (sense 3′, sense 5′, antisense 3′, and antisense 5′) via cleavable disulfide and noncleavable thioether for gene silencing efficiencies. The PEGylation site at the four siRNA termini and PEG molecular weight were not critical factors to significantly affect gene silencing activities. Cleavable siRNA-PEG conjugates showed comparable gene silencing activities to naked siRNA, and exhibited sequence-specific degradation of a target mRNA. Interestingly, noncleavable siRNA-PEG conjugates were processed by Dicer, enabling to exert RNAi effect without showing a target sequence-specific manner. However, only cleavable siRNA-PEG conjugates significantly reduced the extent of INF-α release as compared to noncleavable siRNA-PEG conjugates, suggesting that they can be potentially used for therapeutic siRNA applications.[10] Dendrimer Despite the robust structure of polyamidoamine(PAMAM)dendrimers, they are not stable when complexed with surfactants. Modification of PAMAM dendrimers by grafting PEG chains on the surface of PAMAM substantially improves its colloidal stability in the presence of sodiumdodecylsulfate(SDS). Michael addition reaction was employed to synthesize PEGylatedPAMAM by activating MPEG with 4-nitrophenylchloroformate.The PEGylated-PAMAM dendrimers did not aggregate in the presence of upto 100mM SDS as the complexes were sterically stabilized by PEGchains. ITC and zetapotential measurements revealed that the binding mechanism of SDS and PEGylated-PAMAM was induced by electrostatic interaction and polymer-induced micellization of SDS on PEG chains. The interaction of PEGylated-PAMAM 14 and amphiphilic molecules, such as SDS was elucidated, and this provided a useful basis for the application PEGylated-PAMAM in drug delivery mostly in antiviral and cancer therapy.[11] Insulin PEGylation A novel long-acting insulin based on the following properties: (i) action as a prodrug to preclude supra physiological concentrations shortly after injection; (ii) maintenance of low-circulating level of biologically active insulin for prolonged period; and (iii) high solubility in aqueous solution. A spontaneously hydrolyzable prodrug was thus designed and prepared by conjugating insulin through its amino side chains to a 40 kDa polyethylene glycol containing sulfhydryl moiety (PEG40-SH), employing recently developed hetero-bifunctional spacer 9- hydroxymethyl-7(amino-3-maleimidopropionate)-fluorene-N-hydroxysucinimide (MAL-Fmoc0Su). A conjugate trapped in the circulatory system and capable of releasing insulin by spontaneous chemical hydrolysis has been created. PEG40-Fmoc-insulin is a water-soluble, reactivatable prodrug with low biological activity. Upon incubation at physiological conditions, the covalently linked insulin undergoes spontaneous hydrolysis at a slow rate and in a linear fashion, releasing the nonmodified immunologically and biologically active insulin with a t1/2 value of 30h. A single subcutaneous administration of PEG40-Fmoc-insulin to healthy and diabetic rodents facilitates prolonged glucose-lowering effects 4- to 7-fold greater than similar doses of the native hormone. The beneficial pharmacological features endowed by PEGylation are thus preserved. In contrast, nonreversible, ‘‘conventional” pegylation of insulin led to inactivation of the hormone.[12] PEGylated derivatives of rosin (PD) used as sustained release film forming materials for controlled release formulation. The mechanism of drug release from these coated systems however followed class II transport (n>1.0).[13] Recently approved pegylated products shown in Table 4. CONCLUSION PEGylation improves the biopharmaceutical properties of drugs that increase stability, resistant to proteolytic inactivation, decrease to nonexistent immunogenicity, increase circulatory lives and low toxicity. These type of alter properties improve the efficacy of protein and peptide drug delivery. 15 REFERENCES 1. Molineux G, Pegylation: engineering improved pharmaceuticals for enhanced therapy. Cancer treatment reviews 2002, 28(A), 13-16. 2. Veronese FM, Pasut G, PEGylation,successful approach to drug delivery. DDT(Drug Discovery Today), November 2005, 10(21). 3. Roberts MJ, Bentley MD, Harris JM. Chemistry for peptide and protein PEGylation. Advanced Drug Delivery Reviews 2002, 54, 459–476. 4. Veronese FM. Review Peptide and protein PEGylation: a review of problems and solutions. Biomaterials 2001, 22, 405-417. 5. Leenders F,Kraehmer R. PEGylation Technology and PEGylated Drugs. Celares GmbH, Robert-Roessle-Str. 10, 13125 Berlin, Germany. 6. PEGylating agent information available at http://www.creativepegworks.com/pegylation technology and chemistry.mht updated on 20 April 2011. 7. Pasut G, Veronese FM. PEG conjugates in clinical development or use as anticancer agents: An overview. Advanced Drug Delivery Reviews 2009, 61, 1177–1188. 8. Prego C, Torres D, Fernandez-Megia E, Novoa-Carballal R, Quiñoá E, Alonso MJ. Chitosan–PEG nanocapsules as new carriers for oral peptide delivery Effect of chitosan pegylation degree. Journal of Controlled Release 2006, 111, 299–308. 9. Tanga GP, Zenga JM, Gaoa SJ, Maa YX, Shia L, Toob HP, Wanga S. Polyethylene glycol modified polyethylenimine for improved CNS gene transfer: effects of PEGylation extent. Biomaterials 2003, 24, 2351–2362. 10. Jung S, Lee SH, Mok H, Chung HJ, Park TG. Gene silencing efficiency of siRNA-PEG conjugates: Effect of PEGylation site and PEG molecular weight. Journal of Controlled Release 2010, 144, 306–313. 11. Lima AH, Tamb K. Stabilization of polyamidoamine (PAMAM) dendrimers/sodium dodecyl sulfate complexes via PEGylation. Colloids and Surfaces A:Physicochem.Eng 2011. 12. Shechter Y, Mironchik M, Rubinraut S, Tsubery H, Sasson K, Marcus Y, Fridkin M. Reversible pegylation of insulin facilitates its prolonged action in vivo. European Journal of Pharmaceutics and Biopharmaceutics 70 (2008) 19–28. 16 13. Nande VS, Barabde UV, Morkhade DM, Joshi SB, Patil AT. Investigation of PEGylated Derivatives of Rosin as Sustained Release Film Formers. AAPS PharmSciTech March 2008, 9(1). 17 TABLE 1. Potential benefits of PEGylated products Greater biologic activity Greater passive tumour targeting of liposomes Longer circulating half-life Lower peak plasma concentrations Smaller fluctuations in plasma concentrations Less enzymatic degradation Less immunogenicity and antigenicity Greater solubility Less-frequent administration Greater patient adherence and improved quality of life 18 TABLE 2. PEGylating agent for Amino PEGylation[6] PEG reagents PEGylation PEG-NHS The N-hydroxysuccinimide (NHS) activated ester of PEG carboxylic acid can react with the amino group of lysine. The coupling requires only mild conditions, pH 7-9, low temperature (5-25ºC) for short period of time. The formed amide bond is physiologically stable. PEG-aldehyde Reductive amination with primary amines to produce secondary amines, in the presence of reducing agents such as sodium cyanoborohydride. pH borohydride and sodium is for reductive important amination. PEG-isocyanate Reaction with amine to produce a stable urethane linkage. PEG epoxide Nucleophilic addition PEG- React with amine to produce a stable thiourea linkage. isothiocyanate PEG-COOH Usually the acid needs to be activated, such as NHS ester. PEG-NPC Amine reacts with NPC functionalized PEG under proper conditions. PEG-acrylate Michael addition between amine and acrylate ester 19 TABLE 3. PEGylating agent for Carboxyl, Thiol and Hydroxyl PEGylation[6] PEG reagents for Carboxyl PEGylation PEG-amine Amide formation under DCC or EDIC coupling conditions PEG-hydrazide After activated by EDIC at mild acidic pH, the carboxyl group of proteins readily react with PEG-hydrazide, while the amino groups present in all reagents remain inactive in this particular conditions. PEG reagents for Thiol (-SH) PEGylation PEG-Maleimide Michael addition, thiols react with the C=C bond in the maleimic ring to form a physiological stable linkage. The best reaction condition is at pH 8. PEG-OPSS Disulfide S-S bond formation, which can be reversed by reducing agents such as sodium borohydride and thioethanolamine. PEG- Michael addition, thiols react with the C=C bond to form vinylsulfone a physiological stable linkage. PEG-thiol Oxidative disulfide S-S bond formation. PEG reagents for Hydroxyl PEGylation PEG-isocyanate Hydroxyl groups react with PEG-NCO, however special considerations are required. PEG-NPC Hydroxyl groups react with NPC to from a carbonate linkage. PEG-epoxide PEG-epoxide reacts with hydroxyls best at pH 8.5-9.5. 20 TABLE 4. Approved PEGylated Products[5] Brand name Product Company Indication PEGasys PEG-INF α-2a Hoffmann-La Hepatitis (interferon) Roche PEG-INF α-2b Enzon Hepatitis Amgen Neutropenia Enzon Immunodeficiency PEG-Intron (interferon) Neulasta PEGfilgrastim(granulocyte colony stimulating factor) Adagen PEG-adenosine deaminase Oncaspar PEG-asparginase Enzon Cancer Somavert PEG-visomant Pfizer Acromegaly PEG-hirudin PEG-recombinant Abbot Thrombosis(phase hirudin PEG- PEG-CDP 870 III) Pfizer monoclonal Rheumatoid arthritis (phase III) antibody PEG-Axokine PEG-cilliary Regeneron Obesity (phase III) nurotrophic factor 21 Figure 1. PEGylation process in general 22 Figure 2. Specific PEGylation of Glutamine by transglutaminase enzyme. 23